16 tips for choosing a hammer: types of hammers, purpose

Hammer in household - An irreplaceable thing, especially if you are used to doing a lot with your own hands. Using this simple tool, you can perform not only the usual operations for us, for example, hammer a nail, but also many other works, because today there is a very many different hammerin for various applications. We will figure out what types of hammers are, what their purpose is, and try to decide how to choose a hammer.

1. Hammer construction and basic materials

The first hammer appeared a very long time ago. We can say that this is the first of the tools that people used for their needs. We all saw the hammer, held it in our hands many times, and we know that the simplest hammer consists of two main elements: handle and head.

Head has an asymmetric shape, one part of it has a point, which is called a wedge, and the other part is flat or slightly convex, it is called a striker. This is the main hammer part, which accounts for the main work. It has sufficient strength and area to withstand repeated impacts on hard surfaces. Wedge-shaped part hammer is used to crack something or when chasing. Its shape allows you to develop greater impact force due to the smaller contact surface area.

In the center of the head is a special hole for attaching the handle, which is called hors. Usually it is made in the form of a round or oval hole, which smoothly passes into a cone. After attaching the head to the handle, the part of it that protrudes from the hole is wedged so that it completely occupies the internal cavity of the horse. Such a mount prevents head falling off.

In order to ensure high strength and durability of the head, it is made high tensile metal by forging, casting or milling, followed by heat treatment. Special hardening modes allow you to achieve high surface strength with a viscous core. The hardened surface layer reaches 3-5 mm. This structure provides high hardness, but at the same time. protects the head from fragility.For protect heads against corrosion it is plated or special types of paints are used.

Universal the material for the manufacture of handles the hammer has always been a tree. It is very durable, does not slip in the hand and has a long service life, and if during use you still break the handle, it is very easy to replace or even do it yourself. Very importantso that the fibers of the wood of which the handle is made are perpendicular to the head. In this case, if it breaks, you are not injured.Breed wood must be a certain kind. Beech, birch, ash, oak, hornbeam, maple or mountain ash are well suited for these purposes. Pine, aspen, alder and spruce are not suitable species.

There are handles made of metal or plasticand more modern hammers come with fiberglass handles.This is a new material that has proven very good in use. It does not slip in the hand and helps to reduce recoil force on impact. Metal handles are hollow inside, have the shape of a circle in cross section, and for the convenience of work, are covered with rubber. Plastic handles are also covered with a layer of rubber. Handles made of plastic, metal or fiberglass have two advantages in front of a tree: they do not dry out over time and are not subject to swelling when in contact with water. Choose depending on what material you are more comfortable and more pleasant to work with. The main thing is that the handle is much lighter than the head and has an appropriate length.

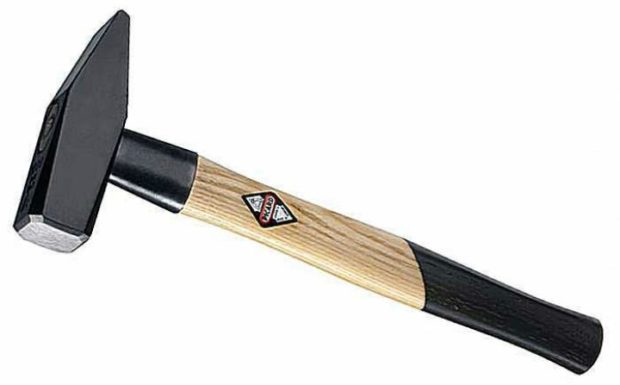

2. Bench hammer and its purpose

Design the bench hammer is described in detail in the first paragraph. It is the easiest and common type working tool. is he is intended for clogging, breaking, bending or straightening parts. The pointed edge in the form of a wedge allows you to score nail with a small hat and perform work in a hard-to-reach place where a wide part of the head does not fit.

Design the bench hammer is described in detail in the first paragraph. It is the easiest and common type working tool. is he is intended for clogging, breaking, bending or straightening parts. The pointed edge in the form of a wedge allows you to score nail with a small hat and perform work in a hard-to-reach place where a wide part of the head does not fit.

The hammer hammer head can have not only a square, but also a round cross-sectional shape. The square type has one disadvantage - if at the moment of impact you distorted the hammer and the inclined angle fell on the surface of the material being processed, a dent will certainly remain on it. Such defects are especially distressing when assembling new furniture.

Since the bench hammer is designed to apply multiple series of blows, it should be completed of very durable material. Great for chrome vanadium steel, which has increased hardness, which will help to avoid deformation or destruction of the striker. Weight the bench hammer ranges from depending on its number. Total exists five numbers, weight No. 1 - 200 g, No. 5 - 800 g. The weight of the hammer is selected depending on the type of work and the physical strength of the worker. Length handles, on average, is 300-400 mm.

3. Joiner's hammer

Design carpentry hammer has a distinctive feature. At one of its ends, a special slot is made, which can have a different breeding angle and slightly curved edges. This bifurcation serves to extract the nails from the required surface. Hammers with a large pitch angle are called Californian, and hammers with a smaller angle are called European. But not all joiner's hammers are made in the form of a nail clipper at one end. There are tools with ordinary wedge at the end and perfectly smoothly brisk.

Design carpentry hammer has a distinctive feature. At one of its ends, a special slot is made, which can have a different breeding angle and slightly curved edges. This bifurcation serves to extract the nails from the required surface. Hammers with a large pitch angle are called Californian, and hammers with a smaller angle are called European. But not all joiner's hammers are made in the form of a nail clipper at one end. There are tools with ordinary wedge at the end and perfectly smoothly brisk.

Handle may be completed made of wood, metal or plastic with a rubber coating, which serve to prevent slipping in the hand. Such hammers are considered rather than percussion instruments, but precision instruments. Weight its head lies in the range of 100-800 gr in increments of 50 g.

Joiner's hammer can look very simple - shock part tool steel and a wooden handle, or have a more ergonomic shape and some additional features. For example, its handle can be made made of high strength material fiberglass or carbon fiber, and the shock part - from titanium or other high-strength steel with special anticorrosion coating and past special heat treatment. As an additional function, a holder for nails can be present, which allows you to perform work with one hand. And its design can be folding or prefabricated, which makes it very compact and convenient for storage.

4. Sledgehammer

it the biggestpowerful and heavy kind of hammer. Weight such a tool can reach 4-10 kg, but there are more serious tools that have the weight of the working part and up to 16 kg. Themapply for jobs that require high impact force but little accuracy, for example, dismantling partitionsold tiles crushing concrete or stone driving pillars into the grounddriving wedges and other hard work.

it the biggestpowerful and heavy kind of hammer. Weight such a tool can reach 4-10 kg, but there are more serious tools that have the weight of the working part and up to 16 kg. Themapply for jobs that require high impact force but little accuracy, for example, dismantling partitionsold tiles crushing concrete or stone driving pillars into the grounddriving wedges and other hard work.

Head this tool is made high tensile steel by forging followed by heat treatment in the form of hardening for the required hardness and may take the form of a parallelepiped or a conventional hammer. By the way hardened layer depth after quenching reaches 30 mm. The handle has a larger diameter and length compared to previous models, which means two-handed operation.

Length the handle is directly proportional to the weight of the working part of the sledgehammer: the higher it is, the handle is longer and can reach 120 cm, but usually is in the range of 80-90 cm. The cheapest sledge hammers have a wooden handle, but can also be all-metal.

Holeinto which the handle is inserted, has a conical shape, and the handle itself is inserted on top and does not need to wedge. This assembly method is completely prevents slipping massive head part. When working with a sledgehammer, you must be extremely careful, because it is considered a traumatic tool. Of varieties sledgehammers some, but the most used is a blunt sledgehammer weighing 2-16 kg, longitudinal silt-nosed transverse, which weigh from 3 to 8 kg. Stick preferred - rubberized, it is more expensive than wooden, but the instrument will be securely held in your hands and dampen vibration upon impact.

5. Mallet

This type of hammers can also include straightening hammers. They are intended for leveling iron products that underwent deformation, drainage systems, roofing works and other works related to the use of sheet metal.

This type of hammers can also include straightening hammers. They are intended for leveling iron products that underwent deformation, drainage systems, roofing works and other works related to the use of sheet metal.

Such a tool has one very interesting feature. The shock part of the straightening hammer is made with an internal cavity, which is filled with sand or fine shot. This structure made it possible to completely suppress the inertia of the hammer during impact. When working, it does not bounce off the surface and practically “sticks” to it. Such hammers got the name inertia-free. They are made of rubber or polyurethane, and some models are made of metal with interchangeable heads of softer material.

Hammers are intended for metalwork and carpentry, namely for straightening, leveling or fitting large elements of soft metals or wood. Shock part tool completed made of rubber or hardwoodfor example, birch or elm. Rubber can be either black or white. Whites mallet it is preferable, since from striking with black rubber on light surfaces dark stripes may remain.

As handle material use wood, plastic or metal, usually the handle has the shape of a circle in cross section. Depending on destination mallet can have a different shape of the shock. The tool for carpentry works has a cylindrical or barrel-shaped shape, and for locksmiths one side has a wedge-shaped shape. The advantage of these types of hammers is that they do not leave dents or marks on the treated surface.

When choosing mallet need to focus on the type of work performed. If these are more precise actions, then a small weight tool from 220 to 450 g is enough for you, if you need a large impact force, then pay attention to a tool weighing from 900 to 1000 g. Price policy This type of hammer is very different, but you should not choose the most expensive mallet. You are unlikely to find differences from the average pricing policy tool, which means that you will overpay for the "name".

6. Pickaxe or Kylo

This hand tool is used for work with solid materials, namely, with stone or rocky soil, for the dismantling of old masonry and many other hard work. Design pickaxes are very simple. It consists of a shock part and a handle. The shock part may be bilateral or one-sided. The second option will look like a long spike, at the end of which there will be a rounding or an ordinary hammer.A double-sided Kylo has either two symmetrical long spikes, or a spike and a narrow blade. In any embodiment, the spikes will be slightly bent, and arc. This design is more productive and allows to reduce recoil force during the strike.

This hand tool is used for work with solid materials, namely, with stone or rocky soil, for the dismantling of old masonry and many other hard work. Design pickaxes are very simple. It consists of a shock part and a handle. The shock part may be bilateral or one-sided. The second option will look like a long spike, at the end of which there will be a rounding or an ordinary hammer.A double-sided Kylo has either two symmetrical long spikes, or a spike and a narrow blade. In any embodiment, the spikes will be slightly bent, and arc. This design is more productive and allows to reduce recoil force during the strike.

A quality pick should be made of high quality tool steel. Handle the pickaxe has a thickening at the end, on which the shock part is attached, which makes its assembly impossible. As material more and more for the handle use fiberglass or metal coated with bicomponent rubber or wood. This is due to their ability dampen vibrations upon impact, insensitivity to moisture and chemicals and anti-slip properties. Weight This tool may be different. For example, a pickaxe for domestic use weighs 500-600 g, and for more serious work - 2.5-3 kg. In the same way, they distinguish between dimensions pick. If the length of the spikes lies in the range from 20 to 30 cm, then this option is more suitable for domestic needs, if from 50 to 70 cm, then for professional ones.

7. Mason's hammer

Design this type of hammer is very successful for fulfillment building or installation work, namely for installation paving slabs, to remove excess stone and give it the necessary shape, to remove the old layer plasters and many other works related to solid materials.

Design this type of hammer is very successful for fulfillment building or installation work, namely for installation paving slabs, to remove excess stone and give it the necessary shape, to remove the old layer plasters and many other works related to solid materials.

Shock part a hammer has two various surface. One is a square smooth striker, and the opposite has a flat, pointed nose. Material for the manufacture of the head serves instrumental steel, which is very strong, solid and practically not subject to deformation or destruction. Handle such a hammer can be made of wood, which is the cheapest option, all-metal pens are less common, and more and more, tools with fiberglass pens began to be produced.

About the merits We mentioned this material in the first paragraph. In order to protect hammer part from occurrence corrosion, it is covered with special varnishes or paints, or performed protective plating. To give it increased hardness, conduct special heat treatment, which consists in hardening followed by tempering. This allows you to maintain a high hardness index and relieve the internal stress of the metal, thereby reducing its brittleness. Such hammers have low weight and affordable price.

Specially for ease of execution masonry was developed automatic mason hammer. He has not yet gained sufficient popularity, but he has very significant advantages. The design of the automatic hammer consists of two laser levels, a pneumatic element that creates a shock moment and a laser receiver that is able to "understand" and receive signals from other laser beams. Using such a tool is very simple but effective.

Suppose you completed a fragment of masonry, but you doubt that its main parameter, strict perpendicularity to the base, was observed. Exactly for leveling masonry and bring it to the ideal and serves as an automatic mason hammer. It is installed directly on the last row of bricks, its laser levels create a mark that you need to focus on, then every brick Stacked under one level. Very simple, understandable, and most importantly, really functional.

If earlier the quality of masonry was determined by the skills of the employee, and one had only to rely on his consciousness and qualifications, now such complex work can be done independently. Especially since labor productivity when using this tool is increasing nearly 5 times, and its high cost will pay off after a couple of months of use.

8. Roofing hammer

The name of this tool speaks for itself, this kind of hammer was developed especially for carrying out roofing works. The purpose of the hammer is to make holes for fastenerspry boards or nails, even cut soft materials or hang up the crate. And all this thanks proper design tool. One of the sides of its shock part is made in the form of a regular shock striker, but the second, which performs the main functions, looks like a pointed forked claw, one of the ends of which is approximately 2/3 shorter than the first.

The name of this tool speaks for itself, this kind of hammer was developed especially for carrying out roofing works. The purpose of the hammer is to make holes for fastenerspry boards or nails, even cut soft materials or hang up the crate. And all this thanks proper design tool. One of the sides of its shock part is made in the form of a regular shock striker, but the second, which performs the main functions, looks like a pointed forked claw, one of the ends of which is approximately 2/3 shorter than the first.

To choose reliable roofing hammer, you need to pay attention to materialfrom which it is made. It should be only vanadium steel. Due to the fact that it is alloyed with a component such as vanadium, which is considered one of the most refractory materials, its strength reaches much higher values than ordinary steels. In addition to the material, must be performed special thermal processing in the form of high-temperature hardening, and to protect against corrosion, the impact part is coated with special varnishes or paints.

Handle It can be made of wood or fiberglass, or be all-metal. Weight a roofing hammer should be chosen depending on the intensity of the work that you plan to carry out. If it is heavy installation work that requires serious effort, then you should choose a heavier tool, weighing from 600 to 900 g. If these are more accurate and simple tasks, then give preference to a lighter hammer weighing from 200 to 500 g.

9. Welder's hammer

Perhaps not everyone knows about the existence of this type of hammer. His used during welding of varying difficulty. He serves to remove slag from the surface of the weld. So that after welding the worker could check the integrity of the seam and the correctness of its performance, performing light blows with a welding hammer, he cleans the surface, thereby ensuring good visibility.

Perhaps not everyone knows about the existence of this type of hammer. His used during welding of varying difficulty. He serves to remove slag from the surface of the weld. So that after welding the worker could check the integrity of the seam and the correctness of its performance, performing light blows with a welding hammer, he cleans the surface, thereby ensuring good visibility.

Using this tool, you can remove scale and splashes of red-hot metal, which are formed during electrode welding. Design The welding hammer is a bit like a pickaxe design. It is also made in the form of a chisel at one end and a thin sting at the other, only it does not have arched bends. Just with the help of a sting, the residues of slag in the weld are removed. Weight This tool is very small, no more than 300-350 gr, but no longer required, because it is more accurate than power work. The most common hilt material - this is a tree, less often it is made full metaland the impact part is made of durable tool steel, followed by heat treatment in the form of hardening.

10. Tin hammer

This kind of hammer designed for assembly or installation work, roofing, straightening surfaces of thick sheet metal or laying paving slabs. Shock part such a hammer is made in the form of a barrel-shaped or cylindrical shape with convex ends. Usually it is made of special rubber, which leaves no residue on the surface. With the help of this hammer, you can bend or, conversely, align or give different forms to materials without damaging their integrity. Therefore, it is often used by motorists. Weight This tool ranges from 300 to 700 g. Handle usually made from viscous wood species such as ash or birch.

This kind of hammer designed for assembly or installation work, roofing, straightening surfaces of thick sheet metal or laying paving slabs. Shock part such a hammer is made in the form of a barrel-shaped or cylindrical shape with convex ends. Usually it is made of special rubber, which leaves no residue on the surface. With the help of this hammer, you can bend or, conversely, align or give different forms to materials without damaging their integrity. Therefore, it is often used by motorists. Weight This tool ranges from 300 to 700 g. Handle usually made from viscous wood species such as ash or birch.

11. Rock hammer

Many people confuse this type of hammer with a sledgehammer because of its size and construction. They are really similar, but there are still differences. Rock hammer has forged and very durable shock part. One end has a flat square shape, and the other is made in the form of a tip, flattened from two sides.Thanks to this design, this tool is successfully used. for work with building structures, hard rocks, as well as for cracking them. It is the presence of the tip that distinguishes this hammer from a sledgehammer.

Many people confuse this type of hammer with a sledgehammer because of its size and construction. They are really similar, but there are still differences. Rock hammer has forged and very durable shock part. One end has a flat square shape, and the other is made in the form of a tip, flattened from two sides.Thanks to this design, this tool is successfully used. for work with building structures, hard rocks, as well as for cracking them. It is the presence of the tip that distinguishes this hammer from a sledgehammer.

From the scope it is clear that the material for the impact part must be made of high strength steel and pass a special hardening to obtain a hardened surface. In order to transmit a large impact force to the desired surface, the tool must have sufficient weight and a long handle. It is these differences that are inherent in the rock hammer. His weight reaches 1.5 - 2.5 kg, therefore, the greater the weight, the longer the stick should be.

For convenience, the handle is made in the form of an oval in cross section, and some manufacturers additionally make it curved. This allows avoid slipping at work. The cheapest material for the hilt is wood. But handles made of fiberglass or fiberglass are in great demand due to their ability to dampen vibration. Less common are all-metal handles coated with rubber.

12. Tile Hammer

it the smallest kind of hammers. He is successful used by finishers, working with tiles. With its help, you can very accurately chop off a necessary piece of tile, apply markings or make a hole that does not contribute to the appearance of cracks. Weight this hammer does not exceed 80 g. His shock part very small and has two sides. One is made in the form of a pointed cone, and the second has a square shape. Handle this tool is mostly wooden. Such small dimensions allow you to do very fine work. So, if repair is your way of making a profit, do not forget to get this assistant for yourself.

it the smallest kind of hammers. He is successful used by finishers, working with tiles. With its help, you can very accurately chop off a necessary piece of tile, apply markings or make a hole that does not contribute to the appearance of cracks. Weight this hammer does not exceed 80 g. His shock part very small and has two sides. One is made in the form of a pointed cone, and the second has a square shape. Handle this tool is mostly wooden. Such small dimensions allow you to do very fine work. So, if repair is your way of making a profit, do not forget to get this assistant for yourself.

13. Hammer for drywall

How often did you have to work with drywall? Probably at least once in a lifetime. After all, it is almost universal material, from which many design elements can be done do it yourself. To facilitate your work, we came up with a special hammer to work with this material. His design has one end made hatchetand the other is rounded. With it, you can chip off the excess parts of drywall.

How often did you have to work with drywall? Probably at least once in a lifetime. After all, it is almost universal material, from which many design elements can be done do it yourself. To facilitate your work, we came up with a special hammer to work with this material. His design has one end made hatchetand the other is rounded. With it, you can chip off the excess parts of drywall.

For example, you are faced with the task of making an arch. You have already completed the main part of the task - made the frame, it remains only to sheathe it. All the necessary elements are already cut, you already hold in your hand screwdriver, with your second hand you attach a fragment and begin editing, and at the last moment you notice that there is clearly an extra piece that extends beyond the necessary limits. Do not unscrew the whole fragment back to trim, right? Here and a drywall hammer is useful. And if you need to hammer something into drywall, then the round shock part of this tool don't leave dents on a soft surface.

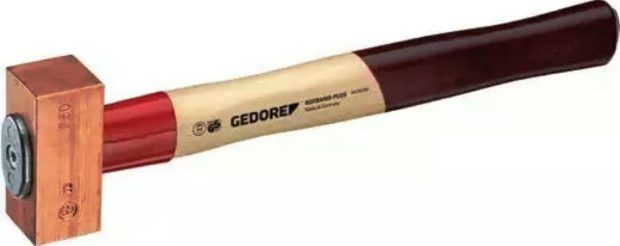

14. Copper hammer

Advantage This type of hammer is that it does not produce sparks when struck. This feature allows you to perform work in hazardous areas. The shock part is usually rectangular in shape and, accordingly, is made of copper, a non-ferrous metal of red color. Copper known for its high resistance to corrosion, it does not change its strength characteristics even at very low temperatures, is not affected by chemicals, therefore, a copper hammer will serve you for many years. Handle This tool is usually made of wood. Weight It lies in the range of 200 g to 2 kg.

Advantage This type of hammer is that it does not produce sparks when struck. This feature allows you to perform work in hazardous areas. The shock part is usually rectangular in shape and, accordingly, is made of copper, a non-ferrous metal of red color. Copper known for its high resistance to corrosion, it does not change its strength characteristics even at very low temperatures, is not affected by chemicals, therefore, a copper hammer will serve you for many years. Handle This tool is usually made of wood. Weight It lies in the range of 200 g to 2 kg.

15. Glazier's hammer

This hammer applies pretty seldomthat we consider an undeserved omission. It performs one single, but very convenient function. With it you can hammer window glazing beads. Indeed, in the cross section, its shock part has the shape of a trapezoid, which tapers towards the end.This way, you will definitely hit the cloves, not the glass or frame. Indeed, this is exactly what happened when you tried to make it an ordinary bench hammer. Weight This hammer is not more than 125 g. It is thanks to the small dimensions about the special shape of the hammer that it is very convenient. Handle They are made of wood, and the impact part of their tool steel.

This hammer applies pretty seldomthat we consider an undeserved omission. It performs one single, but very convenient function. With it you can hammer window glazing beads. Indeed, in the cross section, its shock part has the shape of a trapezoid, which tapers towards the end.This way, you will definitely hit the cloves, not the glass or frame. Indeed, this is exactly what happened when you tried to make it an ordinary bench hammer. Weight This hammer is not more than 125 g. It is thanks to the small dimensions about the special shape of the hammer that it is very convenient. Handle They are made of wood, and the impact part of their tool steel.

16. What to look for when choosing a hammer

In view of a considerable number of types of hammerswhich we examined in detail, you must to be highly attentive when buying. Whatever hammer you need, always pay attention to quality of its execution. Carefully inspect his.

In view of a considerable number of types of hammerswhich we examined in detail, you must to be highly attentive when buying. Whatever hammer you need, always pay attention to quality of its execution. Carefully inspect his.

Wooden handles should not have knots or separate long fibers. They should be perfectly smooth and even without cracks. Plastic, fiberglass or fiberglass handles should not have cracks. Rubber handles must have uniform coating without blisters and delamination. Color should also be uniform. If there is a bright spot somewhere, this indicates a thin coating.

Do not buy hammers with all-metal handles without special thickenings on the handle or without coating. Such a tool will constantly slip and transmit strong vibrations upon impact. Mounting location the handle to the shock must not have gaps or backlash. It should sit firmly in place and even after the application of force should not be displaced.  Now it's time to experience on durability materialfrom which the shock part is made. Since you are in the store, the only thing you can do is take a second hammer and hit them on the surface of the hammer striking you a hammer. The seller is likely to be unhappy, but you will immediately understand whether it is worth making a purchase. On the surface no dents or scratches remain.

Now it's time to experience on durability materialfrom which the shock part is made. Since you are in the store, the only thing you can do is take a second hammer and hit them on the surface of the hammer striking you a hammer. The seller is likely to be unhappy, but you will immediately understand whether it is worth making a purchase. On the surface no dents or scratches remain.

Also pay attention to weight. If you buy a hammer for home usethen 350-450 grams tool will be enough. For heavier work, a weight of at least 600 g is required. If the impact test and visual inspection were successful, then feel free to get your new assistant.