10 tips for choosing gypsum 3D panels for walls: form, installation

Gypsum plaster 3D panels made a real breakthrough in the field interior design. Brand new and original solution many consumers quickly enjoyed the design of the walls. If you have not had time to get acquainted with this element of decor, we’ll tell you how to choose gypsum 3D panels for walls and skillfully use them in the interior of your home, we will consider in detail all possible forms and give do-it-yourself recommendations.

1. What is a 3D panel?

3D gypsum panels - These are square or rectangular plates on which a certain pattern is repeated. The front side of the panel can repeat absolutely any ornament or imitate various materials. The back side of the plate is usually flat. But some manufacturers produce 3D panels, in which the front and back sides follow the contours of each other. It is significantly reduces weight slabs and subsequently facilitates self-assembly. On average, a plate with a flat back side measuring 50 × 50 cm has a weight of about 4.5 kg.

The first 3D panels created and developed in the USA in 2008. Very quickly, Europe became interested in this innovation, and then Russia took it, and already in 2011 the first domestic production appeared on the territory of the country. Eco friendlynon-combustible gypsum 3D panels of factory quality, on average, cost about 4000 rubles per square meter. 3D panels are perfect for those people who not only want to quickly change the internal appearance of their apartment, but also give it greater depth and originality.

2. Production technology

Process production of 3D panels, which is used by almost all manufacturers actually does not represent by myself nothing supernatural. Gypsum mortar is mixed on special equipment. Recommended use gypsum G-16which is very ductile and non-combustible. To give the finished product strength and resistance to shock, some manufacturers add special plasticizers or fiber fibers to the gypsum mixture, thereby degrading the environmental performance of this type of decor. The finished mixture is poured into special plastic formsrepeating the necessary ornament.

Molds for panels are made very carefully, pre-creating a 3D model on a special computer program. Artists and designers with extensive experience work on creating forms. Then the computer model of the form is cut out on a special machine and finalized to the full compliance with the artist’s idea. Only after that the finished matrix can be used in mass production.

During pouring the mixture matrix Little vibrates, this is used to ensure that the material is evenly distributed in shape and does not form internal voids. The following is a drying process. Forms are allowed to brew for 20-30 minutes, after which the panels are removed and sent for further drying to the premises, with controlled temperature and humidity. After complete drying, the product is considered finished.Naturally, the whole process is fully automated, all proportions are strictly observed, and the quality of the surface and edges of factory panels is always at the highest level.

Of course, the use of modern equipment and labor costs for people slightly increase the cost of the finished product. If you are not limited in funds and can afford to spend a decent amount of money on this type of finishing material, then, of course, it is better to buy 3D panels from trusted manufacturers. But if you’re used to do it yourself and want to make sure that you have a really environmentally friendly product without any impurities, we suggest you try to do do-it-yourself panels.

3. DIY 3D decorative panels

Everything is much simpler than you can imagine. Moreover, making 3D panels yourself, you don't have to splurge to deliver and worry about the integrity of the goods, and do-it-yourself things are always more valuable than purchased ones. The only thing you need to be prepared for is the more painstaking and time-consuming process of installing your own panels.

From the previous paragraph it is clear that 3D panels are made injection molding. You can purchase a form with the necessary drawing on the market or order it online. Forms are not only plastic, but also silicone. It’s more convenient to extract finished plates from them, but they cost more expensive, so for a one-time production, plastic is enough for you. Next you will need materials for pouring mixtures. They are inexpensive and sold at every hardware store. You will need gypsum, fiber, lime and drill head in the form of a mixer for mixing the mixture. Fiber is a reinforcing material, the use of which is not necessary, but preferable.

Let's proceed to the manufacture of the panel. Prepare flat surfaceon which your mold and container with clean water will be placed to mix the mixture. Manually kneading a homogeneous mixture without lumps will not work for you, besides, everything needs to be done quickly, so use a drill with a mixer nozzle. For cooking solution mix 300 grams of lime and 2.7 kg of gypsum and add fiber, the mass of which should be no more than 1% by weight of gypsum. Pour the mixture into clean cold water (2 liters) and mix thoroughly. Make sure that there are no lumps and air bubbles, otherwise they will certainly spoil the appearance of your panel. When the finished mixture begins to resemble thick sour cream and becomes homogeneous, you can start pouring it into the mold.

In factories, the molds are located on special vibrating tables, which prevents the formation of bubbles and gives the necessary shrinkage, but you can lightly tap the mold as it fills. Evenly spread the mixture over the entire mold and let it stand motionless for about 30 minutes. The gypsum mixture hardens very quickly, therefore per day you can easily do 6-8 m² finished panels.  The main thing is to be very neat and consistent. After drying, carefully remove the panel from the mold, starting from the corners. Inspect the surface, if its appearance suits you, transfer the product to a flat wooden surface for further drying. Well, if it will be wood grill. This will contribute to the rapid evaporation of excess moisture and faster drying. Follow normal rates temperature and humidity in the room. It is impossible to make panels in a damp, not heated room.

The main thing is to be very neat and consistent. After drying, carefully remove the panel from the mold, starting from the corners. Inspect the surface, if its appearance suits you, transfer the product to a flat wooden surface for further drying. Well, if it will be wood grill. This will contribute to the rapid evaporation of excess moisture and faster drying. Follow normal rates temperature and humidity in the room. It is impossible to make panels in a damp, not heated room.

The subsequent fate of your panels depends only on your imagination. You can paint them or open with clear varnish. This will not only give them a beautiful glossy sheen, but also facilitate wet cleaning. Home-made 3D panels subject to technologynot much different from purchased, except that the straightness of the edges.This is exactly what we had in mind when we talked about more difficult installation. But since gypsum lends itself well to processing, you can trim the edges with sandpaper or a stationery knife. But how nice it will be to boast to guests that this is your doing.

4. Benefits of 3D panels

Gypsum panels gained massive popularity not only because of their unusual and attractive appearance, but also because a number of other the benefits:

- Versatility. All kinds of three-dimensional drawings, which are offered by manufacturers, will be appropriate in absolutely any room. They are excellent complement as interior living room and bedrooms or even the kitchen. 3D panels fit all interior styles, giving it unique features. You can paint the panels, open them with varnish or wallpaper. You can perform both seamless laying and specifically highlight each slab. Whatever you choose, it will be unique anyway.

- Practicality. Properly laid high-quality 3D panels can serve you more than 50 years and not lose your appearance. Gypsum promotes normalization level humidity indoors, therefore dust practically does not settle on it. He has a high heat- and soundproof properties, so using this method of decorating walls, you will not only decorate them, but also insulate and get rid of extraneous noise neighbors. Gypsum does not burndoes not conduct electric current, protects from radioactive radiation, does not emit harmful substances and is very is simple in care.

- Environmental friendliness. Recently it has become very fashionable to give preference to natural materials in interior design. It is not only beautiful, but also a positive effect on your health. Gypsum is environmentally friendly, hypoallergenic absolutely safe for health. Therefore, you can safely use the panels even with decoration children's room. Checking the panel for compliance with the declared environmental friendliness can be very simple, without even requiring special certificates. If panel beats when falling, then it is, indeed, made of gypsum without unnecessary additives.

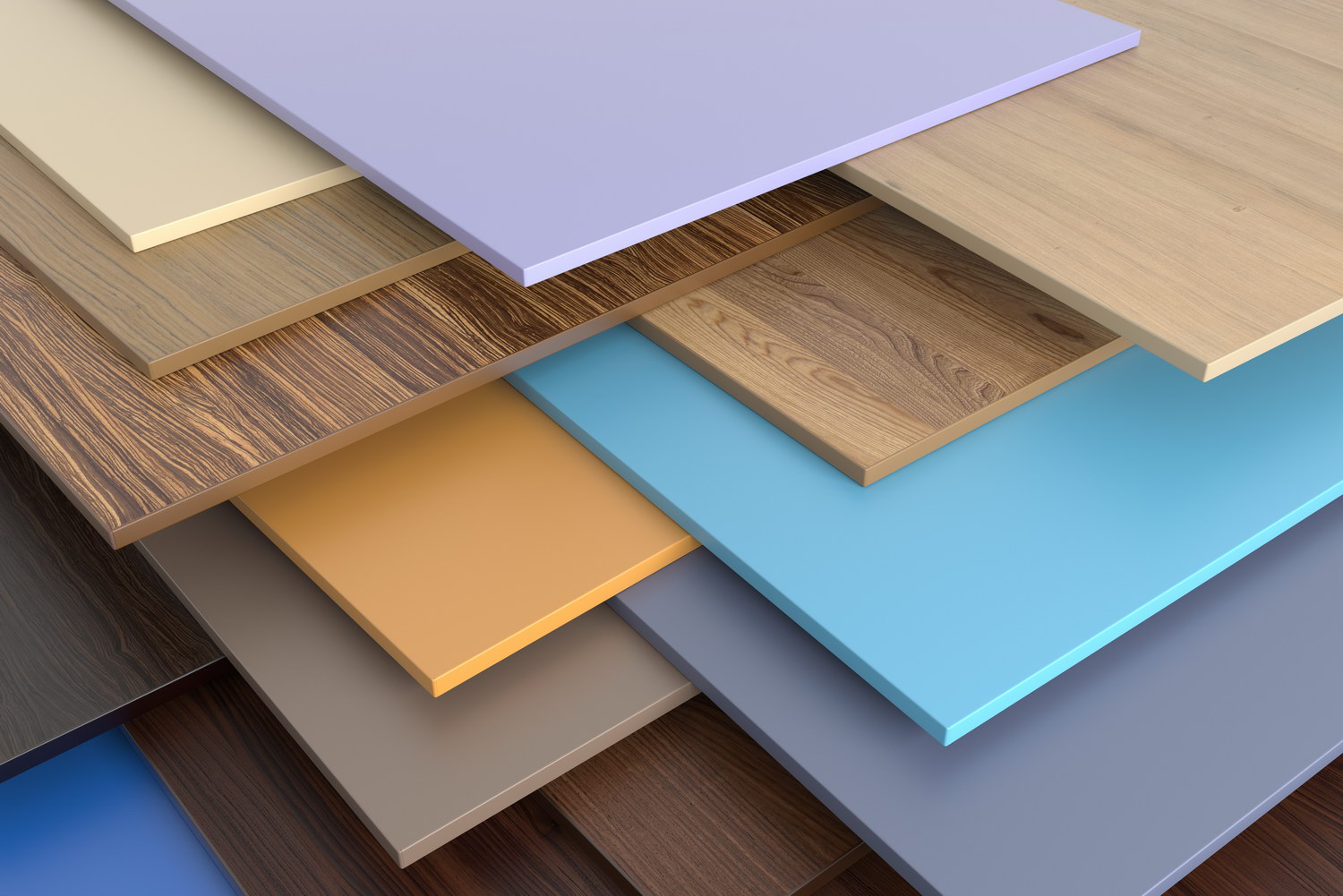

- Cost. In addition to gypsum wall panels, there is also panels of their MDFmetal bamboo glass plastic and other materials. Apart from the plastic panels, which look pretty cheap, gypsum panels are the most affordable. In addition, pricing depends on the complexity of the drawing, so everyone can choose the option that suits him.

5. Disadvantages

Probably, there is not a single type of finishing materials that, with all its indisputable advantages, would not have at least one drawback. The main disadvantage of 3D gypsum panels is their weight. One plate can reach a weight of 5 kg, depending on its size. And if you decide to decorate the entire surface of the wall with an area of 10 m², for example, this will create an additional load on the floors, which is not always permissible by building codes. A partition from drywall and may not be able to withstand such a load. Therefore, it is recommended not to fill the entire space of the wall, but only her fragment. It is also worth mentioning that branded designer 3D panels with a unique pattern will cost you highly expensivebut they really will be exclusive.

6. A variety of forms

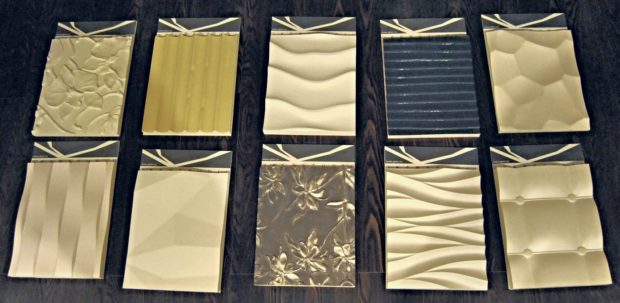

The most popular manufacturers offer 3D panels with really unimaginable patterns. But they can be combined into several major groups.

- Lines and waves. This is the simplest and most common form of 3D panels. They have a very soft smooth forms, and the width and intensity of the lines is quite diverse. They can have a horizontal, vertical or diagonal direction and simulate light bends that leave sea waves or large strips of various widths on the sand.They can also have different heights of protrusion above the main surface of the panel and be barely noticeable or characteristically pronounced. This motive is very good for recreation. This calm, unobtrusive ornament sets for relaxation and gives a feeling of comfort.

- Honeycombs. This version of the 3D panel looks very interesting in hallway or in the lobby. Honeycombs can have both large and small cells. The panels can be smooth and only follow the contours of the honeycombs, or be voluminous and protrude or drown in relation to each other at different depths. The last option looks more spectacular and realistic. Honeycombs can have both the usual hexagonal shape and be slightly elongated. This effect adds more volume to the surface on which it is used.

- A rock. It turns out very well to imitate, so beloved by everyone, brick masonryusing 3D panels. Bricks can have a smooth, or embossed surface, which makes them even more similar to real material. They can repeat masonry in a checkerboard pattern with the same seam, and can be located on the panel perpendicular to each other with a large distance or just repeat horizontal lines. Also, 3D panels are able to simulate chapped plasterrough surface granitespongy coquina and other options for natural stone, both in shape and texture. Such panels look very restrained and naturally. Suitable for decoration fireplace area in the living room and for hallway.

- Fabric imitation and other materials. This is a very interesting type of panels, which can very dignally imitate the upholstery fabric, and even have buttons, as on leather sofas. Can repeat structure woody fibernatural skin or luxurious tapestries. This design looks very gorgeous and expensive, especially in spacious cabinets or libraries, and skillfully selected color will help to achieve maximum naturalness.

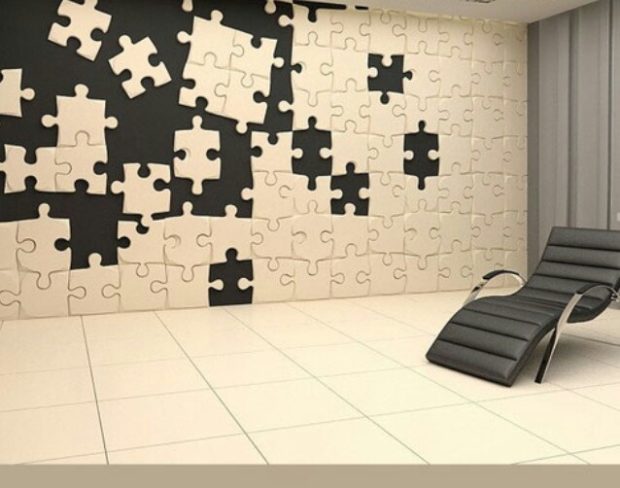

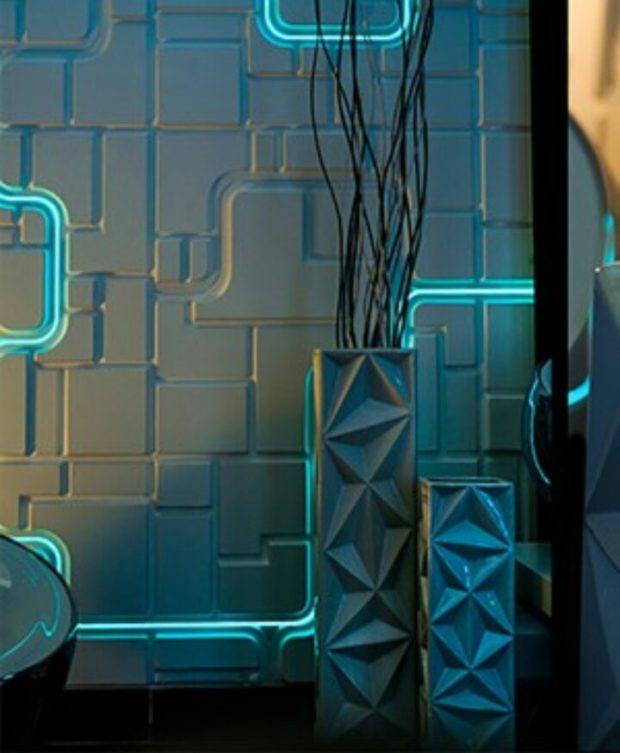

- Abstraction. Abstract panels fit into the interior in the style of a loft, hi-tech or minimalism. Used patterns are very diverse. These are rhombuses, and small labyrinths, and rectangles of different sizes, located at angles to each other and protruding above neighboring elements. This can be pigtails, the effect of crumpled paper, large or small circles, lines resembling a snake, all kinds of bends and fractures, triangles, puzzles and other geometric shapes. Such an ornament does not oblige to anything, but at the same time, it is very original and "alive". Immediately there is a desire to touch such a surface. Such 3D panels will look great, perhaps, in any room.

- Bubbles and Spheres. Imagine a soap bubble show! And on your wall? There are panels that really look like large bubbles different sizes. It looks very unusual and immediately resembles a spaceship. There are panels that resemble raindrops on glass or circles on water, or just small ovals arranged in random order and intersecting each other in different places. Such panels will be appropriate in the bathroomMoreover, there are moisture resistant 3D panels.

- Floral ornament. The variety of forms of this type of panels is probably the richest. it all kinds of flowers large and small sizes, trunks of plants intricately intertwined with each other, leaves of various plants, bamboo, huge asters, orchids, ivy, daisies and roses, or simply separate petals. These panels look very saturated, so we would recommend using this type for decorating a wall panel, otherwise it can be too sticky. Although, this is also a matter of taste.

As you can see, choosing a gypsum 3D panel will be very difficult, therefore imagine in advance yourself, how this or that form of panels in your interior will look. Focus on furniture and the design of neighboring walls.If your interior is dominated by calm, austere colors and shapes, then similar panels should be chosen. Such a tandem successfully will emphasize depth and elegance your the rooms and will look appropriate.

7. How to avoid fake

If you decide to purchase 3D panels from the manufacturer, then be sure to choose the company that has all the sanitary and epidemiological, as well as fireproof certificateswho are able to confirm the quality of their goods. Always give preference to manufacturers who have their own production site. Never Do not buy products online if you have not had the opportunity to personally touch and inspect the quality of the panels of the selected manufacturer, for example, from friends. If, nevertheless, you decide to take a chance, then it will tell you a lot packagingin which the goods will arrive. A self-respecting manufacturer, always take care of its products, therefore, the packaging will be appropriate. In the ideal case, the panels should be packed each in a separate cardboard box and wrapped in a special shockproof film with air bubbles.

They will also be told about many things. panel edges. From a quality manufacturer, they perfect flat and are perpendicular to each other, which allows you to easily perform seamless styling, and not waste energy on grouting uneven joints. Picture decent 3D panels perfect will match on each tile and you do not have to deal with selection.

Surface quality - one of the most important indicators of panels. Manufacturers who strive for market leadership are very sensitive to this parameter. They invent new and improve existing production technologies that would allow achieving perfectly flat surface. You just have to run your hand over the panel and it will immediately become clear to you - a quality product in front of you or the brainchild of an incomprehensible production. The surface should not have roughnesses, irregularities, and especially particles of small debris or abrasive. Having a smooth surface allows you to significantly save on finishing. If the product you received does not meet these requirements, be sure to return it to the seller, otherwise you will learn more during installation than you will get aesthetic pleasure.

8. Tips for use in the interior

Gypsum 3D panels are often used in interior decoration. After all, a skillfully selected pattern can visually make the room a lot biggerthan she really is and expand her. By the way, they successfully decorate not only walls but also the ceilings. This extraordinary solution will appeal to people who love experimentation. Such a ceiling will definitely become the center of attention of your home. If we are talking about wall decoration, then remember that it is not customary to decorate all the walls in one room with panels, and even more so of different shapes. It will be too much and a touch of originality will be lost. Select one wall and turn your fantasies into reality. Using paneling, you can perform not only the decor function, but also several tasks at the same time. Let's consider in more detail:

- Decor. This function is the most obvious. 3D panels will transform in an instant even the most mediocre interior and make it rich and interesting. The panels made of panels made at the head of the bed or above the sitting area in the living room look very profitable. The interior in which there is such a wall looks very original and complete, and does not require additional decorations. For accent wall decoration 3D panels are great, especially if you prefer to give them your favorite color. Choose a central wall or part of it for decoration with this decor element, and also do not forget that spectacularly looks designed in this way TV area and the area around the fireplace.

- Zoning. This is what implies the use of panels not only for decoration, but also as a practical solution. Highly relevant it will be in one-room apartments or studio apartments. Instead of decorating the wall with wallpapers of different colors or textures, it is much more interesting to decorate the wall of a bedroom, combined with the working area, using unusual 3D panels. Thus, you can separate any zone, the main thing is to show imagination.

- Partitions. You can’t imagine how beautiful the partition made of 3D panels looks compared to gypsum plasterboard. The undoubted plus of such partitions is ease of installation and the opportunity to do it translucent. Thus, the room will not seem limited, and the partition itself will look airy and weightless. And the light, refracting and falling into the intervals of the ornament, can create a unique play of shadows. Partitions can have both practicalboth aesthetic and the function.

Do not forget that it is important to choose not only a suitable form, but also color. Light colors are well suited for the classical style, and dark colors will add mystery to your room. Finishing with 3D panels looks very advantageous, which additionally emphasized right lighting. Do not neglect this rule, be sure to use at least a pair of spotlightsaimed at such a wall. Shadows that create bends on the surface of the panels will add depth and comfort to the room. Usually direct the light along the drawing, such an arrangement most favorably emphasizes its texture, so the light source can be located both above and below or below the side of the wall. The most optimal angle of incidence of the light flux is 13-20 degrees. More recently 3D went on sale panels with already integrated LED backlight. You can change the color, and even the intensity of lighting, depending on your mood with the help of a small control panel. Such panels are, of course, more expensive, but the effect is stunning.

9. How to install correctly

If you are not going to resort to the help of the master, and intend to lay 3D panels do it yourself, you need to carefully approach this issue. After all, from the quality of installation directly service life depends and the appearance of the wall so decorated. Before starting installation, leave the panels for 48 hours in the room in which work will be carried out. This will protect against fragility and facilitate installation. Exist two ways panel mounting - on a metal crate and directly on the surface using adhesive mixtures.

- Mount on metal frame involves the use of additional room space and the cost of its construction. Gypsum panels are attached to metal profiles using screws. Holes in the panels themselves are drilled, and after fastening, they are sealed with putty. Not the most gentle way.

- Mounting directly to the surface possible only if available smooth walls. If your walls are not perfect, then additional work on them alignment, or give preference to the first option. Wall surface must be carefully handle soil deep penetration, then it is recommended to process the back side of the panels themselves. After this, apply markup. Via level draw a straight vertical and horizontal line - this will be your guideline for the first panel. It is necessary to apply to the mounting location adhesive mixture. Give preference to mixtures that include gypsum, for example, "Perlfix»From Knauf. If you neglected the proper preparation of the wall before pasting and hope to level it with a thicker layer of adhesive mixture, then be prepared for the fact that its consumption will be several times more than necessary, and its cost is not the cheapest. So, apply a layer of glue to the marked spot and evenlyspread with a notched trowelLean the panel and align it according to the marked lines. The Perlfix mix quickly sets, so you don’t have to hold the panel for too long. Lay the subsequent tiles in a horizontal line, focusing on the first. If you have chosen seamless way stacking, then experts still recommend leaving small gaps, approximately 2-3 mm wide, so that later they can be filled with putty. So you will achieve greater uniformity. There are two ways to fill the seams. - after complete drying, hammer them with putty using a small rubber spatula, or put the putty directly on the joint. Glued the first panel - apply a thin layer of putty on the end, which will be in contact with the next panel. Press it not only against the wall, but also to the end face on which you put the putty. Its excess will immediately come to the surface. They must be carefully removed with a damp cloth. This way you will achieve complete filling of joints without waste of time. If the last panel does not lie completely on the wall, do not be alarmed, with a small hacksaw you can easily saw off a piece the necessary size. It is recommended to process the sawn edge with sandpaper. If after completing installation you notice bumps or gaps in the joints, refine these nuances with a finishing putty.

It doesn’t matter how you fastened the panels to the wall, the main thing is if you to be painted 3D panels, they must be treated with soil. Painting can be done with roller or spray gun. Recommend to choose a water-based, latex or acrylic matte paint.

10. Selection Tips

Before buying panels you must be sure know necessary them quantity, because buying is not a problem, but paying too much will be a shame. It is easy to make the calculation, knowing the dimensions of one panel, even at the place of purchase. The choice of form depends on your personal preferences. Remember, it's better to choose quality manufacturers and make a purchase directly in the store, after evaluating the quality of execution, and not on the Internet. Do not be tempted by the low price. If the price of the panel is significantly different from the average pricing policy, this means that manufacturers use substandard materials and do not have quality certificates that you must require from the seller before buying.  Attach two panels to each other if pattern matches perfect as well gaps at the junction minor, then you have a quality product. Try to touch facial surface selected panel - it should be perfectly smooth and even. If the product you have chosen meets all these requirements, feel free to make a purchase and hurry up to make your interior magical!

Attach two panels to each other if pattern matches perfect as well gaps at the junction minor, then you have a quality product. Try to touch facial surface selected panel - it should be perfectly smooth and even. If the product you have chosen meets all these requirements, feel free to make a purchase and hurry up to make your interior magical!

Good afternoon, is it possible to use gypsum panels for a wall that is constantly cracking, as the foundation settles?