7 tips for which foam to choose

It is difficult to imagine even the smallest repairs without the use of such a universal tool as mounting foam. With its help, you can easily cope with tasks such as sealing joints, eliminating voids and gaps formed after installing new interior or entrance doors, and many other tasks. Going to any hardware store is very easy to get confused, given the extensive range offered different manufacturers. How to navigate and which mounting foam is better to choose to get the desired result, we will understand in this article.

1. One-component and two-component polyurethane foam - what is the difference?

Polyurethane foam or polyurethane foam sealant is a mixture of two chemical substances (polyol and isocyanate), which are obtained from crude oil. As a result of the reaction of these components with each other, pure polyurethane foam is formed, which is the basis of the foam after the completion of the crystallization process. To improve the properties of the material, various catalysts and adhesion promoters, refractory additives, antifreeze components and filler gases are often added to the composition. Due to the porous structure of hardened polyurethane, the foam serves as an excellent insulator. It can be applied to the most diverse surfaces of material - stone, concrete, iron, wood, plastic. Such a wide range of compatibility allows solving a lot of construction issues. Depending on the chemical composition Distinguish between one and two component foam.

- For the most part, all the variety of this material presented on the windows is single component. Packed such a composition in a container. The main disadvantage is a short shelf life due to the possible occurrence of uncontrolled reactions inside the container and a long curing period. It will take about a day for complete solidification. The principle of its operation is very simple - at the exit from the container, the composition enters into a chemical reaction with moisture, which is contained in the ambient air, instantly increases in volume and after the above time completely hardens. The foaming agent is a mixture of liquefied gases - a propellant, which consists of butane, isobutane and propane. The same mixture promotes the formation of pressure inside the cylinder, due to which the foam escapes through the nozzle. Upon contact with air, expansion occurs in a 20-40-fold size, which allows filling even the most inaccessible places with high quality and without the formation of internal cavities.

- Two-component polyurethane foam is more complex and expensive to operate. The difficulty is that immediately before use you will have to mix several forming components with your own hands, which are stored separately in special containers. In this case, it is very important to strictly adhere to certain proportions, otherwise the resulting mixture will not have the necessary characteristics. The chemical reaction that forms when mixed is dispensed with without the participation of air from the environment and is much faster.Additional costs will be associated with the need to purchase a special mixing gun or a gun installation in which the composition will be prepared. Her main honors from a single component material is the curing rate. The process of complete crystallization takes only 20-30 minutes, and excess material can be cut off after 10 minutes after application. Also, the process of polymerization of a two-component foam does not depend on an indicator of air humidity and always passes successfully. Shelf life is also increased due to the separate content of the forming substances. However, the prepared mixture is not suitable for repeated use and implies the complete consumption of the cylinder after preparation.

So, summarize. The use of two-component compounds makes sense only to professional workers in the field of construction and repairs. For a one-time use at home, a container of one-component foam is sufficient. Even a person who has never used this material before can use foam in a bottle with a nozzle in the form of a plastic tube.

2. Key Features

Like any building material, polyurethane foam has a number of characteristics, the quality of the product depends on the indicator of which. All highlights will be indicated on the label. So what is it worth pay attention when buying:

- The degree of primary expansion is an indicator of how many times the volume of foam at the outlet of the cylinder will increase in contact with air.

- The degree of secondary expansion is an indicator of the increase in the volume of material after the expiration of the period of complete crystallization.

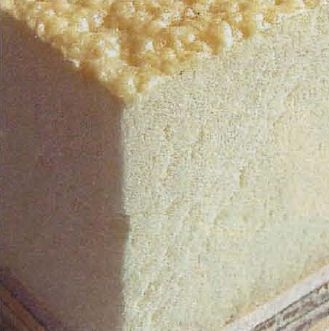

- The density of the foam. It affects the rate of expansion. In household foam, this figure is lower than in professional. To obtain a very tight joint, it is necessary to purchase foam with a low rate of secondary expansion.

- Viscosity is a property of the material, which ensures the non-flowability of the foam on the surface.

- Shrinkage - is indicated in percent and implies a decrease in the final volume of the composition by the specified value.

- The output volume of the foam. On each cylinder you can see the numbers - “50”, “60”, “70”. What do they mean? This is the number of liters of foam obtained at the outlet of the cylinder. But the indicated quantity can only be obtained under condition of operation under the correct temperature conditions and controlled humidity parameters. Usually the actual amount of foam will be less.

- Adhesion to materials - in other words, the ability of the composition to “stick” to various surfaces.

- The time of complete solidification and trimming - given these indicators, you can have an idea of the time it will take to carry out the work, and you will understand how many hours plaster, to grind or give a seam to other influences without harm to it.

- The weight of the cylinder is a very important indicator. Keep in mind that if the volume indicated is 750 ml, then it should weigh at least 850-920 grams. If it is lighter, then the composition inside is much smaller than stated. This can often be found with unscrupulous manufacturers. For clarity, you can hold in your hands cylinders of different brands with the same volume. It is possible that one of them will be clearly harder. It is worth buying.

3. Which foam is better, household or professional

It is very simple to distinguish between household and professional polyurethane foam. Just look at the container - if a nozzle in the form of a thin plastic tube is attached to it, it means that it is intended for domestic use. However, it is unequivocal to say that only beginners use such foam, and professionals must use a nozzle in the form of a gun, it is impossible. Consider the main differences to help you decide and choose the right view.

- The first thing that is immediately noticeable is the amount of packaging.Household foam is sold in containers with a capacity of 300 ml and above, while professional foam - from 750 ml and above.

- An important indicator is the exit of foam from the cylinder. In the case of household aerosol, not all of the composition can be completely blown out. Usually, some part remains inside, and from the volume declared by the manufacturer you get a slightly averaged value. Thus, instead of the required one cylinder, two may be required, and this already affects the costs associated with the repair. In this regard, professional foam, which is blown almost completely, proved to be much better.

- The secondary expansion coefficient in household compounds is very large. In the process of final hardening, they can increase in volume up to two times. The same coefficient for professional foam is almost zero. For better or worse, depends on the nature of the work performed. For example, if you are faced with the task of filling a large gap in the wall or eliminating the creaks of an old wooden floor by blowing foam under it, a significant expansion indicator in this case is a plus. If you set the slopes yourself, plastic windows or doors, it is better to fill the space around them with the composition with the lowest coefficient of expansion. Otherwise, there is a possibility of surface deformation. Only with proper skills in working with this material can household foam be used for such precise work. Usually, specialists fill only 1/3 of the gaps with foam, knowing that they have finally hardened, it will fill the entire space without changing the geometry of the adjacent surfaces.

- The shrinkage rate of household foam is 5-7%. Professional - 0-3%.

- Regarding the need to use an additional device in the form of a mounting gun, household foam wins, of course. It is enough to wind the tube supplied in the kit, shake well, and the foam is ready for use. Professional compositions work only with a pistol, the cost of which is several times higher than the cost of the foam bottle itself. For single use at home, such expenses are impractical. Indeed, in addition to this, it will be necessary to purchase a special solvent that will clean the nozzle of the gun from the remnants of the foam.

- The possibility of reusable use is undesirable for household cylinders, but possible. If it was not possible to use the entire cylinder to the end, clean the remaining cavity of the tube from the remaining foam with a propellant and store in a cool, dark place. Professional foam can be used partially. But it is necessary to store it at the same time with a pistol dressed on a cylinder. In this case, the foam inside does not harden and is suitable for further use. The nozzle of the gun must be cleaned with a special solvent.

- And the most main difference - the nature of the work performed. Household foam is used for one-time, rough work, which does not require accurate dosage. Professional compositions are distinguished by the possibility of high-precision application and are used for sealing joints or thermal insulation.

4. What is “summer”, “winter” and “all-weather” polyurethane foam?

One of important parameters polyurethane foam, about which I would like to say separately, is temperature mode of operation. Be sure to take into account the temperature in the room and beyond before buying polyurethane foam. It is not in vain that this parameter is indicated on cylinders. Following the recommendations of the manufacturer, it is possible to achieve better quality of the material obtained at certain times of the year. Distinguish three kinds assembly foam:

- Summer - used at temperatures from 5 to 35 ° C. It is usually used for repair work indoors or outdoors during the warmer months.

- Winter - the range of operating temperatures is -10-35 ° С.

- All-weather foam - used at ambient temperatures from -10 ° C to + 35 ° C.

Why is that important to comply are these conditions? Because the use of, for example, summer foam at sub-zero temperatures will affect the duration of its complete hardening, the density of the weld obtained, the expansion coefficient and the volume of foam at the outlet. All these indicators will differ significantly from those stated on the label, and the quality of the work performed will noticeably worsen. Complete crystallization time will increase significantly. The same will happen if winter foam is used during the hot season.

Regarding all-weather foam - important nuance its use is the temperature of a cylinder of liquid. Yes, the range of operating temperature allows the use of foam at minus indicators, but professionals recommend heating the aerosol to a temperature of + 10 ° C. In this case, the characteristics of the material will be much higher.

5. How to use the mounting foam

Consider situations when appropriate and when not really, use assembly foam:

- Do not use foam for sealing cracks with a width of less than 1 cm. For these purposes, they are better suited sealants or more ductile materials, for example, putty. In addition, these materials do not have secondary expansion.

- If the gap width exceeds the mark of 10 cm, before filling it with foam, it is better to further reduce the space with wooden beams, bricks or any other sealant. This will significantly reduce the consumption of foam and increase its adhesion to the surface. Otherwise, under its own weight, it can simply slide along the walls of slits of large width.

- The optimal size of the gaps for filling with mounting foam is 2-8 cm.

- For faster polymerization and better adhesion of the foam to the adjacent surface, many recommend slightly moistening the walls before application. And then, spray the installation joint with water from the spray gun after the initial hardening.

- It is not recommended to use foam on surfaces such as Teflon, silicone, polyethylene and other greasy or dusty walls. She just does not stick to such materials.

- Be sure to consider the coefficients of primary and secondary expansion. This will help to understand how thick the seam is to be placed in the gap of a certain width.

- Before using the container, be sure to clean the surface according to the instructions on the packaging.

- If the bottle is too cold or you brought it in from cold, hold it in warm water (not more than 20 ° C).

- To ensure the best mixing of the components among themselves, turn the container upright and shake for 1 minute.

- Use protective gloves. It’s very difficult to wash dried foam.

- In no case do not touch the freshly applied foam until it has frozen. You will not only get dirty, but also disrupt the structure of the material. This can lead to poor hardening or incomplete expansion.

- To get the full amount of foam out of the bottle, be sure to hold it vertically and upside down until the work is completed.

- The mounting foam should be pale yellow throughout its life. But you can see that over time it can darken. This is caused by the harmful effects of ultraviolet rays, which destroy the structure. If possible, seams are better. plaster or paint, thereby protecting from sunlight.

It is very simple to use a cylinder with household foam. It is enough to wind the tube and the working nozzle is ready. But if you still decide to purchase professional foam and special gun you need to be able to to use correctly. The principle of its operation is very simple - the gun is wound on a cylinder, after which the foam enters the barrel through the supply valve. There she remains until you pull the trigger. After that, the material is released with a given volume.  Consider highlights:

Consider highlights:

- Choose guns that are made only of hard metal.

- To facilitate cleaning and replacement of parts, it is better to purchase collapsible than monolithic models.

- Obtain a special cleaner immediately.

- Before installing the gun on the cylinder, you need to unscrew the mounting screw, grease the socket with technical petroleum jelly and only after that proceed with its fastening.

- First you need to set the adjustment unit to the minimum indicator of foam consumption.

- Turn the bottle over and do a couple of test presses. So you can visually assess the need to increase the feed and adjust the volume to your needs.

- Make sure that the cylinder is always upright during operation.

- Upon completion of work or when replacing the cylinder, be sure to thoroughly clean the gun.

Adhering to these key recommendations, you can easily cope with the use of any type of polyurethane foam.

6. Briefly about manufacturers

The key to high quality material is the choice reliable and trusted manufacturer. It is no secret that the cost of a product can say a lot about its properties, because it will not be possible to make a high-quality product from cheap components. But also overpriced not always associated with the use of quality raw materials. Often, too hyped brands spend a lot of money on advertising a product, which automatically increases its price, and you just get a brighter and more memorable package, rather than higher technical specifications than a less expensive product. Therefore consider proven brands with not overpriced:

- Macroflex - has a high rate of adhesion and uniformity of structure. The foam output stated on the packaging is true. However, in recent years there have been many fakes, which has led to numerous complaints about the deterioration of the quality of the goods. The cost, depending on the type of foam, is 150-470 rubles.

- "Moment Installation" - differs in a dense and uniform structure, is well painted, is quite common in a network of construction stores. It has a large indicator of secondary expansion, and after a couple of years it can lose elasticity. The price is 145-245 rubles.

- "Sudal" - a very high-quality product with a fine-grained structure. Differs in the absence of shrinkage. Available in several versions - winter, summer and fire resistant. Has a mild odor. But it is not sold everywhere. Cost - 195-395 rubles.

- "Penosil" - It has a good rate of foam exit from the cylinder, it has a bright white color and a low secondary expansion coefficient. Not intended for outdoor use. At a temperature of more than + 35 °, it ceases to foam. Price - 200-485 rubles.

- "Titanium" - has a dense structure, lack of shrinkage and a small indicator of secondary expansion. It is used for thermal insulation of heating systems and water supply. The foam yield can be defined as medium, not complete. The price varies from 200 to 265 rubles.

7. What to look for when buying

Of course, you will not be able to evaluate the quality of the material directly in the store, but there are several signs which will help you choose a really high-quality product:

- Pay attention to the packaging, or rather its condition. There should be no scratches, dents, nicks or other mechanical damage on the container. Their presence indicates improper storage, which will certainly affect the final result, or negligent transportation, which indicates the unreliability of the manufacturer.

- Be sure to check the expiration date of the composition. The “fresher” the date, the better the substance possesses.

- Turn the bottle up and down several times or shake it lightly. You should feel how the fluid inside rolls easily and quickly. If it seems that the components are “falling” to the bottom of the container, then the curing process has begun. Mix as it should, such a foam will not work.

- The weight of the cylinder according to your sensations should exceed the volume stated on the package.A 500 ml bottle should not weigh exactly 0.5 kg. That means there is much less liquid inside, and at the exit you will get fewer liters of finished foam.

So fast visual inspection It will already say a lot about the product that you are holding in your hands, and will protect it from fakes.