Marmoleum or natural linoleum: 8 tips for choosing and styling

A growing number of people are striving to choose materials of natural origin for the interior decoration of their homes. Such a solution is not only reasonable in relation to one's own health, but also quite expensive. Recall the average cost, for example, cork wallpaper or sexes. But as it turned out, sometimes completely eco-friendly material can have a fairly affordable price. Today we will tell you about such material as marmoleum or natural linoleum, and give some tips for his choice and self-styling, highlight the pros and cons and determine the pricing policy.

1. Marmoleum production technology

It is possible that many readers first saw the name "Marmoleum" and fully believe that this is the latest invention in the field of finishing materials. This is partly true, but only regarding the improvement of the material. The very idea of producing marmoleum arose a very long time ago - back in 1863, almost simultaneously with the invention and the receipt of a patent for production ordinary linoleum. Manufacturers noticed that durable fabrics of natural origin, such as jute, which was obtained from the fibers of plants of the linden family, retain their appearance and strength much longer if they are additionally soaked with oil. Such a fabric, additionally coated with various hardening compositions, was used for flooring. Taking this idea as a basis, British manufacturers invented an improved type of linoleum - marmoleum, which consisted entirely of natural components. In his composition The following materials are included:

- Cork tree;

- Jute;

- Tree bark;

- Vegetable resins;

- Wood flour;

- A piece of chalk;

- Lime;

- Natural oil;

- Natural dyes.

Production technology also not very difficult. All components are mixed together in certain proportions. The resulting mixture is aged for 10 days so that the components are better mixed together and get a single homogeneous mass. After that, natural dyes are added to the composition and thoroughly mixed. The finished mixture takes on the necessary dimensions and shape by pressing, and then dried in specialized chambers.

Due to the fact that the components included can be called cheap, marmoleum is practically don't fake due to the inappropriateness of this venture. The output is a material that is almost identical in its properties and characteristics to ordinary linoleum, only completely natural.

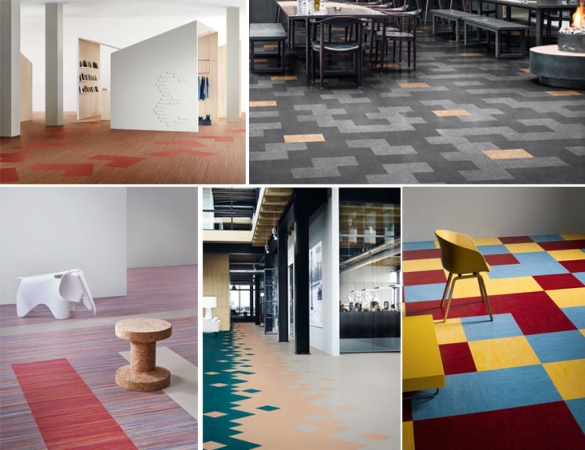

2. Types of marmoleum

Based forms release and possible sizes Marmoleum is of three types:

- Roll - represents sheets 1,5-6 meters wide. Its thickness can be 2-4 mm. The weight of one roll can reach about 120 kg, which means that it will be very problematic to independently lay such a shape of marmoleum within an ordinary apartment.Therefore, rolled marmoleum is most often used to cover floors on large areas - in shopping centers, offices, large playgrounds, etc. At the same time, laying and transportation are carried out using specialized equipment. Another feature that complicates the work with a rolled look of natural linoleum, is its increased fragility. Roll up more than 1 time is not recommended. With repeated twisting, many cracks on the surface are necessarily formed. Such material is no longer suitable for use;

- Tiled - reminds thin tile. It happens in two sizes - 30 × 30 cm or 50 × 50 cm. This form of release is most convenient for flooring in the apartment;

- Panel - looks like a plank laminate flooring, only smaller and wider - 90 × 30 cm. This shape is also quite suitable for self-installation.

3. Wear resistance classes of marmoleum

Tiled and panel marmoleum consists of three layers. The first is a cork substrate, 1 mm thick. This layer is soundproof and heat insulating. It helps to reduce noise by 20% and prevents the penetration of cold from concrete floor slabs in the home. The second layer is a moisture-proof HDF board. For the convenience of laying, some manufacturers additionally mill the lock joint along the perimeter of the plate, as on a laminate. The third layer is the marmoleum itself. Its thickness depends on the class of material.

Total exists Three wear resistance classes:

- 21-23 grade considered the thinnest - the thickness of the top layer is 2 mm. Accordingly, its cost is lower. This is a variety of natural linoleum for general use most suitable for home use.

- Grade 31-33 - Marmoleum for industrial use. The thickness of its upper layer is 2.5 mm, resistant to static loads. Less often, but still applicable for home decoration.

- 41-43 grade - the thickness of the decorative coating reaches 3 mm. Such a coating is intended for places with high traffic and intense loads. Such a floor can withstand up to 100 thousand attacks per day for 5 years. Such material is used for flooring in large airports, industrial buildings, shopping or office centers.

Do not think that the thicker the marmoleum, the better. To cover the floors in the apartment is enough material 21-23 class, which not only easily tolerates frequent loads, but is also not sensitive to static loads. In other words, the legs of even the heaviest pieces of furniture will not leave characteristic marks in the floor even after many years. What can not be said about the coverage of 41-43 classes.

Choosing size coverage, come from the area of the room. Larger panels look harmonious in large rooms. Large fragments of flooring can once again draw attention to the modest size of the room. This is true in the case of a combination of several colors of marmoleum or laying it with the intentional cutting of seams and subsequent grouting. If you intend to cover the floor with plain material without seams, then select the most optimal release form in terms of size. Measure the length and width of the room and calculate how much waste will be obtained when laying the tile, and how much when laying the panel marmoleum. Choose the variety with the lowest number and trim indicator.

4. Advantages and disadvantages of natural linoleum

Of course, one cannot fail to note the advantages and positive features this type of flooring:

- Marmoleum practically no permanent deformation and is able to withstand loads that are 160 kg / cm2;

- Due to the use of natural ingredients during production, it is safe for health and does not cause allergic reactions;

- In addition, he has bactericidal effect and improves the indoor microclimate;

- Natural linoleum has soundproof and heat-saving properties;

- When laying marmoleum does not require particularly careful surface preparation. Due to its plasticity, it will repeat small bumps to a quarter or even a third of its thickness, while its front side will remain flat;

- Due to the fact that the material is subject to coloring over the entire thickness, even when surface scratches, they will almost imperceptible. Accordingly, marmoleum is able to retain its attractive appearance for much longer;

- The coating is resistant even to prolonged exposure to ultraviolet rays, various detergents with chemical compositions, does not soak and does not swell under the influence of moisture;

- No traces of aggressive coloring substances will remain on its surface. Even the paint is easy to mark and does not stick. Thereby caring for marmoleum is very simple and pleasant;

- Natural linoleum does not accumulate static electricity, which means it does not attract dust;

- It is fireproof and does not support the combustion process. A cigarette butt thrown onto the surface of the marmoleum simply smolders and does not even leave a burn. Burning the coating is very difficult;

- The color palette, as well as the variety of textures of natural linoleum is very large. Its surface successfully imitates natural wood or stone. There are over 100 primary colors and over 2000 shades of your choice;

- Marmoleum laying is quite simple and does not require any special skills;

- And finally, the most important thing - the service life of such a coating is about 20 years. This is despite the fact that it is able to withstand the effects of water, chemicals and large power loads. And thanks to the fact that the material is constantly being improved, we can hope that this figure will increase soon.

Like any other material, marmoleum has a number of disadvantages:

- Material is very fragile. Especially its edges, which, with careless movements or improper transportation, quickly chip. Roll marmoleum is generally not intended for multiple folding / unrolling;

- Can say that its weight is pretty impressive - 2.6-3.4 kg / m2. Therefore, marmoleum is used only for cladding floors. On the walls, he simply floats under the influence of his own weight;

- Due to the layered composition, the material difficult to cut. To do this, use a hacksaw with small teeth. But even with such a tool, it will not be possible to achieve a perfectly even edge;

- In connection with the foregoing, certain restrictions arise during installation. Firstly, it is not recommended to cut plates or panels into pieces and try to lay them out in a certain color sequence. You will never achieve smooth joints with this method. Secondly, pruning should be performed only for plates adjacent to the wall, where you can hide the flaw decorative baseboard. But this is rather not a drawback, but a recommendation. After all, you can lay out the desired pattern with ready-made tiles of different colors;

- After some time, the marmoleum hardens and sounds a little apart, but this feature is hard to call a drawback, because on the contrary it’s good for flooring. Not only does the surface hardness increase, but also small gaps in the joints of the plates converge by themselves. You do not have to make any efforts for this. Knowing this fact, always check the date of manufacture and packaging of the coating before buying. Otherwise, already hardened and floated boards will be very difficult to lay.

When buying, also pay attention to availability of warranty and the possibility of replacing the product in case of damage. Remember - the material is very fragile. With improper packaging and transportation, you will pay money for cleaved goods, you will not receive the proper type of coverage and you will not be able to change it. There are also restrictions regarding the place of laying. Manufacturers do not recommend lay marmoleum on top warm floor. I see its heat-insulating properties, you will not get the amount of heat that you expected. And despite its resistance to moisture, it is not recommended to cover them bathroom floor.

4. The average cost of marmoleum

This question immediately arises after familiarizing yourself with the advantages of this finishing material. Everyone wants to get a natural and durable coating at a reasonable cost. It should be understood that cost is determined several factors:

- Form of flooring;

- The thickness of its decorative layer;

- Strength class;

- Decorative properties.

Accordingly, it will be much cheaper to buy a plain marmoleum of 21-23 classes than a material imitating wood or having a bright shade of 41-43 strength class. Cost square meter roll Marmoleum starts at 600 and reaches 2300 rubles. Tiled 30 × 30 cm material can cost about 1,500 rubles. for packaging, in which 7 plates. Panel marmoleum reaches a value of 4000 rubles. for packaging with a similar number of items. The price range is very large. This makes it possible to purchase in-kind coverage, depending on financial capabilities, but not completely abandon the purchase.

The exact numbers are difficult to name due to the regular receipt of new varieties of material. But if we average, we can say that it occupies an intermediate position between synthetic linoleum and natural wood coatings. Some types of laminate may cost more than marmoleum.

6. The best manufacturers of marmoleum

Despite the growing popularity of marmoleum, not many manufacturers are manufacturing this flooring. We will consider the most popular manufacturers who have recommended themselves from the best side and have collected the most positive reviews about their products:

Tarkett-sommer

The company is the result of the merger of the two largest flooring companies. Today, the new Tarkett-Sommer concern produces about 300 million square meters. flooring per year. With these figures, the quality of coverage remains at the best level. In total, this company introduced two rulers natural linoleum.

- The first one, called Linosom Veneto, includes 44 color schemes. The surface of the coating imitates the color of natural marble. This marmoleum is intended for laying in public places - educational and medical centers, entertainment or industrial premises. However, it can also be used for laying in the apartment. Release form - rolls, 200 cm wide and decorative coating thickness 2, 2.5, 3.2 mm.

- The second line is called Narnidur and includes only 8 color schemes. This coating is designed for harsh environments. It is used for flooring in industrial and manufacturing enterprises or sports fields. It combines good elasticity and durability.

Forbo

The manufacturing company is originally from the Netherlands, occupies a leading position in the production and sale of natural linoleum. Product quality is confirmed by numerous certificates. Named its products Marmoleum. The collection includes more than 300 types of various textures and shades. Marmoleum in the form of plates and slats with a castle connection is especially popular. The whole variety of flooring under the Marmoleum brand can be divided into several main groups:

- Marmoleum real - Available in the form of rolls 200 cm wide. The thickness of the decorative layer is 2, 2.5, 3.2 mm and imitates a marble surface. This is a category of especially wear-resistant natural linoleum;

- Marmoleum frresso - the flooring is more refined, its surface resembles old murals. The thickness of the upper layer is 2, 2.5 mm;

- Marmoleum walton - monophonic coating of various colors and shades with a decorative layer thickness of 2, 2.5 mm;

- Marmoleum artoleum - the most unique ruler with a textured surface. Sometimes on the surface you can find reproductions of paintings by famous artists;

- Marmoleum click - a three-layer coating, which consists of a cork substrate with a thickness of 1 mm, a natural chipboard waterproof HDF board with a castle connection and a layer of the marmoleum itself with a thickness of 2.5 mm. Available in the form of slabs measuring 30 × 30 cm or planks measuring 90 × 30 or 60 × 30 cm. Includes 23 colors.

Armstrong DLW

German company that produces its products under the logo Marmorette. It is characterized by simple installation, increased fire safety, wear resistance and durability. There are three lines of flooring:

- Marmorette LPX 2.5 - the coating of this series imitates a marble surface and has a decorative layer thickness of 2.5 mm. It differs in antistatic and antibacterial properties. Available in rolls with a width of 200 cm. Used for flooring in a variety of rooms. Wear resistance class - 23/34/42.

- Marmorette LPX 3.2 is a coating created for commercial enterprises. It has the same properties as the Marmorette LPX 2.5, but has a top layer thickness of 3.2 mm.

- Marmorette PUR 2.0 - this coating line is characterized by the presence of a multi-colored camouflage welding cord. The surface imitates an undirected marble color, which is why it is very popular. Release form - rolls 200 cm wide and 2 mm thick top layer.

- Marmorette PUR 2.5 - the coating has a marble structure and includes a special layer called PUR Eco System, which provides resistance to mechanical damage. The thickness of the upper layer, respectively, 2.5 mm, the release form - rolls 200 cm wide.

- Marmocor Lino Eco LPX - the most cost-effective line of flooring. The price starts from 1300 rubles. per sq. meter. Available in a roll width of 200 cm with a decorative layer thickness of 2 or 2.5 mm. Includes 12 available textures. While other lines include 51 textures each.

The products of the last two manufacturers have almost identical composition and technical characteristics. The only difference is that Forbo uses wood flour in the manufacture, and Armstrong DLW uses wood cork.

7. Laying the marmoleum with your own hands

Now let's move on to the detailed technology of self-laying the marmoleum and the main nuances of this event. Any facing work should begin with surface preparation:

- If the marmoleum will be laid on a wooden base, be sure to verify its integrity and mechanical strength. Damage to floorboards in the form of cracks, chipped strips or large vertical differences is unacceptable. If such damage does occur, cover the floor with an additional layer in the idea of OSB boards or thick plywood. In this case, pay attention to the presence of creaks. If eliminating them does not work out, it is best to remove the old wooden flooring. After all, marmoleum is laid not for one or two years, but for tens of years. You can imagine what condition the wooden floors will have during this time, and what sounds they will make.

- In the case of laying natural linoleum on a concrete surface, it must first be leveled. An ideal mirror plane is not required, but all protrusions and sharp edges must be cleaned. Dents that are too deep should be repaired. putty or any other available solution. After the floor has completely dried, sweep or vacuum thoroughly. This is necessary to maximize the fit of the material and minimize the thickness of the joints.

After the surface of your floor meets all the requirements, you need prepare the necessary for the styling process instruments and fit the material. Remember that marmoleum is a fragile material.And if you chose it in the form of plates with a castle connection, in the process you may need to knock them out. Also, do not forget about the need for trimming. So we need:

- Rubber mallet and wooden spacer;

- Hacksaw for metal or jigsawwhose file should have fine teeth and the opposite direction;

- Pencil and ruler.

Now you need to decide which side of the room is better to lay the trimmed elements and how many there will be. To do this, lay the material on the floor.

Keep in mind that marmoleum is subject to thermal expansions. With increasing temperatures, it will increase slightly in size, and with a decrease, it will return to its original values. In this regard, previously back off each walls in the room 1-1.5 cm. You can draw a boundary line, but it is best to put wooden planks of the appropriate width on the floor. So it will be not only more visual, but also an emphasis will appear. Only after that measure out by what size you need to trim the coating.

It’s better to trim the extreme rows that will go under the furniture, the battery or other masking objects. Many recommend leaving the marmoleum in the room in which it will be laid for a day so that it scores required temperature and became more ductile. After the material has settled down, you have made the marking and cutting, you can proceed directly to the masonry process. Let us consider in more detail the nuances of work with different forms of marmoleum.

Laying Tiled Marmoleum

Installation of plates can be done in two ways:

- With the selection of a picture;

- Without selection of a picture.

In the first case, work must begin from the middle of the room, moving to the edges. In the second case, laying is carried out starting from the smallest wall. Plates with a locking connection that does not require the application of glue on the back side must be laid on a polyethylene substrate to avoid condensation. To do this, use a conventional film, which is laid on top of each other with an overlap of 20 cm. The joints are glued with tape.

- The first tile is placed at the above distance from the wall. Be sure to ensure that the comb is facing the wall, and the groove is in the opposite direction. If you miss this moment, the tile simply will not snap;

- Next, fasten all the tiles of the first row among themselves, turning them under a slight slope, in relation to each other;

- Turning to laying the second row of tiles, be sure to check its parallelism with respect to the wall plane. Such control should be done after laying each subsequent row;

- Use a rubber mallet and a wooden plank if necessary.

Difference laying of plates without a lock connection consists only in the fact that special glue or silicone is previously applied to the surface of the base. Do not apply too much glue, so that after pressing the tiles to the floor, he licks from all sides. Apply it in zigzags of medium thickness. Which glue is worth buying will be indicated on the packaging of the floor covering. It is better to immediately prepare a damp rag to remove glue residue from the surface of the boards before it dries. Walking on the adhesive-based coating is possible only after the time indicated on the packaging of the adhesive.

Laying the panel marmoleum

Conducted by analogy with laying ordinary laminate. But due to the increased fragility of the material is more complex. In order to keep the panels intact and to ensure the convenience of working with them, the connection of the parts together should be done strictly at a certain angle. Recommendations regarding its size should be indicated on the package. We recommend to do for myself small wooden patterns. Take a couple of bars, draw a line on them that corresponds to the required angle and gash it.Each time, joining the panel with the previous one, first place the bars on the floor so that their sharp edge lies in the groove, and then slide the panel over them. When it is time to fasten the details, simply remove the templates.

Flooring Natural Lenolium

The laying of rolled marmoleum is carried out in the same way as the laying of ordinary linoleum. Only in this case you will have only one attempt to deploy the cover correctly. It is advisable to use this type of material for flooring in large rooms. The base should be clean, without grease stains and residues of various building mixtures. Ideally, the floor is coated with a special adhesive. When the sheet lies down and spreads out, grab it around the perimeter with decorative skirting boards.

When laying lockless elements, you can intentionally leave gaps between them. For this, matches are inserted between the plates. You can make both four-sided and bilateral seams, as you like best. After the adhesive has completely dried, the matches are removed and the seams are filled grouting desired color with a rubber spatula.

Any kind of marmoleum is very is simple in care. But in order to maximize its life and avoid scratches, it is not recommended to use too hard brushes for cleaning. Manual dry cleaning is preferred. To remove complex stains, use a damp soft sponge and non-abrasive, gentle detergents. Many recommend the use of specialized means for the care of hard floors - manneiners.

8. What should I look for when buying?

- In an attempt to save and purchase expensive coverage at more than affordable prices, many of us are tempted by all kinds of promotions. Doing this is strongly discouraged if you have never heard of this seller before. You can only agree to attractive offers from trusted stores and suppliers. Otherwise, you either buy a deliberately defective product, or you will be refused a refund if something happens. Indeed, many guarantees do not apply to promotional products;

- Before you go to the store, read reviews on the Internet about the product that you are going to purchase, especially if it is a young and little-known brand;

- Familiarize yourself with the composition and make sure that it does not contain foreign chemical impurities;

- Be sure to check the batch number before purchase. They must be the same. Different batches may have color differences, which after installation will be very noticeable;

- If possible, inspect all castle joints for integrity;

- Do not strive to acquire the highest class coatings for home use;

- Pay attention to the integrity of the edges of the roll material;

- Immediately get specialized glue, if necessary;

- Check for a guarantee of material and the ability to exchange defective products.

A very good article for choosing flooring !!!

It will be necessary to pay attention to it in the store, as to the touch