7 tips for choosing and installing PVC film for the pool

Own swimming pool is no longer a luxury item or something extraordinary. The backyard of almost every country or country house boasts the presence of this element. Moreover, progress does not stand still and for those who do not want to bother too much, ready-made ones are sold frame poolsequipped with everything you need. It remains only to collect and enjoy. More economical and practical owners try to equip pools with their own hands at minimal cost. And it is worth noting - not unsuccessfully. Whatever option you like, you will definitely come across the issue of reliable and durable waterproofing. Let's try to figure it outhow to make a choice and installationfilmPVC for the pool, one of the most budgetary and simplest materials to ensure proper operating conditions.

No. 1. Characteristics of PVC film

Today decoration market offers consumers a variety of cost-effective quality options finishing the inner surface of the pools. However, delving into the topic a little deeper, you can find that the same finish with tiles or mosaics, considering not only its cost, but also the consumption of the adhesive mixture, is an expensive pleasure.

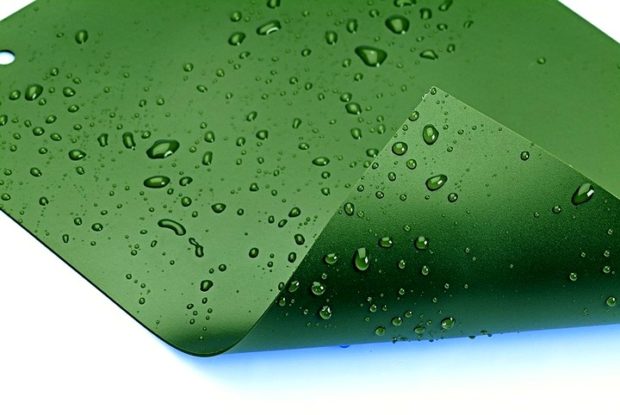

As more affordable but not inferior in technical characteristics waterproofing often used PVC film or in other words a liner, which consists of a base and top layer. On the back there is a thin fabric substrate. This modern coating is made of dense polyvinyl chloride, between which two layers are laid in the form of a polyester fiber. It is necessary for reinforcing the material. It is worth noting that PVC is obtained from vinyl chloride, which contains a high level of chloride compounds. Similar discharge is very harmful to human health however, in quality products, such risks are minimized. And given the fact that a person spends only a few hours in the pool, the liner is absolutely safe for use as a waterproofing. But as insulation for the pond, in which the fish will constantly dwell, it is better to use butyl rubber film.

- During the manufacture of PVC, various additives and stabilizers are additionally introduced into the composition, which provide increased durability and elasticity finished material;

- The film does not deform and does not swell under the influence of various temperatures;

- Some components increase the resistance of the film to ultraviolet radiation. Of course, with constant exposure to sunlight, it will certainly lose its original color saturation, which will be especially noticeable on the water line, but this process will occur much more slowly;

- Also, the surface of the film is treated with fungicidal and antimicrobial compounds. This creates additional protection against exposure to various bacteria, microorganisms, fungi or spores that may be in the water.

Prerequisite which guarantees safe operation of PVC film for health, is the passage of special certification material. Therefore, when buying, do not hesitate to ask sellers about its availability.

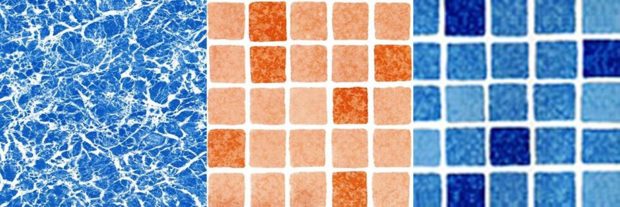

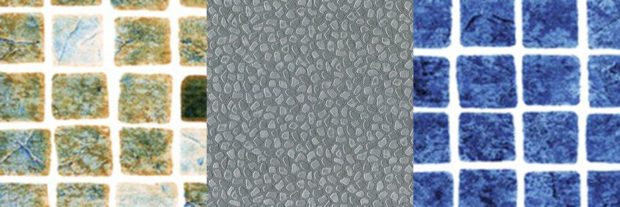

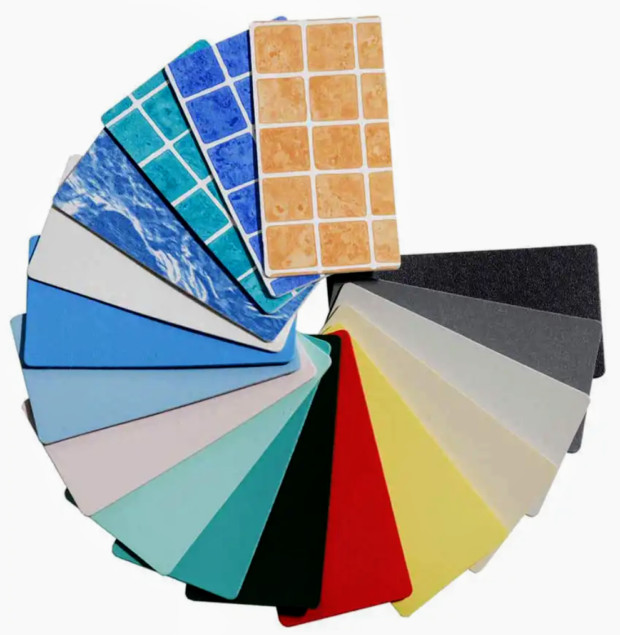

No. 2. Types of PVC films for the pool

As we have already said, the liner can be used both for waterproofing small collapsible structures, and for large pools with concrete bowls. The size and depth of the tank is two key indicators which must be taken into account when choosing the type of film. Overpaying for a denser material, if there is no real need for it, is impractical. But to buy thinner in order to save money is wrong, because in this case the film will wear out much faster and in a couple of years it will waterproofing works repeatedly. Naturally, you will not find any charms from using the liner in this case. therefore note on the following features:

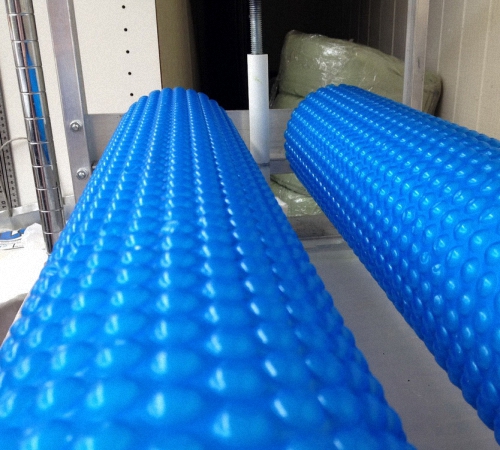

- Any kind of PVC film has the form of release in the form of rolls, which vary in length and width. These parameters, in turn, depend on the thickness of the film and the manufacturer;

- Liner width can be 3.05 m, 6.1 m, 9.15 m, 12.2 m, 15.2 m.

- Length products reaches 15.2 m, 30.5 m, 45.75 m, 61.0 m.

Depending on the thickness of the material and coating, a liner happens four types:

- Single layer - thickness from 0.6 to 0.8 mm. This kind of film can be used for finishing frame prefabricated pools. It is strong enough and flexible, which allows you to pull it with the least effort on the frame structure. At the same time, it serves as a reliable reservoir for water and restrains its pressure with minimal deformations. For stationary pools, it is not recommended to be used not only because of insufficient thickness, but also because of its frost resistance. This material is simply not intended for preservation in the cold season. A thin film has the lowest cost and most often has a pale blue color with a rough anti-slip surface;

- Layered - 1.5 mm thick. In its density and tactile sensations, a multilayer liner resembles a commercial one linoleum. The film consists of three layers, which are interconnected by hot welding. The reinforcing function is performed by the inner layer of polyester fabric. It is this kind of material that is suitable for lining stationary pools. It is resistant to temperature changes, able to tolerate frosts and withstand water pressure in large area tanks;

- Film with acrylic coating - a thin layer of acrylic acts as an additional bactericidal protection of the material. It does not allow dirt to accumulate and settle to the surface, prevents the growth of microorganisms and microscopic algae, does not contribute to the accumulation of limescale and prevents the harmful effects of various salts on the texture of the liner;

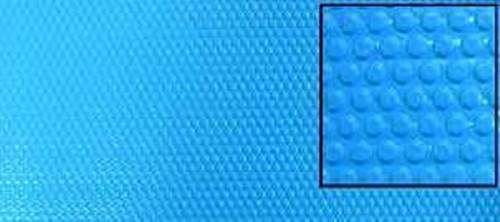

- Anti-slip coating - is a three-dimensional ribbed pattern that is applied to the surface of the material. A film with such a coating has the highest cost. But also provides increased security. It is rational to use it when arranging children's pools or on steps. In addition, protrusions soften random strokes and make them less painful.

No. 3. Advantages and disadvantages of PVC film

It can be safely stated that the use of PVC film allowed us to take a big step forward in the construction and decoration of pools. After all, with the right choice and observing the installation technology, you can get a lot advantages:

- One of the main advantages of the liner is the ability toto have waterproofing work in the shortest possible time. In addition, one person can handle the job;

- Ease of work. To work with the film, you do not need to have any special skills.And if you possess such qualities as scrupulousness and accuracy, then completely master the independent installation;

- At the moment, this type of finish is the most economical in comparison with other finishing materials for pools;

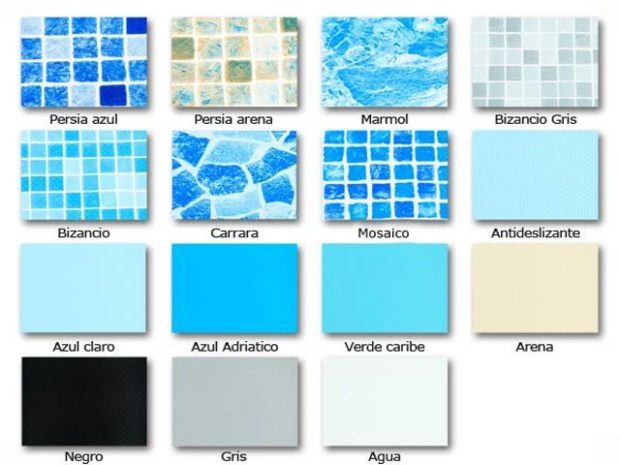

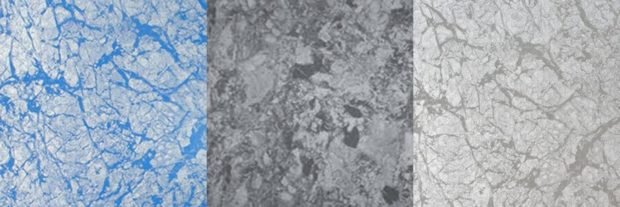

- The film does not spoil the appearance of the pool. Along with waterproofing, the liner also performs a decorative function. After all, its surface can be of various colors or have a “mosaic” or “marble” pattern. Many argue that the joints of the canvases are a visible defect, since the canvases need to be welded together. This nuance is really noticeable - mostly on monophonic films. But do not forget that a lot depends on the quality of installation. When holding it at the proper level, the junction can be almost invisible;

- Due to the increasedelasticity and elasticity, with the help of the liner, you can finish the pools of complex curved shapes, which you can not do with the help of tiles. At the same time, the contours of the pool will not undergo any changes;

- You have the opportunity to increase the safety level of your pool by opting for a liner with anti-slip and antimicrobial coatings;

- When finishing with a film, there are no sharp traumatic corners, as happens with poor-quality laying of tiles;

- There is no possibility of spontaneous formation of cracks or chips;

- The reinforced film withstands sub-zero temperatures without losing its qualities;

- Resistance of the material to ultraviolet rays;

- In case of damage to the coating, it is not necessary to completely replace it. You can perform local waterproofing repairs;

- The material is strong enough to damage, it is necessary to have a deliberate mechanical effect;

- The service life of high-quality coating with proper installation reaches 10-15 years.

TO disadvantages material can include the following points:

- The occurrence of small scratches and scuffs in places of intensive use, for example, on the sides or steps;

- The time-consuming cleaning process;

- Film without an acrylic coating is not intended for use at low temperatures;

- Visible joints - perhaps for someone this is really a significant drawback.

As you can see, the advantages of the material are enough to prefer it to other types of finishes.

Number 4. Large manufacturers of PVC film for the pool

The most popular question is how much does pvc film cost? It’s worth saying right away that the price directly depends on the thickness of the material. The name of the manufacturer also plays an important role. Firstly, by purchasing a film at an attractive price, which is significantly lower than the average market price, you have a unique opportunity to purchase uncertified material. In other words - fake. It follows, secondly - health hazard which may be material produced without compliance with sanitary standards. Particles of heavy metals, arsenic and other harmful elements may be present in such a film. She will definitely have a very bad smell. Buy a liner from trusted manufacturers that you have heard about, read reviews, or your friends and acquaintances recommend from personal experience. On the Russian market the following brands have earned trust:

On the Russian market the following brands have earned trust:

- Agrilac - An Italian company that specializes exclusively in the manufacture of PVC waterproofing. In this regard, their products are characterized by high quality indicators. At the same time, such a narrow focus made it possible to maintain more than affordable cost for the goods - from 150 rubles. per square meter;

- IZOFOL - Polish manufacturer of waterproofing materials. The assortment of goods is not large, but this fully compensates for the high quality and durability of the Polish film. The price starts from 200 rubles / sq.m;

- RENOLIT - German quality and a diverse range of coatings are available to customers for 200-250 rubles / sq.m .;

- WTB ELBEsecur - Another well-known German manufacturer, which specializes in the production of various waterproofing materials. The brand offers few color solutions, but their product has a double safety margin, which allows the coating to withstand significant loads. Cost - from 230 rubles / sq.m .;

- Azure - Russian manufacturer, which is notable for good coating quality. The average price is 650 rubles / sq.m .;

- Flagpool - A French company that produces high-quality film, but with a rather modest assortment of colors. Almost all varieties have a uniform color and are represented in various shades of blue. The price of the product is from 1000 rubles / sq.m .;

- Elbtal - German manufacturer of expensive film with a reflective effect and a reinforced layer. The design of the liner is made in the form of a decorative pattern. The cost starts from 1400 rubles / sq.m .;

- Alkorplan - A Belgian manufacturer that specializes in producing elite films whose design is very realistic repeats the texture of natural stone. The quality of the coating is at the highest level, however, like its cost - from 1,500 rubles / sq.m .;

No. 5. How to choose PVC film for the pool?

When choosing consider the depth and configuration your pool. The deeper and more intricate it is, the thicker the film should be. For frame structures of standard sizes, you can buy a ready-made and soldered liner. You also need to pay attention to the appearance of the coating itself:

- It must be elastic;

- It should not crumble and crumble. This is easy to verify by performing an oblique cut with a clerical knife or scissors. You should see evenly spaced reinforcing fiber threads, if provided. If not, just evaluate the structure of the material;

- The color of the film should be the same and uniform along the entire length of the roll;

- If you are buying a film with an anti-slip coating, make sure that the protrusions have the same shape, height and symmetrical arrangement;

- The film should not have a pungent odor.

If all these parameters correspond, this indicates that you have a high-quality product that was produced in a factory.

No. 6. Where to buy PVC film for the pool?

To purchase a truly high-quality product, you must contact specialized shops. When buying online or at small points, you may encounter the following troubles:

- The seller will not provide you with a guarantee on the purchased goods. And not from the manufacturer, not from your outlet, which should already cause you to suspect and discourage the desire to purchase goods here;

- In addition to the warranty, delivery may not be available. For people with private vehicles this may not be a problem, but for the rest, given the weight of the rolls, this will incur additional costs. Indeed, reliable implementers can always provide free or at minimal prices delivery;

- The lack of a certificate confirming the compliance of the broth with sanitary standards;

- And the most unpleasant thing is the substitution of goods. It may happen that they show you a sample of a really high-quality film at the appropriate price. You place an order, pay for it, after which you will be sent a film of the same thickness and color, but a completely different manufacturer, of course, much less cost. You can find out about this only if the film has a characteristic odor, like that of cheap analogues. Or when after several years of operation, the waterproofing layer is worn out.

Therefore, be vigilant and do not purchase goods at dubious points. Even if the price is very tempting. On the contrary, this is an occasion to once again think about the origin of the material.

Therefore, be vigilant and do not purchase goods at dubious points. Even if the price is very tempting. On the contrary, this is an occasion to once again think about the origin of the material.

Number 7. PVC swimming pool trim

For those who are determined to carry out waterproofing work on their own, it will be useful to know what to properly finish in several stages. Due attention should be given to each of them. After all, only a properly mounted canvas can withstand the load and please you with a long service life. And you will not fall into the number of those users who leave negative reviews about this method of isolation and call it short-lived and unreliable.

Prepare the following in advance instruments:

- Stationery knife or scissors;

- Roulette wheel;

- Screwdriver and hammer drill;

- Dowels and screws;

- Elastic glue;

- Pinch roller to be used for butt joints;

- Silicone roller;

- Welding hair dryer and nozzles;

- Fixing strip or corner;

- Nonwoven fiber backing;

- Well, the film itself, of course.

Now in detail about the technology of plating.

Preparing the pool for finishing with a liner

Like many other critical jobs, film installation should begin with proper surface preparation pool. To do this, you must:

- Perform a thorough visual inspection of the pool bowl and identify any defects. In the case of laying a bowl of blocks or bricks it can be cracks and gaps in the joints and just uneven masonry. Walls must be leveled, and then cleaned. There may be sagging or various bulges on the concrete surface, which must be leveled and ground. If a crack or deep cleavage is found, first puttyand then grind the restored place. Exfoliated tiles must be replaced;

- If there is significant damage to the bottom of the pool, it is necessary complete screed. The fastest way, which makes it possible to start subsequent work in a few hours, is the use of self-leveling solutions. Before using them, you need to clean the surface of dirt, dust, grease stains, carefully prime it and allow to dry;

- Particular attention should be paid to problem areas such as edges and corners. In these places, the solution may not adhere well to the substrate;

- After the pool bowl has a smooth and integral surface, you need to make sure that all embedded parts are flush with the walls and equipped with sealing flanges. This will ensure proper tightness;

- It is better to use flanges from stainless steel or plastic with a rubber gasket, which is resistant to the aggressive effects of chlorine;

- Now you need to remove all the debris and empty the cavity of the bowl;

Arrangement of the substrate

This stage is mandatory. As a substrate use geotextile, which not only prevents the reduction of dynamic loads on the film and its premature abrasion, but also allows water to cool much more slowly. is he prevents heat loss through the concrete bottom and walls.

- For its installation, it is necessary to draw up a diagram of the installation of mounting strips, to which the substrate will first be attached, and then the PVC sheet itself. There are no clear recommendations for their location, since all pools differ in configuration. The only thing that can be recommended is to use strips 200 cm long, not more than 8 cm wide, 2 mm thick;

- Next, the geotextile is attached with metal strips that are screwed with screws, according to the drawn pattern to the walls. Here it is worth being careful and not forget about one feature of these bands. On the one hand, they are covered with plastic, to which the film will then be welded. Accordingly, the plastic should "look" at you. Another recommendation regarding the frequency of fasteners. The best indicator is every 10-12 mm, at least. This will ensure proper fixation density and reliable clamping of geotextiles to the walls around the entire perimeter of the pool;

- Instead of strips, it is better to use special corners on the edges of steps;

- If the internal shape of the bowl has radial surfaces, it is necessary to cut small triangles on the strips on both sides of the middle so that it is possible to bend them without problems. Moreover, the smaller the radius, the more often it is necessary to make incisions.

Pay Attention, that geotextiles should be fixed evenly, without wrinkles, folds, assemblies, and even less gaps. The sheets should be superimposed on each other with an overlap of 3-4 cm. If you mount the substrate yourself, in order to avoid its displacement, you can put several points of elastic glue on the wall and press the material. It is better to do this closer to the middle, and not along the edges of the sheets. When the substrate is securely fixed, you can proceed to fasten the film itself. Also, do not forget to attach the mounting strip around the entire perimeter of the pool on the sides, at a distance of 5-8 cm from the edge of the bowl. A film that covers the walls will be attached to it at the very end.

PVC film mounting

This is the most crucial stage on which the final result depends. It is best to mount the film at positive temperatures - at least + 15 ° С. So it will be more malleable and will stick well. Begin with cloth cutting:

- You must understand that after filling the pool with water, the film will experience significant loads. She will be stretched. Moreover, how much she will have to stretch depends entirely on the configuration of the pool. The more steep corners and turns, the greater should be the supply of canvas. If on average the sheets are stacked on top of each other with an overlap of 3 to 4 cm, then at corners, radii, and similar elements, this figure should be doubled;

- Start with sheets that will cover the bottom. Their length should be such that they go on adjacent walls by 5-8 cm;

- Now you need to hang sheets on the walls of the pool. This must be done in a vertical manner. The easiest way to control this parameter is with a plumb line. Mark up so that the sheets go vertically at each other 5-8 cm, and at the corners and bottom - 10-15 cm;

- Keep in mind that the film will stretch under water pressure not only in the vertical, but also in the horizontal direction.

- Leave enough stock;

- After cutting, you can start welding. For convenience, pre-fasten the first two sheets with a point using the quick tack method. This will allow them not to move, but you will be given the opportunity, if necessary, to correct their position. During soldering, all sheets must lie flat and not form wrinkles. They cannot be removed after;

- Welding is carried out using a hairdryer. If carbon deposits form in the process, they are removed with a wire brush;

- In the end, you need to weld the film to the mounting strip on the sides of the pool and carefully roll the edge with a special roller;

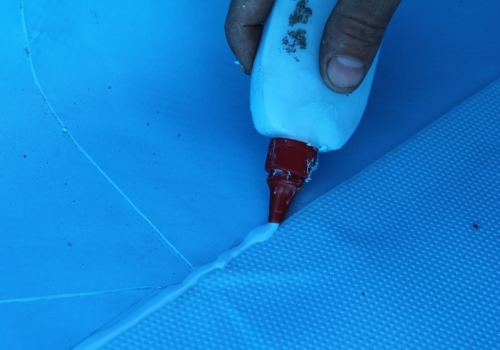

- Seams can be treated with a special sealant for additional tightness and let it harden for 30-40 minutes.

The work is completed, it's time to check the finished waterproofing. To do this, fill the pool with water. This should be done slowly and use only warm water.