How to choose a heating cable for pipe heating: 9 tips

If you’re tired of fighting frozen every winter water pipes and sewers, it's time to think about their high-quality thermal insulation. After the appearance on the market of heating cables, which instantly received huge demand, a similar problem is no longer insoluble. In this article we will tell how to choose a heating cable for pipes, consider its types, differences and disadvantages. We will determine when it is advisable to mount the cable on top of the pipe, and when inward and whether such installation is safe. We will give tips on choosing the power of the heating element and consider trusted manufacturers.

1. What is a heating cable for?

Someone will say that using a heating cable to prevent pipe freezing expensive and irrational. And it’s much more logical to find out how deep the soil freezes at the lowest temperatures in your region, and simply simply deepen the trench by the required amount. So it is, but far it’s not always possible to go deeper 1.5-1.7 meters. For instance:

- If you dig trenches for laying pipes yourself in order to save money or you just like to personally control everything, then considerable physical effort will be required. After all, there is a difference - to go deep by 0.5 meters or 1.5?

- Far from always, the soil on the ground in its composition is strong and homogeneous. You can stumble in the process of work on hard rocks;

- If the area is swampy, then in the rainy season or snow melt, the groundwater level can rise very much, which will lead to flooding of communications. Moreover, this process will be regular, adversely affect the condition of the water supply system and will certainly lead to its destruction;

- In regions where the temperature drops much in winter, even significant deepening of the trench can not always prevent local freezing;

- The place of entry of pipes into the house will still remain unprotected;

- And, in the end, what if the water supply system is already finally installed and buried, and the problem has recently been discovered? It will be much simpler, and in this case cheaper, to install the heating cable inside the pipes, rather than dig it out, dismantle, deepen and reassemble.

It follows that sometimes the use of a heating cable is an unavoidable necessity.

Generally application area includes several main areas:

- For private needs - heating water pipes and sewers, preventing freezing of the roof. In the latter case, the cable is laid in the places of formation of icicles and ice cover. Thanks to this, there is no need to regularly clean the roof. Core element floor heating systems heating cable is also;

- For commercial - heating pipes or fire extinguishing systems;

- For industrial - when work is carried out with increased danger, or there is a need to heat various liquids in large tanks. For example, petroleum products or other chemical compounds.

2. What parameters influence the choice?

Before you get the right amount of cable, you must clearly determine what type will do exactly for your needs. All variety of this product. varies by five major featured:

- Type - the cable can be self-regulating or resistive. In this case, the principle of operation of both heaters is the same. Heating occurs due to the current that flows through the inner cores;

- According to the material of external insulation. The possibility of application under certain conditions depends on this criterion. For example, to organize a heating system for sewers or drains, you must choose a cable with a polyolefin coating. For cable, which will be mounted on the roof or used in industrial needs, where additional protection from exposure to ultraviolet rays is required, there is fluoropolymer insulation. If the cable is laid in the inner cavity of the water pipes, it is better to choose a food coating, that is, fluoroplastic insulation. This will prevent a change in the taste of water, which sometimes takes place;

- The absence or presence of a screen (braid). The braid makes the product stronger, resistant to various mechanical influences, in addition, the screen performs the function of grounding. The absence of this element indicates that you have a product in the budget category;

- Temperature class - distinguish between low-, medium- and high-temperature heaters. This indicator is very important when arranging a heating system for a water supply system and a drain. Low-temperature elements are heated to a temperature of + 65 ° C, do not exceed 15 W / m in power and are suitable for heating pipes of small diameter. Medium-temperature conductors are heated to a maximum of + 120 ° C, power reaches 10-33 W / m, they are used to prevent freezing of pipes of medium diameter or for heating the roof. High-temperature thermal cables are able to heat up to + 190 ° C and have a specific power of 15 to 95 W / m. This type is advisable to apply for industrial purposes or in the presence of large diameter pipes. For domestic use, such conductors are considered too powerful and expensive;

- By power. Power characteristics of the coolant must be taken into account without fail. If you pick up a low power conductor, then you simply will not achieve the desired result. Exceeding the required indicator can lead to too high levels of energy consumption, which in practice will be unjustified. The choice the necessary power level first of all depends on diameter heated pipes. According to the recommendations of specialists, for pipes with a diameter of 15-25 mm, power of 10 W / m is enough, for a diameter of 25-40 mm - 16 W / m, for a pipe with a size of 60-80 mm - 30 W / m, for those that exceed 80 mm in diameter - 40 W / m.

3. Resistive heating cable

This type of conductor can consist of one or two steel conductive cores that are coated with an insulation layer, shielding and an outer protective sheath. Some cables have two layers of insulation. Single conductor differ in some characteristic features:

- They need to supply power to both ends of the cable;

- They create a very strong electromagnetic field, which is harmful to the human body;

Two-core heaters include one heating and one conductive core, which eliminates the need to bring the power source to two ends. This greatly facilitates the installation process.

To general the benefits resistive cable can include:

- High power;

- Sufficient flexibility;

- Affordable cost;

- Long service life under proper operating conditions and observance of installation features.

disadvantages quite significant:

- Strict length limit. Resistive conductors release immediately a fixed length. It is strictly forbidden to shorten them yourself.Such actions will lead to an increase in resistance due to a decrease in length, which in turn will lead to overheating and failure;

- In case of excessive accumulation of dirt and debris in the place of cable laying or in the presence of places where the cable crosses itself, overheating and failure are inevitable;

- Due to the fact that the cable cannot be cut, it becomes impossible to perform local repairs even if a small area is damaged. The cable will be fully replaced;

- Heat transfer remains constant over the entire length of the heater. Sometimes this leads to overheating of the cable in certain areas or its rapid heating;

- The use of a temperature controller is mandatory. This is necessary in order to be able to constantly control the temperature and prevent the conductor from overheating. This nuance makes the resistive cable not very suitable for use in places with limited access.

An improved version of the resistive cable is zone resistive cable. Its key difference is that it is divided into small zones. This makes it possible to independently adjust the cable length and carry out local repairs or replacements. Its cost is slightly higher. During installation, temperature sensors should also be used, and during operation, ensure that no debris accumulates around the cable.

4. Self-adjusting cable

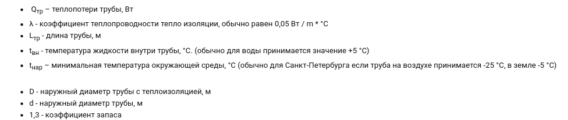

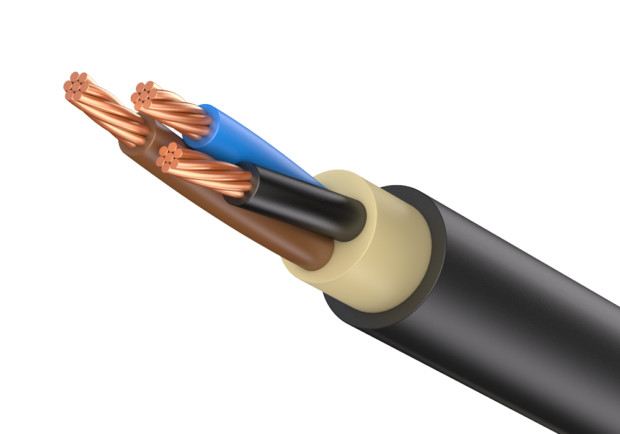

More convenient in terms of operation is such a kind of heating cable as self-regulating. It has a more complex structure and is not single-core. Self-regulating conductor includes in itself:

- Copper conductors, through which voltage is supplied to the self-regulating matrix. The maximum possible length and power of the conductor directly depends on the cross-sectional area of the cores. For example, with a cross-sectional area of 0.5 mm or 0.7 mm, the power will be 11 W / m and 17 W / m, respectively. At the same time, the length of one cable cut will be no more than 100 m. The cross-sectional area of 1.1 mm provides a power of 25 W / m, and the length should not exceed 80 m;

- Self-regulating semiconductor matrix - responsible for heating the cable. The material from which the matrix is made is able to respond to changes in ambient temperature and change the value of electrical resistance and heat transfer. This feature makes the use of such a heating cable very convenient and practically does not require human intervention. When choosing a self-regulating cable, it is very important to pay attention to such a parameter as "Aging matrix." This is a process that is accompanied by a decrease in the amount of heat generated. The loss of heat transfer of high-quality conductors even after 8-10 years of use does not exceed 10%. While low-quality cables in a year can completely lose their properties;

- Internal insulation - protects the self-regulating matrix. It should be strong enough, holistic, have good thermal conductivity. Insulation resistance must be at least 1 ohm according to generally accepted standards;

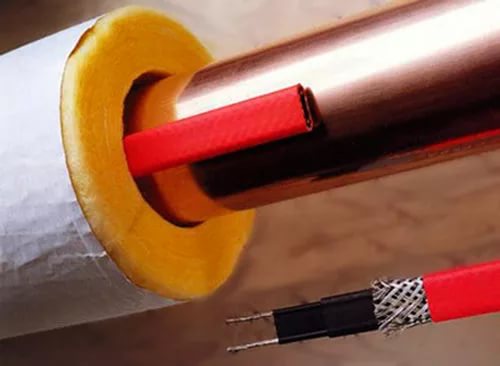

- Screen or braid - is necessary to protect the user from electric shock. The braid is usually made of tinned copper. Self-regulating conductor must have a shielding braid;

- External insulation - necessary to protect the product from environmental factors and mechanical stress.

To buy really quality cable Be sure to pay attention to the marking. If there are Latin letters CT, CF or CR, this indicates the presence of a copper screen and external insulation.

In the absence of such markings, it can be argued that this is a semi-finished product of a self-regulating cable. Like any product, the conductor has, like advantages, and disadvantages. First about the pros:

- First of all, it is the reliability of the design. Of course, now we are talking about a full-fledged product with a screen and insulation;

- Resistance to voltage drops;

- Even with a high power conductor, power consumption will be relatively small, which makes operation economical;

- In addition, savings are achieved by monitoring the system for temperature changes and independently increasing or decreasing the heating temperature. That is, without need, the conductor will not work at maximum power;

- With overlapping installation there is no risk of overheating and failure;

- Self-regulating conductor is practically maintenance-free;

- The cable is sold for cut, so you are not limited in length. Accordingly, it can be independently shortened as necessary;

- Due to the flat shape of the cable, it is possible to create the most tight fit of the conductor to the heated surface, which significantly reduces heat loss;

- When the matrix is heated to a temperature of 85 °, the system temporarily stops further heating, which protects not only the cable from overheating, but also the surface of the pipe from melting;

- There is no need to use a temperature controller;

- Long term of operation - 30-40 years.

TO disadvantages can include:

- High cost;

- Lack of couplings and glands for connection. They will have to be bought separately.

As you can see, self-regulating conductors have radical differences from resistive conductors, which have recently practically ceased to be used for heating water pipes.

5. Installation methods

As practice shows, it is permissible to install a heating cable not only over the pipe, but also inwards.

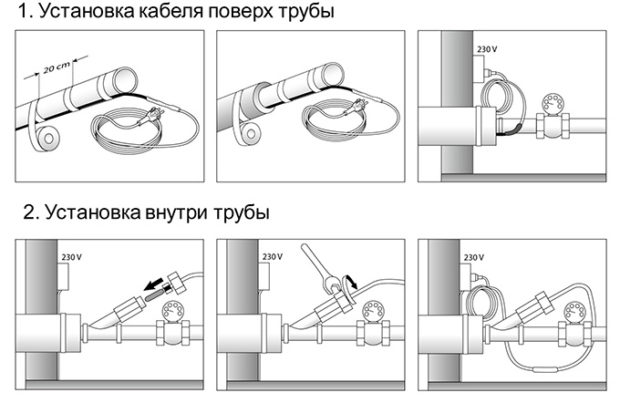

Outdoor mounting

For this type of installation, any type of conductor is suitable. Advantage this method is:

- Its simplicity and ability to perform styling yourself;

- With this arrangement of the heater, the throughput of the pipe does not change, which can not be said about the internal installation.

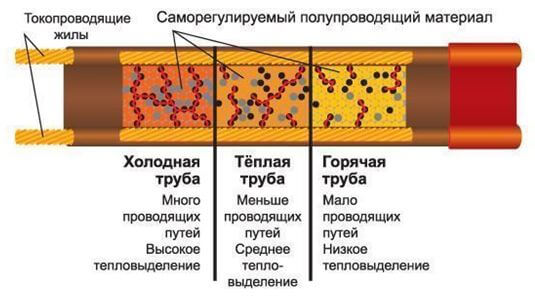

Depending on the diameter of the heated pipe and the characteristics of the local climate, a cable is recommended. pave in several ways:

- A cable of sufficient power is permissible simply to wrap tightly to a pipe of small diameter using a special adhesive tape. Such installation is suitable for regions with a temperate climate;

- For regions with more severe climates, it is better to lay the cable, wrapping it around the pipe. The lower the temperature drops in winter, the smaller the distance between the turns should be. This method of laying is used and, if necessary, heating pipes of medium and large diameter;

- Do not forget that if you use a resistive cable, when you reach the end of the pipe, you need to return its end to the beginning of the winding, since you need to connect a current source to both ends;

- In this case, avoid overlapping cable turns. This can lead to overheating;

- The average step between turns is recommended approximately 5 cm;

- The cable must always be tightly wound to the pipe, preventing it from sagging or lagging from the surface.

Before mounting on top of pipes, you need to prepare them surface. Metal pipes need clean from rust and other contaminants. Plastic can be wrapped with foil tape, which will ensure their uniform heating along the entire length.

Indoor installation

It is advisable to choose such a method with a sufficient pipe diameter (cross-section of more than 40 mm) so as not to reduce their throughput or when the pipeline is already filled with a layer concrete or bitumen, and there is simply no way to realize the outer winding. Single core resistive conductors are not suitable for indoor installation. When choosing a self-regulating cable, be sure to pay attention to the outer insulation material, which should not emit harmful substances and be resistant to alkali. Also, the cable must have an appropriate protection class - at least IP68.

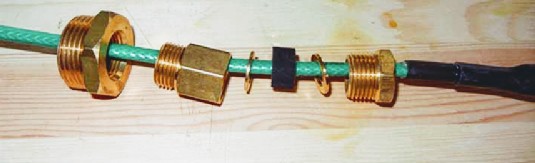

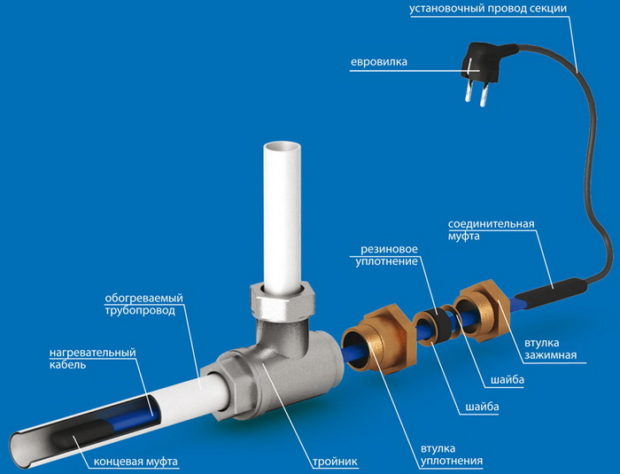

Installation itself is carried out by introducing the cable into the pipe to the desired length.The end, which will be connected to the network, is output through a tee, which is wound at the output point. In order for the system to be airtight, a special sleeve should be used, the elements of which should be put on the cable in the order shown in the figure.

It is worth noting that internal way mounting has several limitations:

- Pipes should not have mechanical connections;

- Cranes

- Rotary elements.

6. Useful tips regarding installation work

There are some recommendations which will help you avoid mistakes when installing or choosing the heating element itself:

- For mounting on a pipe with unstable temperature readings, it is better to choose a self-regulating cable. It is especially important to consider this if part of the pipe is in the building, part is laid on the street, and then again enters the building. For heating, a different amount of heat will be required in different areas. A resistive cable will not only not be able to provide this condition, but will also consume the same amount of electricity, thereby making its use not economically advantageous;

- The choice of heat-insulating material for heated pipes should be given special attention. Properly selected insulation will significantly reduce the consumption of heat and electricity and extend the cable;

- If you have decided that you will lay the cable on top of the pipe while wrapping, be sure to check the permissible bending limits. Otherwise, if the cable is bent over permissible norms, its performance may be impaired;

- In the case of using a heating cable on household pipes, it is mandatory to connect it through a current leakage relay. This is necessary to protect against electric shock in case of damage to the outer insulation of the conductor;

- It is not difficult to choose the cable length when laying on top of the inside of the pipe - it is equal to the length of the pipe with a small margin. However, when winding the cable onto the pipe, the length calculation must be done as 1.6 - 1.7 of the pipe length;

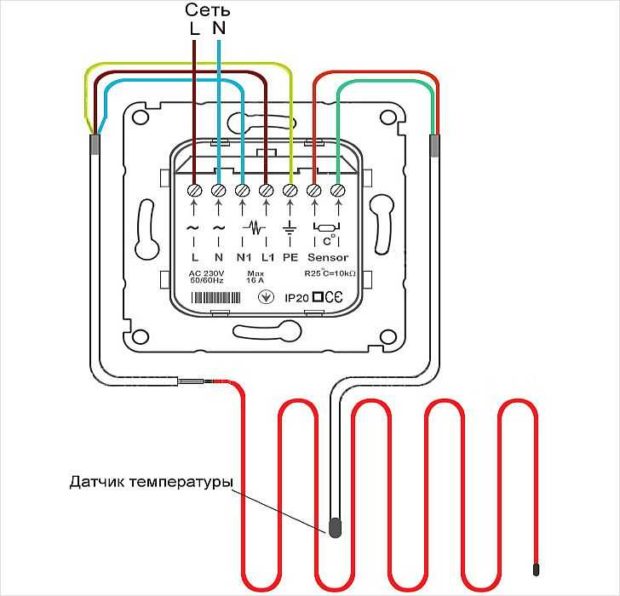

- Even if you choose a self-regulating cable type, to further minimize energy costs, install a temperature sensor. Set the following parameters on it - switching on at a temperature of + 3 ° С, switching off at + 13 ° С. This mode will extend the life of the heaters, because they have a certain resource of working hours;

- When installing the sensor, it is very important to do this correctly. The main difficulty is to isolate it from the influence of the heater, but at the same time maintain contact with the pipe. Only in this case will he read the correct readings.

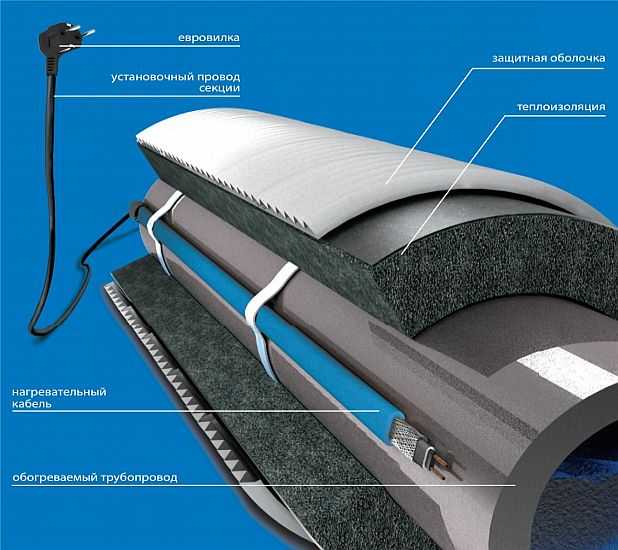

7. Is subsequent warming of the heated pipeline necessary?

Another topical issue in organizing a pipe heating system is whether subsequent thermal insulation of the heated pipeline is needed. If you do not want to warm the air and operate the cable at maximum power, then insulation is definitely necessary. Insulating layer thickness It is selected depending on where the pipes are located and what minimum temperatures are peculiar to your region. On average, to insulate pipes that are located in the ground, a heater with a thickness of 20-30 mm is used. If the pipeline is elevated - at least 50 mm. Very important choose the "right" insulation, which will not lose its properties even after a few years.

- It is not recommended to use mineral wool as an insulating material. They are not intended for use in high humidity conditions, and when wet, they instantly lose their properties. In addition, if wet cotton wool freezes, then with increasing temperature, it crumbles and turns into dust;

- Also, materials that are capable of being compressed by gravity are not always suitable. It concerns foam rubber or foamed polyethylenewhich, when compressed, lose their properties.It is permissible to use such materials if the pipeline passes in a specially equipped sewage system, where it simply cannot pressure anything;

- If pipes are laid in the ground, it is necessary to apply rigid thermal insulation “pipe in pipe”. When another rigid pipe of larger diameter is worn over heated pipes and a heating cable. For an additional effect or in the case of operation in harsh conditions, you can wrap the pipes with the same foamed polyethylene, and then put on the outer pipe;

- Allowed to use polystyrene foam, which represents fragments of pipes of different lengths and diameters. It has high thermal insulation properties, is not afraid of moisture and is able to withstand some loads, depending on the density. Such a heater is often called a "shell".

8. Cable selection, depending on the heat loss of the pipe and its length

In order to choose the right type of heating cable and its power, you need consider the following parameters:

- The purpose of the heated pipe is water or sewer;

- Pipe material;

- Its diameter and length;

- Cable laying method - external or internal;

- Material and thickness of thermal insulation;

- The lowest temperature in your area.

Knowing the above parameters, it is possible to calculate the heat loss of the pipe per 1 meter and more accurately select the required power and length of the heating cable. Heat losses must be taken into account during the calculation without fail. After all, the cable power should be enough to compensate, otherwise the heating system simply will not perform its functions. To the main factors that are necessary take into account when calculating heat loss include:

- Place of installation of the pipe;

- Minimum ambient temperature;

- Pipe diameter;

- The length of the pipe to be heated;

- Thermal insulation thickness and coefficient of its thermal conductivity;

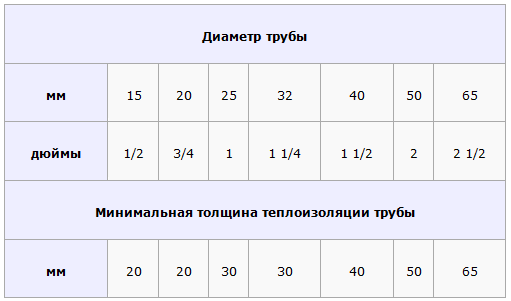

If you are at a loss in choosing the thickness of the insulation, focus on the table in which the recommended values are indicated.

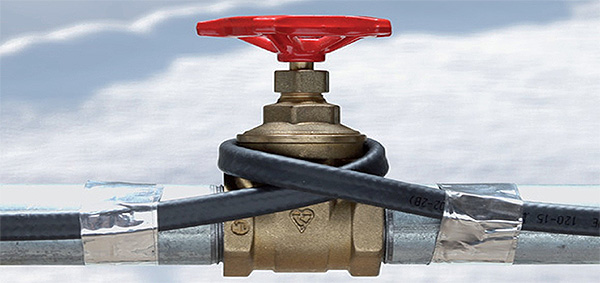

The larger the pipe diameter and the thinner the insulation layer, the more heat we will need. If you find it difficult to determine the minimum temperature, just ask the appropriate request on the Internet. You can also proceed to determine the coefficient of thermal conductivity of a particular heat-insulating material. Be sure to take into account the presence of additional fittings, suspensions, supports and other elements on the pipe that will affect the length of the heater. After all, various valves, taps, etc. it should also be braided with a cable.

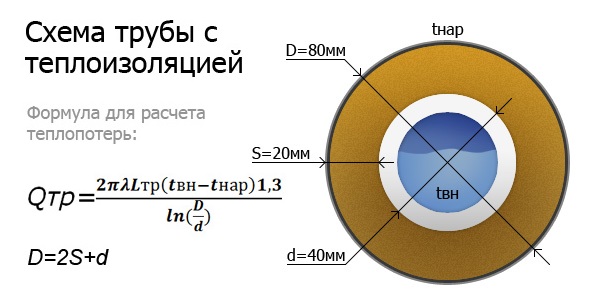

So, when all the values are known to us, you can use the formula to calculate the heat loss:

Where:

Substituting the known values, it is easy to obtain a specific value of heat loss, and on this basis calculate the necessary length rower cable according to the formula:

Lк = 1.3 * Ltr * Qtr / Ore.

Where:

- Ltr is the length of the pipeline, m;

- Rud.kab. - power density of the cable;

- 1.3 - coefficient, which implies that 1.3 meters of cable falls per 1 meter of pipe. May vary depending on the installation method. For example, when laying cable coils externally, it should be taken as 1.6 or 1.7.

For the convenience of calculations, you can use the table, which shows the values of heat loss depending on the diameter of the pipe and the thickness of the insulation with a thermal conductivity of 0.05 W / m ° C.

9. Manufacturer's choice

In order for the heating cable to serve you for more than one or two years and meet the declared parameters, it is necessary to purchase products verified brands. Only in this case, the cost of its purchase will be justified. The following manufacturers have earned the trust:

- Thermo Industri AB - Swedish manufacturer, which is one of the largest in Europe. For quite some time now, the company specializes in the production of cable heating systems. Such a narrow focus can guarantee proper product quality and reliability. Production lines are represented by modern equipment. The use of modern technologies allows the production of heating systems that are safe to operate;

- Eltrace - A French manufacturer that adheres to two main criteria for finished products - quality and affordable cost. The company produces a self-regulating type of cable, which, depending on the application, includes two lines. Tubes-heat - for domestic and industrial pipelines. Traceco - for any type of heating systems;

- Thermon and Raychem - Trademarks originating in the United States. The advantages of their products include safety and reliability, economical energy consumption, convenient installation. It is worth noting that the self-regulating cable of these companies has a certificate of international quality control;

- Devi - A manufacturer from Denmark, whose products are of high quality. Initially, the company specialized in the production of heating elements for industrial needs. But already in the early 60s one of the first heating systems based on an electric cable was released. The company has extensive experience, which ensures high reliability of their products.

A very interesting and useful article on self-regulating cables. Thanks to the author. The author, can you calculate how long the water will heat up from T = 15g. C to T = 40g. C in a plastic flat tank for a summer shower with a volume of 150 liters. and the length of the heating cable inserted inside is 5 meters? I want to use this cable to heat up the shower water, the tank of which is installed outdoors. Thank you, Yuri