Forged window grilles: 10 tips for choosing

In stock bars on the windows at the present time you will not see anyone. And if earlier, when the first lattices were just beginning to “decorate” the window openings of rare apartments, unpleasant associations arose at their appearance, now the demand for this type of security products is growing every day. Most often, in this way, owners of apartments on the lower or, conversely, extreme floors tend to secure their home, those near whose windows there are all kinds of ledges or visorstaking advantage of which, it is easy to reach the opening. Also, more and more often you can see sheathed windows of country houses or country houses, where the risk of being robbed is much higher than in ordinary apartments of multi-storey buildings.

The desire of people to preserve the property acquired over the years is a completely understandable and sound decision, however, many are still repelled by the plain and stereotyped welded window bars. In this regard, many prefer them more elegant and sophisticated, but no less reliable and durable forged products. In this article, we will analyze how they differ. forged window grilles, consider several methods for their manufacture and give selection tipswhich will certainly be useful to you.

1. The process of manufacturing forged products

Before you start looking for the main differences between forged and welded gratings, you need to understand what the forging process actually is and what it can be. Forging – this is one of the ways to give the metal in a plastic state the necessary shape and configuration. The work uses special hammers or a press. It was by the forging method that, in ancient times, both dangerous knightly swords and sickles for home were made. This is probably why, when we hear the phrase “forged lattices”, pictures of films with medieval castles immediately appear in our heads, the rooms of which are lit with torches, and forged elements with peaks at the ends are visible on the windows.

According to the method of imparting plasticity, the processing process is divided into two types:

- Cold forging - when in the process of giving the metal the necessary shape, the workpiece is not exposed to heat. The formation of elements occurs using various devices and multifunctional metalworking equipment. We can say that cold forging is an almost automated process, during which template elements are created, which are then attached to a special frame by welding and form a finished lattice configuration. Accordingly, a product created in this way will have a higher value than conventional welded gratings, but more affordable than products made by the method of art, that is, hot forging;

- Hot forging - The process is truly unique, creative, requiring the artist to have an artistic taste and spatial thinking. In the process of processing, metal billets are heated until they become sufficiently plastic and pliable.Holding the fragment with special forceps, the master with the help of a hammer or second forceps gives it the necessary shape. This can be all sorts of curls, petals, peaks, flowers, geometric shapes, heraldic elements, coats of arms, vignettes and much more. It is by hot forging that it is possible to produce products that differ in the highest aesthetic qualities. Looking at them, it seems that you see not a heavy canvas, but graceful lace. Everything will directly depend on the imagination and dexterity of the blacksmith. Of course, such laboriousness directly affect the cost of the product. After all the elements of the future lattice are made, the product is preassembled together according to the corresponding sketch. If all sizes and conditions have been met, they are interconnected by the influence of certain temperature and power regimes on the material. After cooling, the junction in its strength characteristics is almost identical to the structure of the original bar.

IN material quality for the manufacture of forged gratings most often use special carbon steel with high impact strength. The form of supply of metal is round or square rods with a cross section of 10 or 12 mm or strips. If you want to create a lattice, which will play a more decorative role, bars and smaller cross-sections can be used, or a combination of several blanks of different sizes. For the manufacture of gratings individual orders materials such as copper or brass may be used. They are very ductile, perfectly forged and have high decorative characteristics. But you need to be prepared for the fact that their application will make the final cost of the lattice even higher.

2. Advantages and disadvantages of forged gratings

Despite the cost of the product, there are no gratings through which you cannot penetrate or which cannot be removed or bent. Those who want to enter your home will definitely do it. Therefore, the main issue will still be how long does it take for an attacker to to deal with a particular type of grill. This is influenced by many factors, ranging from its configuration or pattern to the method of installation. Naturally, the more time it takes to eliminate the obstacle, the higher the likelihood that the ill-wisher will be noticed by vigilant neighbors or bystanders, or the security service will arrive in time, if installed signaling.

However, compared with welded, forged products can still provide some advantages:

- Increased strength gratings due to the special manufacturing method and quality of the raw materials used. In its process, the upper layer of metal is hardened, and the core has plastic properties. Such material will not be brittle, which means it is harder to break;

- The same fact allows us to achieve wear resistance material that is practically not affected by environmental factors;

- Durability forged products are tens of years old;

- Most often, metal is used for manufacturing, with a special anticorrosion coatingwhich does not require subsequent protective coating. To preserve the aesthetic appearance of the grate, it is enough to cover its rods with a special transparent varnish every few years, after the factory coating has already worn out;

- In addition to excellent performance, forged elements differ more interesting and presentable external view;

- The customer has a unique opportunity to make gratings. according to my own sketch, you just need to find a good master;

- Forging goes well with other types of finishing materials. It looks especially harmonious in combination with stone facades;

- In addition, you have the opportunity to make a mount for the visor above the front door, railings, gates and other elements in the same style and design with window grilles. This will emphasize the consistency and sense of style of the owner of the house.

TO disadvantages products can be attributed their high cost. Especially those made by hand. Therefore, it is advisable to order such gratings only to protect the window openings of a private house, and not the windows leading to the basement.

And long production time, if it is an individual or atypical product. Yes, and a standard lattice can be made within a few weeks, provided that its area is not more than 3 square meters. meters.

3. Types of gratings as intended

Depending on the thickness of the rods used in the construction, their frequencies and the distance between two adjacent elements, three types of gratings are distinguished:

- Decorative - the most sophisticated and delicate products that are made from thin blanks and can resemble a spider web. The distance between the rods in this case, can be anything, either very large or quite small. The design of such a grid depends entirely on the wishes of the customer;

- Security - The most strict and reliable lattices, which differ in the simplest design. However, such straightforwardness in this case is not a disadvantage;

- Decorative and security - the optimal type of product for use as protection for residential buildings. Their design combines both high reliability and external attractiveness. The design of such products can be very diverse. And those who could not find a suitable option for themselves among typical products can draw their own sketch of the future lattice and go to the manufacturer.

4. Types of gratings by the method of opening

Like welded, forged gratings have differences in their design in terms of the possibility of opening the wings.

- Deaf Lattices - are permanently fixed to the window opening and do not have the ability to open. On the one hand, due to the lack of a castle as the most vulnerable spot, they provide the highest degree of protection. However, at some point, such security can play a trick on you, which can even cost your life. A commonplace example is a fire in a house that blocked the ability to leave the building through the front door. The window opening is also tightly protected, and you are trapped;

- Swing - this design, as a rule, consists of two wings, one of which is stationary, and the other is attached to the hinges and has the ability to open. The lock connection can be both mortise and hinged and located on the inside of the grill. Hacking such a product is much easier than deaf. However, for its own safety, it is recommended that at least one swing grate be installed to enable evacuation. The main thing is to clearly determine the storage location of the key to the lock and always keep it in that place;

- Sliding - the most unsafe type of lattice in terms of breaking. It is attached to the frame, consists of several wings, which are moved inside the frame relative to each other using hinges. It is this element that is the most vulnerable. When folded, the grille can occupy no more than ¼ of the window opening.

5. Differences in mounting location

Depending on the characteristics of the building or the wishes of the customer, the grilles can be mounted in different ways, in relation to the window opening itself. Three installation methods are used:

- Outer or consignment note - used when the walls of the house do not differ in great thickness and strength. With proper installation, the lattice frame will have a larger size than the window opening;

- Interior - It is used extremely rarely, since few people want to see from the inside of the grille on all windows.Even if they are very beautiful, well, all the same, on a subconscious level, unpleasant sensations will arise. However, this type of installation cannot be excluded. The grill is attached directly to the slopes indoors. That is, before entering your house, an attacker will first have to open the window itself, and then the grate. In this regard, the time spent on hacking will increase, which can sometimes become an important factor;

- Mounted - The most reliable way to install a forged structure. In this case, the grill is mounted on the outside, but not on the facade, but in the window opening itself, as close as possible to double glazing. This greatly complicates access to the fasteners.

6. Methods of performing fasteners

Forged gratings can be attached to the facade or to the window opening using different types of fasteners:

- Welding to special mortgages in the form of rods - this method is most often used for fastening the grill in an overhead way. First, special embedded elements of their metal are mounted on the walls around the window perimeter, and then reciprocal fastenings are welded to them on the lattice frame. Such fasteners are the easiest and fastest to cut. Since, firstly, there is a weld that is vulnerable and brittle, and, secondly, all fastenings are visible to the naked eye;

- FROM using bolts - in this case, special anchor bolts are used, which are mounted directly in the plane of the wall or slope. For reliable fixation, it is recommended to use at least 8 fixation points. And the larger the lattice area, the more often there should be their number;

- Through method - used exclusively for mounting window grilles in wooden houseswhen it is not possible to securely fix bolts or embedded in the wall plane. In this case, the wall around the perimeter of the window is drilled through, and the fastener itself is fixed indoors.

7. Design and possible shape of forged gratings

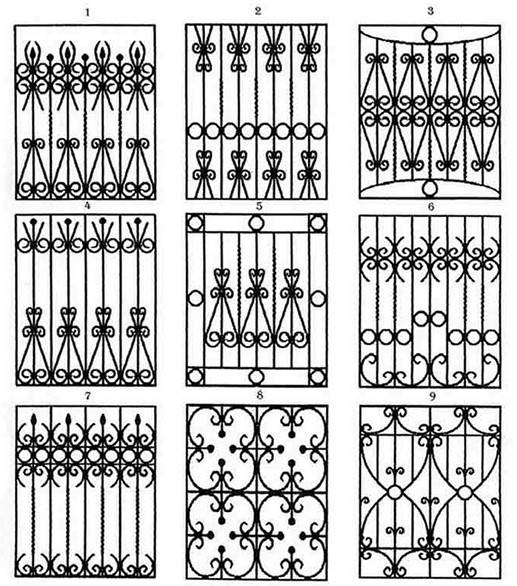

The pattern on forged gratings can be the most diverse and non-standard. And in this case, they will not only perform a security function, but will really decorate the window opening. In its configuration they can be:

- Executed in form rectangular grids when the rods are interconnected by means of binding, twisting. They can form a pattern by changing their direction, by bending. In this case, a metal mesh is used as the basis for the design of the lattice. In addition to the rods, it may include various geometric elements;

- One of the most common is forged grille with diagonal arrangement rods. They can also be intertwined or superimposed on each other, have a wavy direction, which makes the appearance of the product more interesting;

- Surely you often came across the so-called ring forged lattice. From the name it is clear that in this case the design consists of many forged rings that can overlap each other, creating a multilayer product.

Atypical and more interesting products may have characteristic elements that can be attributed to different styles and which can be successfully chosen for one or another facade style. For example, the following styles are most demanded:

- Classical;

- Gothic;

- Greek;

- Modern;

- Country

In addition to such differences, forged grilles can have a different shape which allows you to choose the product for any configuration of the window opening and depending on the depth of its drowning in the plane of the facade. This separation is called spatial and spatial and can be of three types:

In addition to such differences, forged grilles can have a different shape which allows you to choose the product for any configuration of the window opening and depending on the depth of its drowning in the plane of the facade. This separation is called spatial and spatial and can be of three types:

- Flat gratings - are installed strictly parallel to the plane of the window itself. All structural elements are in the same plane.You can diversify the design with the help of small decorative elements in the form of peaks or leaves, which will barely protrude beyond the common plane;

- Voluminous the gratings can have a protruding part both from below and from above, or be convex in the middle. Such designs are most beautiful and functional. For example, the protrusion at the bottom can be used to place flower pots. A larger upper part will make it possible to open the window or the entire window at least a little, if suddenly the sashes open outwards.

8. The correct sequence of actions when ordering forged gratings

The order of forged gratings is accompanied by certain characteristic differences, which must necessarily be met by performers:

- As in all cases, it all starts with accurate metering. A specialist must come to your site and perform all necessary actions;

- After that, you should choose the desired lattice design, decorative elements;

- Based on your wishes, a detailed sketch should be drawn up. If you have chosen a non-standard product, which will also be made manually;

- After the final approval of all the details, the sketch is taken into work;

- Specialists select the optimal material and perform the strength calculation of the product;

- After that, the sketch is transferred to production, and the master begins the phased production of all structural elements;

- When everything is ready, there is a preliminary assembly, verification of appearance and final dimensions with a working drawing;

- Only after this the construction is finally assembled, a protective coating and final verification are applied.

- Only after passing through all these stages, a conscientious manufacturer will bring you the finished product and take up its installation.

9. What to look for when ordering?

You, as a person who does not know all the intricacies of the process, should know several points that will help you understand whether your order is made qualitatively or not:

- A truly reliable product will have a frame made not of a tape, but of a T-shaped profile. Probably, to refuse the finished product, if you suddenly find that this is not so, it is impractical, so it is better to stipulate this point in advance. And the matter is not even in the strength of the product, but in its reliability. After all, the tape profile will be much easier and faster to saw;

- Try to choose a lattice design that will not differ in the presence of a large number of voids and a large distance between the elements. Even if the cells will have a size of 20 × 20 cm, this will already enable a person of a thin physique or teenager to squeeze into it. Therefore, it is better that the voids do not exceed 15 cm in width or length;

- Be sure to check the availability of anti-corrosion coating on the metal. It can be either special varnish, or paint or powder coating.

10. What affects the cost of the product and how much does it make?

The cost of forged grids can indeed be quite significant. Its formation is influenced by several factors:

- First of all, it’s preparation method. More affordable at the cost will be products made by cold forging. Hot forging is highly valued and costs the same;

- Acting complexity and bulk or layering designs. The more non-standard and decorative elements the final design includes, the higher the cost. Indeed, in order to make miniature flowers that will look natural, it will take a lot of work and patience of the master;

- Accordingly, the more metal was spent on the implementation of your idea, the more expensive it will be;

- And of course - the larger the area of the product, the higher the cost.

Average price policy is from 2 to 3 thousand rubles per square meter of a standard product. And from 7 thousand rubles per meter of handmade lattice of unusual design. Also, do not forget to add another 20-30% of the cost of the product for its installation.Choose only trusted companies whose work you saw as an example of your relatives or housemates. And, of course, it is better for the same organization to manufacture and install. So it will be a little cheaper, and in which case it will be easier to make a claim. Otherwise, you may encounter a situation where the installers put the blame on an allegedly unscrupulous manufacturer and vice versa, and you will find yourself in the extreme situation.