Linoleum underlay on concrete floor: 6 tips for choosing

Linoleum, as a kind of flooring, does not lose its relevance due to many advantages. This is ease of care, and affordable cost, and a variety of colors and textures, and ease of installation, as well as durability and wear resistance. In order for the coating to possess all of the above properties, it is necessary to carry out the correct installation. However, many experts are of the opinion that linoleum underlay on concrete floor is a necessity. Others argue that this is a waste of money. Let's figure out who is right and which substrate to choose if its use is appropriate in your case.

When is a backing needed?

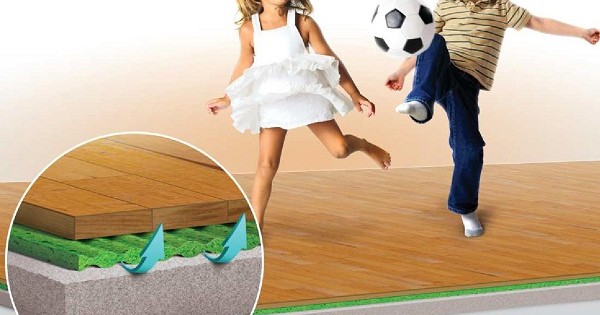

The substrate is an intermediate layer between the floor plane and the coating itself.  Use when laying on a concrete base is necessary in several cases:

Use when laying on a concrete base is necessary in several cases:

- When there is a need insulate floors. The floors in the apartments located on the ground floors above the arched openings are very cold. The same can be said about the concrete floors on the ground floor of a private house. The substrate in this case will act as a heat insulator;

- For sound insulation. In apartment buildings there is very good audibility, which can be reduced by using a substrate that has soundproofing properties;

- When need align the floor plane. If concrete screed performed poorly, it must first be aligned. If the differences are within 2-7 mm, and the irregularities themselves are smooth, without sharp protrusions or holes, you can mitigate the shortcomings with the help of a substrate.

When the backing is useless?

- When there are large differences and dents on the floor plane. The substrate will not be able to compensate for such deep defects. And linoleum itself when laid on such a plane will quickly become worthless. Necessary local or complete surface leveling;

- When linoleum with a backing layer is used. Such material is more expensive, but sometimes the expenses are justified.

Cork backing

Cork backing is made from crushed wood bark and natural adhesive components.  This material has the following advantages:

This material has the following advantages:

- Environmental friendliness;

- Durability. The substrate retains its properties for 25-30 years;

- High soundproof properties;

- Convenient packaging in the form of rolls 1 meter wide and 10 meters long;

- The thickness variation is from 2 to 10 mm.

The thicker the substrate the surface is softer, but its strength is reduced. The best indicator of the price / quality ratio is a thickness of 3-4 mm. For laying under linoleum this is more than enough.

The thicker the substrate the surface is softer, but its strength is reduced. The best indicator of the price / quality ratio is a thickness of 3-4 mm. For laying under linoleum this is more than enough.

TO disadvantages include:

- Softness of the material. In places where heavy furniture will stand, dents form over time;

- High price.

For additional thermal insulation We advise you to purchase a cork substrate with a foil layer.

Jute backing

Using a jute linoleum substrate will provide the following advantages:

- High degree of rigidity. This material does not deform and does not sag even under heavy loads and after a long period. It is recommended to use in rooms with a large floor load;

- Durability. The material will last you about 75 years, or even more. That is, when the time comes to change linoleum itself, the substrate can not be changed. On top of it you can even lay laminate;

- Moisture resistance.The material does not absorb moisture and does not rot under its action;

- Fire resistance. Some manufacturers impregnate the material with special solutions that ensure its resistance to burning;

- Density variation. There is a jute on sale with a density of 450 to 750 g / meter. The higher the density, the higher the resistance to deformation;

- Thickness variation - from 2 to 5 mm .;

- Reasonable cost. Approximately 1000-1300 rubles. for 10 square meters.

High rigidity of the substrate can be attributed simultaneously to disadvantages as high bumps on a concrete base eventually push the material from the back. In short, jute is not flexible. If the submarine was laid on a surface with deep holes, they will certainly appear over time.

High rigidity of the substrate can be attributed simultaneously to disadvantages as high bumps on a concrete base eventually push the material from the back. In short, jute is not flexible. If the submarine was laid on a surface with deep holes, they will certainly appear over time.

Linen background

There is a liner backing, but finding it is sometimes problematic. This is the only fact that can be attributed to disadvantages.  However, the material has following advantages:

However, the material has following advantages:

- Environmental friendliness. The canvases are formed by felting on special equipment, which eliminates the use of adhesives. For reliability, the material is stitched;

- Breathability. The substrate can breathe, which is very important when in contact with the concrete base. The material protects the concrete from excessive evaporation of moisture and thereby prevents the formation of mold;

- High rigidity;

- Excellent heat and sound insulation properties due to the fibrous structure;

- The thickness variation is from 3 to 7 mm. As a universal substrate for any floor coverings, 5 mm thick material can be used. For linoleum, 3-4 mm is enough;

- Affordable price, which is slightly lower than the cost of a jute substrate.

Can say that it optimal choice both in price and in a set of operational characteristics.

Foam backing

Foamed polyethylene is used in construction quite often and in different interpretations.  The substrate of this material has the following advantages:

The substrate of this material has the following advantages:

- The most low cost among possible options for substrates;

- Availability. You can buy such a substrate in any store;

- A variety of release forms. Both rolls and sheets are available to customers, which makes it possible to choose the most convenient option. Note, that the sheets have higher stiffness. They are recommended to be used if the concrete base has many small irregularities;

- High resilience. This indicator must be monitored when buying. Just squeeze a piece of the backing with two fingers. If dents remain, and the material does not return to its original state, it is better not to buy such a product. This is how frankly cheap polyethylene from unknown manufacturers behaves.

TO disadvantages foamed polyethylene include:

- Not so long service life - no more than 10 years, after which the elasticity decreases, and the material begins to sag. But do not forget that this is the cheapest option;

- Air tightness. If the polyethylene is laid on an incompletely dried base, the formation of mold is inevitable, since there will be nowhere to go of excess moisture. Such a substrate can only be used on dry surfaces.

Combo substrate

This type of substrate is made of several materials - jute, linen and wool.  Moreover, the finished coating has the benefits jute and linen backing and a few more:

Moreover, the finished coating has the benefits jute and linen backing and a few more:

- It has the highest thermal insulation properties due to the presence of natural wool in the composition. it best choice for very cold floors;

- Wear resistance. Even after 50 years of operation, the material retains its rigidity and elasticity;

- Opportunity to purchase a substrate for a meter.

TO disadvantages include a higher cost - 150-200 rubles. per sq.m. and the presence on the market of low-quality combined substrates. Not always for this money you really get what you expect.

TO disadvantages include a higher cost - 150-200 rubles. per sq.m. and the presence on the market of low-quality combined substrates. Not always for this money you really get what you expect.