Soundproofing the riser and sewer pipes: 5 tips

Comfortable can be called, first of all, that housing, where nothing violates the peace of the owners. This is mainly about various extraneous sounds. People set multi-chamber double-glazed windowsto reduce the noise coming from a busy street and sew up walls various materialsto reduce hearing from neighbors. But what to do with the constant strange sounds coming from sewer pipes? It is immediately worth noting that it will not completely eliminate annoying noises. It turns out only to lower their level of audibility. To do this soundproofing of a riser and sewer pipes. In the article we will explain the causes of noise, givesoundproofing tips and its self-assembly.

The causes of noise and its types

Often, those who replaced the old cast iron or metal sewer pipes on plastic, I had to face the fact that the new pipes were too noisy, in some cases even “singing”.  The largest number of extraneous sounds occurs precisely in the riser. Despite the fact that the old cast-iron pipes were almost silent. In this case the main role is played by the nature of the materialor rather its structure. If cast iron is a eutectic alloy, which, roughly speaking, consists of many fine particles, then plastic is uniform in structure. Cast iron particles could dampen noise due to the presence of voids between them, that is, air, which is the best sound insulator, and due to friction between the particles. Plastic has no such features.

The largest number of extraneous sounds occurs precisely in the riser. Despite the fact that the old cast-iron pipes were almost silent. In this case the main role is played by the nature of the materialor rather its structure. If cast iron is a eutectic alloy, which, roughly speaking, consists of many fine particles, then plastic is uniform in structure. Cast iron particles could dampen noise due to the presence of voids between them, that is, air, which is the best sound insulator, and due to friction between the particles. Plastic has no such features.

In addition, there is additional reasons affecting the occurrence of noise and their intensity:

- The presence of air in the riser. Sometimes you can listen to the air "walking" through the pipes. This occurs due to leaks in the sewer system, and the type of noise is called airborne;

- Excessively high wastewater speed. If the drains pass through the sewer pipe at a high speed and at the same time they come into contact with the internal elements of the system or with each other, shock noises are formed;

- Structural noise occur when vibrations and vibrations of building walls and ceilings are transmitted to the surface of the sewer pipe. In places of direct contact of the riser with hard surfaces, vibrations are formed. Such noise, if they exceed the permissible noise levels, can be harmful to health.

Greatest discomfort residents of the lower floors of multi-storey buildings will feel. At that moment, until the drains reach the level of the first floors, they will already gain decent speed. In the process of falling, they will collide not only with each other and the inner walls of the pipes, but also with the air in the pipe. And the higher the rate of runoff, the greater the resistance will be provided by air. As a result, each discharge of water from above will be accompanied by a loud rustling sound. Structural noises cause no less discomfort, so any work to eliminate unpleasant sounds should be started precisely with their minimization.

What affects the noise level

We have already said that the main reason for the formation of noise is the peculiarity of the material.In addition, over time, a coating layer of a certain thickness formed on the inner surface of the old cast-iron pipe, which served as an additional sound insulator.  As you know, on smooth inner walls plastic pipes a similar plaque does not form. Other factors also affect the noise level:

As you know, on smooth inner walls plastic pipes a similar plaque does not form. Other factors also affect the noise level:

- Wall thickness. The thicker the pipe, the higher its ability to dampen sounds;

- Weight of the pipe. This parameter directly depends on the thickness of the pipe. The higher it is, the heavier the pipe, which increases its ability to noise absorption;

- Proximity pipe location to the wall. In many houses, the risers are mounted in such a way that in some places it is barely possible to stick your palm between the wall and the pipe. Due to its close proximity to the wall, the pipe may vibrate and make sounds;

- Lack of tough fixation pipes. When building vibrations occur that are transmitted to an unsecured pipe, their audibility will increase significantly;

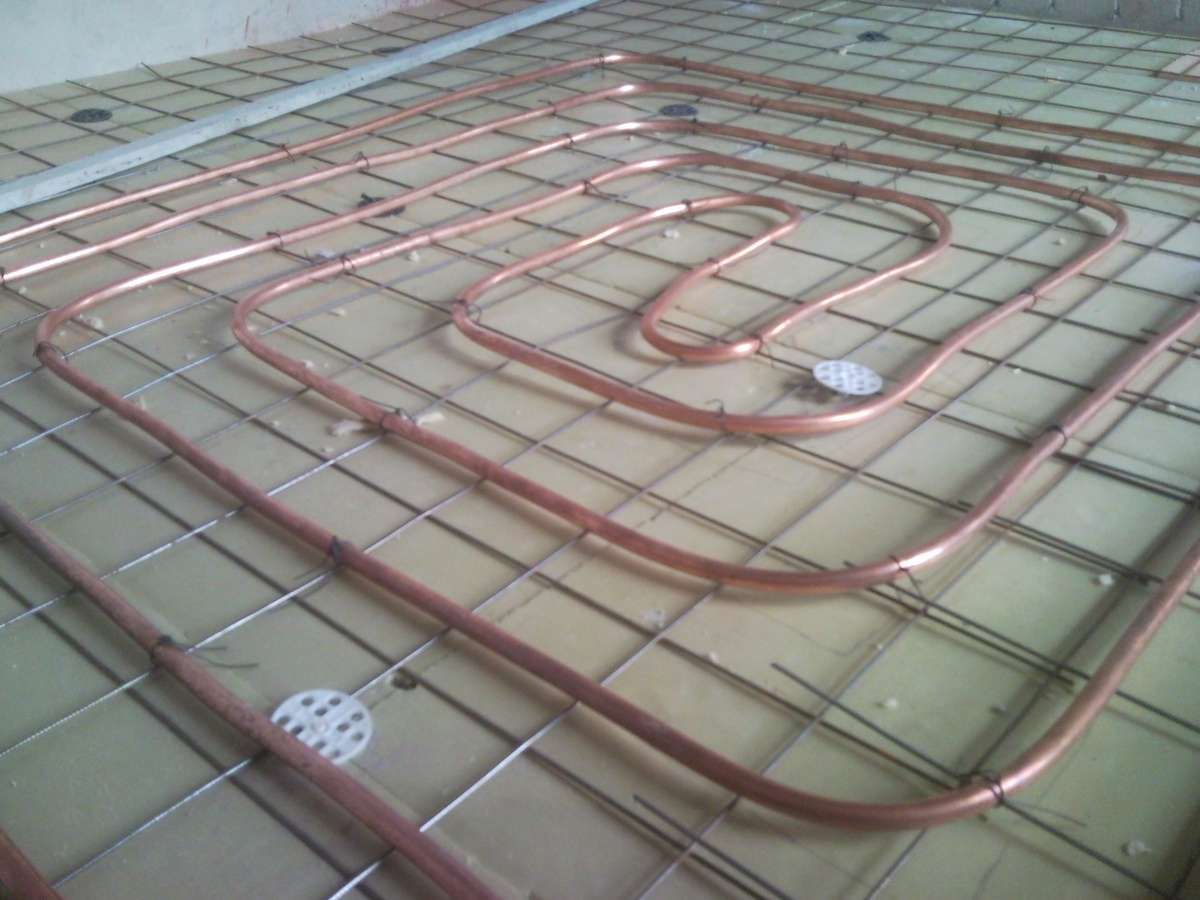

- No damping pad in places where pipes pass through floors. Many installers neglect the need to lay special rubber layers in places where the riser enters the floor or ceiling. In addition, the gap around the riser, which is formed when replacing cast-iron crossings with plastic ones, is often filled polyurethane foam. This is fundamentally wrong, since the foam not only does not have sound-absorbing or damping properties, but, on the contrary, can make any vibrations more loud.

Noise Reduction Activities

All of the following measures are aimed at reducing the noise level arising from the transmission of vibrations from floors to the pipe.  But fit they are only by who has not yet replaced the old water supply on plastic but plans.

But fit they are only by who has not yet replaced the old water supply on plastic but plans.

Use of silent pipes

At the moment, some manufacturers of plastic pipes produce a special kind of them called "Silent pipes."  She made polypropylene with some differences:

She made polypropylene with some differences:

- firstly, the walls of such a pipe have a large thickness;

- secondly, the structure of the material is different;

- Thirdly, the pipe is multilayer.

The outer surface of quiet pipes is made of durable and resistant to mechanical damage polypropylene. The inner surface is also made of this material and is perfectly smooth and durable. main feature pipes - its "filling". A layer of plastic is laid between the outer and inner walls, which includes particles of various mineral powders. Such a composition has enhanced soundproofing properties.

It is very simple to distinguish quiet pipes from ordinary ones - they are white and marked in the form of two longitudinal strips of red and green or yellow. Experts say that they really reduce the noise level to almost zero. But at the same time they possess disadvantages:

- Have a high cost;

- Provide shorter service life - about 20 years.

Partial riser replacement

If your old pipes are made of cast iron, you can perform a partial replacement.  This is relevant when replacing the riser in the toilet and only if the cast-iron sewage is in a relatively normal condition:

This is relevant when replacing the riser in the toilet and only if the cast-iron sewage is in a relatively normal condition:

- Before proceeding with the dismantling of the cast-iron riser, which involves breaking concrete floors to remove the cores, perform a visual inspection;

- If no defects such as cracks are found on the crosses and the riser at this point has always been airtight, you can perform a partial replacement while retaining these elements;

- To do this, cut out the main part of the pipe and leave a distance to the upper and lower crosses, which will allow the connection of cast-iron elements with a plastic pipe;

- The condition of the inner surface of cast-iron pipes is evaluated. The plaque formed during operation must be removed.This can be done mechanically, or using various chemicals such as "Mole". The liquid must be carefully applied to the surface and left overnight, after which it will be easier to remove the petrified plaque. There is no need to completely clean the inside of the pipes. The main thing is to provide clearance.

This method has immediately several advantages:

- You exclude the possibility of the formation of the most harmful type of noise - structural, since cast-iron crosses passing through concrete floors can dampen vibrations;

- Less materials will be required to complete the work, which will lead to lower costs;

- There is no need to dismantle part of the concrete floor to remove the crosspieces. For this type of work, some teams require additional payment;

- Since the length of the section of the plastic pipe will not exceed 2-3 m, the sounds in it will be much quieter than if you changed the riser completely together with the neighbors from below and above, and the pipe was solid.

But this method also has disadvantage - This is the presence of two vulnerabilities, namely the joints of cast iron and plastic. Therefore, if the plans to sew pipes plasterboard boxBe sure to wait at least 1 week before starting work. If the joints were made poorly, during this time the defect will manifest itself.

But this method also has disadvantage - This is the presence of two vulnerabilities, namely the joints of cast iron and plastic. Therefore, if the plans to sew pipes plasterboard boxBe sure to wait at least 1 week before starting work. If the joints were made poorly, during this time the defect will manifest itself.

Install retaining rings and damping pads

This is an additional event, which can be done both with an already completed water supply system, and immediately at the time of replacement.

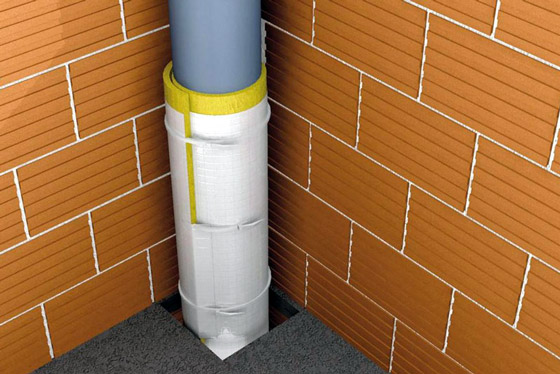

- If the riser is completely replaced, make sure that the workers insulate the pipe in the place where it passes through the ceilings. Usually, a special sleeve with polyurethane foam filling is used for these purposes;

- If the riser is already installed, but there is a gap in the ceilings around the passage, you can install an independent gasket. To do this, you need to buy a piece of pipe of a larger diameter than that of the riser, cut off two fragments of the required length, cut the resulting glass along and fasten around the pipe. You can connect the two halves with construction tape or special noise insulation tape. The gap between the pipe and the glass must be filled with polyurethane foam filler;

- To ensure the immobility of the pipe and to minimize the fluctuations transmitted from the walls to the pipe, it is better to use special clamps with a rubber layer to fix it. They are called damping. If you have already bought ordinary clamps, you can modify them yourself. To do this, it is enough to fix on the inner surface of the ring a piece of rubber sealant, porous rubber or a flap of rubber from old tires.

Sound Insulation Tips

After all possible measures to minimize the level of structural noise are completed, it remains to perform sound insulation of the free surface of the pipes.  All materials suitable for these purposes, depending on the form of their release, can conditionally be divided into 4 groups:

All materials suitable for these purposes, depending on the form of their release, can conditionally be divided into 4 groups:

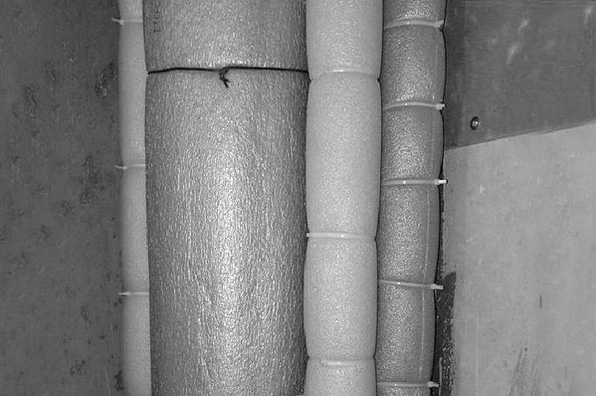

- Roll - those that can be cut into strips of the required length. It is necessary to install rolled noise insulation in such a way that the material is as tight as possible to the pipe surface and does not have gaps at the joints. The pipe diameter is measured, a strip of the appropriate size is cut off. The material is wrapped around the pipe so that the joints fit close to each other. The material is fixed using construction tape, which in this case needs to be pulled quite strongly. If the gap between the wall and the pipe is minimal, it is better to choose a roll polyurethane foam insulation;

- In the form of a shell. For insulation of pipes, a shell from polystyrene foam. Mounting it is very simple. The two halves of the shell have a groove-tooth connection. Two halves lean against the pipe and either simply snap into place, or one half is placed above the other and the tooth just starts into the groove.After joining, the shell is also recommended to be fixed with tape;

- In the form of a tape. The special soundproofing tape is simply wound on a pipe. Winding should be done so that each subsequent turn overlaps the previous one by at least 1/3 of its width. Then the insulation layer will turn out uniform and without gaps. If the thickness of the tape is small, several layers can be wound. This will increase the degree of sound insulation;

- In the form of a casing. Cases are made of foamed polyethylene and come in different diameters. The casing is selected by measuring the diameter of the pipe, which must be soundproofed. The outer diameter of the pipe should be equal to the inner diameter of the casing. Please note that there is a technological seam on polyethylene cylinders, it is thin and has a darker color. Cut the casing in this place. After you put the polyethylene on the pipe, you need to connect the ends with tape or clamps. In addition to sound insulation, a casing made of polyethylene will prevent the formation of condensation on the surface of pipes in the cold season.

Pay attention to the table below, which compares the noise level with user-friendly examples. When choosing a soundproofing material pay attention to the labels on the package. It always indicates the level of noise that it can absorb. Using the table will make it easier for you to navigate.

What materials should not be used

There are several types of material that can be called useless in terms of sound insulation quality:

- Polyurethane foam. Although coating the outer surface metal bathtubs polyurethane foam really makes the sound of water falling into it not so loud, this method does not work with plastic pipes. Moreover, in this case there is a risk of making the noise more audible;

- Mineral wool. This material has proven itself as a heater, but the soundproofing properties of cotton wool are minimal. In addition, according to sanitary standards, mineral wool can not be used in the living room in the open. Microscopic particles of fiberglass, falling into the air, can cause diseases of the respiratory system and skin.