How to choose paving slabs or paving stones

Today, paving slabs are becoming an increasingly popular material that is used in the arrangement of paths, private courtyards, summer cottages, areas near shops and entire streets. There are many reasons for this demand: tile is a highly aesthetic, strong and durable material, which has a huge selection of colors and sizes. The demand for these products is great, but the offer is great, so before buying, it is advisable for everyone to carefully familiarize themselves with the main types of paving slabs and choose the best option for themselves. Also, do not forget about the reputation of the manufacturer of paving slabs.

Operating conditions for paving slabs and pavers

The first thing you need to pay attention to before you buy paving slabs is their thickness, which should depend on the conditions under which it will be exploited.

The first thing you need to pay attention to before you buy paving slabs is their thickness, which should depend on the conditions under which it will be exploited.

- So, if you need to lay out a path, path, sidewalk, any pedestrian zone only, then you can choose a product with a thickness of 50-60 mm.

- Squares, parking lots, roads with low traffic require the use of tiles 60-80 mm thick.

- Truck parking, gas stations, tram tracks, helipads, high-traffic roads should be tiled 100-120 mm thick.

It is important that the smaller the size of the tile, the greater its strength.

You also need to pay attention to the resistance of the tile to temperature extremes. Each item can be rated by quantity. defrost / freeze cyclesin which the product does not deform and does not lose its strength properties. In the domestic climate, it is better to choose a tile for which this parameter is not less than 150, and even better - 200 or more. In the certificate for this product must be specified this parameter.

You also need to pay attention to the resistance of the tile to temperature extremes. Each item can be rated by quantity. defrost / freeze cyclesin which the product does not deform and does not lose its strength properties. In the domestic climate, it is better to choose a tile for which this parameter is not less than 150, and even better - 200 or more. In the certificate for this product must be specified this parameter.

Differences of paving slabs from pavers

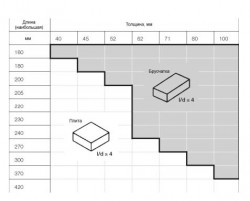

Many people mistakenly believe that paving slabs and paving stones are one and the same. Although there are no fundamental differences, there are still several parameters by which these two materials can be distinguished. Paving slabs can have absolutely any form. One of the criteria for the difference between paving stones and tiles is the ratio of the geometric dimensions of length, width and thickness (see the table on the right for a table of such ratios). Paving stones are most often made in the form of regular geometric shapes - bricks.

Another difference is the thickness of the product: paving stones with the same length are always much thicker than tiles. That is why places with high loads, for example, crowded streets and squares, it is better to lay out with paving stones.

Technology and material of manufacture

Today, paving stones and paving slabs can be made in many ways: some of them are more common, some are less, but they all differ in their advantages and disadvantages.

Made of natural stone

Many centuries ago, natural stone was used everywhere for construction and cladding, and therefore paths were paved with this material. Today, many people realized that few other artificial materials have the same durability, strength and beauty that a natural stone has, so attention to the material is returning.

Many centuries ago, natural stone was used everywhere for construction and cladding, and therefore paths were paved with this material. Today, many people realized that few other artificial materials have the same durability, strength and beauty that a natural stone has, so attention to the material is returning.

After extraction, natural stone is to be processed: it is split into pieces of a certain size, and then polished to give a smooth smooth surface, polished to create a shiny surface. Thanks to the heat treatment, it is possible to slightly change the color of the material, and tumbling involves the effect of water on the material, as a result of which sharp corners are rounded off.

Clinker pavers

Clinker pavers replaced natural stone in the 19th century: its production is still quite expensive, but the result is worth it. The technology allows us to produce a sufficiently durable material comparable to natural stone, characterized by high durability, frost resistance, it does not fade in the sun, can withstand huge loads. So, for example, one element of clinker pavers is able to withstand about seven full freight cars.

Clinker pavers replaced natural stone in the 19th century: its production is still quite expensive, but the result is worth it. The technology allows us to produce a sufficiently durable material comparable to natural stone, characterized by high durability, frost resistance, it does not fade in the sun, can withstand huge loads. So, for example, one element of clinker pavers is able to withstand about seven full freight cars.

Clinker pavers are based on a special plastic claywhich together with quartz, feldspar fired in furnaces at a temperature of 1000-12000FROM. As a result, the material turns out to be the color of fired clay, but if you need to give the paving stones a different shade, then the appropriate minerals are used to get a noble brown, black, white color, etc. The resulting shade does not fade with time in the sun and after tens and hundreds of years remains in its original form. Coarse sand can be added to the firing mixture to get a rough surface that will not slip in winter.

All mineral particles that are used in the production of such pavers are sintered under the influence of high temperature, forming a solid monolithic material. Such products do not absorb water, are not affected by aggressive chemicals, and due to the absence of all kinds of voids and inclusions, the compressive strength is much higher than that of other materials, the paving stones are almost not abraded, not bent. It almost does not respond to moisture and temperature changes, which compares favorably with products from concrete.

All mineral particles that are used in the production of such pavers are sintered under the influence of high temperature, forming a solid monolithic material. Such products do not absorb water, are not affected by aggressive chemicals, and due to the absence of all kinds of voids and inclusions, the compressive strength is much higher than that of other materials, the paving stones are almost not abraded, not bent. It almost does not respond to moisture and temperature changes, which compares favorably with products from concrete.

The advantage of clinker pavers It also consists in the simplicity of its laying: on an ordinary road base, and in a country house - on compacted sand with crushed stone or on a cement-sand mixture. Clinker pavers are widely used in European cities for paving sidewalks, bridges, carriageways, as well as in our country for arranging sites near shopping centers, houses, etc.

Concrete tile

To date, the most common production of paving slabs from concrete. It is obtained in two main ways: vibropressing and vibrocasting. Each has its own advantages and disadvantages and is more preferable in specific conditions.

Manufacturing method

Vibrocompression

In this case, pre-prepared concrete mix They are laid out in a mold on a constantly vibrating table, and on top of the mold a special press - punch tightly enters, which presses the mixture until it is completely densified, and the pressure is about 30-35 atm. The punch also constantly vibrates, and after pressing it rises, leaving the finished form on the table. This is a high-performance method that can be fully automated.

In this case, pre-prepared concrete mix They are laid out in a mold on a constantly vibrating table, and on top of the mold a special press - punch tightly enters, which presses the mixture until it is completely densified, and the pressure is about 30-35 atm. The punch also constantly vibrates, and after pressing it rises, leaving the finished form on the table. This is a high-performance method that can be fully automated.

Tiles made in this way are suitable for those places that are under constant load and which do not require a particularly elegant approach when arranging, since in this way it is possible to form tiles of more or less simple but accurate shapes: square, rectangular, hexagonal, etc.

Vibro-pressed tiles differs in high operational properties: it is durable, frost-resistant, durable, almost does not wear out, retains its original color for a long time. Its surface is a little rough, so it’s great for paving streets, stops, warehouses, garden paths etc. In addition, such a tile can be additionally sanded, polished or even applied with anti-slip strips.

Vibration casting

Vibration casting involves filling concrete or plastic molds with a concrete mixture.which are put on a vibrating table and tamped. Since there is no more impact on future paving slabs in this case, the process takes more time and becomes more expensive. When the mixture in the tile was tamped, it is left with the mold to stand in a warm place for about 12-15 hours.

Vibration casting involves filling concrete or plastic molds with a concrete mixture.which are put on a vibrating table and tamped. Since there is no more impact on future paving slabs in this case, the process takes more time and becomes more expensive. When the mixture in the tile was tamped, it is left with the mold to stand in a warm place for about 12-15 hours.

In quality, strength and durability such a tile is almost not inferior to the pressed version, however, sometimes small flaws can be found in terms of geometry. This material has higher aesthetic properties: it can have any shape, color and even contain a drawing. Most often, vibrocast tiles have a shiny surface, so it looks presentable. But in winter it becomes covered with a thin layer of ice and becomes very slippery. In addition, when exposed to frozen water, such a material may crack, so many manufacturers use special modifiers and plasticizers in the manufacture that increase the cost of products.

Polymer sand mixture

Polymer sand tiles are often confused with plastic., and all because both types of tiles include polymeric materials, but in different quantities. In this case polymers in the composition of the tiles only 25% and they are represented by polyethylene, polystyrene or polypropylene. The remaining 75% is occupied by dye and sand. The latter has special requirements: it must be clean, well sifted, calcined, medium in size.

Polymer sand tiles are often confused with plastic., and all because both types of tiles include polymeric materials, but in different quantities. In this case polymers in the composition of the tiles only 25% and they are represented by polyethylene, polystyrene or polypropylene. The remaining 75% is occupied by dye and sand. The latter has special requirements: it must be clean, well sifted, calcined, medium in size.

Prepare polymer sand tiles in three different ways.: hot pressing the mixture, vibropressing the dry mixture or vibrocasting using plasticizers. The last two methods make it possible to obtain tiles with very low porosity, and the first - high-quality and durable material.

The advantages of this type of coating its longevity, strength, frost resistance, abrasion resistance, light weight, moisture resistance, since water does not penetrate the tile itself, but is collected in droplets on it. In addition, this tile is resistant to aggressive chemicals, gasoline, has a huge selection of possible colors and textures, as well as ease of installation.

The advantages of this type of coating its longevity, strength, frost resistance, abrasion resistance, light weight, moisture resistance, since water does not penetrate the tile itself, but is collected in droplets on it. In addition, this tile is resistant to aggressive chemicals, gasoline, has a huge selection of possible colors and textures, as well as ease of installation.

Despite a number of advantages, such material still gives out its artificiality a little. and in some types of landscape design will be inappropriate. In addition, the polymer sand tile method to expand under the influence of high temperatures, therefore, when laying it is recommended to leave a gap of 3-5 mm.

Plastic tile

Plastic tile is 100% polymermost commonly used is polyvinyl chloride or polypropylene. This tile has very weak decorative properties, has a lattice structure, is often used in the arrangement of areas around pools, terraces, garages, winter gardens, campsites, the transition from the entrance gate to the house, garden paths, demarcation of beds, etc. Grass can grow through the slots in the tile at the cottage, forming a rather interesting effect.

Plastic tile is 100% polymermost commonly used is polyvinyl chloride or polypropylene. This tile has very weak decorative properties, has a lattice structure, is often used in the arrangement of areas around pools, terraces, garages, winter gardens, campsites, the transition from the entrance gate to the house, garden paths, demarcation of beds, etc. Grass can grow through the slots in the tile at the cottage, forming a rather interesting effect.

The plastic tiles at the ends have special grooves, thanks to which it is easy to assemble, and the installation process is not just quick, but instant, when compared with other types of tiles. But you need to prepare the perfect base so that immediately after laying the plastic tile is not crushed or deformed.

Despite the apparent fragility, this tile can withstand huge loads, has high frost resistance, does not fade, and also does not slip. The coating can be very quickly disassembled and moved to another place, thereby redeveloping the garden.

Rubber tile

Rubber paving slabs relatively recently appeared on the market of building materials. It is made from rubber mass., colored filler and special polyurethane binders.

Rubber paving slabs relatively recently appeared on the market of building materials. It is made from rubber mass., colored filler and special polyurethane binders.

Due to the fact that rubber crumb based, the material turns out to be soft and elastic, so it is relatively safe when dropped, which is why it is used at arrangement of children's and sports grounds. This tile is quickly mounted, behaves perfectly with a sharp change in temperature, does not fade in the sun. It is durable, easy to care for, does not slip when water gets in.

Such material is often used in the design of garden paths, terraces, verandas, as well as in car services, in underpasses, garages, parking lots, fitness centers, etc.

Forms and sizes of paving slabs

Paving slabs can vary significantly in shape and size. So, in length, it ranges mainly from 16 to 42 cm, but in terms of various forms, a variety of options can be found. Different manufacturers offer a different range of products, but most often you can see such types of tiles as a snake, coil, brick, antique, scales, lily, rhombus, mosaic, gzhelika, rondo cross and rings, etc.

If the task is to make the process of laying tiles the simplest, most effective and fastest, then it is better to choose the one that has the same size, and this is vibropressed concrete tile. Vibrocast tiles may have some differences between the individual parts, so the installation process will be difficult. But such material is more aesthetic, and the final result will be worth the effort. If there are a lot of various bends and depressions on the tiles, then before you start laying it in a given place, you need to practice and lay out a small piece somewhere nearby.

Marking and classification of paving slabs

The shape and size of the tile appear in its labeling, from which it can be judged what kind of tile is in the package.

Classification of paving slabs in form is as follows:

- K - square tile;

- P - rectangular tile;

- Ш - hexagonal tile;

- D - a tile for a border which is intended for hexagonal plates;

- F - figured tile;

- EDD - road decoration elements.

So, if the designation 4K is on the tile, it means that it is a square tile of the fourth standard size with a thickness of 7 cm.

Concrete tiles are also classified as used for concrete production:

- B 22.5;

- At 25;

- At 35, etc.

Practical Tips for Choosing the Most Popular Cement-Based Paving Slabs

In order for paving slabs to serve you for a long time and keep its original appearance for the maximum time, when choosing it, you need to pay attention to a number of factors:

tile made on the basis of cement, check for the correct ratio of all components in its composition by the sound with which the individual elements hit each other: a ringing sound means that everything is normal, and a dull one indicates an excess of water, plasticizers, a violation of technology, etc .;

tile made on the basis of cement, check for the correct ratio of all components in its composition by the sound with which the individual elements hit each other: a ringing sound means that everything is normal, and a dull one indicates an excess of water, plasticizers, a violation of technology, etc .;- must be extremely careful with saturated colors tiles: conscientious manufacturers use expensive pigment, which is quite small enough to give the whole mixture a bright shade, and unscrupulous use cheap dye in large quantities, which is then quickly washed out during operation;

- tile color everywhere should be uniform, and to check, it is enough to break one of the tiles and study the scrapping;

- yellow spots on the back of the tile they say that the production process was not observed, and that clay sand was used together with concrete, which reduces strength and durability;

- tile surface should be free of bubbles, chips, cracks, etc.

What documents should the seller have

Another important point when choosing paving slabs is checking all the necessary documents from the seller.

Another important point when choosing paving slabs is checking all the necessary documents from the seller.

- So, upon purchase on demand, a certificate of conformity must be provided, which confirms that this product is manufactured according to accepted standards.

- The presence of a conclusion on testing specific products, which indicates strength, frost resistance, water absorption, concrete class, etc., is highly recommended.

A responsible conscientious seller will always be able to show the necessary documents, and ignoring the request for the necessary certificates should raise suspicion.

Yes, the option with concrete tiles is the most successful and common. This option is very cheap and practical.

Great article on the choice of paving slabs. Thank you for such extended information.