How to choose the right polyurethane foam for insulation

In anticipation of winter frosts, many are thinking about organizing appropriate thermal insulation to make their home as comfortable and economical as possible. It is not too late to tackle this issue so that the first serious cold can be met in a warm and comfortable house. But the process of warming is preceded by a process selection of thermal insulation material. Today, polyurethane foam, which has a lot of advantages, is in high demand. Its main advantages, as well as the main parameters of choice, require more careful consideration.

Polyurethane foam is obtained on the basis of the reaction of the polyol and isocyanate, when water is added to which carbon dioxide is formed. The result is a porous material, more than 70% of which is occupied by air bubbles, which gives this type of insulation unique properties.

Advantages and disadvantages of polyurethane foam

Considering the key properties of this material, it is worth noting that it is widely used and in the form of plates, and in the form of a sprayed insulation. In principle, most properties are common, but there are still some differences. So what are advantages are characteristic for polyurethane foam?

Highly low thermal conductivity, which allow us to call the material the best heat insulator among all known and used heaters. So, its thermal conductivity is 0.019 W / m * K: for comparison, a similar indicator in the popular mineral wool is about 0.041 W / m * K.

Highly low thermal conductivity, which allow us to call the material the best heat insulator among all known and used heaters. So, its thermal conductivity is 0.019 W / m * K: for comparison, a similar indicator in the popular mineral wool is about 0.041 W / m * K.- Polyurethane foam can be called relatively durable material, which will allow you to forget about the problems with thermal insulation for the next 25-30 years. But modern research shows that its longevity is even greater.

- The material is completely safe for health people and can cause neither allergies, nor any other more serious illness.

- This material has good resistance to temperature extremes, extremely low and high temperatures, it will not crack, thereby forming cold bridges, through which frost can penetrate the house, lowering the level of protection of the home;

- Rot resistant and rodents;

- Resistance to fire.

- Light weight insulation does not burden the building structure.

- Polyurethane foam tolerates the effects of many acids, alkalis and oil products, and when it covers metal surfaces, it even protects against corrosion.

- The material is also good sound insulatorTherefore, it will be possible to make the house not only much warmer, but also calmer, which is especially true in cases of the proximity of major traffic intersections.

- Low ability to water absorption.

All worth mentioning separately. advantages of a sprayed polyurethane foam coating. So, the spraying technology itself allows you to create a holistic monolithic coating that perfectly fills all cracks and complex hard-to-reach relief forms. The absence of seams and rags that are formed during the cutting process affect the appearance of the surface: it turns out to be almost perfect and even. The sprayed polyurethane foam has high adhesion to all types of surfaces, and moreover “sticks” to indirect walls.Before spraying with any special composition, it is unnecessary to process the surface, and additional fasteners are not needed, which can also be considered a competitive advantage.

All worth mentioning separately. advantages of a sprayed polyurethane foam coating. So, the spraying technology itself allows you to create a holistic monolithic coating that perfectly fills all cracks and complex hard-to-reach relief forms. The absence of seams and rags that are formed during the cutting process affect the appearance of the surface: it turns out to be almost perfect and even. The sprayed polyurethane foam has high adhesion to all types of surfaces, and moreover “sticks” to indirect walls.Before spraying with any special composition, it is unnecessary to process the surface, and additional fasteners are not needed, which can also be considered a competitive advantage.

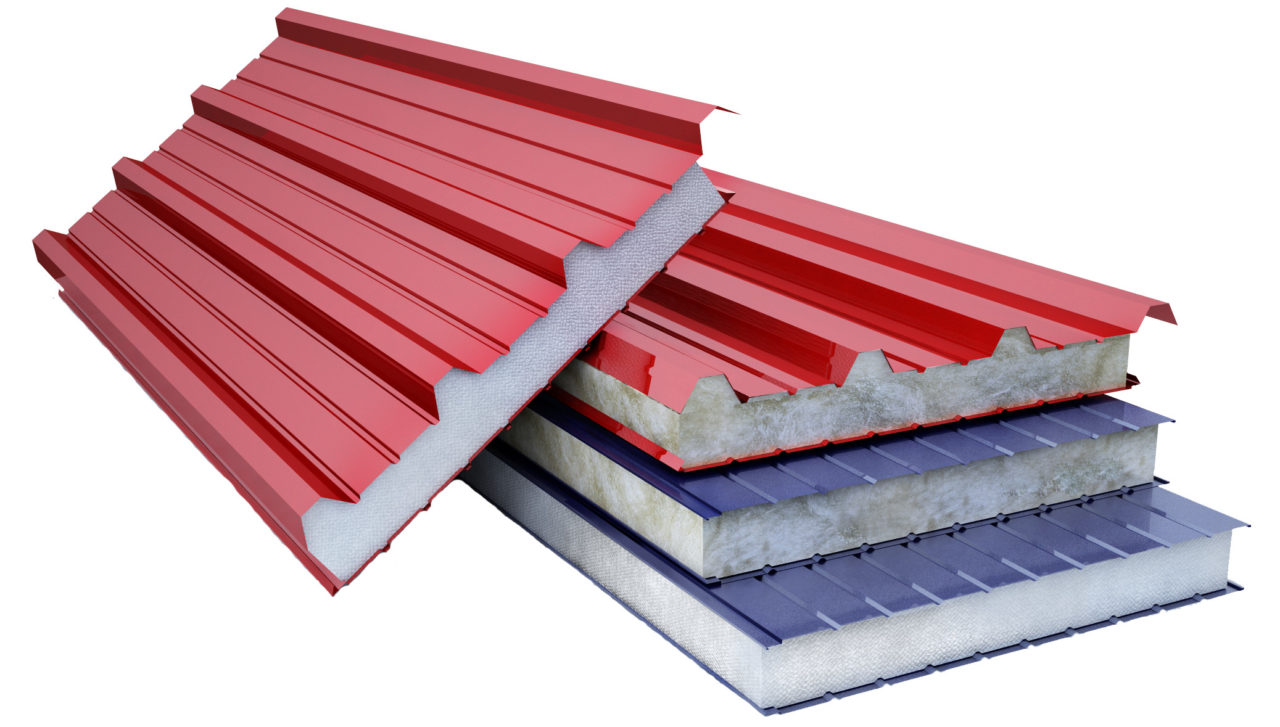

As for polyurethane foam boards, then at their lower price they also boast a number of additional advantages. So, their installation can be carried out at any time of the year, the process itself is quite simple, and if necessary, the plates can be cut or sawed to give optimal sizes. To fix the insulation, an additional frame or something like that is not needed: glue applied along the edge of the plate and diagonal, as well as plastic dowels, are enough. The panels can be made with a locking mechanism, so that as a result the room is as much as possible protected from external influences. In addition, unlike sprayed polyurethane foam, in this case, individual protection against aerosol fog is not required.

As for polyurethane foam boards, then at their lower price they also boast a number of additional advantages. So, their installation can be carried out at any time of the year, the process itself is quite simple, and if necessary, the plates can be cut or sawed to give optimal sizes. To fix the insulation, an additional frame or something like that is not needed: glue applied along the edge of the plate and diagonal, as well as plastic dowels, are enough. The panels can be made with a locking mechanism, so that as a result the room is as much as possible protected from external influences. In addition, unlike sprayed polyurethane foam, in this case, individual protection against aerosol fog is not required.

Disadvantages of this type of insulation can be attributed the following qualities:

- is he afraid of direct ultraviolet rays, which can lead to its gradual destruction, but the way out of this situation is quite simple, because you only need to apply a protective coating in the form of paint or plaster, which is still applied on top of any insulation.

- The material is not flammable and does not support combustion, but with prolonged exposure to very high temperatures may start to smolder. That is why you should not use it near places that can get very warm, or just use additional protection.

Spray foam cannot be applied on cold surfaces, therefore, work on its application have a strict seasonality, which cannot be said about the plates.

Spray foam cannot be applied on cold surfaces, therefore, work on its application have a strict seasonality, which cannot be said about the plates.- If the wind is too strong, the sprayed polyurethane foam is overused.

- Work on the application of sprayed insulation should only be carried out in personal protective equipment, since the resulting aerosol is very dangerous for good health. But for several hours, the cured layer of polyurethane foam becomes completely safe.

- It is undesirable to use this heat-insulating material when warming a roof from a bituminous tile, which can overheat and lose some of its properties.

- The price of polyurethane foam is not the lowestbut the buyer receives the material with the highest levels of thermal insulation.

As you can see, many of the disadvantages of polyurethane foam are easy to negate, which makes it one of the most optimal materials for insulation. Today it is sprayed polyurethane foam that is in ever-increasing demand, and it is called heater of the future. All this allows you to use in various fields: for insulation of houses, industrial buildings, roofs, floors, walls, etc.

The choice of sprayed polyurethane foam

All work on the spraying of polyurethane foam is carried out by professionals, and the durability of the insulation layer depends on the level of their skill. In this case, you should carefully approach only to the question of the choice of specialists, using the recommendations of friends or reviews on the Internet. Nevertheless, in order to control the work of the team and choose the appropriate one, you must be aware of what thickness the spraying will need, what density, and which brand to choose the material.

All work on the spraying of polyurethane foam is carried out by professionals, and the durability of the insulation layer depends on the level of their skill. In this case, you should carefully approach only to the question of the choice of specialists, using the recommendations of friends or reviews on the Internet. Nevertheless, in order to control the work of the team and choose the appropriate one, you must be aware of what thickness the spraying will need, what density, and which brand to choose the material.

So, cell structure material required should be closed: in this case, the material has high strength and can be used in a variety of fields. The open-cell insulation is susceptible to moisture, more fragile and brittle.

Depending on where the insulation will be used, it is important to choose the right required density. It is worth noting that this indicator does not affect non-thermal insulation properties: insulation with a density of 30 and 60 kg / m3 will be equally reliable.The difference is only in terms of waterproofing: the thicker the insulation layer is used, the more reliable the waterproofing will be, because polyurethane foam has similar properties, and when using it, an extra layer of waterproofing will not be needed. If you need to insulate the foundation or ground floor, then you need to choose a heater with a density of at least 23 kg / m3.

Layer thickness polyurethane foam should be at least 50 mm, despite the surface material: for wood, and for metal, and for bricks the required layer remains approximately the same. The required thickness is selected depending on climatic conditions, own requirements and some other parameters.

Layer thickness polyurethane foam should be at least 50 mm, despite the surface material: for wood, and for metal, and for bricks the required layer remains approximately the same. The required thickness is selected depending on climatic conditions, own requirements and some other parameters.

It’s clear that you won’t be able to spray polyurethane foam on your own, so pay attention to the level of specialistsas well as what equipment do they work. Its high quality will ensure high quality thermal insulation while saving material. Preference should be given to the technique that works under high pressure.

The brand of material for insulation is also able to tell a lot. It is better to choose those brands that have already established themselves in high quality. Here are just a few of them:

- Basf - A German company that is considered a recognized leader in the chemical industry. Among other products, it also produces polyurethane foams, which are widely represented in Russia. Moreover, the company is so interested in the domestic market and wants to please the buyer that it has made a special type of insulation that can be applied at low temperatures.

Baymer - Another German manufacturer who has established himself well in the market and is in steady demand among professionals.

Baymer - Another German manufacturer who has established himself well in the market and is in steady demand among professionals.- Synthesia - The Spanish company, which has a wide representative office in Russia. Today, the production of polyurethane systems has become the main area of activity, and the direct delivery of European-quality materials allows you to create the most comfortable indoor conditions.

- Huntsman-nmg - a company that has a lot of representative offices around the world, including in many regions of Russia. The product has all the necessary documentation, and is also certified according to the ISO standard.

- Isolan - polyurethane systems that are produced in Russia. The plant in Vladimir is equipped with modern equipment and uses only modern technology, which allows producing the highest quality materials, while competing with European companies.

Also, polyurethane foam of Chinese and Belarusian production is presented on the market, but its quality is not the highest, therefore, specialists using similar products should be treated with caution.

The choice of polyurethane foam boards

When choosing, it is worth paying attention to all the necessary certificates of conformity, which will guarantee that the material will not cause any harm to health. In addition, it is important that the appropriate storage conditions are observed so that the material does not lose its performance properties. Taking into account the fact that polyurethane foam is afraid of direct sunlight, it is better to store it under a canopy. It is important that the packaging is complete and reliably protects the material from external influences.

When choosing, it is worth paying attention to all the necessary certificates of conformity, which will guarantee that the material will not cause any harm to health. In addition, it is important that the appropriate storage conditions are observed so that the material does not lose its performance properties. Taking into account the fact that polyurethane foam is afraid of direct sunlight, it is better to store it under a canopy. It is important that the packaging is complete and reliably protects the material from external influences.

On sale there are both ordinary plates, and slabs with a protective reflective layer, which improves thermal insulation qualities, and also becomes a powerful barrier to dangerous ultraviolet rays.

But an important role in the selection of products is played by the name of the manufacturer, as well as his reputation, reviews about him. All this allows you to identify several companies that are worth trusting. Here is some of them:

Penoflot PC has been operating on the market since 1988 and specializes in the production of polyurethane foam products, including plates. All products have appropriate certification, which confirms the high culture of production and the quality of the finished product.

Penoflot PC has been operating on the market since 1988 and specializes in the production of polyurethane foam products, including plates. All products have appropriate certification, which confirms the high culture of production and the quality of the finished product.- "YEW" - Another domestic company that uses the latest equipment and is constantly working to improve product quality, conducting research and introducing innovations. The main place among the company's products is occupied by polyurethane foam boards, which are controlled at every stage of production and meet all requirements.

- LLC "SK" - A relatively young organization that has already made itself quite loud. The company itself manufactures heat-insulating plates and, if necessary, is engaged in their installation.

- Lissant - A group of factories that specializes in the production of heat-insulating boards, and primarily polyurethane foam. The company uses only high-quality raw materials, constantly monitors its products, which ensures the maintenance of a consistently high quality product.

- PE "TeploEkonom" - Belarusian company operating since 2009. It produces both heat-insulating plates from polyurethane foam and spraying it.