How to choose basalt slabs for insulation and sound insulation

Basalt slabs today are considered one of the most popular materials that are used for heat and sound insulation of premises. They are distinguished by excellent sound absorption indicators, low coefficient of thermal conductivity, strength, durability, environmental friendliness and low price, which ensured this material is widespread. Actually basalt slabs are modification of basalt wool, but working with the slabs is much more convenient, and in terms of strength they win. How to choose a basalt slab for insulation and sound insulation of a room, and which manufacturers should I pay attention to?

Basalt plate is made from natural raw materials, namely rocks (most often basalt, dolomite, diabase, clay), which first melt at a temperature of 15000C, and then, together with binders and hydrophobizing additives, solidify in the form of the finest fibers. As a result, the structure of the starting material changes, and the fibrous structure determines all the properties of the resulting plates.

Advantages and disadvantages of basalt slabs

Many properties of basalt slabs are identical. mineral wool, but this material received an additional several advantages. So, the main advantages are as follows:

Many properties of basalt slabs are identical. mineral wool, but this material received an additional several advantages. So, the main advantages are as follows:

- low thermal conductivity (about 0.04 W / m * K), it is explained by the fibrous structure of the material in which air is trapped. The latter, as you know, has a very low coefficient of thermal conductivity, and this is the basis for the principle of operation of this heat-insulating material. So, for example, a plate 10 cm thick is comparable in effectiveness with a 30 cm wooden heater;

- sound absorbing properties again explained by the structural features of the material. A sound wave, passing through the fibers of a basalt plate, is damped and even converted into thermal energy. As a result, a room protected by such material becomes much quieter and more comfortable, and the strength of sound and vibrations is much reduced, passing through a layer of a basalt plate;

- fire resistance meets the highest fire requirements, therefore, this heat and sound insulator can be used in almost any room and building;

- resistance to aggressive chemicalsincluding oils, acids and alkalis, makes it possible to use basalt plates even in industrial enterprises;

vapor permeability, possible due to the structure of the material, allows it, with proper installation and operation, to remove excess moisture into the atmosphere, thereby ensuring an optimal microclimate in the room;

vapor permeability, possible due to the structure of the material, allows it, with proper installation and operation, to remove excess moisture into the atmosphere, thereby ensuring an optimal microclimate in the room;- strength characteristics plates allow you to use them for insulation and sound insulation of any building systems. In the manufacturing process, the fibers are reoriented, taking a completely different direction, which provides tremendous strength to the material, which does not lose over time;

- basalt slabs have good hydrophobic and water repellent properties. This is achieved, firstly, due to the non-hygroscopic structure of the material, and, secondly, through the use of special additives that increase the natural water-repellent properties;

- biological resistance;

- high durability, because the basis of the material is stone filaments, the life span of which is huge.With proper installation and compliance with all operating requirements, basalt slabs will last at least 70 years, although many studies by scientists show even longer service life;

- ease of installation due to the fact that basalt slabs are easy to transport, cut and fasten to any surface.

This material has practically no disadvantages. Its cost remains very affordable, but it is slightly higher than the price of Styrofoam or foamed polyethylene, which makes some buyers think. In addition, during the operation of the heat and sound insulating layer, gaps between the basalt slabs may form. This process takes place under the influence of natural forces, but ultimately leads to the formation of bridges of cold.

This material has practically no disadvantages. Its cost remains very affordable, but it is slightly higher than the price of Styrofoam or foamed polyethylene, which makes some buyers think. In addition, during the operation of the heat and sound insulating layer, gaps between the basalt slabs may form. This process takes place under the influence of natural forces, but ultimately leads to the formation of bridges of cold.

Still unique heat- and soundproofing properties of this material allow its use in various fields. Basalt slabs are widely used for warming and soundproofing walls, ceilings, internal partitions, floors, facades and roofs of houses in all types of buildings. So, this material is used both for apartment buildings, and for low-rise buildings, and even for light frame-type enclosing structures. Moreover, for different types of work, plates are used not only of different thicknesses, but also of different densities.

Selection of basalt slabs

So that all the unique properties of basalt plates can be used to the maximum, you need to choose the right material that will meet the technical parameters. First of all, attention is paid to plate density.

The lightest density slabs up to 35 kg / m3 indispensable for non-loaded structures, pitched roofs, as well as for warming and soundproofing attics, attic, frame walls.

The lightest density slabs up to 35 kg / m3 indispensable for non-loaded structures, pitched roofs, as well as for warming and soundproofing attics, attic, frame walls.- Density basalt slabs 35-50 kg / m3 have the same scope as the previous type of plates, but can also be used as a heat and sound insulation layer in the facades of low-rise buildings.

- Density plates 50-75 kg / m3 can be used for insulation of floors and ceilings, partitions, as well as the middle layer in the three-layer structure of the walls of low buildings and as the lower heat-insulating layer in facade structures.

- Density basalt slabs 75-100 kg / m3 - An excellent option for insulation of external walls, and is also well suited for the arrangement of ventilated facades. It is used in both civil and industrial construction.

Density plates up to 125 kg / m3 also well suited for ventilated facades, can be the top layer in the organization of two-layer thermal insulation.

Density plates up to 125 kg / m3 also well suited for ventilated facades, can be the top layer in the organization of two-layer thermal insulation.- Density basalt slabs 125-150 kg / m3 if necessary, make soundproofing of the partitions perfectly, insulate the wall under a further coating of plaster.

- Density plates up to 175 kg / m3 are used as an independent heat-insulating layer for reinforced concrete surfaces, walls, facades and partitions.

- Density Slabs 175-200 kg / m3 perfectly suited for the organization of sound insulation of floors under the screed.

It is worth remembering that plates with a lower density have higher heat-insulating characteristics, which means they will be a more efficient insulation. As the density increases, the thermal conductivity increases. On the other hand, a denser plate becomes synonymous with strength and durability, which means that it is impossible to clearly say which plates are worse and which are better. The choice must be made depending on the characteristics of the room.

As for the choice of the thickness of basalt plates, there can be no single right advice, and in each case the thickness can be different. This parameter depends on the climatic conditions of the region, the place of use of the insulation, the nature of the room, the material and the thickness of the walls, roof, etc. When calculating, you can use normative document SNiP 23-02-2003, special programs or sites, which are a calculator where the user needs to enter all the source data, and then in a matter of seconds he gets the result. You can try to independently calculate for residential premises according to the following scheme.

As for the choice of the thickness of basalt plates, there can be no single right advice, and in each case the thickness can be different. This parameter depends on the climatic conditions of the region, the place of use of the insulation, the nature of the room, the material and the thickness of the walls, roof, etc. When calculating, you can use normative document SNiP 23-02-2003, special programs or sites, which are a calculator where the user needs to enter all the source data, and then in a matter of seconds he gets the result. You can try to independently calculate for residential premises according to the following scheme.

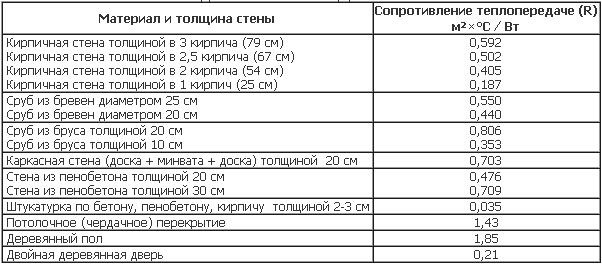

- We determine the standard indicator of thermal resistance of walls, floors and coatings for a particular region according to the table. For example, you need to choose a basalt soundproofing insulator for walls in St. Petersburg, which means R = 3.06 m2* K / W.

- We determine the coefficient of resistance to heat transfer of the insulation. It should be specified by the manufacturer, since plates with different densities can have slightly different indicators. On average, we take the thermal conductivity coefficient for basalt plates for 0.041 W / m * K.

- We determine the heat transfer resistance of existing walls of the house. Let's say it is built in 2.5 bricks, and the wall thickness is 67 cm. Then the heat transfer resistance in this case will be 0.67 / 0.502 = 1.33 m2* K / W. If there is a layer of plaster or other coatings, their heat transfer resistance is also taken into account.

- In order to compensate for the difference of 3.06-1.33 = 1.73 m2* K / W, it is necessary to use a basalt slab with a thickness of 0.041 * 1.73 = 0.07 m, or 7 cm. Today, there are slabs with different thicknesses on sale, but as a rule, the following are found: 50, 60, 80, 100 , 120 and 150 mm. In some cases, to improve sound insulation, it is recommended to use thicker plates than calculated.

The largest manufacturers on the market in Russia

It is no secret that the manufacturer’s positive reputation is a guarantee that the purchased product will certainly be of high quality and will meet all the declared properties. Today, several major manufacturers appear on the market, among which are the following.

Rockwool - The world leader in the production of heat and sound insulation based on stone wool. The company's assortment is so extensive that it allows you to choose a material that is ideal for use in any environment. Today, the company includes 28 plants in 18 countries, and the products are widely represented on all continents, including in Russia.

Rockwool - The world leader in the production of heat and sound insulation based on stone wool. The company's assortment is so extensive that it allows you to choose a material that is ideal for use in any environment. Today, the company includes 28 plants in 18 countries, and the products are widely represented on all continents, including in Russia.- IZOVOL - A leading Russian manufacturer of basalt slabs. In the assortment there is a huge selection of products, therefore, it will be possible to choose the material for any conditions. In addition, company specialists are always ready to advise the best option, and products represented in all regions of the country. The manufacturer’s website has convenient system for calculating the necessary thickness of a basalt plate with a clear interface and clear results. It takes into account all the features of the room, up to the type of heating, and ultimately advises which plates are best suited in this case.

LLC Bogdanovichsky Mineral-Wadded Plates Plant - A modern enterprise that uses the latest technology and equipment for the production of basalt slabs manufactured under the Izba trademark. For the manufacture of products using Italian equipment. In addition, full control is carried out at all stages of production, and all finished products have quality certificates. The assortment includes a huge number of items of heat-insulating basalt slabs intended for use in various fields. For the convenience of users, each type of product has received a corresponding name, which suggests the possibilities of its use. Each type of product is accompanied by all the necessary documentation and extensive information with its technical characteristics.

LLC Bogdanovichsky Mineral-Wadded Plates Plant - A modern enterprise that uses the latest technology and equipment for the production of basalt slabs manufactured under the Izba trademark. For the manufacture of products using Italian equipment. In addition, full control is carried out at all stages of production, and all finished products have quality certificates. The assortment includes a huge number of items of heat-insulating basalt slabs intended for use in various fields. For the convenience of users, each type of product has received a corresponding name, which suggests the possibilities of its use. Each type of product is accompanied by all the necessary documentation and extensive information with its technical characteristics. TekhnoNikol Corporation - A modern company that produces a huge number of building materials.Vast experience since 1992, the use of modern European equipment and tight control over production technology have allowed to achieve huge quality of manufactured products, which have proven themselves not only in the Russian market, but also beyond. Among the heat and sound insulating materials that are produced by the company, there are basalt plates, which are represented here by several types with different product densities.

TekhnoNikol Corporation - A modern company that produces a huge number of building materials.Vast experience since 1992, the use of modern European equipment and tight control over production technology have allowed to achieve huge quality of manufactured products, which have proven themselves not only in the Russian market, but also beyond. Among the heat and sound insulating materials that are produced by the company, there are basalt plates, which are represented here by several types with different product densities. CJSC Izorok - A company located in Russia, but using 100% of foreign capital. It is located in Tambov, on the territory of the plant built in the 80s. After its modernization, heat-insulating materials began to be produced there, including and basalt slabs. The range includes materials with different densities, and specialists are always ready to provide advice. Sales are carried out in all regions of the country.

CJSC Izorok - A company located in Russia, but using 100% of foreign capital. It is located in Tambov, on the territory of the plant built in the 80s. After its modernization, heat-insulating materials began to be produced there, including and basalt slabs. The range includes materials with different densities, and specialists are always ready to provide advice. Sales are carried out in all regions of the country.- ECOVER - a relatively new player in the domestic heat and sound insulation market. The opening of the plant in the Sverdlovsk region took place in 2010, and now it is a young, modern enterprise that specializes in the production of basalt heat and sound insulation. The range includes plates with different parameters, among which you can definitely find exactly what you need.