How to choose the right foamed polyethylene for insulation and soundproofing

Polyethylene has long been very popular and is well known to each of us in the form of a transparent film. Who would have thought that the same material might also used as reliable heat and sound insulation. It has unique properties, but at the same time its price is affordable, which allows this material to become more widespread. What did he conquer the domestic user with, and what are the most important foundations for choosing foamed polyethylene?

Foamed polyethylene was first obtained more than 50 years ago, it is already well known in many European countries and America. The unique properties of this material allowed him to conquer domestic users. It is made on the basis of ordinary polyethylene, and as a result, many individual closed pores are formed, giving the foamed polyethylene unique heat, noise and waterproofing properties.

Advantages and disadvantages of foamed polyethylene

This heat and sound insulating material is unique in the totality of its properties. The list of its benefits include:

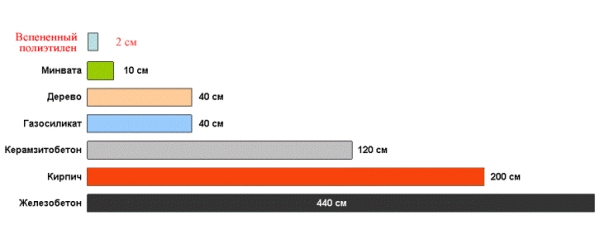

low thermal conductivitywhich is 0.031-0.038 W / m * K. In practice, this means that very little material will be enough to create an effective thermal insulation layer. So, a layer of foamed polyethylene of 2 cm is equivalent to 10 cm of mineral wool, namely this insulation is now most often used;

low thermal conductivitywhich is 0.031-0.038 W / m * K. In practice, this means that very little material will be enough to create an effective thermal insulation layer. So, a layer of foamed polyethylene of 2 cm is equivalent to 10 cm of mineral wool, namely this insulation is now most often used;- excellent sound insulation, which is achieved due to the features of the internal structure of the material. So, foamed polyethylene with a thickness of 20 mm is able to reduce the level of external noise by 6 times, and you will be protected from the hum of cars, the clatter and conversations of neighbors;

- the material is extremely low water absorptionTherefore, it can be used under any conditions;

foamed polyethylene durable, elastic and resilientand all these qualities are preserved even when the temperature drops to -600FROM;

foamed polyethylene durable, elastic and resilientand all these qualities are preserved even when the temperature drops to -600FROM;- material does not rot, it does not develop fungus or mold;

- durable, and its service life reaches 100 years;

- such a heater easy to transport and mount;

- huge range of productssince the foamed polyethylene can be additionally reinforced, covered with foil, have components that make it more durable, for example;

- low price - One of the most powerful arguments when choosing this particular heat and sound insulator. The cost allows you to purchase it for almost anyone.

The only problem of this material - its ability to quickly ignite, but this property can be reduced almost to nothing by adding flame retardants, special substances that make the material more resistant to high temperatures and prevent ignition.

Types of foamed polyethylene

Today, several types of this material are produced, which allows you to choose the best option for each specific case.

So, in the production of this heat and sound insulator can be used high or low pressure polyethylene. The finished material may have a slightly different structure:

- foamy;

- cellular;

- porous.

Depending on the scope of use, material may be produced. in different forms:

polyethylene foam sheet indispensable for warming and soundproofing walls, ceilings, roofs, foundations;

polyethylene foam sheet indispensable for warming and soundproofing walls, ceilings, roofs, foundations;- tiled;

- tube found application, if necessary, to perform heat and sound insulation of ventilation ducts, door or window openings, etc .;

- film great for greenhouses;

- coated. So, the material can be foil on one side, and then it is great for wall insulationlocated beyond heating radiatorto reflect all radiated energy. If the foil coating is bilateral, then it is good to use the material for insulation of the roof, because in this case the rays of the sun and heat from heating elements, and the optimal indoor microclimate will be easy to maintain in both winter and summer.

But most often, foamed polyethylene, depending on the molecular structure, is divided into non-cross-linked and cross-linked.

Unstitched polyethylene completely preserves the structure of molecules and molecular bonds of polyethylene. It is made of polyethylene by an extrusion method with the addition of a blowing agent, which foams the initial product. Previously, freons were used as a gasifier, which, due to the high heat of evaporation, were ideally suited for this process. Now, after the ban on the use of freons that deplete the ozone layer, a propane-butane mixture or isobutane is used instead. All transformations occur in the extruder, after exiting from which, with a sharp drop in pressure, the gas begins to expand, forming bubbles. And since the temperature outside the extruder is much lower, the finished mass quickly solidifies. The final product of production is a translucent material with many large pores. Its strength is inferior to cross-linked polyethylene, since here the intermolecular bonds are much weaker. This dictates the scope of non-cross-linked foamed polyethylene.

Unstitched polyethylene completely preserves the structure of molecules and molecular bonds of polyethylene. It is made of polyethylene by an extrusion method with the addition of a blowing agent, which foams the initial product. Previously, freons were used as a gasifier, which, due to the high heat of evaporation, were ideally suited for this process. Now, after the ban on the use of freons that deplete the ozone layer, a propane-butane mixture or isobutane is used instead. All transformations occur in the extruder, after exiting from which, with a sharp drop in pressure, the gas begins to expand, forming bubbles. And since the temperature outside the extruder is much lower, the finished mass quickly solidifies. The final product of production is a translucent material with many large pores. Its strength is inferior to cross-linked polyethylene, since here the intermolecular bonds are much weaker. This dictates the scope of non-cross-linked foamed polyethylene.

This kind of foamed polyethylene is widely used as a heat and sound insulator in housing and industrial construction, and also as an insulator from water and condensate, but only in those rooms where large loads and high temperatures will not affect it. In European countries, this material is used as packaging for a wide variety of items, even fragile ones, as it dampens shock loads. In the food industry, he found application due to his complete hygiene and inertness.

Crosslinked Polyethylene get chemical or radiation way. Chemical method involves the melting of polyethylene under high pressure together with the initiators of the reaction and antioxidants. Peroxides, which often act as the initiator of the reaction, undergo a number of transformations, while forming bonds between individual polyethylene molecules. A similar effect can be obtained when exposed to a polyethylene beam of energy, which is what radiation method receiving material. As a result, foamed polyethylene gets a fine-grained structure, which determines its greater resistance to loads, chemicals, moisture and temperature.

Crosslinked Polyethylene get chemical or radiation way. Chemical method involves the melting of polyethylene under high pressure together with the initiators of the reaction and antioxidants. Peroxides, which often act as the initiator of the reaction, undergo a number of transformations, while forming bonds between individual polyethylene molecules. A similar effect can be obtained when exposed to a polyethylene beam of energy, which is what radiation method receiving material. As a result, foamed polyethylene gets a fine-grained structure, which determines its greater resistance to loads, chemicals, moisture and temperature.

Crosslinked Polyethylene - a more versatile material, a reliable heat and sound insulator, which can be operated in a wide temperature range, which determines its distribution. It is great for warming walls, ceilings, ceilings, floors, pipelines, it is often used simply as a soundproofing or as a waterproofing foundation, cellars and basements. In addition, this material has gained enormous distribution in mechanical engineering, automotive, and medicine. For the insulation of an apartment, it is better to choose stitched foam polyethylene to get a more durable, durable and reliable coating that will certainly cope with any loads.

The choice of foamed polyethylene

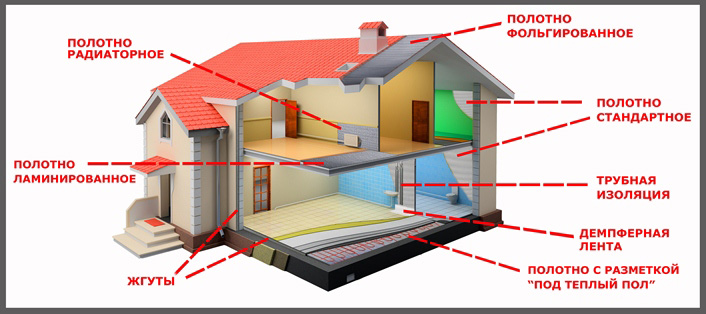

Since this heat and sound insulator has recently been used in domestic construction, therefore, few are guided in its assortment and can choose the most suitable material. So, in some cases it is appropriate to use foil polyethylene, which is great for indoor insulation. It can be fixed to heating radiators so that the heat does not go outside, but, reflected, returns to the room. It is also appropriate to insulate the floor and ceiling in this way so as not to give off heat to neighbors or the atmosphere. Such material is even mounted on the door. It remains the same effective barrier to noise, and in addition it is also used for thermal insulation of pipes, ventilation systems, while protecting them from ultraviolet rays and vibrations. It can also be used for insulation and sound insulation of walls, partitions, attics and attic. As mentioned above double foil It shows itself perfectly when warming the roof, while maintaining the optimum indoor temperature in winter and summer.

Since this heat and sound insulator has recently been used in domestic construction, therefore, few are guided in its assortment and can choose the most suitable material. So, in some cases it is appropriate to use foil polyethylene, which is great for indoor insulation. It can be fixed to heating radiators so that the heat does not go outside, but, reflected, returns to the room. It is also appropriate to insulate the floor and ceiling in this way so as not to give off heat to neighbors or the atmosphere. Such material is even mounted on the door. It remains the same effective barrier to noise, and in addition it is also used for thermal insulation of pipes, ventilation systems, while protecting them from ultraviolet rays and vibrations. It can also be used for insulation and sound insulation of walls, partitions, attics and attic. As mentioned above double foil It shows itself perfectly when warming the roof, while maintaining the optimum indoor temperature in winter and summer.

For thermal insulation of walls and ceilings, sheets and rolls of foamed polyethylene are most often used, which may differ in some parameters (thickness, length, width). In addition, special the substrate under the laminate, drywall and parquet, which are designed to perform several functions at once, including be an additional support, leveling the surface and parallel soundproofing room. Separately issued underfloor underlay with pre-marked markup. Such material allows maximum use of the generated heat, which will not go to neighboring rooms. Also on sale is polyethylene for insulation of pipelines, window and doorways, which is also known under a separate name Vilaterm. Depending on the situation, one or another type of foamed polyethylene is selected.

In appearance, cross-linked polyethylene can be easily distinguished from non-cross-linked. The latter will give itself out as larger pores, it will be more brittle and less durable. Crosslinked is more expensive, but it is preferable, especially when you want to make the most durable heat and sound insulation. The fact that in Europe non-cross-linked polyethylene is not used for thermal insulation of buildings already says a lot, therefore, only thermal-reinforced cross-linked ones should be primed for thermal insulation.

The largest manufacturers on the market in Russia

The best reference in terms of product quality is the name of the manufacturer. So who can you trust?

Armacell - A large German company, which also produces thermal insulation based on foamed polyethylene. It is sold under the brand name Tubolit in almost all countries of the world. Products have become synonymous with the highest quality, as their manufacturing technology is constantly being improved, numerous studies are being carried out, equipment is being updated, and the range is expanding so that the materials are as efficient and convenient as possible. All this allows the company to occupy a leading position in the world.

Armacell - A large German company, which also produces thermal insulation based on foamed polyethylene. It is sold under the brand name Tubolit in almost all countries of the world. Products have become synonymous with the highest quality, as their manufacturing technology is constantly being improved, numerous studies are being carried out, equipment is being updated, and the range is expanding so that the materials are as efficient and convenient as possible. All this allows the company to occupy a leading position in the world.- Odeflex - Turkish manufacturer that offers foamed polyethylene in tubes and rolls. A few years ago, the products of this company were universally presented on the domestic market, but now it is increasingly being supplanted by national manufacturers.

- LLC Stroytehizolyatsiya - A company based in Belarus and actively exporting its products to the Russian market. The assortment includes tubes of different thicknesses and diameters, designed for thermal insulation of pipelines, air conditioning systems, industrial systems. They are sold under the name Steinoflex 400 and have a longitudinal section that facilitates the installation process.Steinophon 290 is also available - a universal heat and sound insulating material, which is supplied in the form of mats of different thicknesses without coating, or foil from one or two sides.

Bilaveri - a large Ukrainian manufacturer of foamed polyethylene. The range includes roll material, with or without foil coating, pipe insulation and sealing plaits. The company values its reputation, therefore it produces only the highest quality products, confirmed by numerous certificates. The manufacturer is widely known in the Ukrainian market and begins to conquer the CIS countries.

Bilaveri - a large Ukrainian manufacturer of foamed polyethylene. The range includes roll material, with or without foil coating, pipe insulation and sealing plaits. The company values its reputation, therefore it produces only the highest quality products, confirmed by numerous certificates. The manufacturer is widely known in the Ukrainian market and begins to conquer the CIS countries.- Euro isolation Plus LLC - A domestic company that is known in the market of foamed polyethylene since 2008. Products are known under the trademark "Euro isolation", manufactured on the most modern equipment using new technologies that are constantly being improved. The quality of products is supported by relevant documentation, including certificate of conformity and sanitary and epidemiological conclusion. The range includes expanded polyethylene mats, pipe insulation, damper tape, self-adhesive insulation, underfloor heating substrate, foil insulation.

LLC Izodom - The largest Russian manufacturer of thermal insulation materials made of foamed polyethylene. The company is located in Voronezh, has been operating since 2006, distributes its products throughout the country and to neighboring countries. The manufacturer is trying to constantly improve production technology and expand the product range, so now its products are represented by a huge assortment from the substrate and reflective insulation to mats and plaits.

LLC Izodom - The largest Russian manufacturer of thermal insulation materials made of foamed polyethylene. The company is located in Voronezh, has been operating since 2006, distributes its products throughout the country and to neighboring countries. The manufacturer is trying to constantly improve production technology and expand the product range, so now its products are represented by a huge assortment from the substrate and reflective insulation to mats and plaits.- Izhevsk Plastics Plant OJSC- An enterprise that was founded back in 1985. At the beginning of this century, the production of foamed polyethylene was mastered: it is made both cross-linked and non-cross-linked, and the product range is constantly expanding.

- ETIOL LLC - A company that was formed in 1991 on the site of OJSC Polymersynthesis. It is engaged in the processing of plastics, and recently began production of expanded polyethylene, which is already actively used in various fields throughout the country.