7 tips for choosing a plastic lining

Many of us are familiar with plastic lining, because cheapness, practicality and a good appearance provide the material with widespread use in various fields. Today it is used for exterior and interior decoration, for ceiling cladding and the walls. For each sphere, it is better to use a material with a certain set of characteristics, but here's how to choose a lining so that it meets the requirements put forward, we will try to figure it out.

No. 1. What material properties do you need to be prepared for?

The base of the plastic lining is polyvinyl chloride, and the properties of this substance determine the main characteristics of the material. Key benefits include:

- water resistance. The polymer material is not able to absorb or leak moisture, therefore it is used for exterior decoration and for lining ceilings and walls in bathrooms;

- resistance to low and high temperatures. Since the material does not absorb water, there is no deformation during frost, and in the heat the lining will not warp and change shape;

- light weightthat facilitates transportation and installation. It will be possible to refuse the services of movers, because the lining for facing can be conveyed even in the hands. The reason for the low weight is the ease of raw materials and the hollow structure of the lining, which at the same time provides strength to the material;

- good performance heat- and soundproofing. Due to its structure, the lining blocks most of the sounds and helps retain heat;

- ease of installation and lack of dirty processes;

- hygiene. Fungus plastic lining is certainly not scary;

- ease of carewhich consists in wiping with a damp cloth;

- huge choice of colors and textures;

- low cost.

Inherent in the material and other properties that limit the scope of its use. Among the shortcomings are:

- fragility. Mechanical influences, even not the strongest ones, that can cause deformations, and scratches and damage to the material cannot be fixed in any way;

- air tightnessTherefore, it is better not to use plastic lining for decorating living rooms. A compromise is to use it only as part of a decorative finish;

- certain combustibility, but subject to fire safety rules, the probability of negative consequences is the slightest.

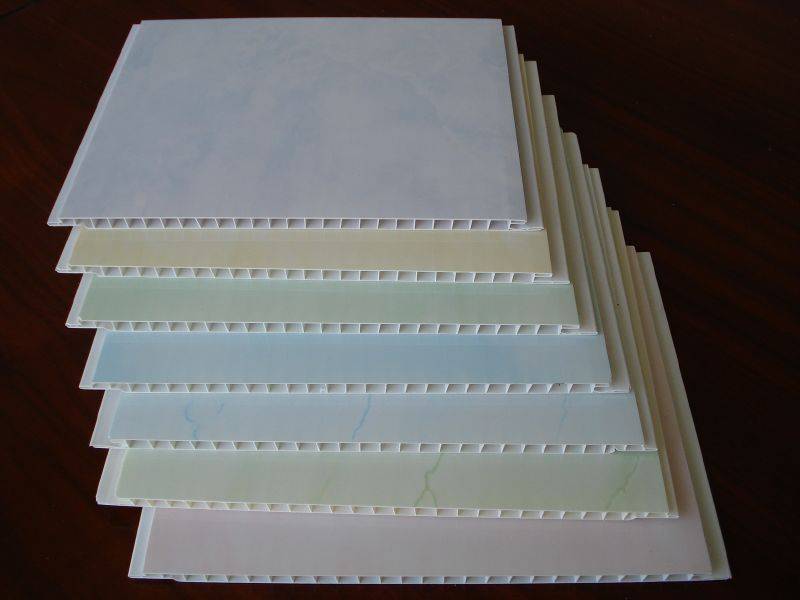

No. 2. What should be the thickness of the plastic lining?

The thickness of the plastic lining conditionally divided into wall and ceiling. Of course, no one forbids the use of wall clapboard for cladding the ceiling and vice versa, but often it is impractical. The thickness of the material intended for ceiling decorationis about 8 mm, and now there is a tendency for manufacturers to reduce this indicator, so often you can find material with a thickness of 7 mm, and even 4-5 mm.

Normal lining thicknessintended for wall decoration - 10 mm. In this case, we can already talk about an acceptable level of strength.The length may also differ: wall lining, as a rule, is made with a length of 2.7 or 3 m, less often 6 m, and the similar indicator of the ceiling material is usually 6 or 12 meters, but the specific figures depend on the manufacturer.

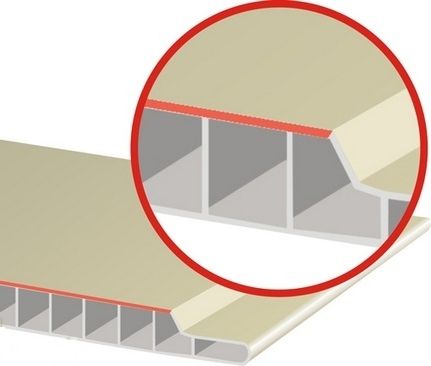

You need to consider front thickness. If you look at a section of a plastic lining, we will see that between the two outer sheets there are so-called stiffeners located at an equal distance from each other and forming a hollow structure. Stiffeners not only connect two sheets, but also take on the entire impact of external influences. Through the front side of the lining these stiffeners should not be visible. It should be as thick as possible, which determines the aesthetics of the material and its strength.

No. 3. The number of stiffeners and the distance between them

Concerning number of stiffeners, then the more there will be, the better and the more resistant the lining will be to mechanical damage. Important and distance between stiffeners. It should be no more than 10 mm. Pay attention that the stiffeners are not wrinkled, and that they do not deform during transport and installation. Even if the front panel remains integral, a dent will be visible on its surface.

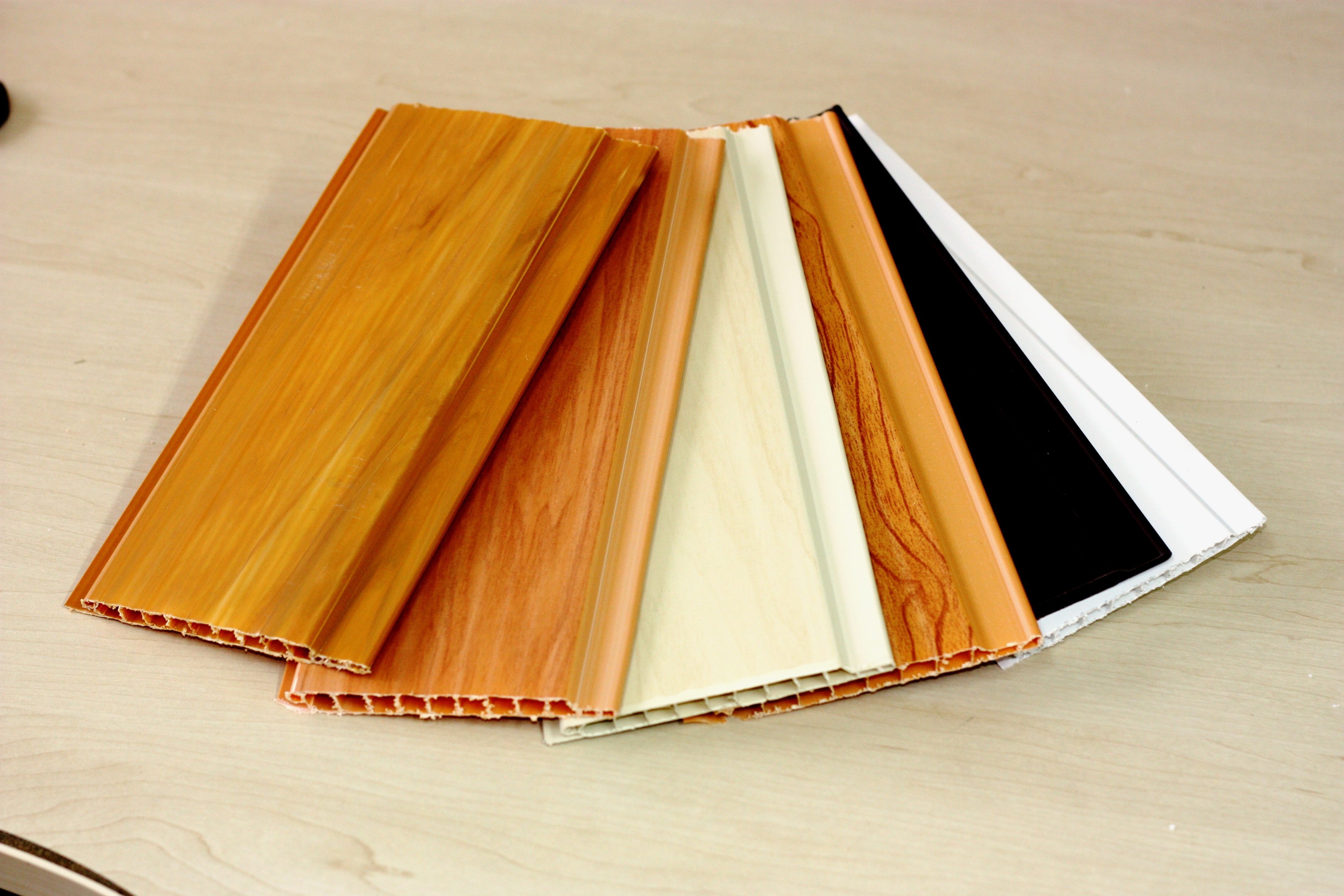

Number 4. Color plastic lining

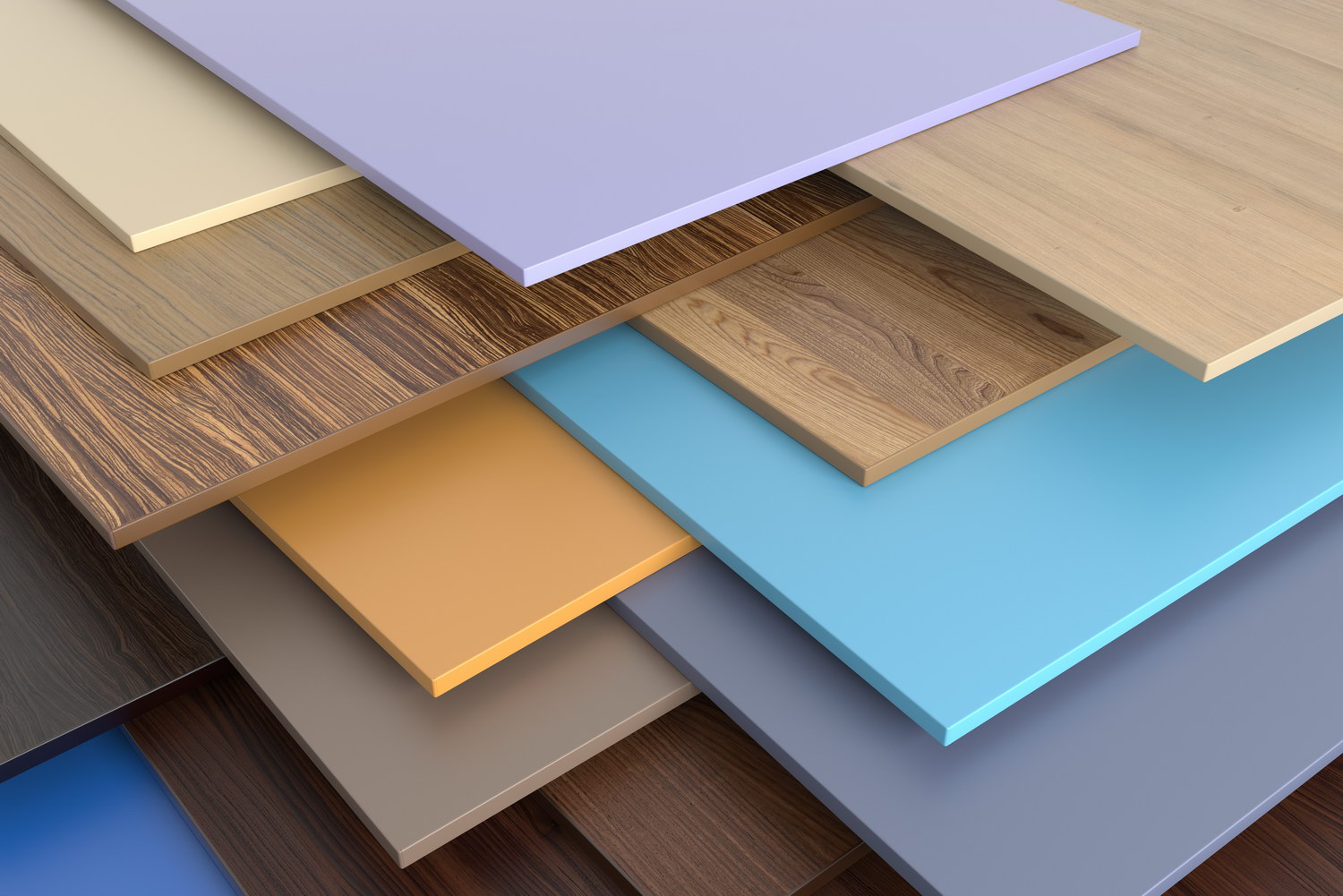

The plastic lining is painted by adding a coloring pigment to the raw material, and not by applying it to the material. This explains the fact that the material does not lose its original appearance for a long time. Currently there are about 70 different shadesin which the lining can be painted. Plain white is especially popular, but if necessary, you can choose another desired shade.

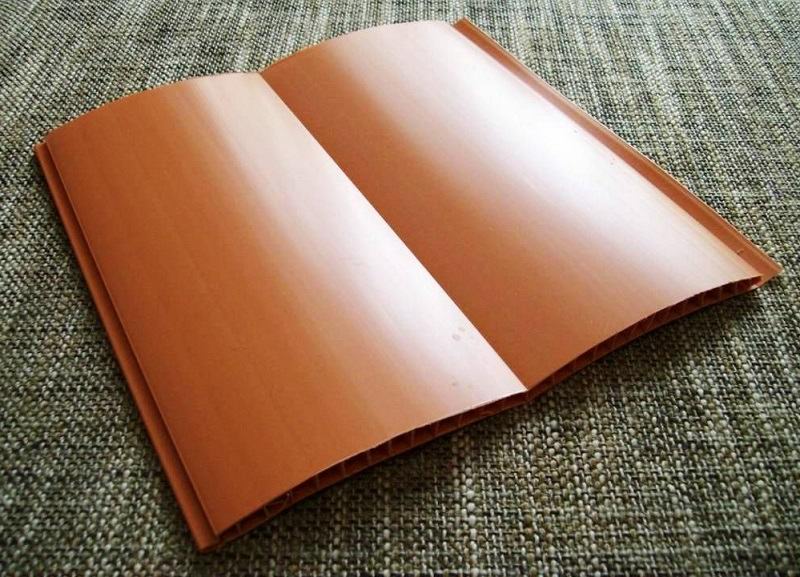

Lining can imitate the texture of wood, stone, tiles or bricks, and can be decorated with a simple abstract pattern. For exterior decoration of balconies or facades recommend using a lining under a tree or a stone.

The surface of the material can be matte, semi-gloss or gloss.. The main difference is in the surface layer, since gloss can be achieved by applying varnish. By the way, he plays an additional protective function.

No. 5. Lining with and without seams

For cladding, you can use a seamless lining and embossed, or with seams. In the first case, it is possible to obtain an almost seamless coating, which is especially useful for organizing space bathrooms, baths and saunas. In this case, the water will not fall into the recesses, it will be easier to care for the walls and ceiling, and the probability the appearance of mold at the seams is significantly reduced.

For outdoor decoration it is better to choose lining with seams.

- At first, it is more suitable for facade works from purely aesthetic indicators.

- Secondly, temperature differences in the environment can cause linear expansion, and the suture joint will not allow the material to deform.

No. 6. What to look for when buying?

When you have decided on what characteristics the material should have and proceed to purchase it, it is worth examining the lining very visually and checking its quality. Here some tipsthat will help you choose a really good material:

- the surface should be evenly stained, stiffeners must not be visible through it;

- to test the strength You can press the panel a little to bend it. Damage to quality material will not remain, their presence is a consequence of an excessive amount of chalk, which leads to the fragility of the panels;

- the amount of chalk in the lining should not exceed 20%. You can check this indicator without conducting complex analyzes. You need to try to bend the corner of the panel: if it is plastic, then the manufacturer complied with all the necessary standards, and the material is high-quality, and if a strip or crack appeared at the bend, then it is better to refuse to buy such a lining;

- check necessary how tight the panels fit into the groove. If the conditions of manufacture or storage were violated and the material was deformed, then there is no talk of tight joining of individual parts;

- when buying is better inspect each itempaying particular attention to edges that are more likely to be damaged;

- unscrupulous manufacturers out of a desire to reduce the cost of the production process can use low-quality and even toxic raw materials. Before buying, it will not be superfluous ask for certificates on products. Should especially alert smell from the panel;

- weight of plastic lining although small, it should not be lower than the set value. So, 1 m2 material weighs 1.1-1.5 kg, if less, then the thickness of the lining, the outer layer or the number of stiffeners is less than necessary;

- trademark. Well-known companies have earned a reputation for years and will not lose it with low-quality products. It’s better to pay attention to their product when choosing, but we’ll dwell on the names of these companies below.

Number 7. 10 best plastic wall paneling manufacturers

Plastic lining is widely produced in Russia and in the CIS countries. European countries are almost not represented in this segment, China often offers not the best quality material, so it is better to choose from domestic manufacturers.

Dekoplast LLC

The company began operations in 2004, when it launched production plastic panels and window sills in the leased area. Demand for products grew rapidly, and in 2005 the company acquired its own production facilities, carried out a complete reconstruction and purchased the most modern equipment. The product range was constantly growing, and today the company is considered one of the largest manufacturers of PVC products in Russia. Until now, the company maintains a high development dynamics. Today in the assortment of the company is white and several types of colored clapboard.

The company began operations in 2004, when it launched production plastic panels and window sills in the leased area. Demand for products grew rapidly, and in 2005 the company acquired its own production facilities, carried out a complete reconstruction and purchased the most modern equipment. The product range was constantly growing, and today the company is considered one of the largest manufacturers of PVC products in Russia. Until now, the company maintains a high development dynamics. Today in the assortment of the company is white and several types of colored clapboard.

Green Line LLC

The company is from the Vladimir region, which has been on the market for more than a dozen years. Here modern equipment is used, constant monitoring of the production process is carried out. In the range of plastic lining and related products. The trump cards of the company's products are a wide range of colors and options.

The company is from the Vladimir region, which has been on the market for more than a dozen years. Here modern equipment is used, constant monitoring of the production process is carried out. In the range of plastic lining and related products. The trump cards of the company's products are a wide range of colors and options.

Profile OJSC

The company has been manufacturing a wide range of polyvinyl chloride products for about 40 years. Powerful modern production allows you to fulfill any customer orders as soon as possible. Moreover, a supply chain has been established throughout the country. Buyers note a huge range of products and their high quality, proven over the years.

LLC "Kant"

The company that produces plastic lining since 2003 under the brand name "Ferasco". The assortment includes products of a huge number of colors and textures. Initially, the manufacturer's goal was to provide residents of the Samara region with high-quality and inexpensive facing material, but over the years the scale of production has grown so much that they began to provide products to other regions of the country. The company offers to make individual orders for the production of lining with clearly defined parameters. According to calculations, this saves up to 20% of the material that is trimmed.

The company that produces plastic lining since 2003 under the brand name "Ferasco". The assortment includes products of a huge number of colors and textures. Initially, the manufacturer's goal was to provide residents of the Samara region with high-quality and inexpensive facing material, but over the years the scale of production has grown so much that they began to provide products to other regions of the country. The company offers to make individual orders for the production of lining with clearly defined parameters. According to calculations, this saves up to 20% of the material that is trimmed.

LLC "V-plast"

The company is located in the Moscow region and offers residents of the region a wide range of finishing materials, including and plastic lining. The manufacturer carefully monitors the needs of customers and tries to use the data, offering a lining with new decorative qualities and parameters. Among the strengths of the enterprise is a wide range of plastic lining, prompt processing of orders and the ability to manufacture any volume of products.

The company is located in the Moscow region and offers residents of the region a wide range of finishing materials, including and plastic lining. The manufacturer carefully monitors the needs of customers and tries to use the data, offering a lining with new decorative qualities and parameters. Among the strengths of the enterprise is a wide range of plastic lining, prompt processing of orders and the ability to manufacture any volume of products.

LLC "Niko-Plast"

A company from the Stavropol Territory, which has grown from small production in this industry giant. Today, about four hundred products are produced from PVC here, and plastic lining occupies an important place. The customer can directly participate in the production process, i.e. according to his requirements, material with specified parameters can be made.Reliable equipment is used, monitoring is constantly conducted, and experienced employees work at the enterprise, which ensures a consistently high quality product.

A company from the Stavropol Territory, which has grown from small production in this industry giant. Today, about four hundred products are produced from PVC here, and plastic lining occupies an important place. The customer can directly participate in the production process, i.e. according to his requirements, material with specified parameters can be made.Reliable equipment is used, monitoring is constantly conducted, and experienced employees work at the enterprise, which ensures a consistently high quality product.

LLC NPO Plastic

The largest enterprise manufacturing plastic products. The company is constantly increasing production volumes, expanding its product range and working to maintain high quality. Today, the company's products are in demand not only in Russia but also in the CIS countries. The employees explain this success with responsibility, a desire to please each client, carrying out prompt delivery and manufacturing plastic lining according to individual requirements.

Europlastservice

The company has been on the market for 11 years, and during this time it grew from a small production into a large enterprise with a developed dealer network in many cities of the country. The company is confident that PVC is considered one of the best materials for the manufacture of finishes, so a huge range of products is made from polymer here, an important place in which falls on a plastic lining. The range is constantly updated, in the presence of all the necessary certificates, and if necessary, the customer receives free samples of the material in order to make a choice.

The company has been on the market for 11 years, and during this time it grew from a small production into a large enterprise with a developed dealer network in many cities of the country. The company is confident that PVC is considered one of the best materials for the manufacture of finishes, so a huge range of products is made from polymer here, an important place in which falls on a plastic lining. The range is constantly updated, in the presence of all the necessary certificates, and if necessary, the customer receives free samples of the material in order to make a choice.

LLC "Plastic"

A company from Orenburg that specializes in the production of plastic lining. In the assortment you can find products of different colors and textures, as well as accessories necessary for installation. The manufacturer cares about the environment using recycled materials in the manufacture of products, which does not affect the quality of the lining.

LLC "Stroy-Finishing"

The company offers a range of building materials, focusing on PVC products. Production is carried out on modern equipment, and quality control is carried out at each stage. The result is a durable, durable plastic lining, which has earned recognition not only in the country, but also abroad.