7 tips for choosing a professional flooring

Lightweight, durable, inexpensive and attractive-looking corrugated board is very popular today in organizing the rooferecting fences, garages and warehouses. Such a wide scope of use of the material is due to its structure and the presence of profiled sheets of different thickness and width, with different coatings. How to understand the huge modern assortment and choose a professional flooring that will best meet the requirements. Our tips will help you navigate and approach the purchase of this building material fully equipped.

No. 1. What does corrugated board consist of?

Profiled sheet or corrugated board - This is a sheet of cold rolled steel coated with a protective layer of polymer, zinc or aluminum. The profile is attached to flat sheets on the forming shafts of the machines, it can take the form of waves or trapezoid. Its goal is not only to improve the decorative qualities of the material, but also to obtain additional strength properties.

Profiled sheet or corrugated board - This is a sheet of cold rolled steel coated with a protective layer of polymer, zinc or aluminum. The profile is attached to flat sheets on the forming shafts of the machines, it can take the form of waves or trapezoid. Its goal is not only to improve the decorative qualities of the material, but also to obtain additional strength properties.

The main advantages of corrugated board:

- resistance to corrosion, negative environmental influences;

- durability. Service life reaches 50 years;

- strength;

- fire resistance;

- ease of installation and maintenance;

- wide selection of colors;

- affordable price.

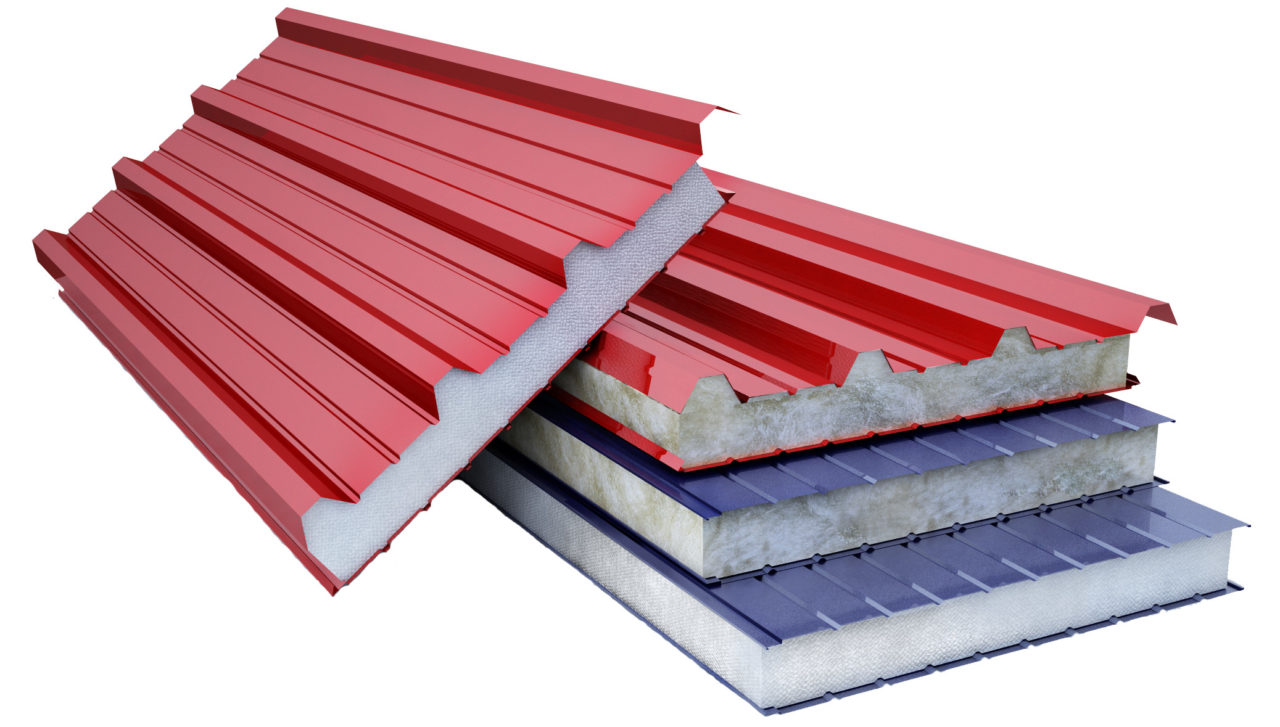

Among the minuses They call a high level of noise when rain drops fall on the corrugated sheets, as well as heating the material in the sun. These shortcomings can be minimized if you do not forget during construction soundproofing material and properly assemble the roofing "pie".

Among the minuses They call a high level of noise when rain drops fall on the corrugated sheets, as well as heating the material in the sun. These shortcomings can be minimized if you do not forget during construction soundproofing material and properly assemble the roofing "pie".

According to its main properties, corrugated board is very look like metal siding, but these materials have differences. Decking does not copy the structure and pattern of stone or wood, but it will cost the buyer many times cheaper, and installation is much easier, which becomes a significant advantage for those who do construction work with their own hands.

Decking is distinguished by a greater length and area of sheets, which accelerates its installation and reduces the number of joints. The scope of use of corrugated board is wider than that of metal siding, because it can be used not only for facade cladding, but also for the arrangement of the roof and as an independent material for the construction fences and garages.

No. 2. Which protective coating is better?

To protect the basics of steel sheeting, protective coatings are used, which are polymer materials or metals. The most common types of protective coatings at the moment are:

- zinc coating hot applied by immersion of a sheet of steel in molten zinc. The thickness of the protective layer is 25-30 microns. Such material is the cheapest and is used during restoration and repair work;

- aluminum zinc coating Consists of aluminum, zinc and silicon. The corrugated board covered with such a composition receives good protection against aggressive substances, therefore it is used for roofs in areas where large industrial enterprises, busy roads or the sea coast are located;

- polyester. This is the most popular coating, used in 85% of cases to protect roofing sheeting.The polymer reliably protects against corrosion, frost and heat, resists mechanical damage and maintains its original color for a long time. Separately, it should be noted matte polyester coating, which looks especially advantageous;

- plastisol. The thickness of such a coating ranges from 175 to 200 microns, due to which it perfectly tolerates mechanical damage and exposure to aggressive substances. But in terms of resistance to high temperatures and color fastness, this polymer is inferior to other types of protective coating, therefore, it has found application in northern areas with not very intense solar radiation;

- pural. Polyurethane based coating was developed by Ruukki. Thanks to the addition of polyamide and other substances, the material turned out to be resistant to sunlight, aggressive substances and corrosion. Due to the excellent appearance, such sheets can be used not only for the roof, but also for facade cladding;

- polyvinyl dentafluoride perfectly protects steel from all atmospheric phenomena and corrosion. The initial color is perfectly preserved for a long time, so the facades are often trimmed with such material;

- acrylic and polyvinyl chloride protect the material well from corrosion, and corrugated board with such a coating is inexpensive.

Large manufacturers of corrugated board have research laboratories in their structure, therefore they are developing new polymer coatings consisting of several components. The secrets of their compositions are not revealed, but thanks to them it is possible to obtain a professional sheet with unique qualities and decorative properties.

No. 3. Dimensions of corrugated board

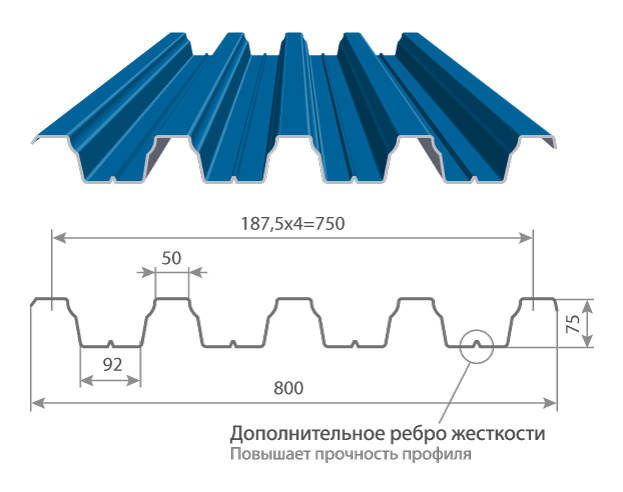

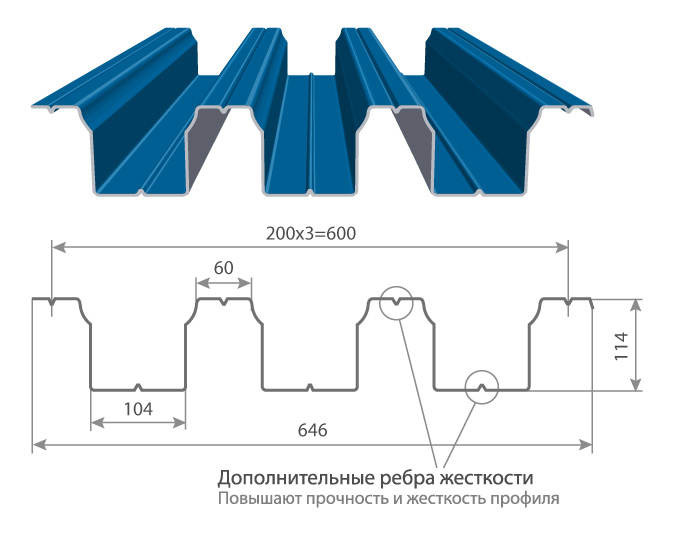

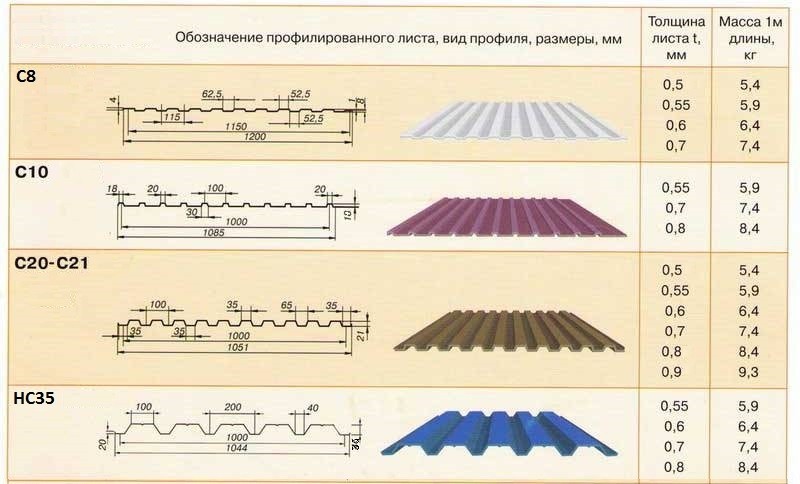

The parameters of corrugated board vary widely. Width is from 113 to 120 cm, and length can be from 30 cm to 12 m. Depending on the destination, sheets with more suitable parameters are selected. Of particular importance sheet thickness, since strength depends on it in many respects. This parameter ranges from 0.4 to 1.2 mm. Strength is also affected by profile height: the higher it is, the greater the load-bearing capacity of the sheet. The height of the profile is from 8 mm to 7.5 cm and significantly affects the scope of use.

Number 4. The main types of corrugated board

To cover the roof, construction of the fence or facade cladding, it is better to choose a different material. The huge popularity of the material has become a catalyst for the emergence different types of corrugated board:

- wall. Used for wall cladding and the construction of internal partitions. The profile height is minimal and ranges from 8 to 35 mm. It is marked with the letter C;

- roofing. The name suggests the main scope of use of this material - roof arrangement. In addition, such corrugated board can be used for the construction of non-residential premises, including garages and hangars as well for fence construction. A distinctive feature of the material is a high strength indicator, rigidity, and ability to withstand heavy loads. Roofing decking differs from metal tiles profile shape: the latter resembles ceramic tiles, and corrugated board - slate. The corrugation height of such a corrugated board is 44 mm or more. Marked with the letter H;

- carrier. This is the most versatile corrugated board that is used in the construction of external walls, the construction of fences, the decoration of house facades, and can also be used to organize roofing. Such a corrugated board has a profile height of 35-44 mm, and special grooves are even present on the corrugation. The service life of such material is 40-60 years. Marked as HC.

The wave height is such an important indicator that is indicated in marking corrugated board. You can understand what kind of material is in front of you by the letter designation that speaks of the type and the figure that follows it. The number means the height of the wave, expressed in mm. For example, the designation C8 indicates that before you is a wall corrugated board with a wave height of 8 mm.

Sometimes other parameters are indicated in the marking. In this case, the second number will indicate the thickness of the sheet in mm, the third - the width, and the fourth - the length. For example, corrugated board marked C8-0.5-750-11000 will have a thickness of 0.5 mm, a width of 750 mm or 75 cm and a length of 11 m.

No. 5. What are the most popular types of corrugated board

Manufacturers offer corrugated board with very different parameters. Some even offer customization, but The following types of corrugated board remain the most popular:

- C8 It is mainly used for wall cladding. There are examples of using it as a roofing material: of course, it is better to choose a different type of corrugated board, since for this it is necessary to equip a continuous crate, and most importantly, a roof with a large slope;

- C10 also used for decorating walls, as well as for the construction of fences with a height of not more than 2.5 m;

- C18 suitable even for the construction of small architectural forms. If there is a need to equip the roof precisely from such material, then the step of the crate should be 40 cm;

- C21 It is used for the construction of temporary structures, the construction of fences. Suitable for roofing, lath pitch from 40 to 80 cm, depending on the angle of the slope;

- C44 suitable in cases where it is necessary to erect a fence of increased strength, build a hangar, garage or change house. Due to the increased strength, it allows you to equip reliable roofs, even with a step of a crate up to 2 m, but it is better to use a crate with a step of 50-100 cm;

- H57 Ideal for roofing, sometimes used as fixed formwork or fence material. The step of the crate can reach 3m;

- NS35 universal in use, often has an additional ribbed surface. When arranging the roof from such corrugated board, the step of the lathing is 1.2-1.5 m;

- HC44 it is often used in roofing works, it has additional stiffening ribs, which distinguishes it from C44 and makes it more durable and resistant to loads. Crate pitch - 2.6-3 m;

- H60Despite the marking, it is widely used in the arrangement of the roof, it can be the basis for a soft roof or an independent material, it is used in the arrangement of fixed formwork. The crate for such material is performed in increments of 3 m;

- H75 refers to the most popular types of corrugated board, as it is versatile in use. In terms of strength, one of the best, which is achieved thanks to additional ribs. The step of the crate for such a material is 4 m;

- H114 has two additional stiffeners, due to which the material has phenomenal strength and can be used to equip the roof with a step of a crate of 6 m.

No. 6. What else to consider when choosing?

It is important to immediately determine the necessary shade of corrugated board, as manufacturers offer about a hundred different colors. Wherever the material is used, for the arrangement of the roof or the construction of the fence, it is important that it harmonizes with the surrounding objects, fits into the selected color scheme and does not merge with the environment.

When buying, it is important to visually inspect the material for compliance with accurate geometry. The compliance of all parameters with the declared ones is the guarantee of simplicity in work and accurate appearance of the finished object.

Number 7. Which manufacturers can be trusted?

Decking is produced in many European countries, in China, South Korea, India and Turkey, production is widely developed in Russia. The products of domestic factories are competitive, outperforming many Turkish and Chinese companies in quality. Consider the proven world and domestic manufacturers of corrugated board.

TOP 5 world manufacturers of corrugated board

RUUKKI

A well-known Finnish company offers a huge selection of building materials, among which there is corrugated board. In the assortment of material with different thicknesses and different types of coatings. The manufacturer's professional flooring is in great demand all over the world, and offices and representative offices are located in all corners of the planet.

A well-known Finnish company offers a huge selection of building materials, among which there is corrugated board. In the assortment of material with different thicknesses and different types of coatings. The manufacturer's professional flooring is in great demand all over the world, and offices and representative offices are located in all corners of the planet.

Arcelormittal

The company appeared in Luxembourg in 1976 as a small production, and today it is one of the largest manufacturers of steel and steel products. Production facilities are located in several European countries, and products are delivered worldwide. The structure of the production includes its own research center, where they are constantly working on improving the products. The company's corrugated board enjoys great millet in the domestic market.

Emimar

This Latvian company began its activities only in 2007. Today it is a huge modern enterprise, producing a huge number of products from sandwich panels to roof hatches. The assortment has a corrugated board of various types and sizes, there are also all the necessary components on sale, it is possible to carry out production on order, so that there is a minimum of waste during construction work.

This Latvian company began its activities only in 2007. Today it is a huge modern enterprise, producing a huge number of products from sandwich panels to roof hatches. The assortment has a corrugated board of various types and sizes, there are also all the necessary components on sale, it is possible to carry out production on order, so that there is a minimum of waste during construction work.

U.S. Steel

Production is conducted in North America and countries of Central Europe. Over decades of manufacturing steel products, the company has become a world leader, and today it is well known in many countries. The professional flooring of this manufacturer is also sold in Russia, but its prices are quite high.

Pruszynski

The Polish company, which has become a giant in the industry and conducts production in many European countries. Everywhere modern equipment is used, careful control is being conducted. Decking is one of the key areas of the company. Not only wall and roofing sheeting is produced, but also special-purpose material, including transparent and perforated. The Russian market is only getting acquainted with the products of the manufacturer and has already appreciated its advantages.

The Polish company, which has become a giant in the industry and conducts production in many European countries. Everywhere modern equipment is used, careful control is being conducted. Decking is one of the key areas of the company. Not only wall and roofing sheeting is produced, but also special-purpose material, including transparent and perforated. The Russian market is only getting acquainted with the products of the manufacturer and has already appreciated its advantages.

TOP 5 Russian manufacturers of corrugated board

Metal Profile

The leader of the domestic market for the production of sheet steel. The company has been operating on the market for 18 years, it launched production not only in Russia, but also in neighboring Belarus and Kazakhstan. High quality of products is achieved through the use of modern equipment and high-quality raw materials. Decking is made of various types from C8 to H114, so the consumer gets the opportunity to purchase high-quality material with the necessary parameters and reasonable price.

Steel Plass

The company has been operating since 1997 and since then has occupied a significant place in the domestic market as a manufacturer of corrugated board. There are several production lines equipped with modern equipment; the products of the company are acquired by both large construction organizations and private individuals. Decking is made from brand C8 to H158, has a different color and coating.

The company has been operating since 1997 and since then has occupied a significant place in the domestic market as a manufacturer of corrugated board. There are several production lines equipped with modern equipment; the products of the company are acquired by both large construction organizations and private individuals. Decking is made from brand C8 to H158, has a different color and coating.

Profmetall

The company specializes in the manufacture of metal roofing materials. The main place in production is occupied by corrugated board, which is manufactured on the latest Polish equipment, taking into account all state standards. Decking from C8 to H114 has excellent performance, and a huge number of color options.

The company specializes in the manufacture of metal roofing materials. The main place in production is occupied by corrugated board, which is manufactured on the latest Polish equipment, taking into account all state standards. Decking from C8 to H114 has excellent performance, and a huge number of color options.

ProfStalRent

The company is considered one of the leaders in the field of production of corrugated board. To get quality products, European equipment is used here, and steel is purchased from the best domestic and world manufacturers. In the assortment of professional flooring of different colors, with different coatings and with a wave height of 8 to 114 mm, so any consumer can find the material that is needed.

Chelyabinsk specialized factory "Profnastil"

The company has been operating since 1974 and today specializes in the production of corrugated board. The workshops use Italian, German and Finnish equipment, which allows you to get quality products at affordable prices. The pride of the company is a modern automatic line for applying protective polymer coatings, which becomes the key to the durability of the manufactured sheets.