5 Tips for Choosing a Terrace Board

What to finish floor on the terrace, the veranda, balconyby the poolso that it is both beautiful and practical? Surely, many puzzled over this issue, faced with numerous shortcomings of traditional materials, until the terrace board appeared in the 90s. First, it was lined with floors on balconies in Japan, and later the material quickly spread throughout the world and found wide application. Non-slip, resistant to moisture and sunlight, strong and durable ideal for outdoor use - all this is only part of his virtues. A huge assortment and the appearance of unscrupulous manufacturers complicate the choice of a terrace board, but our tips will help you cope with this task.

No. 1. What are the main benefits of decking?

A terrace board includes a group of materials made either of wood or with its use. Various production technologies, which will be discussed later, leave an imprint on the properties of the material, but, nevertheless, all types of terrace boards are characterized by such Common key benefits:

- resistance to precipitation, sunlight, high humidity;

- ease of installation and maintenance;

- a huge selection of colors and textures, which allows you to easily find the solution suitable for any conditions;

- the material does not rot, does not fade in the sun and does not peel;

- strength and durability.

It is not surprising that with these properties, terrace boards are widely used when used in environmental conditions. It serves much better and longer than a regular board, and is not inferior to it in decorative qualities, surpassing numerous alternative options.

No. 2. What types of decking exist?

Today, a terrace board is understood to mean several types of coating. If alone are natural wood or heat treated woodthen others - wood flour and binding polymeric materials. What are the features of these boards?

Natural wood decking

To produce such a board an array of wood is used. Since the material will continue to be used in ambient conditions at high humidity and under the influence of sunlight, the wood should be naturally strong, moisture resistant and resistant to temperature fluctuations. Those are best suited tree speciesthat grow in similar conditions. it exotic trees, including sequoia, merbau, teak, yarra, scratch and kumaru. Among domestic breeds most meet the requirements larch, as well as oak and ash, because their strength when wet increases, and this is an indispensable property for a terrace board.

Terrace board differs from other facing materials from natural wood by the presence of corrugation on the front surface, as well as longitudinal cuts. During production, wood is treated with special substances, increasing its resistance to rot and pests.

- Among the main advantages material it is worth noting environmental friendliness, the ability to stain or tint wood in a certain shade.

- Among cons the presence of natural wood inclusions, such as knots and cracks, but this gives the coating a special chic. After laying, the surface of such a board will sometimes have to be additionally treated with protective materials.

Thermoprocessed wood decking

High temperature wood processing technology was used by the Vikings. Nowadays, this process has been improved in Germany and Finland, and now the wood is “hardened” thanks to exposure to steam with a temperature of about 2000FROM. Such processing allows you to completely change the properties of the tree, making it practically inert to moisture, ultraviolet and other negative factors. At the same time, it is possible to maintain maximum environmental friendliness, because no varnishes and impregnations are used at the same time.

Wood treated with steam gets an original beautiful texture, it reacts more evenly to temperature changes, and gets high resistance to decay. Naturally, the service life also increases.

- Of the minuses It is worth noting only the increased cost of such a board.

As for the species of wood, it can be used larch, hornbeam, pine, oak, beech, ash and others.

Composite wood decking

Wood-polymer composite decking (WPC) is also called composite or deck. Today, it is gaining the greatest popularity due to its affordable price, excellent appearance and phenomenal performance.

The composition of the WPC board includes such components:

- organic or mineral filler. This sawdust, wood shavings or fiberglass, wood flour;

- binder material. It can be of artificial origin (most commonly used is polyethylene, polyvinyl chloride and polypropylene) or of natural origin (for example, grain starch or paper waste).

In the vast majority of cases, it is used polymer binder, and basically it is:

- polyethylene. The cheapest option with some drawbacks. The material is less durable, more abrasion and slippery than made on the basis of other polymers;

- PVC A board using PVC will have a higher price, but also with such excellent performance as high density, fire resistance, and the absence of a sliding effect when water gets in.

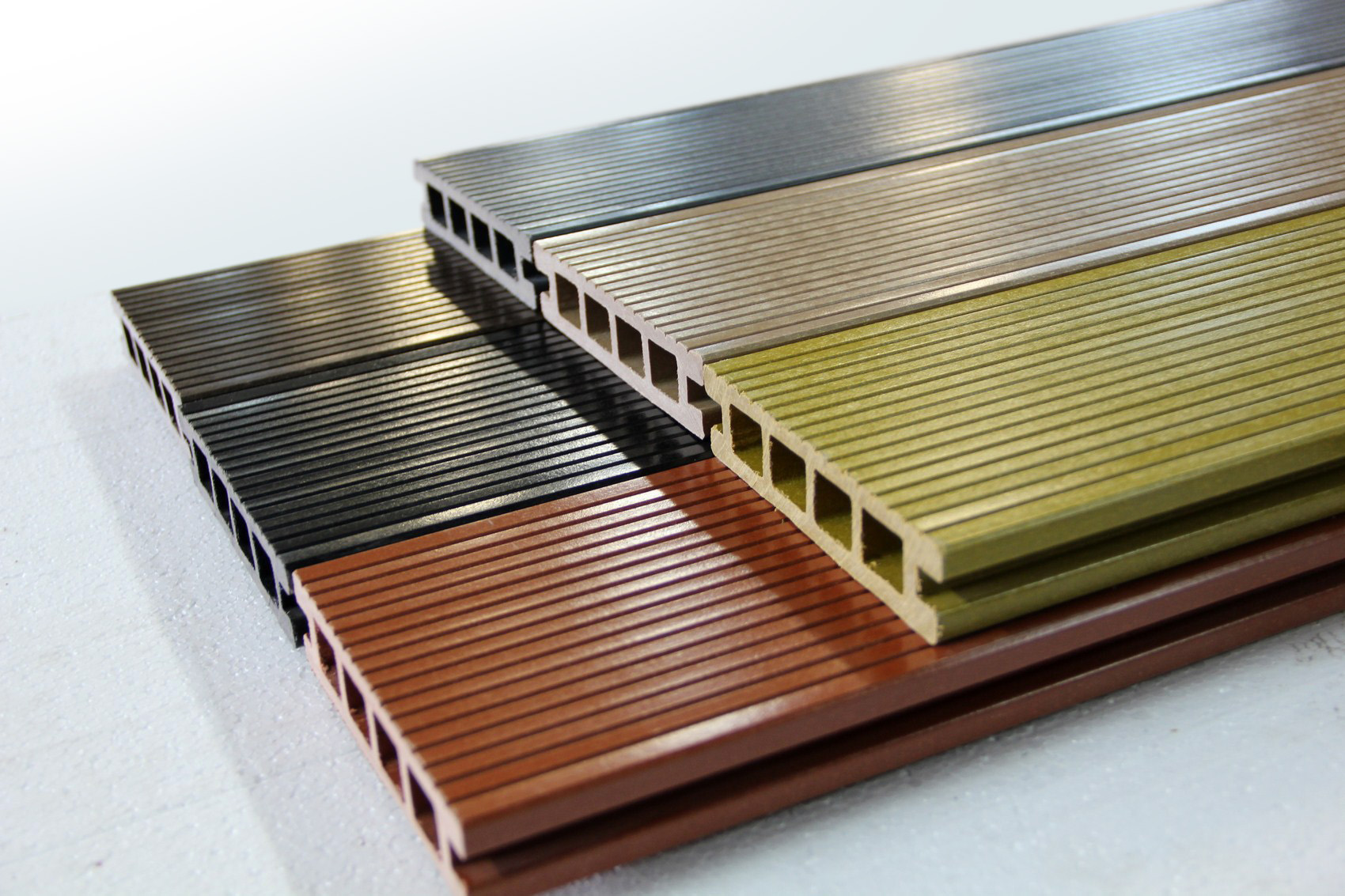

WPC can be stained directly during production in bulk or after manufacture. In the first method of staining, of course, the color fastness will be higher.

- The benefits the material has a lot, among them, of course, resistance to moisture, mold, low temperatures, and a wide selection of colors.

- Among the minuses the ability to lengthen when exposed to high temperatures, which must be taken into account during installation.

If your plans to purchase just this type of terrace board, then when choosing it is worth considering uniform mixing of the components of the mixture. Voids and color splashes should be completely absent - this is an indicator of quality material that will last for many years. Swollen and undulating surface give out violations of production technology.

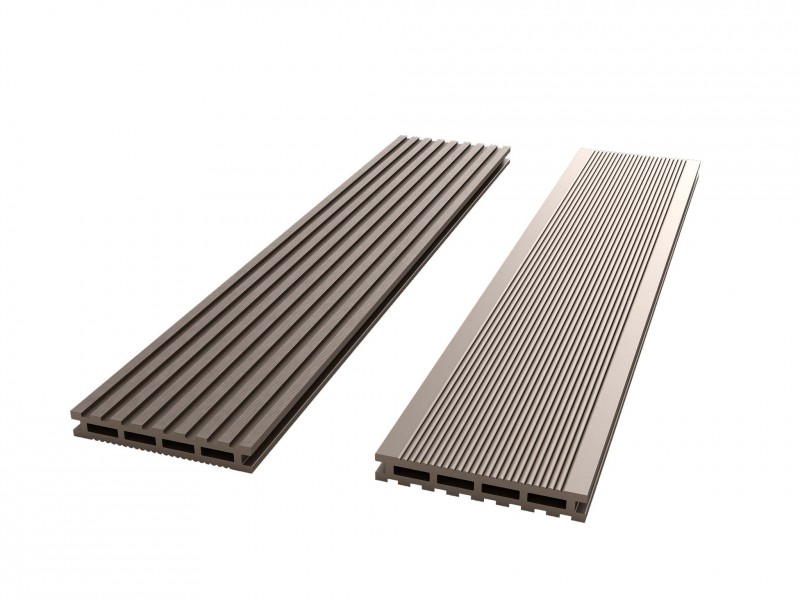

No. 3. What should be the profile of the terrace board?

Since the terrace board is used in conditions of environmental influence, where precipitation is not excluded, it is important that when wet the surface does not become slippery. Otherwise open balconyterrace or patio after rain it will be impossible to get out. To solve this problem, a terrace board is attached corrugated profile. Smooth board is much less common.

When hit on a corrugated surface, water is evenly distributed between the ribs of the profile, and a person steps on them only, so the chance to slip is reduced to zero.The corrugated surface has another side: dirt, residues of branches, dry leaves and other garbage can collect in the recesses. It is not difficult to clean the surface from such pollution: it is enough to direct a stream of water from the hose.

Depending on where the board will be used, and what degree of sliding is necessary, choose material with different frequencies and depths of longitudinal cuts. If you want to protect yourself as much as possible, it is better to choose a board with more frequent and deep cuts.

As for the color of the coating, it is worth choosing based on the shade of the flooring in the house so that there are no sudden transitions. Remember that a terrace board made of natural wood can always be repainted.

Number 4. Features of a terrace board depending on the place of its laying

The scope of use of a terrace board is very wide today: unglazed balconiesterraces garden paths, patio, space about basinas well as parking saunas and baths, moorings, verandas, etc. Naturally, in all these cases, the material should have slightly different properties. The first parameter that you should pay attention to is density. The relevant information should be indicated on the packaging, in extreme cases, you can check the density data from the seller.

Balconies and loggias are places with minimal traffic, so here you can use a board with not the highest density. Places around basin although they are exposed to a small load, since people walk barefoot here, they are subject to constant exposure to humidity. That is why in these cases it is better to use a medium-density board, so the higher the density, the less material absorbs moisture.

Places where people walk in rough shoes, and these are terraces, pergolas, garden paths, it is better to finish with a dense board, otherwise after a while you can notice the “trampled path” on the material.

Depending on the load will be used board with different thickness, but it is divided into the following types:

- thin (with a thickness of 19-22 mm);

- medium (with a thickness of up to 30 mm);

- thick (with a thickness of up to 48 mm).

No. 5. Which manufacturers can be trusted?

Great demand for decking creates an ever-growing supply. This is good for buyers, because the choice is only expanding, but, on the other hand, this trend makes us more and more cautious, because every day more and more unscrupulous manufacturers enter the market who want to get instant benefits.

Sly domestic sellers often go to the trick and give out Chinese products for French and Swedish, where there is no terrace board production. If quality comes first, it is better to overpay a little and give preference to proven foreign companies, or to some domestic companies that have been holding the brand for many years in a row.

TOP 5 world manufacturers of terrace boards

Relazzo classic

Terrace Reliquo Classic WPC board made famous by REHAU. The manufacturer has existed for more than 60 years and during this time managed to gain a foothold as a leader in the polymer industry. The terrace board of the company is one of the best offers in the market of floor coverings for the street. It is a reliable, practical and beautiful material, which is produced by its own technology from polypropylene, wood fibers, as well as biological and mineral components. Products are successfully used in both cold and hot climates.

Terrace Reliquo Classic WPC board made famous by REHAU. The manufacturer has existed for more than 60 years and during this time managed to gain a foothold as a leader in the polymer industry. The terrace board of the company is one of the best offers in the market of floor coverings for the street. It is a reliable, practical and beautiful material, which is produced by its own technology from polypropylene, wood fibers, as well as biological and mineral components. Products are successfully used in both cold and hot climates.

Thermory

Production is in Estonia, Products are popular all over the world. The company offers a heat-treated terrace board, and a special technology allows us to produce durable and durable products that look very beautiful thanks to special oils. Used wood ash, spruce and pine.

Legro

Hungarian company Introduces on the domestic market a terrace board from WPC, which is produced using polypropylene, a wood component and additional additives that give the material a beautiful appearance and practicality. All this, combined with ease of installation and a wide range, explains the popularity of the manufacturer's products.

Hungarian company Introduces on the domestic market a terrace board from WPC, which is produced using polypropylene, a wood component and additional additives that give the material a beautiful appearance and practicality. All this, combined with ease of installation and a wide range, explains the popularity of the manufacturer's products.

Grinder

German manufacturer composite terrace board, which uses its own development in the production of products, which explains its reliability and high competitiveness. There are not many different shades in the assortment, but they are all classic and will easily fit into any interior.

Woozen

Large South Korean company LG Hausys part of the LG concern and produces WPC terrace board under the brand name Woozen. Although the company has been represented on the market for this building material for only 5 years, it has already managed to excel. A special embossing technology is used, which allows you to make a composite board as resembling a natural tree as possible, but in terms of properties much superior to it. Other manufacturers do not have similar offers yet.

Large South Korean company LG Hausys part of the LG concern and produces WPC terrace board under the brand name Woozen. Although the company has been represented on the market for this building material for only 5 years, it has already managed to excel. A special embossing technology is used, which allows you to make a composite board as resembling a natural tree as possible, but in terms of properties much superior to it. Other manufacturers do not have similar offers yet.

TOP 5 Russian manufacturers of terrace boards

"MultiPlast"

Kazan company, which has become a leader among domestic manufacturers of WPC decking. Products are manufactured under the MultiDeck trademark, manufactured on Italian equipment and meet the most stringent standards, which, along with an affordable price, has caused huge demand for products both in all regions of Russia and in neighboring countries. The terrace board is represented by several collections and a huge number of colors.

Kazan company, which has become a leader among domestic manufacturers of WPC decking. Products are manufactured under the MultiDeck trademark, manufactured on Italian equipment and meet the most stringent standards, which, along with an affordable price, has caused huge demand for products both in all regions of Russia and in neighboring countries. The terrace board is represented by several collections and a huge number of colors.

Ecodec

This Moscow company It has been working since 2010, and during this time managed to recommend its products. Imported equipment and special technology are used, which allows to obtain a composite board of high strength. In addition, another strong point of the company's products is the design and variety of colors.

Terradek

This company one of the first in Russia began to produce a terrace board. Today in its assortment is a board made of solid exotic wood, which is supplied from southern countries. These are Kumaru, Merbau, Irpe, Garapa, Tatachuba and other tree species. In addition, a WPC terrace board is also produced, and the manufacturing technology is constantly being improved.

This company one of the first in Russia began to produce a terrace board. Today in its assortment is a board made of solid exotic wood, which is supplied from southern countries. These are Kumaru, Merbau, Irpe, Garapa, Tatachuba and other tree species. In addition, a WPC terrace board is also produced, and the manufacturing technology is constantly being improved.

Thermo Wood

The company produces terrace ash wood board. The manufacturer has a spacious warehouse where a large volume of heat-treated workpieces is always stored, which allows you to quickly fulfill orders of any volume. The company also produces and board from WPC, constantly expanding the range.

Westwood Polymer

The company produces products under the brand name Terrapol - This is a WPC deck board. Among the advantages are consistently high quality and a huge assortment of shades. In addition, the company personally carries out the installation of a terrace board, and the experience gained allows us to do our job quickly and with maximum quality.

The company produces products under the brand name Terrapol - This is a WPC deck board. Among the advantages are consistently high quality and a huge assortment of shades. In addition, the company personally carries out the installation of a terrace board, and the experience gained allows us to do our job quickly and with maximum quality.

Greetings, the article is very helpful. Thanks to the author for this. Well, that we have learned to make a terrace board.