8 tips for choosing bulk floors

Self-leveling floors not so long ago appeared on the construction market and managed to capture several areas of application. They are widely used as a finishing decorative coating, as well as a base and as a durable industrial coating. Naturally, the composition of the mixtures and their properties, depending on the intended purpose of use, will differ greatly. How to understand such a rather big assortment for a novice and choose bulk floors with the optimal set of characteristics?

No. 1. What to choose when choosing?

Despite the variety of bulk floors, all types are characterized by such advantages:

- perfect flat surface and seamless;

- a high level of moisture resistance is typical for most types of bulk floors;

- durability and strength;

- fire safety;

- lack of harm to human health.

The main minus coatings - a high price for some types of bulk floors, but if it does not bother, then you need to be prepared for thorough surface preparation and strict adherence to the instructions for coating.

Navigate when choosing a certain type of bulk floors is necessary for a number of factors:

- specifics of the roomwhere floors will be poured: technical or residential premises, inside or outside the house;

- the main goal. Self-leveling floors can be used. for leveling the floor or as a topcoat;

- material and quality of the initial surface;

- Operating conditions flooring, the likelihood of mechanical stress, direct contact with liquids, aggressive agents;

- the need for additional properties, such as anti-skid, etc.

Bulk floors are represented by such main types:

- cement;

- gypsum;

- polymer. They are used as a topcoat and are divided into polyurethane, epoxy and methyl methacrylate.

No. 2. Cement bulk floors

Self-leveling floors of this type are most often used simply for surface leveling under its further finishing. In fact, this is an alternative to a conventional cement screed. The appearance is as simple as possible, which makes it impossible to use such bulk floors as a finish. Nevertheless, in some cases they are used independently when there are no special requirements to the quality and decorativeness of the coating.

The mixture for bulk floors is sold in bags and diluted with the required amount of water before pouring. The basis of the mixture is cement and sand. High quality cement - guarantee of strength and hardness of the coating after drying. Plasticizers, acidity modulators, antifreeze additives, components that retain moisture, and other substances are used to give the solution plasticity and fluidity. Due to such additives, the finished mixture spreads evenly and forms a flat surface.

Among the benefits versatility, reasonable price, strength, durability, resistance to low temperatures. Installation of cement bulk floors can be performed even by beginners. In addition to a not very decorative appearance, to cons low resistance to aggressive substances can be attributed.

No. 2. Plaster bulk floors

Such floors will cost even cheaper, and in composition they are very similar to cement bulk floors, only gypsum is the main component here, which follows from the name. Such mixtures are used only for leveling and as a basis for further finishing.

The properties of gypsum bulk floors are due to the characteristics of the main component of the mixture. Gypsum quickly hardens, allows you to make a thicker screed, dries quickly, but is afraid of moisture, so you can use such floors only in dry rooms, and even with small loads on the floor. To take advantage of benefits such as low price and quick drying, experts recommend using gypsum floor only under the tile, which absolutely does not leak moisture, but even in this case apply it in the bathroom Not recommended.

No. 3. Polyurethane bulk floors

Such coverage has received widespread and used literally everywhere: in shopping centers, swimming pools, medical facilities, in warehouses, as well as in residential premises where the best performance is required from flooring (kitchen, bath, but can be used in rooms).

Compounds based on polyurethane compound have an impressive range of positive qualities:

- elasticity and resistance to mechanical stress. Sharp heels and most falling heavy objects are not at all afraid of the cover;

- moisture resistance;

- resistance to aggressive substances, therefore, such a coating can be used even in chemical laboratories and in enterprises;

- strength and durability;

- good heat and sound insulation;

- ease of cleaning and hygiene;

- ability to withstand temperature changes;

- ease of repair. Even if you succeed in damaging the coating, then the place of scratches or cracks can be sanded and varnished;

- original appearance, the ability to create a bright individual design. The coating can be matte or glossy.

Among the minuses it can be noted the high price, cold surface, the complexity of installation and dismantling if necessary.

Number 4. Epoxy bulk floors

The basis of such floors is epoxy resins, as the name implies. In addition, hardeners and some other additives are a part. Epoxy bulk floors have a lot of advantages, among which it is especially worth highlighting:

- hardness, rigidity and strength;

- resistance to moisture, household chemicals, most aggressive substances;

- abrasion resistance;

- resistance to temperature extremes.

The coating has obvious minus - fragility and inelasticity. If a more or less heavy object falls, the floor may be damaged.

The combination of characteristics of epoxy floors allows them to be used in rooms where there are no shock loads, but humidity can be increased. These are pools, pharmaceuticals, laboratories, hospitals, car washes, child care facilities and residential buildings.

A kind of coating can be called epoxy urethane floors, which combine the hardness of epoxy bulk floors and the elasticity of polyurethane. This coating is phenomenal durability and is used at stations, airports and metro, where the flow of people is very large.

No. 5. Methyl methacrylate bulk floors

Such floors are used mainly for industrial premises, as they have a lot of amazing qualities:

- high wear resistance, even higher than that of polyurethane floors;

- quick solidification. The coating freezes in an hour, and after another hour it fully gains strength characteristics, and you can walk on it, ride or even lay the finishing layer of the finish, if necessary;

- moisture resistance;

- chemical resistance;

- high speed of installation work.

The main disadvantage of coverage - pungent odor during drying, but this problem can be solved if proper ventilation. After drying, there will be no unpleasant odors.

No. 6.Type of coating composition

Bulk floors can be:

- thin layer;

- self-leveling;

- highly filled.

Thin floors received the greatest distribution, as they can be used in residential buildings and in public buildings, and the price is the most reasonable. Such compositions are applied in a layer of several millimeters on the prepared base, while maintaining maximum durability.

Self-leveling floors have a thickness of 4-5 mm, due to which they can withstand solid mechanical loads. They are distinguished by high durability, strength and ease of installation, because they easily spread on the surface without forming tubercles.

Highly filled floors They have increased strength, resistance to wear, and withstand shock, therefore they are used in industrial premises. Such properties are achieved due to the increased amount of quartz sand.

Number 7. Design of bulk floors

Cement and methyl methacrylate floors cannot boast of brilliant decorative qualities, which cannot be said about polyurethane and epoxy bulk floors. They can be painted in any of thousands of colors or have an interesting color. For the most interesting and original solutions use the following methods:

- adding decorative chips to the mixture - paint particles of different shapes and sizes, due to which it is possible to achieve an imitation of marble, granite or other materials;

- can be applied to the base layer polymer paint drawingand then fix it with varnish. The drawing can be performed both independently and according to stencils;

- look great transparent floors with interesting filling. Coins, shells, pebbles or any other small elements are used;

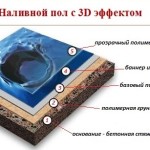

- bulk floors with 3D effect - This is the most impressive way to decorate bulk floors. In this way, volumetric and maximally realistic images are obtained that completely change the perception of the room. The effect is achieved by using a picture with a suitable image, on top of which a transparent polymer coating is poured.

Number 8. Which manufacturers can be trusted?

Bulk floors today are represented by a huge number of domestic and foreign manufacturers.

The best global manufacturers of bulk floors

Knauf

The world famous German company initially produced building materials from gypsum, later expanded its activities, and today production and representative offices are located in dozens of countries. The company's products are well represented in Russia, where they have already managed to appreciate its high quality. The manufacturer offers gypsum bulk floors, for which gypsum of the highest quality is used, therefore the coating is superior in strength to cement bulk floors. There are also polymer bulk floors in the assortment, but they are not so extensively represented in our market.

The world famous German company initially produced building materials from gypsum, later expanded its activities, and today production and representative offices are located in dozens of countries. The company's products are well represented in Russia, where they have already managed to appreciate its high quality. The manufacturer offers gypsum bulk floors, for which gypsum of the highest quality is used, therefore the coating is superior in strength to cement bulk floors. There are also polymer bulk floors in the assortment, but they are not so extensively represented in our market.

SIKA

This Swiss company offers mainly compositions for industrial and public buildings. The assortment has self-leveling floors of all types, and our own research centers allow us to produce coatings with specific properties by adding the necessary components.

Ceresit

Ceresit is a trademark used for a wide range of building mixtures by the German company Henkel. The production of this giant is located in several countries, there are representative offices in 120 countries, and the products are in constant demand for many years in a row. The assortment includes bulk floors designed to level the surface for further laying of the cladding.

Ceresit is a trademark used for a wide range of building mixtures by the German company Henkel. The production of this giant is located in several countries, there are representative offices in 120 countries, and the products are in constant demand for many years in a row. The assortment includes bulk floors designed to level the surface for further laying of the cladding.

Weber

An international company that is a subsidiary of Saint-Gobain. Production facilities are located around the world, products are widely represented on all continents. Self-leveling floors are produced under the Vetonit trademark; the assortment includes mixes for leveling and finishing, for residential and industrial premises.

The best domestic manufacturers of bulk floors

LLC "TeoHim"

The company produces bulk floors under the Elakor trademark and today is a confident leader in this field. Offers bulk floors for residential and industrial premises. Product ranges include polyurethane and epoxy floors. The assortment has transparent floors to create a 3D effect, antistatic compounds and floors that are as resistant to burning as possible.

The company produces bulk floors under the Elakor trademark and today is a confident leader in this field. Offers bulk floors for residential and industrial premises. Product ranges include polyurethane and epoxy floors. The assortment has transparent floors to create a 3D effect, antistatic compounds and floors that are as resistant to burning as possible.

Ivsil

A large company that once produced only cement-sand mixtures, and now is a leader in the domestic market for the production of innovative multicomponent compositions. Bulk floors are represented by compositions for leveling and finishing work.

UNIS

The company in the market since 1994 and today is one of the leaders in the number of sales of dry mortar. Products are in demand not only in Russia but also in the CIS countries. Production facilities are located in five cities of the country; gypsum from our own quarry is used for the production of products, which allows us to control the quality from the stage of raw material extraction. The company includes a powerful research laboratory. The assortment of self-leveling floors designed to level the surface.

The company in the market since 1994 and today is one of the leaders in the number of sales of dry mortar. Products are in demand not only in Russia but also in the CIS countries. Production facilities are located in five cities of the country; gypsum from our own quarry is used for the production of products, which allows us to control the quality from the stage of raw material extraction. The company includes a powerful research laboratory. The assortment of self-leveling floors designed to level the surface.

Bolars

This domestic company boasts a modern plant, the availability of research and control laboratories and the latest equipment. Product quality is not much inferior to European counterparts, and the emphasis is on dry building mixes. In assortment there are bulk floors on a cement and plaster basis.

Industrial floors

The company has been operating since 1995 in the manufacture of floor coverings and dry mixes. Bulk floors are presented under the PRASPAN trademark, these are polymer coatings.