6 tips for choosing and installing window grilles

Lattice - An old proven method to protect your home from unauthorized access. Despite their wide distribution, many still choose lattices completely wrong. Some look only at the aesthetics of the product, others pay attention to the possibility of plowing, while others do not argue their choice at all and make an order for the design in the first company they come across. It is not surprising that then unpleasant consequences of rash choice are revealed. We will understand that, first of all, it is necessary to consider when choosing a lattice, and what it should be in order to protect as much as possible and not spoil the interior of the apartment and house facade.

It should be noted that there are no such lattices that the thief would not be able to break out or cut. The choice comes down to find a product that you will need to crack for as long as possibleand after all, the longer an attacker fidgets, the more likely his neighbors or passers-by will notice his attempts to enter the house.

No. 1. The method of fastening the grill

To a greater extent, the level of protection of the home depends on how the grill is installed. there is several ways to fix the grill:

- stationary gratings - those that cannot be opened;

- swingingin which one or two wings open, as in the windows;

- sliding (grating-curtains), which are manufactured as a pantograph;

- removablewhich differ from the stationary ones in that they are attached to the wall using screw bolts.

Stationary gratings - the most robust designs of all existing, because their fittings are mounted directly into the wall. Similar designs are recommended for owners of apartments located on the first floor. Even attackers learned to overcome such lattices, and they do it very simply: they attach the cable to the lattice and attach it to the truck - many structures break out without much difficulty, therefore fittings the gratings should go into the depth of the walls by at least 8 cm. The reverse side of the reliability of stationary gratings is inability to open them during fire. No one is safe from such unforeseen situations, so hinged grilles must be installed at least on one window in the apartment.

Swing grilles if necessary, they can swing open, leaving the window opening completely free. This is convenient not only from the point of view of fire safety, but also if you wish not to clutter up the view from the window with steel bars. One or both sashes can swing open, and protect the window from outsiders padlock or mortise lock.

Lattice curtains recognized as the most unreliable designs, as they are made from strips of metal that are movably fixed crosswise, which affects its burglar-resistant qualities. Mounted such grilles from inside the room, and some products when opening only 80% free up the window opening - be careful when choosing. Sliding grates are used in suburban and private houses where the burglar is used signaling, which works on broken glass, and the lattice located inside the window opening will become an obstacle that an attacker will not be able to overcome before the arrival of the guard.

Removable grilles should have been a compromise in terms of strength and fire safety. The designs are quite reliable, but inferior to the stationary ones in this parameter, but unscrewing the bolts that are used to secure the grill will be problematic in a state of panic.

No. 2. Type of profile for grille

Lattices are made using these types of profiles:

- bar - a profile, as a rule, of circular cross section, which is obtained by pressing or rolling. Lattices from a bar turn out very strong and rather esthetic. A bar with a diameter of 12-20 mm is used;

- square - profile of a square section. It also produces products that are good from an aesthetic point of view, and in terms of strength they are not inferior to bars. A profile with a cross section of 12 * 12, 14 * 14 and 16 * 16 mm is used;

- band - a flat profile with a rectangular section. Width up to 20 cm, thickness up to 6 mm. The simplest and far from the most artistic pieces are made from a strip, and in terms of strength they cannot be compared with the two previous options, but they confidently win at a price;

- combined option involves the use of different types of profiles.

No. 3. Lattice material

The bar, square and strip can be made of different types of material, on which the properties of the finished product also depend. Most often used for the production of gratings:

- structural steel - the most inexpensive and least durable option, but the grilles are quite budget ones;

- reinforcing steel - A much more durable option than structural steel. By strength, a bar of reinforcing steel with a diameter of 14 mm is equivalent to a bar of structural steel with a diameter of 20 mm. To eat such material, you will need hydraulic scissors and some time, so such a grill can be considered a reliable barrier for criminals. Increased strength results in reduced ductility, so it will be difficult to obtain complex ornate patterns from such a material;

- special steel - expensive and most reliable material. The rods have record strength with a small diameter, which means that the grill will be minimally noticeable, and the view from the window will be more complete. It is difficult to get spectacular curls and other decorative elements from special steel, but a thief will definitely not cope with such a grill. And not every team of the Ministry of Emergencies will be able to cut this design, for example, to free the prisoners in a flaming apartment. To do this, you need a plasma cutter, which is not in the equipment of all rescuers. Lattices of this type are expensive, so they are rarely installed in ordinary apartments. Maybe this is for the best. Designs are suitable for installation in banks and other institutions where money and valuables are stored.

To be as sure as possible of the reliability of the protection of the home, it is better to choose the grating in profile thickness is at least 14 mm. To saw or bend metal of such thickness, a decent amount of time will be required, and this is the main task of a good lattice.

When choosing a grate, do not discount the opportunity thieves through her rods. To prevent even the smallest attacker from entering the house, the distance between the rods should not be less than 15 * 15 cm.

Number 4. Grid Production Technology

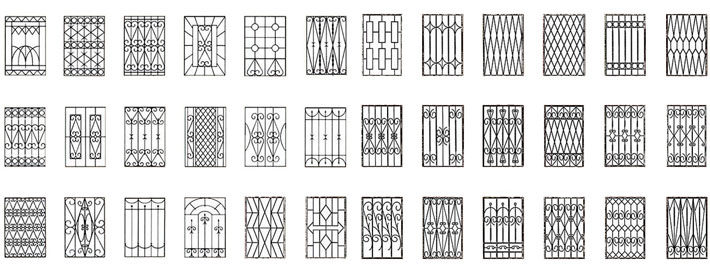

Most window grills are welded, as it is cheaper. More openwork and designs can be obtained by forging. Casting technology is used much less frequently.

Welded gratings

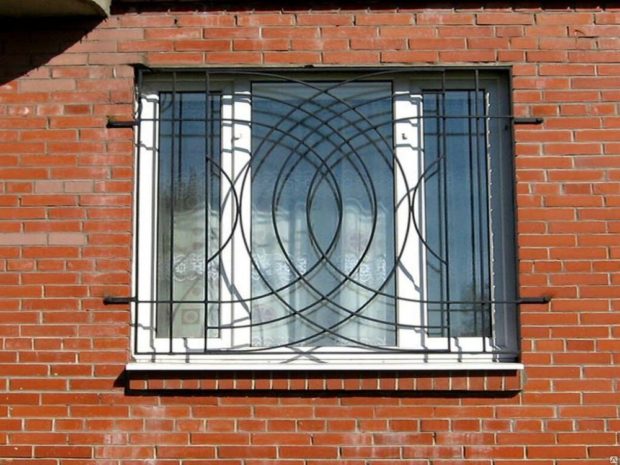

There is a popular belief that welded gratings - These are primitive designs with a very simple design. To prove this point of view, they usually give an example of a lattice in the form of the rising sun. Such in the days of the Soviet past were very popular, and they are still used.However, the welding technology allows you to create much more interesting designs that will not only protect, but also decorate the window.

Welded Grid Production Technology simple enough. First, blanks of the required size and shape are made from a rod, strip or square. All according to the previously drawn up sketch. Elements can be straight or in the form of geometric shapes, but can be bizarrely bent. Interesting details are obtained by means of torsion, when the rod or square is twisted several times along the axis. When all the elements are ready, they are laid out on a non-combustible surface and begin to weld. Welding spots are cleaned and smoothed, they can be hidden with special clamps - this is a ringing method. Sometimes small forged elements are welded to the welded gratings. In general, the design is not so primitive and boring, as many believe.

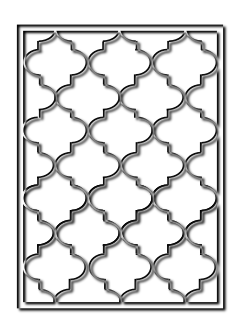

Lattice pattern it can be absolutely anything: manufacturers' catalogs are striking in variety, and besides, there is the opportunity to custom-made grilles. A pattern can consist of repeating elements, be symmetrical or abstract. Welded joints can be decorated with clamps, peaks, sheets and petals. Today, the lattice is not the same primitive patterns that were used in the not so distant past, but it is also not worth overdoing it in this matter, so as not to significantly reduce light transmission.

Advantages of welded gratings:

- low price;

- speed and relative ease of manufacture;

- high strength.

Less - less spectacular appearance than forged gratings, but manufacturers are working hard on this shortcoming, so you can’t call it critical.

Forged grilles

Forged lattices are made of square and bar, and skillfully made products resemble lace. Such gratings are more expensive than welded ones, since the process of their manufacture is rather laborious, and in terms of reliability, such structures are in no way inferior to welded counterparts. They are perfect for the windows of a country house, and for an apartment in a multi-storey building, it is better to use welded products.

According to the production technology, forged lattices are:

- regularin which there is a clear symmetry. They are made from a rod with a diameter of 20 mm or more. Such gratings are cheaper than analogs, they resist breaking quite well, but they look a little rougher than irregular gratings, and due to the thickness of the steel they take too much light;

- irregular lattices are an example of openwork and airiness. Such lattices can be called a real work of art in metal. However, an irregular design is easier to crack, so the master needs to accurately build a sketch to get maximum burglary resistance. For these reasons, such gratings are more expensive than regular ones;

- mixed products consist of regular and irregular elements, and it is precisely the zones of their junction that become weak spots.

The main advantage of forged lattices is a high level of aesthetics and even artistry. Such a design will not spoil the window, but even decorate it. A combination of a forged lattice and the same railings for a staircase will look harmonious. One minus is a higher price.

Cast grates

Structures of this type are inferior in terms of strength to welded and forged gratings. They are quite fragile, poorly resist breaking, but they are inexpensive, and art casting allows you to get quite interesting patterns. Cast grilles are rarely used, sometimes they are put in offices where there is an alarm system, and windows face the central busy streets.

No. 5. The method of coloring and design of the lattice

The color of the lattice also affects its perception. It’s good that today, with the help of coloring, you can achieve any shade: from standard black to noble bronze, antique silver, etc. Painting is always carried out after preliminary priming of the metal, which protects it from corrosion.

To cover the surface of the lattice using:

- alkyd enamels - the most common choice, and domestic ones are not inferior in quality to imported analogues. The composition dries quickly, can be any shade, but quickly becomes cracked. During drying, it gives toxic fumes, so a day or two after painting it is better not to be near the grate;

- nitro enamel It dries quickly, is safe, but is not resistant to weathering;

- powder coatingIt has maximum resistance to negative environmental influences, does not fade in the sun and very well protects metal from corrosion. The warranty for such coverage is usually 20 years. It is applied under production conditions and literally sinter with the main surface.

Lattices can be not only flat but also voluminous, which is clearly visible from the side view. Such products, even when welded, look much prettier and look better on the window. The most popular option is an S-shaped grid.

Grid color selected depending on the features of the facade and the design of the window structure. For example, the brick facade is in good harmony with the grilles of black, brown and red, but if white plastic windows are installed, then you can use white grilles. By the way, light-colored gratings take the least light and look less bulky. The facade of a private house, made in the classical style, can be decorated with grilles coated in bronze or silver.

No. 6. Where and how to install the grille?

Some types of gratings assume only one installation option: for example, sliding gratings are installed only inside the window opening. In other cases, you can choose. Most of us prefer to install the grill. outside the apartment, arguing for such a choice, mainly with aesthetics and convenience. In this case, maximum attention should be paid to the strength of the structure and the reliability of its installation.

From a security point of view, the best option is to install a grill. inside the window when using a security alarm. It turns out that the thief will first break the glass, which will trigger the alarm, and he simply will not have time to break into the grate, get into the apartment and take valuables. In this case, you can choose almost any type of gratings.

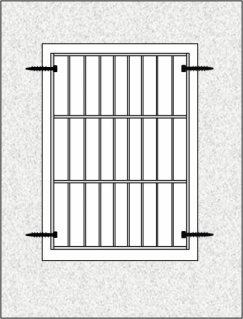

The grill can be installed:

- at the ends of the window opening;

- overlay. In this case, the grill is mounted only outside the window, and it should be larger than the opening.

Depending on the selected option and wall material home installation will be different. Let's say you need to set the grilles in wooden house overlay. In this case, holes for through bolts are drilled in the walls, on which the grate will be held. The ends of the bolts indoors are tightened with nuts. If the method of installation at the ends of the window opening is chosen for a wooden house, then special eyes must be used that are welded to the frame of the grill. Thanks to the holes in them, the grill is attached to the wall with screws up to 10 cm long.

Depending on the selected option and wall material home installation will be different. Let's say you need to set the grilles in wooden house overlay. In this case, holes for through bolts are drilled in the walls, on which the grate will be held. The ends of the bolts indoors are tightened with nuts. If the method of installation at the ends of the window opening is chosen for a wooden house, then special eyes must be used that are welded to the frame of the grill. Thanks to the holes in them, the grill is attached to the wall with screws up to 10 cm long.

If it is necessary to install the grill at the ends of the window opening in a brick house, then it will be necessary to drill in the attachment points bricks cement mortar holes with a depth of 12 cm and a diameter of 1.6 cm. Such holes are made 2-3 on the sides and 1-2 on the top and bottom, they insert the embedded pins protruding 2-3 cm so that they can be welded to them grate. Similarly, installation is carried out in the case of concrete walls.

As you can see, the grill can really become a reliable protection and a nice accessory for the window, if you take responsibility for its choice.