9 tips for choosing blocks of aerated concrete (gas blocks)

Lightweight, strong, durable and inexpensive aerated concrete has recently been increasingly used in private residential construction. Its operational qualities can significantly save financial and time resources for the construction of the building. The scope of use of aerated concrete blocks is expanding day by day, and manufacturers, responding to growing demand, offer an increasing assortment: aerated concrete blocks can differ in density, thermal insulation qualities, shape and size. To make the right choice of aerated concrete blocks, you need to know the purpose of their use and be familiar with their main types.

No. 1. Aerated concrete by type of production

For the production of gas blocks use cement, sand and special blowing agents (usually aluminum dust), sometimes add lime, gypsum, as well as industrial waste, including slag from metallurgical industries and ash. The mixture is diluted with water, poured into a pre-prepared form, where the reaction of interaction of aluminum with cement or lime mortar takes place. The resulting hydrogen foams the cement slurry, resulting in spherical interconnected pores with a diameter of 1 to 3 mm. After setting the resulting solution, it is taken out of the mold, cut into billets and dried.

According to the type of final processing, aerated concrete blocks are divided into:

- autoclave. Their hardening takes place in autoclaves under the influence of saturated steam supplied under high pressure. it more durable and expensive stuff. Such blocks are recommended for use in erection bearing walls;

- non-autoclave. Harden in electrically heated drying chambers or in natural conditions. Their main advantage is lower price due to the simplified production method.

No. 2. Advantages and disadvantages of aerated concrete

Regardless of some production features, all aerated concrete blocks boast a decent set the benefits:

great thermal insulationdue to the porous structure of the material;

great thermal insulationdue to the porous structure of the material;- big sizes, a light weight and ease of processing significantly simplify and accelerate the construction of buildings from the gas block;

- good vapor and air permeability. According to these indicators, blocks of aerated concrete close to the tree. In practice, this means that in a house built from such material there will always be an optimal microclimate;

- fire resistance;

- environmental friendliness and security. In the manufacture of gas blocks do not use hazardous synthetic substances;

- resistance to damage by rodents, insects and microorganisms;

- frost resistance. On average, the gas block withstands up to 50 freezing / thawing cycles without loss of basic operational properties;

- regarding low cost.

Among the main shortcomings of aerated concrete select:

high hygroscopicity. This main disadvantage of the material is associated with its structure and ability to retain moisture inside. Water absorption can reach 35%.When moisture is absorbed, thermal insulation qualities deteriorate, serious material deformations can occur. You can get around this disadvantage by arranging a reinforced waterproofing, construction of a reliable drainage system and window drains. Moreover, facade Needs a mandatory finish, for which decorative tiles are great;

high hygroscopicity. This main disadvantage of the material is associated with its structure and ability to retain moisture inside. Water absorption can reach 35%.When moisture is absorbed, thermal insulation qualities deteriorate, serious material deformations can occur. You can get around this disadvantage by arranging a reinforced waterproofing, construction of a reliable drainage system and window drains. Moreover, facade Needs a mandatory finish, for which decorative tiles are great;- the possibility of cracks with improper installation of the foundation. Cracks can appear both along masonry lines and in blocks due to shrinkage of the foundation, to which such large aerated concrete blocks are very sensitive. So that the advantage does not turn into a disadvantage, you need to pay maximum attention to the correct installation of the foundation;

- problems with fasteners. Reliably keep in aerated concrete can only screws. Nails and screws easily enter the wall from aerated concrete and just as easily fall out of it, so special fasteners will be required.

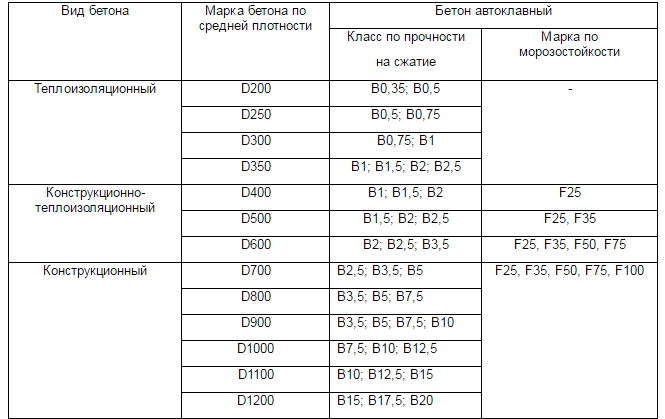

No. 3. Gas block brand

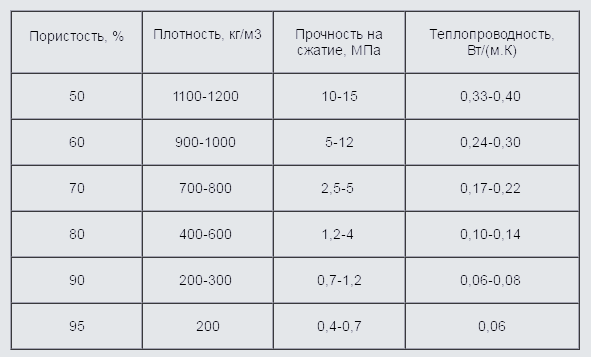

The most important and determining the scope of use characteristic of aerated concrete blocks is their density. Measured in kg / m3, and its numerical expression is reflected in concrete branddenoted by D. At the moment, gas blocks of grades are produced from D200 to D1200. The lower the density, the more fragile and lightweight the material, but the better it retains heat, so blocks of different densities are used for different purposes and are divided into several species:

- structural. The heaviest and strongest blocks are used to erect load-bearing walls of houses above three floors. This class includes blocks of grades from D700 to D1200;

- structural insulation blocks of grades from D500 to D600 can be used for the construction of load-bearing walls of low-rise buildings, as well as partitions;

- heat insulating blocks grades from D200 to D350 are used as a heat insulator, as well as for the arrangement of non-bearing internal partitions.

Number 4. Gas block compression strength

The compressive strength of the material is directly dependent on the density. The higher the density, the more durable and reliable the material will be. Strength class is indicated by the letter B and the following coefficient. For example, B2.5 will correspond to the compressive strength of 2.5 MPa, which has a gas block brand D500. The D700 brand block will have a strength class of up to B5. In order to compare, the compressive strength of a brick is determined within 15-20 MPa, therefore it is not recommended to build buildings from five floors above aerated concrete, but the material is more than suitable for the construction of small private houses, garages and other buildings.

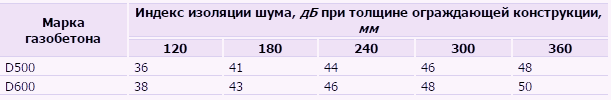

No. 5. Soundproofing qualities

Aerated concrete - fine sound insulator, but the ability to suppress external noise varies depending on the density of the material, construction technology and wall thickness. So, for example, a gas block of the D500 brand with a partition thickness of 120 mm provides noise isolation at 36 dB, and with a partition thickness of 360 mm - 48 dB. Similar indicators for aerated concrete brand D600 - 38 and 50 dB. Regulations regulate sound insulation between rooms at 41 dB, between the room and a bathroom - 45 dB, between different apartments, apartment and stairwell, lobby, corridor - 50 dB. Even a gas-block of a structural-heat-insulating type allows achieving the necessary sound insulation values.

No. 6. Gas block frost resistance

In the harsh domestic climate, it makes sense to pay attention to the indicators of frost resistance of the material. This parameter can be judged by number of freeze / thaw cycles without loss of basic operational properties. To date, blocks are on sale from F15 to F100, where the coefficient following F is the numerical expression of the cycles that a particular material will withstand. The choice must be built on the climatic features of the region, but for the construction of external walls it is better not to use a gas block with frost resistance below F50.

Number 7.Size and shape of gozoblok

Gas blocks on the market may vary in size and even shape. Depending on the purpose of use, one or another material is chosen. The most common option is rectangular blockswhich can be divided into several types:

wall or masonry. Used for construction of load-bearing walls, less often - partitions. They have a standard length of 600 mm and a height of 200 mm, but different widths - from 200 to 500 mm;

wall or masonry. Used for construction of load-bearing walls, less often - partitions. They have a standard length of 600 mm and a height of 200 mm, but different widths - from 200 to 500 mm;- gas block for partitions has the same length and height parameters, but a smaller width - from 75 to 150 mm;

- gas block for jumpers not all manufacturers produce it. The length of such blocks is 500 mm, the height is 200 mm, and the width is from 250 to 400 mm.

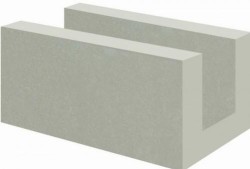

In addition to smooth rectangular blocks, the following types of material are also produced:

U-shaped blocks Usually used to equip hidden building elements. With their help, you can create monolithic stiffening belts, while the internal space is filled with reinforcement and concrete;

U-shaped blocks Usually used to equip hidden building elements. With their help, you can create monolithic stiffening belts, while the internal space is filled with reinforcement and concrete;- tongue-and-groove blocks at the ends they have protrusions and depressions for the most accurate and durable connection of neighboring elements. The need disappears use adhesive solution for processing vertical seams;

- gripper blocks differ in the presence of cutouts on the sides of the block to simplify handling;

- type blocks hh due to their structure they allow laying a layer of thermal insulation between partition plates.

Number 8. What to consider when external inspection of the unit?

To be sure of the durability and reliability of the constructed building, personal inspection of gas blocks must be given special attention. We pay attention to the following details:

geometry accuracy. Responsible manufacturers, which will be discussed below, offer blocks with exact dimensions, without deviations (allows 1-2 mm) and chips, because this is the key to simplicity and cost-effectiveness of installation. Moreover, thick joints that become inevitable with insufficiently accurate geometry can create cold bridges;

geometry accuracy. Responsible manufacturers, which will be discussed below, offer blocks with exact dimensions, without deviations (allows 1-2 mm) and chips, because this is the key to simplicity and cost-effectiveness of installation. Moreover, thick joints that become inevitable with insufficiently accurate geometry can create cold bridges;- color. A good autoclave gas block has a uniform light gray color. If the blocks of one batch differ from each other in color, have stains, then we are talking about products of inadequate quality. The presence of oily spots and cracks is unacceptable;

- packaging. The material must be sealed, and on each pallet the material must contain information about the batch number, and a quality passport must be attached to each batch.

No. 9. The best manufacturers of aerated concrete

The name of the manufacturer is the guarantee of the quality of gas-generating units, because large companies that have been working on their reputation for many years will not spoil it by producing products that do not meet standards. Let us dwell on the largest manufacturers of aerated concrete blocks.

Xella group

Xella Group - a group of companies with a center in Germany. It produces gas blocks under trademarked Ytong. The manufacturer's plants are located in different countries, including and in Of Russia, where production is carried out according to German technology with careful quality control, which allows domestic buyers to purchase European-level products at affordable prices. Xella Group laboratories are constantly working to improve the materials they produce. The manufacturer’s assortment includes wall blocks of brands D400 and D500 of various sizes, blocks for partitions, U-shaped and arc-shaped blocks, glue for Ytong gas blocks and the necessary tools for working with aerated concrete are also sold.

Xella Group - a group of companies with a center in Germany. It produces gas blocks under trademarked Ytong. The manufacturer's plants are located in different countries, including and in Of Russia, where production is carried out according to German technology with careful quality control, which allows domestic buyers to purchase European-level products at affordable prices. Xella Group laboratories are constantly working to improve the materials they produce. The manufacturer’s assortment includes wall blocks of brands D400 and D500 of various sizes, blocks for partitions, U-shaped and arc-shaped blocks, glue for Ytong gas blocks and the necessary tools for working with aerated concrete are also sold.

Aerok SPb

This is a large domestic enterprise specializing in the production of autoclaved gas blocks. Founded in 2004, included to the group of companies "LSR Group"manufactures products under the well-known brand AEROC. Among the strengths of the manufacturer is a fully automated production, equipped with the latest German equipment. Largely thanks to this company, in some regions of the country the use of D400 blocks became widespread.Not so long ago, the production of D300 B2.0 F50 blocks was launched, which the company proposes to use in low-rise construction as load-bearing single-layer walls. The range of gas blocks is wide, includes material strength from D300 to D600 and compressive strengths from B2.0 to B5.0, U-blocks and jumpers are also available. Volumes of production - about 400 000 m3 aerated concrete per year.

This is a large domestic enterprise specializing in the production of autoclaved gas blocks. Founded in 2004, included to the group of companies "LSR Group"manufactures products under the well-known brand AEROC. Among the strengths of the manufacturer is a fully automated production, equipped with the latest German equipment. Largely thanks to this company, in some regions of the country the use of D400 blocks became widespread.Not so long ago, the production of D300 B2.0 F50 blocks was launched, which the company proposes to use in low-rise construction as load-bearing single-layer walls. The range of gas blocks is wide, includes material strength from D300 to D600 and compressive strengths from B2.0 to B5.0, U-blocks and jumpers are also available. Volumes of production - about 400 000 m3 aerated concrete per year.

DSK GRAS-Saratov

Another major domestic manufacturer of autoclaved aerated concrete. The company includes two factories and own sand pitThat allows you to control the quality of products at absolutely all stages. The total capacity of the manufacturer's plants is over 900,000 m3 aerated concrete per year. The location of production facilities in different districts allows us to provide our products to 15 regions of the country. The production uses Dutch equipment that allows the production of gas blocks with the most accurate geometry. Aerated concrete blocks are made of grades from D300 to D700 and compressive strength from B1.5 to B5.0 of different sizes. There are blocks with a groove-comb system, with hand grips and U-blocks.

Another major domestic manufacturer of autoclaved aerated concrete. The company includes two factories and own sand pitThat allows you to control the quality of products at absolutely all stages. The total capacity of the manufacturer's plants is over 900,000 m3 aerated concrete per year. The location of production facilities in different districts allows us to provide our products to 15 regions of the country. The production uses Dutch equipment that allows the production of gas blocks with the most accurate geometry. Aerated concrete blocks are made of grades from D300 to D700 and compressive strength from B1.5 to B5.0 of different sizes. There are blocks with a groove-comb system, with hand grips and U-blocks.

Dmitrovsky Aerated Concrete Products Plant

Gas blocks of the enterprise are known to domestic buyers under the trademark Aerostone. Every year the company produces about 500,000 m3 aerated concreteusing modern German equipment for this. The products comply with European and domestic quality standards, and control at the plant is carried out by German specialists. Blocks of grades from D400 to D600 of various sizes are available, there are wall and partition walls, as well as U-shaped blocks.

Gas blocks of the enterprise are known to domestic buyers under the trademark Aerostone. Every year the company produces about 500,000 m3 aerated concreteusing modern German equipment for this. The products comply with European and domestic quality standards, and control at the plant is carried out by German specialists. Blocks of grades from D400 to D600 of various sizes are available, there are wall and partition walls, as well as U-shaped blocks.

Bonolit - Building Solutions

Production facilities are located in the Moscow region. Gas blocks under the trademark Bonolit produced on German equipment, the design capacity of the line is 450,000 m3 aerated concrete per year. The assortment is represented by blocks for load-bearing walls, partitions and lintels, the density of products from D300 to D600.

Production facilities are located in the Moscow region. Gas blocks under the trademark Bonolit produced on German equipment, the design capacity of the line is 450,000 m3 aerated concrete per year. The assortment is represented by blocks for load-bearing walls, partitions and lintels, the density of products from D300 to D600.

H + H International A / S

Today H + H International A / S - international group of companies, whose history begins in 1909 in Denmark. In 1949, the manufacturer's enterprises began to specialize in aerated concrete, and today it is one of the largest manufacturers of aerated concrete in the world. Factories are located in 4 countries, including in Russia. In 2009, the company’s plant was equipped in the Leningrad Region, equipped with the most modern production lines. Today here 450,000 m are produced annually3 aerated concreteincluding wall and partition blocks and U-blocks under trademarked H+H.

Today H + H International A / S - international group of companies, whose history begins in 1909 in Denmark. In 1949, the manufacturer's enterprises began to specialize in aerated concrete, and today it is one of the largest manufacturers of aerated concrete in the world. Factories are located in 4 countries, including in Russia. In 2009, the company’s plant was equipped in the Leningrad Region, equipped with the most modern production lines. Today here 450,000 m are produced annually3 aerated concreteincluding wall and partition blocks and U-blocks under trademarked H+H.

“Lipetsk plant of house-building products”

The company uses aerated concrete production technology and equipment of the German company Hebel, which explains the high quality of the products and the accuracy in observing the dimensions (a deviation of a maximum of 1 mm is allowed). The factory produces wall and partition blocks of different sizes and brands from D300 to D700.

The company uses aerated concrete production technology and equipment of the German company Hebel, which explains the high quality of the products and the accuracy in observing the dimensions (a deviation of a maximum of 1 mm is allowed). The factory produces wall and partition blocks of different sizes and brands from D300 to D700.

"Elgad-ZSI"

The production is located in Kolomna, it produces autoclaved aerated concrete under trademark EL-BLOCK. Factory productivity - up to 400,000 m3 aerated concrete per year. The consistently high quality of the products is guaranteed using the equipment and technology of the German company WEHRHAHN, which provide for the complete automation of the production process and its tight control. Smooth and tongue-and-groove gas blocks are produced, wall and partition, with hand grips and without them, as well as special O-blocks, the holes in which allow reinforced masonry walls.

The production is located in Kolomna, it produces autoclaved aerated concrete under trademark EL-BLOCK. Factory productivity - up to 400,000 m3 aerated concrete per year. The consistently high quality of the products is guaranteed using the equipment and technology of the German company WEHRHAHN, which provide for the complete automation of the production process and its tight control. Smooth and tongue-and-groove gas blocks are produced, wall and partition, with hand grips and without them, as well as special O-blocks, the holes in which allow reinforced masonry walls.

The unique performance properties of aerated concrete blocks and their wide range on the market have made it one of the most popular materials in the field of private low-rise residential construction.

Is there still a topic with the delivery of pallets in NN that no one has heard? Right now in the night, hardly anyone will answer by phone