8 tips for choosing a metal roof tile

Outwardly similar to natural tile, but lighter and cheaper metal tile has become one of the most popular roofing materials. It is used to equip the roofs of private and multi-storey buildings, industrial buildings and commercial facilities. High demand due unique performance, excellent appearance, a wide variety of textures and colors. When choosing a metal roof tile, you need to consider a lot of factors: from sheet thickness and type of protective coating to the shade and shape of the profile. Far from the least role is also played by the name of the manufacturer.

No. 1. Features of the production of metal

The main for the manufacture of metal can serve one of the following materials:

- steel sheet;

- aluminum sheet;

- copper sheet.

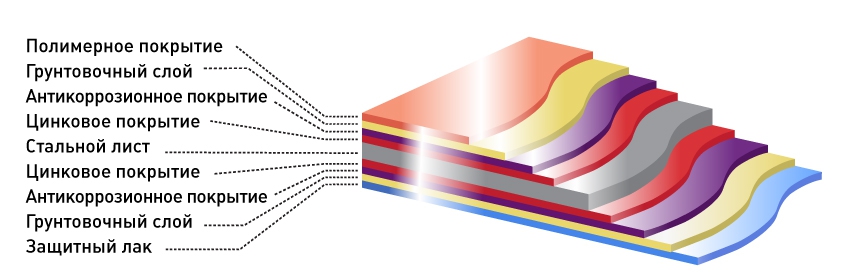

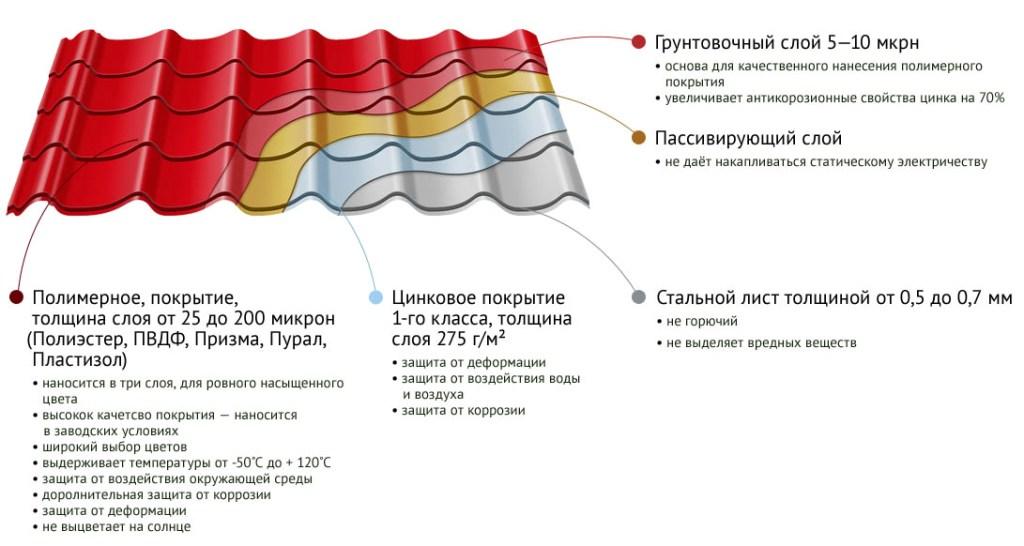

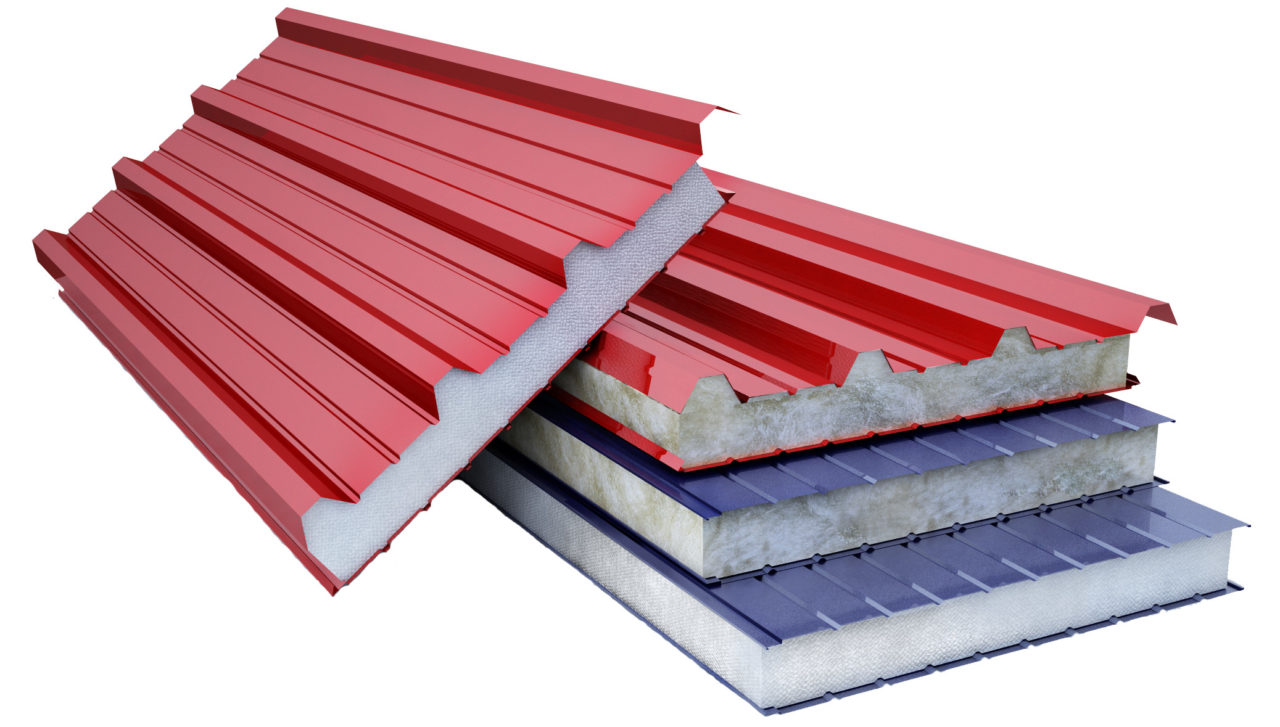

The most commonly used galvanized steelwhich, thanks to stamping, gives a certain profile that imitates natural tile. On top of the protective layer of zinc can be used phosphate layerwhich increases corrosion resistance. The next layer is primer, which improves adhesion to the polymer-decorative coating. Backside also undergoes galvanization and is additionally protected by a layer of transparent varnish, which prevents small scratches. The strength of the material depends on the thickness of the steel sheet, and the period of preservation of the original appearance and resistance to negative environmental factors depends on the type of polymer coating.

The most commonly used galvanized steelwhich, thanks to stamping, gives a certain profile that imitates natural tile. On top of the protective layer of zinc can be used phosphate layerwhich increases corrosion resistance. The next layer is primer, which improves adhesion to the polymer-decorative coating. Backside also undergoes galvanization and is additionally protected by a layer of transparent varnish, which prevents small scratches. The strength of the material depends on the thickness of the steel sheet, and the period of preservation of the original appearance and resistance to negative environmental factors depends on the type of polymer coating.

Aluminum sheet It can do without anti-corrosion coating, but an additional protective polymer layer is still used, because it allows to increase the strength and durability of the material. Aluminum tile is lightweight, which simplifies transportation and installation, but it does not have many color options, and it costs more than steel counterparts.

Copper sheet metal It is very expensive, rarely used, but it looks excellent, and the appearance only improves over time, because a greenish patina coating appears. It also protects the material from negative factors, so no additional protective materials are used. You can see such tiles on some old houses.

Since the most common metal tile made of galvanized steel, then we will focus on this material.

No. 2. Advantages and disadvantages of metal tiles

The metal tile is catching up in popularity slate. It was brought to the market leaders in roofing materials. numerous benefits, among which:

simplicity and high speed of installation, because the area of the sheets of material is large. This, in turn, allows us to talk about a small number of seams, and therefore about high strength the roof;

simplicity and high speed of installation, because the area of the sheets of material is large. This, in turn, allows us to talk about a small number of seams, and therefore about high strength the roof;- light weight. Metal is a relatively lightweight material, which reduces transportation costs, reduces the load on the foundation and the rafter system. Weight 1m2 metal tiles range from 4 to 7 kg;

- durability. Manufacturers give a guarantee for their products for 10-15 years, but subject to proper installation and operation, the material can last for 50 years;

- weather resistance. Due to the protective polymer coating, the material easily tolerates high humidity, high and low temperatures, and rain and melted snow will flow freely from the smooth surface of the material;

environmental and fire safety. The metal tile does not emit harmful substances and does not burn;

environmental and fire safety. The metal tile does not emit harmful substances and does not burn;- wide color gamut. Each more or less large manufacturer offers about a dozen different colors of the material, not to mention several options for the shape of the profile;

- ease of maintenance. It is enough to check reliability only once a year. fixtures;

- relatively low cost. The material itself and the cost of its installation are low, in addition, there is no need to strengthen the foundation.

There are metal tiles and some limitations:

increased noise during rain and wind, but this can be avoided by organizing normal soundproofing. In those houses where the installation of metal was performed in accordance with all the rules, there is no specific noise during rain;

increased noise during rain and wind, but this can be avoided by organizing normal soundproofing. In those houses where the installation of metal was performed in accordance with all the rules, there is no specific noise during rain;- large material losses when arranging roofs of complex shapes. On the other hand, the cost of the material is not so high, so in some cases its use is justified;

- violation of the protective layer of the material can lead to corrosion;

- limitation of the angle of inclination of the roof slope. It is desirable to use a metal tile for arrangement roofs with a tilt angle of more than 14°otherwise, there may be problems with snow melting, which may be interfered with by the raised protrusions of the material.

The existing shortcomings are not able to cross out the numerous advantages of metal, which today is used to equip buildings for various purposes.

No. 3. Steel sheet thickness

When choosing a metal tile, first of all, attention must be paid to the thickness of the steel sheet. From this parameter material strength depends and ease of transportation. Standard thickness - 0.5 mm. Such a metal tile can be used for roofing of residential, public and industrial buildings. Some manufacturers today offer a material with a thickness of 0.55 mm - it is even more durable and tough, it is used where increased demands are made to the roof.

On sale today it is easy to meet a metal tile with a sheet thickness of 0.45 mm. Such material is much easier to deform, therefore, it can be used to equip only outbuildings, pergolas, canopies and other similar objects. 0.4 mm thick sheets poorly suited even for these purposes, they are difficult to transport and assemble, since thin material is easily deformed.

You can distinguish 0.4 mm thick sheets from similar ones with a thickness of 0.5 mm even by weight - the first ones are 25% lighter. More accurate results will give micrometer check, which is better to arm yourself before buying metal, so as not to fall for the tricks of unscrupulous sellers.

Number 4. Galvanizing quality

Standards are intended to use 275 g of zinc per square meter of metal. This layer provides reliable protection of the material and allows the manufacturer to give him a long-term guarantee. To save money, some manufacturers use 220 and even 180 g of zinc per square meter. The cost of such material, of course, is lower, but it will also serve less.

Standards are intended to use 275 g of zinc per square meter of metal. This layer provides reliable protection of the material and allows the manufacturer to give him a long-term guarantee. To save money, some manufacturers use 220 and even 180 g of zinc per square meter. The cost of such material, of course, is lower, but it will also serve less.

Recent studies have proved that the use of aluminum in a galvanized layer can improve the degree of protection of the material from negative atmospheric effects, so you can safely opt for such a metal tile.

No. 5. Type of polymer coating

The polymer coating has an additional protective function. The layer must be uniform. over the entire surface of the sheet, otherwise over time, the metal tile under the influence of sunlight will fade spots.For applying a decorative protective layer, different polymers can be used, which differ in stability, strength and other performance characteristics, as well as in cost.

In the production of metal tiles, such types of polymer coating:

- glossy polyester, or polyester enamel - the cheapest coverage. It has high ductility, resistance to ultraviolet rays, corrosion resistance, can be used in any climatic zones. Such a polymer coating is very delicate, it is easy to damage it during transportation and installation, so ideally scratches after all work is better to paint over with a special paint. The thickness of the polymer layer is usually 25 microns, but there are products where this parameter reaches only 18-20 microns - such a metal tile is not suitable for use as a roofing material, it can be used only indoors;

- matt polyester. It differs from a glossy analogue not only with a more noble matte surface, but also with improved performance. The coating is applied with a thickness of 35 microns, characterized by high ductility, increased resistance to ultraviolet rays, as well as resistance to mechanical damage;

- plastisol - more expensive and durable coating based on polyvinyl chloride and plasticizers. It is applied with a thickness of 200 microns, which ensures increased resistance to damage and the ability to create a texture pattern on the polymer layer with imitation of leather, birch bark and other materials. A metal tile with such a coating is difficult to scratch, it is characterized by durability and high color fastness. The main disadvantage of the material is its low resistance to high temperatures, so in hot climates it is not recommended to use it;

- pural. The coating can be matte and glossy, made on the basis of polyurethane, applied with a layer thickness of 50 microns. It has the highest resistance to fading, boasts wear resistance, high strength, resistance to aggressive environments and mechanical damage, easily tolerates temperature jumps, can be used in any climatic conditions and even in areas with high humidity and salty air. Minus is the price. A metal tile with a pural will cost more than with any other coating;

- polyvinyl fluoride coating applied with a thickness of 25-30 microns, consists of acrylic and vinylidene fluoride. It has a glossy surface, resistance to aggressive environments and ultraviolet rays.

There are other types coatings that are used much less frequently:

- Prisma - a coating based on polyurethane and an alloy of aluminum and zinc, developed at the Corus factory in England. It has increased resistance to mechanical damage and corrosion. Such coverage is guaranteed for 15 years;

- TerraPLEGEL - multilayer protective coating, consists of two layers of polymer, quartz sand and a layer of polyester. Using sand allows you to achieve the highest strength. The rough surface of the coating imitates the natural tile quite accurately;

- Solano possesses texture with dot stamping. A polymer layer with a thickness of 200 microns allows you to reliably protect the metal from corrosion and mechanical damage. The warranty for such coverage is 50 years.

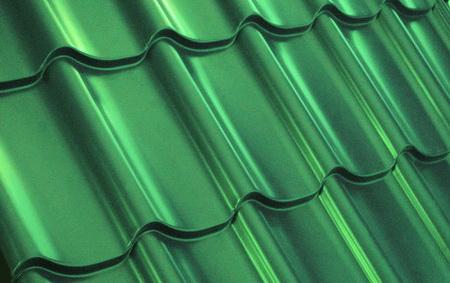

No. 6. Color of metal

The color of the roofing material is selected depending on your own preferences, architectural design and color facade. The most popular shades of metal - dark green, dark red and chocolate brown, but there are several dozen available options. When choosing, it is worth considering that the roof of dark shades will warm up more. There is an opinion that it is better to choose a metal tile of lighter shades, the main argument in favor of which is less noticeable fading.The shade can be anything - a quality-made material will fade evenly without staining.

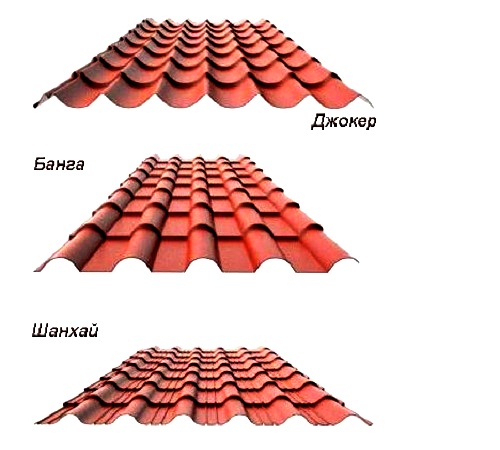

Number 7. Type of profile metal

Along with a shade, the type of profile also affects the perception of metal. The height, pitch and waveform may be different. Manufacturers produce metal tiles with such main types of profiles:

- Monterrey Such a metal tile strongly resembles natural clay, has a smoothly rounded profile, has gained the highest popularity;

- Cascade. It differs in acute-angled shapes and slightly resembles a bar of chocolate, often used for roofing complex shaped roofs;

- Joker. Such a metal tile is distinguished by the presence of regular waves, from a distance it resembles a natural tile, therefore, it is appreciated by connoisseurs classic style;

- Banga. A profile of this type began to be produced recently; it has an increased wave height;

- Andalusia. The profile has a wave shape, its main feature is the ability to fasten in a hidden way due to the presence of special locks;

- Shanghai. It has a high profile, the presence of waves and several grooves, it looks interesting and unusual, it has been used in the domestic space recently.

Number 8. Tile manufacturers

The popularity of metal has led to the emergence of a huge number of unscrupulous manufacturers. To reduce the cost of production, they do not use the highest quality raw materials and spent equipment, but the accuracy of the sheet size depends on the reliability of the latter. Responsible domestic manufacturers use modern imported equipment, so the quality of their products is not much inferior to foreign counterparts. The difference in the price of metal from a well-known reputable manufacturer and a little-known dubious company can be as little as 10-15% - the savings are not worth the risk, especially since large companies give a guarantee on their products.

When buying, it is worthwhile to clarify the duration of the warranty period and see the quality certificate. Some large companies mark the metal tile with the date of production, the name of the manufacturer and information about the origin of the raw materials.

In the domestic market, the most popular products are manufacturers:

ARECO - A Swiss company operating since 1944. Uses quality raw materials manufactured by the best European companies. The quality of the finished metal tile is the highest, its assortment is wide, but mainly material of green, red and brown shades coated with polyester enters our market;

ARECO - A Swiss company operating since 1944. Uses quality raw materials manufactured by the best European companies. The quality of the finished metal tile is the highest, its assortment is wide, but mainly material of green, red and brown shades coated with polyester enters our market;- Mera system - Swedish manufacturer of high quality metal tiles. Products are coated with plastisol, glossy and matte polyester;

Poimukate Oy - A Finnish company with a long history, a veteran of metal production. During this time, the company has established itself in the local and European markets; many solutions developed by the company's specialists are now used by all manufacturers of metal tiles. New technologies are constantly being introduced here, new types of protective coatings are being explored. The cost of production is very high;

Poimukate Oy - A Finnish company with a long history, a veteran of metal production. During this time, the company has established itself in the local and European markets; many solutions developed by the company's specialists are now used by all manufacturers of metal tiles. New technologies are constantly being introduced here, new types of protective coatings are being explored. The cost of production is very high;- Takotta Is another Finnish metal tile manufacturer with a long history. Products are produced in different colors and profiles, with different types of coatings, a 15-year guarantee for it;

Grand line - A large domestic manufacturer that uses imported automated equipment and imported high-quality raw materials. Products are characterized by precise geometry and a wide range of colors;

Grand line - A large domestic manufacturer that uses imported automated equipment and imported high-quality raw materials. Products are characterized by precise geometry and a wide range of colors;- Metal Profile - one of the leading domestic manufacturers, uses imported equipment and raw materials, produces metal tiles of different colors and with different types of profiles. Depending on the type of protective coating, the warranty period is different, for certain types reaches 12 years.

A beautiful lightweight and durable metal tile will serve faithfully for many years, subject to the choice of high-quality material and its proper installation.

Well just a FIRE article. I think that it will help a lot in choosing a roof covering, and if you added a couple more stores to view the goods, then I think it would be really cool

Yes, it is generally difficult to choose the right metal roof tile; there are a lot of nuances. I ordered metal siding "wood-like"

Cool article!

The article is wonderful and voluminous, the material is very good. I think many will find it useful all indicated, especially manufacturers on which it is worth paying attention.