8 tips for choosing roofing material for roofing

Ruberoid has long established itself as a practical and inexpensive roofing material, and it can also be used as part of a roofing pie. Depending on the type of base and topping, roofing material is used for different purposes, and with the advent of modern varieties of material, the scope of its use has expanded significantly. To make the right choice of roofing material for the roof, you need to know the basic properties of all its types and the features of each of them.

No. 1. Advantages and disadvantages of roofing material

Ruberoid is widely used as roofing and waterproofing material, used for arrangement roofs garages and houses with flat and pitched roofs. The material is sold in rolls, consists of several layers. The basis of the long-known ruberoid roofing cardboardwhich is impregnated with bitumen and protected from above by sprinkling. The latter serves as protection against ultraviolet rays, mechanical damage, increases the waterproofing properties of the material and prevents its bonding in rolls. Topping can be made of different materials, and as the basis today, not only roofing cardboard is used, but more on that below.

Ruberoid is widely used as roofing and waterproofing material, used for arrangement roofs garages and houses with flat and pitched roofs. The material is sold in rolls, consists of several layers. The basis of the long-known ruberoid roofing cardboardwhich is impregnated with bitumen and protected from above by sprinkling. The latter serves as protection against ultraviolet rays, mechanical damage, increases the waterproofing properties of the material and prevents its bonding in rolls. Topping can be made of different materials, and as the basis today, not only roofing cardboard is used, but more on that below.

For all types of roofing material, such common positive traits:

complete water resistant, which allows the use of roofing material as waterproofing material when arranging roofs and foundations, and not so long ago, there was no worthy alternative to it at all;

complete water resistant, which allows the use of roofing material as waterproofing material when arranging roofs and foundations, and not so long ago, there was no worthy alternative to it at all;- low cost;

- the use of modifying polymer additives allows to obtain a material resistant to ultraviolet radiation and temperature extremes. New types of roofing material will last about 15-50 years, depending on the composition.

Traditional ruberoid has significant disadvantage - high sensitivity to temperature extremes. In the heat, bitumen softens, in the cold it becomes too brittle and crack, so the durability of such a material is low - 5-8 years. These disadvantages are corrected by a change in some constituent components in modern roofing material samples, so the demand for the material remains stably high.

No. 2. Type of topping of roofing material

The properties of the roofing material and the scope of its application depend on the type of powder used. Most often, such materials are used as spillage:

coarse powder made of stone chips, labeled with the letter K. Such roofing material can be used as the upper and lower layer of the roofing cake, as well as for organizing waterproofing;

coarse powder made of stone chips, labeled with the letter K. Such roofing material can be used as the upper and lower layer of the roofing cake, as well as for organizing waterproofing;- flake topping from mica slate is indicated in the marking with the letter C. Roofing material of this type can be used to equip the upper layer of the roof;

- roofing material with fine-grained sprinkling from sand (M) can be used as the lower layer of the roof or for arranging waterproofing;

- roofing material with dusting (P) chalk and talcum powder can only be used to equip waterproofing or at the bottom of a roofing pie.

No. 3. Roofing marking

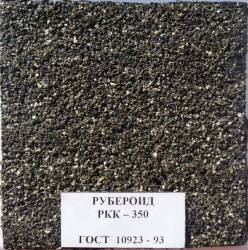

The properties and purpose of the roofing material can be judged by its labeling. According to GOST, the material should be indicated by an alphanumeric abbreviation of the type RKP-300, where the second letter indicates type of roofing material (K - roofing, P - lining), and the third - about the type of topping. The number indicates cardboard brand, which underlies the roofing material, and speaks of its density in g / m2. For example, the marking RKK-400 means that in front of you is a roofing roofing material with coarse topping with cardboard with a density of 400 g / m2. For roofing roofing material, cardboard of brands 350 and 400 is used, and cardboard of brand 300 is used only for the lining roofing material. Sometimes another letter is used in the marking, which speaks about the specific properties of the material: C means that the roofing material will be painted in some color to enhance decorative qualities, E - means that before you is an elastic material.

The most widely used roofing material of these brands:

- RKP-300 - soft roll material, used as the bottom layer of the roofing cake and as a waterproofing;

- RKP-350 can be used as both the lower and upper layers;

- RPP-300 is used only as a lining layer;

- RKK-400 is most often used as the top layer for roofing, has good resistance to negative weather conditions.

Ruberoid is sold in rolls 10-15 m long and 1-1.1 m wide.

Number 4. Roofing material

The traditional roofing material, used as a roofing material for many years, is created on the basis of special cardboard, and this is its weak point. When the bitumen coating loses its main beneficial properties, and the sprinkle disappears, the roofing material has to be changed. To increase longevity today, in addition to cardboard, as a basis for roofing material use:

As a coating can be used not only bitumen, but also tar, a mixture of tar and bitumen, polymers and bitumen-polymer mixtures. The use of new materials as a base and coating has led to the appearance of modern types of roofing material. They are more expensive, but have excellent performance and require detailed consideration.

No. 5. Modern types of roofing material

The most common are such modern varieties of roofing material:

- rubemast - A fairly popular rolled roofing material, is an improved version of the traditional roofing material. It is distinguished by the presence a thicker layer of bitumen from the bottom of the cardboard, and due to the addition of plasticizers and additives, it gets improved performance. This is a cheap material that can last up to 15 years, it is ductile, crack resistant;

- stekloizol has the same structure as a regular roofing material with one exception - instead of cardboard is used fiberglass or fiberglass. Atactic polypropylene is used as a protective layer. It turns out a durable, flexible and elastic material, resistant to decay, high and low temperatures (can withstand temperatures from -45 to +100aboutC), with excellent heat and soundproofing properties. It can be roofing and lining. To take full advantage of the material, it is necessary to comply with all the nuances of installation, and only professionals can do it;

- self-adhesive ruberoid. This material appeared on the market quite recently, it does not require heating during installation, since the lower part of such roofing material is made of a special substance covered with a protective film. Installation of the material is very simple, does not require careful preparation of the roof surface. The color of the material is dark gray, used where it is not possible to use an open flame. Service life is not the highest - up to 10 years;

- only. The basis of the material is also roofing cardboard, but it is impregnated with coal or shale tar products, has mineral sprinkling, and is produced in rolls. Roofing has high biostability, excellent hydro and vapor barrier properties.It is recommended to lay the material in several layers in order to achieve a longer service life, because only it is even less durable than the traditional roofing material. Today it is used mainly as a temporary roofing;

- glassine. It is based on roofing cardboard, impregnated with soft oil bitumen, and has improved performance compared to ordinary roofing material. It is used as an independent roofing material, as part of a roofing cake, sometimes even used for foundation waterproofing. Durability of about 12 years;

- hydroisol It is made on the basis of asbestos paper impregnated with oil bitumen. Used as an independent roofing material, can be used for coating pipelines. Withstands temperatures up to +80aboutC, color - black;

- armored roofing material - A type of ordinary roofing material, characterized by a higher density of cardboard used (its density is 500g / m2 and above) and colored sprinkles. Such material is more resistant to ultraviolet rays, its service life reaches 15 years;

- uniflex - polymer-bitumen material, is produced using rubber, due to which excellent indicators of frost and heat resistance are achieved. Basis - fiberglass, polyester or fiberglass. It can be used as an independent roofing material, as part of a roofing cake, for arranging ventilated roofs, a service life of up to 25 years;

- reinforced roofing material They are made on the basis of fiberglass, which is reinforced with a special mesh and covered with a bitumen-polymer composition. The material has increased resistance to mechanical damage, can withstand severe loads, which due to the reinforcement are evenly distributed over the entire area. Granite or slate is used as a sprinkle. Such a roofing material is not susceptible to the formation of fungus, has high adhesion to various bases, one layer of it replaces 3-4 layers of a regular roofing material. Service life reaches 18 years;

- isospan and bicrost can be used only for waterproofing or as a subroofing film.

All modern types of roofing material based on fiberglass or polymer are often grouped euroruberoids. The latter are sometimes referred to as liquid roofing material or liquid rubber. This material is obtained from a mixture of bitumen, polymers, rubber, plasticizers and mineral additives, it is applied to the surface with a roller or spray, forming a seamless and easily repaired surface.

No. 6. Installation method of roofing material

Depending on the characteristics of the substances used in the production, roofing material can be mounted in different ways. According to the type of installation, roofing material is divided into the following types:

- surfaced. This type includes the traditional roofing material and all modern materials coated with bitumen. Previously, only such an option was used for laying roofing material. Installation consists in heating the lower layer of bitumen with a gas burner, it melts, becomes sticky and elastic, due to which it is fixed to the roof. During installation, toxic substances are released, there is a high risk of burns, special equipment must be used;

- self adhesive. The material has already been mentioned above, the installation is carried out due to the presence of an adhesive coating on the bottom of the roofing material. You don’t have to heat anything, you just need to remove the protective film and press the material to the base;

- bulk. It is applied by spray, roller or brush. It is unnecessary to use the burner, installation and repair of damaged coating is simple.

Number 7. What should I look for when buying?

When buying a roofing material, you must carefully examine it:

on each roll there should be a marking by which it is possible to judge the possible scope of use of the material. In addition, the roofing material must have a mark of compliance GOST 10923-93;

on each roll there should be a marking by which it is possible to judge the possible scope of use of the material. In addition, the roofing material must have a mark of compliance GOST 10923-93;- The material must not have cracks, creases or tears. Cracks are allowed only on the edge and not more than 2 cm long;

- in the cut of roofing material there should not be light areas and areas without impregnation, the impregnation layer should be uniform;

- Rolls should be packed in thick paper and transported on special supports.

Number 8. Large manufacturers of roofing material

In the construction market, ruberoid is represented mainly by products of domestic manufacturers. In conditions of high competition, each manufacturer is trying to introduce advanced technologies in their production and improve product quality.

The largest domestic manufacturers of roofing material:

group of companies "TechnoNICOL" includes several production sites across the country. All enterprises are equipped with modern computerized production lines, a research laboratory operates, which produces control of products. The traditional ruberoid, bicrost, glassine, rubemast, uniflex and other materials are produced.

group of companies "TechnoNICOL" includes several production sites across the country. All enterprises are equipped with modern computerized production lines, a research laboratory operates, which produces control of products. The traditional ruberoid, bicrost, glassine, rubemast, uniflex and other materials are produced.- Omskkrovlya OJSC The company has been operating since 1970 and uses West Siberian oil as a raw material. The products have passed the test of time, meet the most stringent quality standards, and therefore are used not only in all regions of Russia, but also abroad. The plant produces traditional roofing material of various modifications, rubemast and glassine;

LLC "Yugstroykrovlya" - a relatively young company that managed to become one of the largest manufacturers of rolled roofing materials in the southern region. The manufacturer makes various types of roofing material, modern weldable coatings based on fiberglass, including rubemast and steklohydroizol;

LLC "Yugstroykrovlya" - a relatively young company that managed to become one of the largest manufacturers of rolled roofing materials in the southern region. The manufacturer makes various types of roofing material, modern weldable coatings based on fiberglass, including rubemast and steklohydroizol;- CJSC Soft Roof - Samara plant with more than 80 years of history. It is one of the leading domestic enterprises producing rolled roofing materials. Products are used in industrial and civil engineering in all regions of the country. It produces traditional roofing material of different brands, as well as reinforced roofing material and glassine;

CJSC Diversified Production Company KRZ - Ryazan company with a long history. Once it provided roofing material to the entire central part of Russia, over time, the range of products was expanded by other roofing materials. Today it is a high-tech enterprise equipped with modern production lines. Among other things, ruberoid of various brands, glassine and rubemast are produced here.

CJSC Diversified Production Company KRZ - Ryazan company with a long history. Once it provided roofing material to the entire central part of Russia, over time, the range of products was expanded by other roofing materials. Today it is a high-tech enterprise equipped with modern production lines. Among other things, ruberoid of various brands, glassine and rubemast are produced here.

Despite the emergence and widespread use of many other roofing materials, roofing material continues to enjoy stably high demand. Its modern types allow you to inexpensively equip a durable, reliable and durable roof.

Everything is great described, thanks!