11 tips for building a concrete pool and decorating the walls of the pool in the country

Fans of water procedures sooner or later come to the idea of constructing their own pool on a summer cottage or suburban area. There are a lot of options for its arrangement, and there are inflatable and frame pools on sale, which are inexpensive and can be mounted very quickly. If the main requirement for the pool is durability, strength and ability to withstand frost, temperature extremes and mechanical damagethen it’s better to opt for concrete bowl. You won’t be able to buy the finished one, so you’ll have to bother and fill the pool of a certain shape. This can be done by resorting to the services of specialists, or you can do it yourself - the process, although time-consuming, is quite feasible with some skills, and significant savings. So, what are the stages of the construction of the pool of concrete and what materials can be used to finish the walls and bottom of the pool? We study the subtleties of the process and evaluate your own strengthto decide whether it will be possible to do all the work with their own hands, or whether at least partial help from professionals will be needed.

Before you start arranging a stationary concrete pool, make sure again that this is the best option, and it fully meets the requirements of the family and the frequency of rest by the water:

- if you go to the cottage weekend only, and it’s not always, it’s better to choose inflatable pool;

- if the pool will be operated throughout the summer season, and the family is large, it is better to pay attention to more durable collapsible frame pools. They can generally be after the swimming season disassemble and store;

- if there is a place, means, skills and high requirements for the strength of the pool structure, then the best choice is to create a concrete bowl for it. It will turn out more expensive than buying an inflatable or frame pool, but this is a capital structure that can be operated for years.

No. 1. Advantages and disadvantages of the concrete pool

Owners of cottages and suburban areas choose concrete pools thanks to their numerous benefits:

- durability. The design will last at least 25 years, and during this time about a dozen inflatable pools and 3-4 frame pools will become unusable. The benefits are clear;

- aesthetics. For finishing the walls and bottom, you can choose a material of any color, and tiles or mosaics will serve a lot;

- opportunity to equip the pool any size and shape;

- comfort.

The main disadvantages are the cost of arrangement and the complexity of the process. In addition, the functionality and durability of the pool will largely depend on the correct design, the choice of finishing materials and the quality of all technological processes.

No. 2. Do I need a permit to build a concrete pool?

In most cases, you can do without coordination with government services, but if you plan to build a large-scale structure, it is better to issue it in the BTI accordingly, otherwise then the pool will not be in the certificate of ownership. In the future, an already constructed facility may be legalized, but it is easier and cheaper to coordinate everything in advance.

If you are building a pool with a depth of more than 2.2 m, a length of more than 4 m and a width of more than 2.2 m, which will be equipped with a launch pedestal or used for diving from the side, then permission of the Ministry of Emergencies and consumer supervision. In cases where the pool has a decent depth and is equipped diving tower, it will be necessary to approve the project in sports instances, and the construction should be entrusted to specialists, but it is understandable - it is impossible to erect such a structure on your own. It is not difficult to build a small pool for family use on your own, and no documents will be required.

No. 3. Preparatory work and design

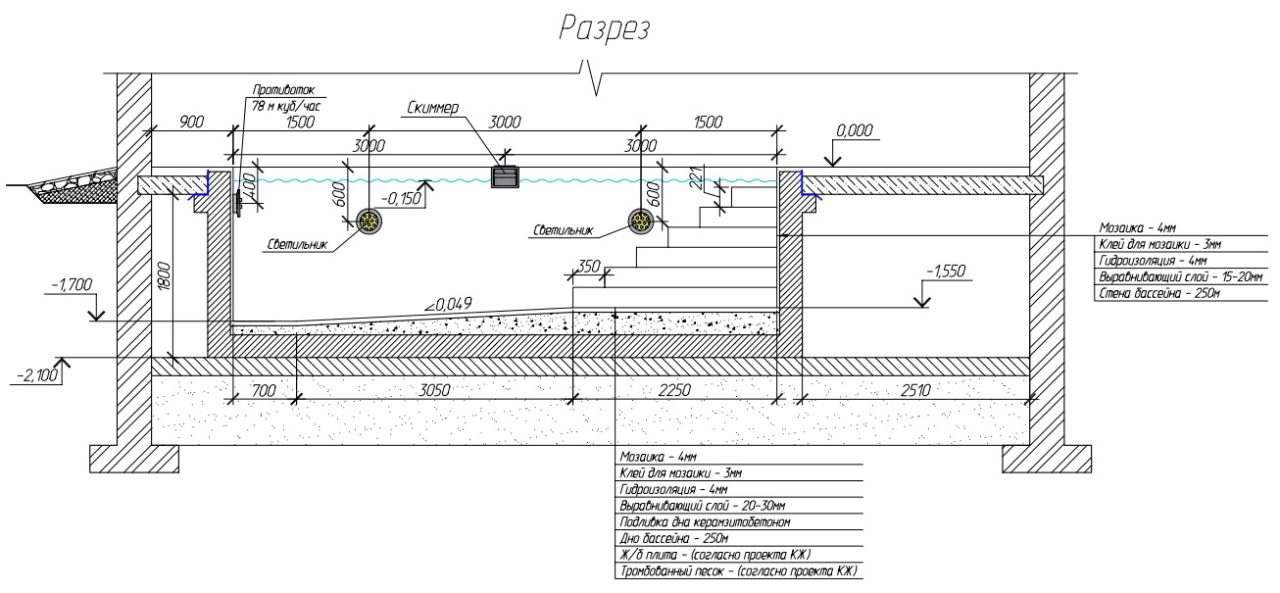

The first stage on the way to the construction of a concrete pool is the creation of a project and the thinking over of all the technical details of the future facility. It is important to immediately determine size and shape of the structure: these parameters directly depend on what place is allocated for the construction, and how many people will swim in the pool. A pool with a depth of 1.5 m and a length of 5.5 m is quite suitable for a comfortable stay, but in case of equipping a diving tower, the depth of the bowl should be at least 2.5 m. Do not forget to take into account that there should be room for normal access around the pool him or for arrangement recreation areas. In addition, it is necessary to provide a place for the installation of all necessary equipment.

To place the pool too close to the buildings is not recommended, so that the shadow does not interfere with the natural heating of the water. Under the crowns of trees, the structure should also not be erected to facilitate future maintenance of the pool.

To create the correct pool project it is necessary to know the features of soils, the level of groundwater, and also take into account the load on the walls and bottom of the pool, which determines their thickness. It is worth taking into account the proximity of neighboring foundations, as well as the depth of underground utilities, the distance to the points of supply and discharge of water and many other points. If you plan to build a more or less large pool, it is better to consult with specialists or even order the design of the future pool from them.

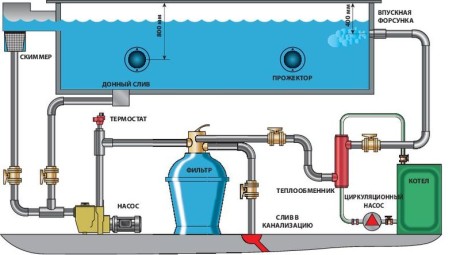

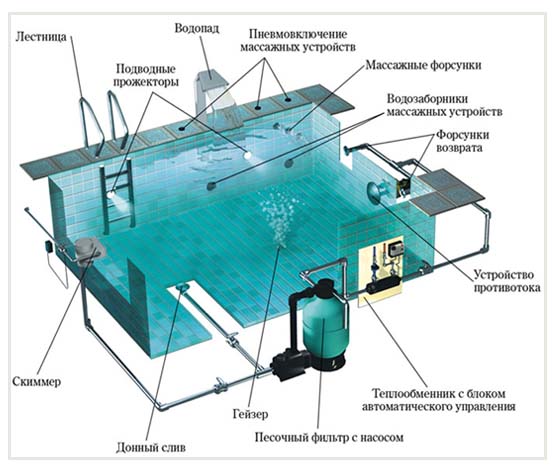

In the preparatory phase it is advisable to determine the budget, choose a facing material for the walls, and also think about acquiring a filtration system, an electric heater, a chlorine generator, arranging a staircase, a canopy, and lighting. Also at this stage water exchange systemwhich may be:

- skimmer. Well suited for pools with right angles. The water line runs through the middle of the skimmer’s window, and the contaminated water enters it under the influence of a circulation pump and through the bottom discharge enters the filtering equipment, where it is cleaned of mechanical impurities, disinfected, heated and returned to the pool;

- overflow. It will cost more than a skimmer, but it will be more effective. Water with such a system reaches the edge of the pool and through the overflow gutters enters the tank with an automatic topping device. From there, the water goes to the cleaning and heating, and then returns to the bowl.

Number 4. Site preparation and digging

The chosen place for digging the pool is enclosed by a strong rope, the margin on the sides should be 1 m for the placement of technical equipment, arrangement of sand and gravel pillows and formwork. Average, wall thickness make about 40 cm - this is for not very large pools. For the smallest structures, the construction of a concrete bowl with a wall thickness of 30 cm is allowed.

Excavation can be done on its own if you need to dig a small pit.Otherwise, you will have to turn to friends, a special team for help, or use appropriate technique. The walls of the pit should not be perfectly vertical: it is better to make a slope of 5-7 degrees to avoid shedding of soil. The bottom of the bowl is also performed with a bias towards the future discharge, this is approximately 3-4 cm per 1 m.

No. 5. Arrangement of sand cushions and waterproofing

Gravel and sand cushion provides even load distribution and high-quality concrete pouring. To create a reliable foundation for the concrete pool bowl, first pour sand layer 20-25 cm thick, and preferably 30 cm thick and carefully tamped. Then poured crushed stone layer 10-20 cm thick and fraction size 20 * 40 mm, it is also carefully rammed. Important when backfilling and tamping do not break the bottom angle. If desired, between a layer of sand and crushed stone can be used reinforced concrete piles, which will serve to further strengthen the structure.

Next stage - concrete foundation. To do this, use ready-made concrete, which is delivered to the place with a special mixer, or else home-made. Since it will be needed a lot, it is better to use concrete mixer. For footing you can use concrete grade B25. You can independently prepare a suitable concrete composition at the rate of 325 kg cement, 625 kg of sand, 1250 kg of crushed stone and 170 l of water per 1 m3. Thickness - 10-15 cm, and the concrete base should be 2-5 cm more from each edge of the future concrete bowl. If the level of the concrete base is below the groundwater level, you will have to additionally equip drainage, for which they dig a trench 25-50 cm wide around the perimeter and cover it with large gravel.

Layer on top of concrete waterproofingwhat is it suitable for roofing material (stacked with an overlap of 15-20 cm), bitumen, liquid rubber or PVC membrane. Waterproofing material should go to the walls 25-30 cm. A cement-sand screed is placed on top of the waterproofing.

No. 6. Reinforcement and arrangement of formwork

In fact, the construction of the concrete basin of the pool is the creation of a typical reinforced concrete structure consisting of reinforcing metal and concrete. For reinforcement choose 8-14 mm ribbed steel bar, for the formation of an oval-shaped bowl, you can use a rod with a diameter of 10 mm, which is sold in bays and has no length limit. Reinforcement mesh equip with cells 20 * 20 cm. Reinforcement is carried out in two tiers, it is desirable to lay fragments under the rods of the bottom of the bowl bricksso that when pouring concrete they remain in the thickness of the mortar. Do not forget to make releases of reinforcement for fastening the frame of the walls.

For the construction of the frame reinforcement knit with wire section of 2-3 mm - welding cannot be used. Welds become a hotbed of corrosion, since during the welding process the structure of steel is violated and carbon is burned. In addition, in the absence of backlash at the joints, there is a strong voltage on the frame during pouring concrete, which can lead to a violation of the integrity of the frame. It is very important to hold frame waterproofingas water can penetrate the concrete and damage the fittings. After assembling the frame, it is treated with polymer paints, double staining can be used, sometimes multilayer staining or polymer mastics are used. After this, you can fill the bottom of the bowl with concrete, ramming it well and getting rid of excess air in its mass.

Reinforcing frame of walls it is built in the same way as the bottom. When assembling the frame, it is important not to forget to leave windows for placement of embedded parts of pool equipment. To fill the walls you need formworkdetermining the shape of the bowl. It is most convenient to make from moisture resistant or laminated plywood - the material bends well and allows you to create any shape of the pool. An alternative is a unified metal formwork.Between themselves, the individual elements of the formwork are connected with screws, metal corners or nails. Internal struts and external supports are fastened carefully, since the weight of the concrete is significant, the distance between them is about 50 cm. The filling is carried out with 50-60 cm belts with mandatory vibration compaction and deaeration.

Number 7. Features of concrete pouring

Since water will constantly influence the bowl of the concrete pool, the choice of concrete is especially carefully chosen. is he should withstand water, be frost-resistant and very durable. Concrete of grade B25 and higher in strength, W6 and higher in water resistance and F100-150 in frost resistance are suitable.

Concreting the pool bowl is done in one of the ways:

- continuous casting;

- casting in two stages.

Continuous fill allows you to get a monolithic bowl - this is a big plus. But for the realization of the undertaking, the coordinated work of several units of equipment will be required, including a concrete mixer and a concrete pump.

Most commonly used concrete pouring in two stages: first make the bottom, then the walls of the bowl. The most dangerous place in this case is the junction through which water can flow. To avoid such consequences, a self-expanding cord with a cross section of 2.5-3.5 cm is used. When immersed in water, such a cord increases significantly in volume and covers all the cracks. During the hardening of concrete, it is better to periodically wet it with water.

Do not forget that for embedded elements it is necessary to equip windows and make formwork. entrance filler and drain pipes and other elements are attached to the frame using wires, otherwise they may be shifted when pouring concrete. If the project involves the arrangement of a smooth entry into the water in the form steps, then they move to their arrangement after the concrete thicket is ready. The principle is the same: installation of formwork from plywood and concrete pouring.

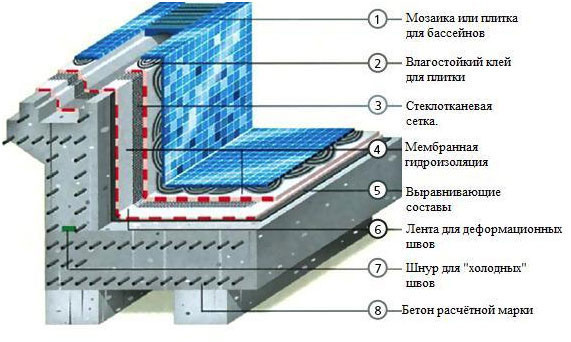

Number 8. Leveling and waterproofing

After the concrete has hardened, it is possible to remove the formwork and carry out ironing with cement milk, for which 3-4 handfuls of cement are dissolved in a bucket of water. The solution is constantly shaken and applied to the surface with a plaster brush. Irregularities must be aligned via plasteringwhich is carried out in one of the following ways:

- grid plaster. In this case, uses the usual sand-cement mixturewhich to provide better adhesion and strength inflict on pre-attached steel plaster mesh;

- applying plaster to glue. The method involves treating a concrete surface with special penetrations with deep penetration. Due to the components that make up their composition, adhesion to the applied layer of plaster, which includes the adhesive polymer, increases.

After plastering is carried out grinding and cleaning. Then executed waterproofingfor which you can use:

After plastering is carried out grinding and cleaning. Then executed waterproofingfor which you can use:

- acrylic and epoxy resinswhich, after application during solidification, form a continuous polymer film;

- penetrating waterproofing. Such products are distinguished by the presence of active chemical components in the composition, which penetrate into the concrete mass, react with calcium hydroxide, forming insoluble compounds based on it. They fill capillaries and all microcracks up to 0.4 mm in size;

- two-component cement-polymer compounds used for waterproofing large pools. They include cement and elasticizers, so even cracks up to 1 mm can be isolated with their help;

- sealing tapes can be used to seal the joints of the walls and the bottom.

When performing waterproofing, special attention is paid to the joints of the walls and the bottom, to the seams that appeared during the pouring of concrete, to the recesses, cracks and places of entry of communications.The choice of waterproofing method largely depends on the final finishing material: it should be perfect for tiles and mosaics, and when using PVC film, all waterproofing works are minimized.

No. 9. Pool of concrete rings and blocks

To simplify their lives, many summer residents go to tricks. Not wanting to deal with formwork and concrete mortar, some use prefabricated concrete blocks. In this case, the installation process is reduced to pouring a flat base and mounting the walls of the blocks. They are fastened with a solution, and every third row is strengthened by a grid. After all this, it remains to carry out waterproofing and decoration.

Another option is to use ready-made concrete ringdesigned to equip wells or sewers. It is mounted on a layer of cement mortar, then, as usual: waterproofing and decoration.

No. 10. Pool wall decoration

For finishing the walls and bottom of the concrete pool commonly used:

- tile;

- mosaic;

- PVC film:

- less often wood or natural stone.

Tiling

For facing the walls and bottom of the pool is better not ordinary ceramic tileused in bathrooms as well porcelain, which has a much lower coefficient of water absorption. Porcelain tile more frost-resistant and heat-resistant, does not absorb dirt, has good ductility. It is better to lay tiles with a rough surface at the bottom of the pool.

Tile laying is carried out on special adhesives. If the bottom and walls are decorated with the same tile, then you can start finishing from the bottom. When the drain is on one side, the tile can be laid in rows, taking into account the angle of inclination. If the drain is located in the center of the bowl, then the installation is carried out at the corners of the triangle. To do this, first determine the lines leading from the corners of the pool to the opposite corners of the drain hole. The bottom will be divided into four conditional triangles, along which the tiles are installed to better take into account the slope. The tiles begin to be laid from the wall row, then the lighthouse row is laid perpendicularly to it, and then they proceed to the installation of horizontal rows.

On the pool walls tile mounted in the same way as on the walls of the apartmentchecking the level and making the same seams. Lay the tile in horizontal rows, and if symmetry is especially important, then start from the middle of the row. The only difference is that the seams must be made thicker so that the water pressure does not cause cracks in the tile. Seams are processed frost and moisture resistant grouting.

Mosaic finish

The installation of the mosaic is much like the installation of tiles. It is a wear-resistant, durable material with a beautiful appearance. The best choice - glass mosaic, which absolutely does not absorb moisture and is distinguished by record longevity, however, such material is not cheap. A more affordable solution is ceramic mosaic. With the help of mosaics, you can create interesting ornaments, lay out panels, and some combine the tiles with mosaics to reduce the cost.

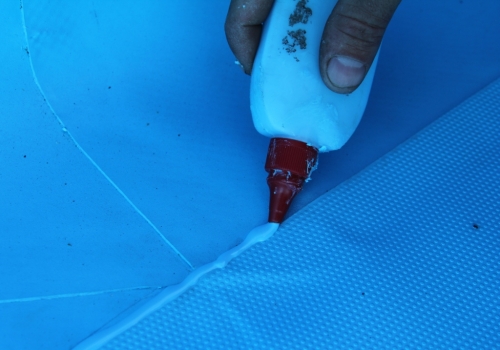

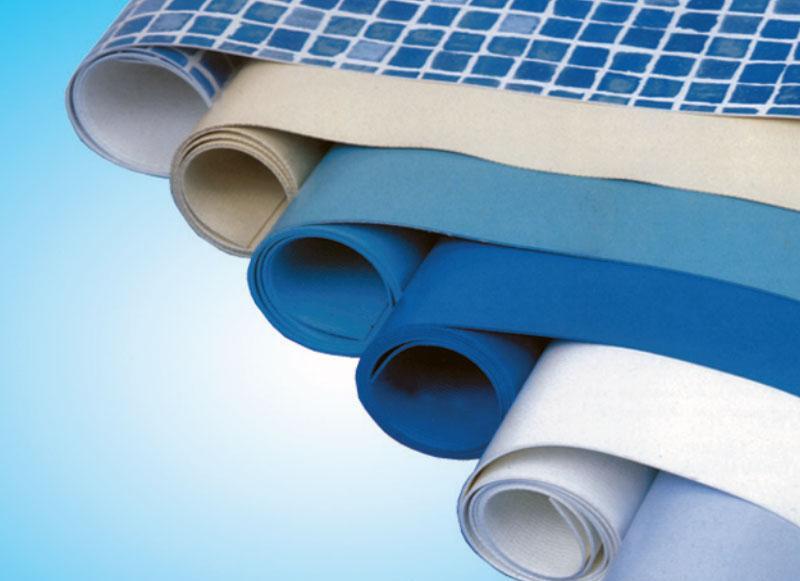

Pvc film

Pvc film differs in the low price, excellent waterproofing qualities, ease and relative simplicity in laying. It withstands the effects of sunlight, temperature extremes, chemicals, easy to clean. Among the minuses is not a record longevity, it will last on average for 7 seasons.

The film thickness, as a rule, reaches 1-1.5 mm, it consists of 4 layers, one of which must be a strong synthetic material, for example, polyesterol or Kevlar. At the moment, these types of films are used to equip pools:

- polyvinyl chloridebased on plasticized PVC. The material is treated with special impregnations to protect against fungus and bacteria, the appearance is diverse;

- butyl rubber film It has the best indicators of durability and strength, it easily tolerates temperature extremes, severe frosts, it can be cut with scissors and glued.Ideal for large outdoor pools.

Under the film it is important to use geotextile. The material itself is mounted with an overlap, fixed by hot welding, the seams are sealed with hot PVC. This is followed by stretching the coating along the walls of the bowl and welding it to a pre-mounted mounting strip. The final stage is the welding of the film in the inner corners of the pool. Everything is clearly described in visible.

No. 11. What else to consider?

Think about the need canopy: It not only protects the pool from some pollution, but also allows you to maintain the warmth of the water. You can choose a ready folding canopy - these are not very expensive designs that are difficult to create on your own. Alternative - metal frame construction and installation polycarbonate, you end up with something like greenhouses.

After the construction of the concrete bowl and its lining, all the necessary equipment is installed for filtering and heating the water. Hydrotechnically the pool device is similar to a bathbut the drain is slightly different. It is equipped with a damper and a multi-turn shut-off valve: when discharging water, it will first be necessary to move the damper, and then open the valve, the siphon on the drain will not be equipped, the outlet pipe should be at least 60 mm in diameter. As for the heating of water, a boiler is usually used, sometimes special solar heaters for pools. Also think about lighting pool.

The construction of a concrete pool is not an easy task, and if it is still quite possible to equip a small bowl with your own hands, then a massive construction will require professional help. Before starting construction, evaluate your own capabilities and budget well - this will help save your nerves and time.