7 tips for warming the house with expanded clay: floor, walls, roof, foundation

Lightweight, durable and durable expanded clay is made from natural raw materials and has high thermal insulation qualitieswhile costs much cheaper than similar materials. He also has some disadvantages, but subject to all installation conditions, they are nullified. We deal with the basic properties of the material and the features of house insulation with expanded clay, the nuances of its use in the thermal insulation of floors, walls, roofs and foundations.

No. 1. Expanded clay: production and fractions

For the production of expanded clay use low-melting clay grades with a quartz content of 30%. They are processed in special chambers, where they are heated to a temperature of 1050-13000C for 30-40 minutes, as a result of which there is expansion and formation of porous granules with a melted hermetic shell, which gives the material the necessary strength. The more pores in expanded clay, the better.

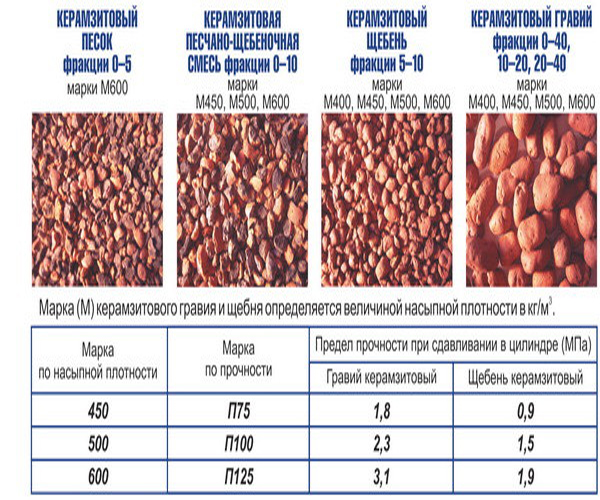

In the production process, as a rule, granules of different fractions:

- expanded clay sand with a granule size of up to 5 mm;

- expanded clay crushed stone - granules resembling cubes in shape;

- expanded clay gravel - granules of oblong shape.

Expanded clay size of granules of such fractions is allocated: 5-10 mm, 10-20 mm and 20-40 mm.

No. 2. Advantages and disadvantages of expanded clay

Expanded clay gained wide popularity not only thanks to low pricebut also at the expense of others the benefits:

- good heat-insulating qualities. The coefficient of thermal conductivity is 0.07-0.16 W / m * K. Frankly, this is not the highest result among all heaters, but expanded clay expanded on competitors in many other respects;

- great sound insulation;

- high strength and preservation of the original form under the influence of high and low temperatures;

- fire resistance and frost resistance, achieved due to the "hardening" of expanded clay in the manufacture;

- light weight. All 1 m3 expanded clay from 250 to 800 kg;

- inertness to moldfungus and rodents;

- due to flowability it can fill a cavity of any shape and size, used to insulation of floors, walls, foundation and roof;

- resistance to aggressive chemicals;

- environmental friendliness;

- durability;

- installation can be done independently - no specific equipment is needed.

Among disadvantages:

- insulation layer cannot be thin;

- the tendency of granules to dust formation, so when working with expanded clay it is better to use a respirator;

- expanded clay is able to absorb moisture. He gives up the accumulated moisture, but very slowly, so it is better not to use the material in very damp rooms, but in any case it will be necessary to equip the waterproofing layer.

No. 3. Physicotechnical properties of expanded clay

When choosing expanded clay for home insulation, pay attention to its properties such as:

- bulk density material determining the weight of 1 m3 expanded clay, indicated in stamps and may be from 250 to 800 kg / m3, in total 10 brands are presented. Expanded clay of the M400 brand has a density of 400 kg / m3, eg. The lower the density, the better the thermal insulation qualities;

- strength. The higher the weight of expanded clay, the greater should be its strength so that the material does not collapse under the pressure of its own weight.Strength for expanded clay M400 should be at least P50, for expanded clay M450 - P75, etc .;

- strain factor shows shrinkage of material. Allowable value of 0.14 mm / m;

- coefficient of thermal conductivity a good expanded clay is 0.07-0.16 W / m * K, a lower-quality material has a coefficient of 0.2 W / m * K and higher, it is better not to take it for insulation.

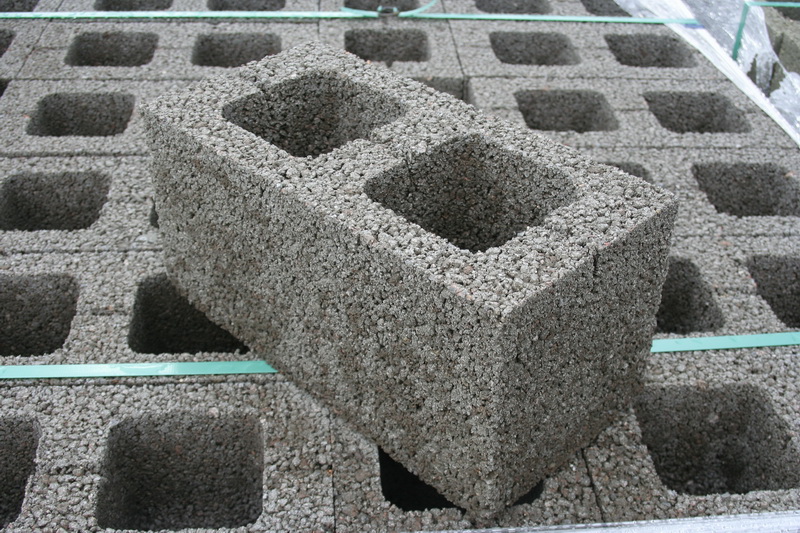

Due to its properties, expanded clay has a wide scope of application. It is used as a filler in production. expanded clay blocks, as a decorative and drainage material, but still the main area is thermal insulation, and not only structures, but even soil.

Number 4. Expanded floor insulation

Expanded clay - one of the most suitable materials for floor insulationespecially if the budget is limited. Warming can be done in one of several existing ways.

Classic version provides for the following sequence of actions:

- thorough cleaning of the floor surface from dust and dirt;

- laying a layer of waterproofing, which is used as a durable plastic film, to connect it, you can use construction tape. The edges of the film should go on the walls above the expanded clay level with a screed;

- previously it is better to mix expanded clay of different fractions in order to get maximum strength and thermal insulation;

- putting beacons, on which a layer of expanded clay will be poured. The first lighthouse is installed at a distance of 2-3 cm from the wall, the rest are mounted parallel to it at a distance of the length of the rule, which will subsequently align the solution. This stage should be given attention, since it depends on how smooth the floor will be after performing the screed. Lighthouses are made of metal profiles or pipes, which are put on piles of strong cement, gypsum or alabaster mortar. Guides carefully level using level;

- expanded clay filling, its careful ramming and leveling. The layer should be at least 10-15 cm in order to achieve thermal insulation qualities, this must be taken into account when calculating the level of floors;

- preparation of cement milk (cement slurry) and pouring a layer of expanded clay. This is necessary to give it strength, otherwise during subsequent pouring screed mortar its level may be impaired. You can reinforce the surface with a metal mesh - this will provide it with additional strength;

- pouring the floor with a finishing cement screed about 3 cm thick. The mortar begins to be poured from the walls, opposite the door and stretched as a rule to obtain a flat surface. In a week you can walk on this floor, but it gains its final strength after a month. At this time, you can periodically wet the surface with water, preventing the appearance of cracks.

You can do without the time-consuming process of preparing the mortar and pouring the screed, using simplified dry technology:

- vapor barrier is laid on the surface of the main floor;

- expanded clay is poured along the lighthouses, for reliability it can, of course, be fixed with cement milk;

- dense gypsum-fiber sheets are laid on expanded clay, which are fastened with glue.

It’s similar to the dry method lag insulation option:

- laying a vapor barrier layer;

- installation of impregnated wooden blocks antiseptic. To get a strictly vertical level, you can use wooden linings. The bars are fixed to the floor using self-tapping screws in increments of 0.5 m;

- expanded clay is poured clearly along the upper edge of the bars;

- covering the structure with a vapor barrier layer;

- laying plywood, chipboard, OSB, after which you can mount the finishing floor.

No. 5. Wall insulation at home with expanded clay

Expanded clay is used for wall insulation three-layer masonry method, which is applicable only for newly built houses: the first layer is the load-bearing wall, the second layer is expanded clay with cement milk, the third layer is the exterior finish. There are three technologies:

- masonry with horizontal three-row diaphragms. Together, two parallel walls are being erected, one of them with a thickness of brick, the second - in half of the brick, the distance between them is 15-25 cm. After laying every fifth row in the cavity, a heater is poured, rammed and poured with cement milk, after which they are laid out of the brick in three rows, the corners are made without cavities for greater strength. After completion of work, the outer layer finished with facing brick, plaster or other material;

- well masonry involves the construction of two walls at a distance of 15-35 cm from each other and their dressing through a row with jumpers of 70-110 cm. Well cavities are covered with expanded clay and filled with cement milk;

- embedded masonry also involves backfilling with expanded clay space between two parallel walls as they are erected. Walls are connected to each other with brackets from reinforcement.

If insulated walls frame house, then expanded clay insulation must be very carefully tamped. Walls wooden house most difficult to insulate expanded clay. Since its thermal insulation properties are slightly worse than that of its closest competitor - mineral wool, it is necessary to leave cavities with a thickness of 20-40 cm, and this is a significant load on the bearing walls, so an additional foundation will have to be made outside. The complexity of the technology and the cost of all additional manipulations practically negates the efficiency of expanded clay insulation, so for wooden houses it is better to consider another option for wall insulation.

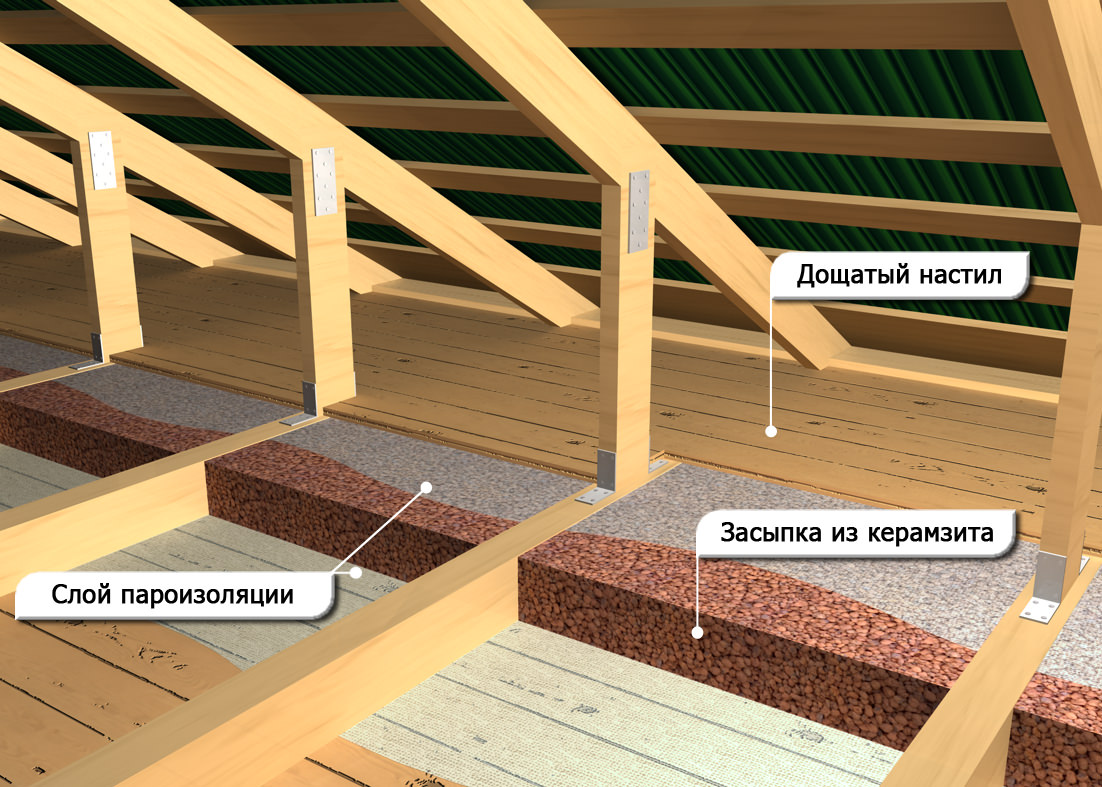

No. 6. Roof insulation with expanded clay

The process of roof insulation resembles the technique of floor insulation with expanded clay. It’s easy to do all the work yourself:

- flooring vapor barrier. You can use glassine, plastic wrap, foil or styrofoam;

- some masters advise fixing a layer of vapor barrier with soft clay, but you can do without it;

- expanded clay filling, and it is recommended to take expanded clay gravel, which fills all cavities well, sometimes it is mixed with polystyrene foam crumb. Expanded clay is well compacted, after which it is possible to perform a screed for greater structural strength;

- flooring roofing materialwith which a layer of expanded clay is pressed. Installation is carried out lapped, the seams are isolated with tape or bitumen mastic;

- styling roofing material.

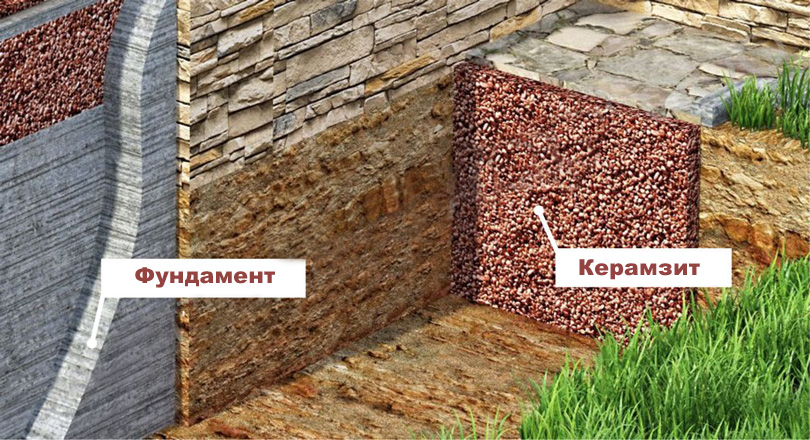

Number 7. Warming of the foundation with expanded clay

You can also insulate the foundation with expanded clay with your own:

- the foundation is freed from the ground, a trench is pulled out with a width of about 80-100 cm;

- performance foundation waterproofing bituminous mastic of hot or cold application, or a rolled roofing material. Under the mastic, it is necessary to apply a special primer that dries in 2-3 hours;

- in places of high occurrence of groundwater, it is necessary to arrange drainage around the house to effectively remove moisture and ensure a longer service life of expanded clay, which is afraid of humidity. At a certain distance from the house, a foundation pit is dug with a depth below the level of the foundation, and they are laid at the bottom geotextile, they fill it with rubble and lay pipes with holes, they fill it with rubble, cover it with the edges of geotextiles and fill it with sand;

- laying film on top of waterproofing. It should completely cover the foundation, and on the soil side should be approximately at the level of drainage. After this, expanded clay is poured and rammed;

- installation of the blind area, for which, along the perimeter of the building, formwork 10-15 cm high is performed, a reinforcing mesh is laid in it and poured with concrete.

Cheap and environmentally friendly expanded clay can become a reliable thermal insulation, provided that reliable waterproofing is performed.

In my experience, the best insulation is expanded clay with foam. baby + screed. Thanks for the post.