7 tips for choosing pipes for a warm water floor

Water underfloor heating is a solution to the problem of arranging the most comfortable home. It allows you to effectively distribute heat in the house, and, unlike the electrical analogue, requires low maintenance costs. It is not surprising that systems of water heat-insulated floors are becoming increasingly popular and often become an independent source of heat in the house. The quality of such a system and its durability equally depend on the selected materials and professionalism of installation. With features pipe selection we will understand in more detail for a warm water floor, and it is better to entrust their installation to your own peace of mind for specialists.

No. 1. Pipe requirements

The water system of underfloor heating has more than enough advantages. This is cost-effectiveness, and uniform heating, and durability, and the ability to adjust the temperature, and the lack of heating radiatorswhich often only interfere with organizing a dream interior. The easiest way is to arrange heating with a water heated floor in a private house - in a high-rise building, the task is much more complicated. It will be necessary to reconstruct the existing heating system or install your own electric boilerso as not to disrupt the heating system of the whole house and not to take away heat from neighbors.

Reliability and durability of a warm floor depend in many respects on pipes, which will have to be under the screed for decades, while maintaining integrity and tightness. They are nominated by such requirements:

- durability and ability withstand pressure and temperature drops. Pipes designed for hot water supply are not suitable. Pay attention to products known and reputed manufacturerswhich give a guarantee for pipes of 50 years and more;

- reliable insulation and tightness, because the heating system must be protected from oxidation;

- elasticity and bending stability. During installation, the pipes are bent to achieve uniform floor heating, so during their installation and further operation they should not break and crack, thereby violating the tightness of the system;

- optimal pipe diameter - 16 or 18 mm, while the height of the floor increases slightly, and the need for additional equipment to ensure normal hydraulics of the system disappears;

- the expansion coefficient should be 0.25 mm / mK, thermal conductivity - 0.43 W / mK.

In underfloor heating systems, mainly metal-plastic and polyethylene pipes are used, less often - copper, polypropylene and corrugated steel pipes. Norms forbidden to use cast iron pipes.

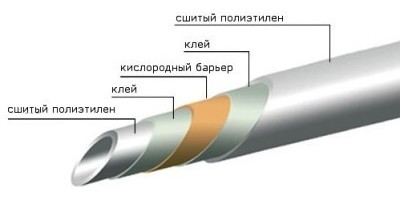

No. 2. Metal-plastic pipes for underfloor heating

Plastic pipes almost the most widespread. Durability and excellent performance are explained multilayer structure of the material. The inner layer is extruded cross-linked polyethylene, which is responsible for the performance of the pipe. Next is a layer of aluminum, which is attached to polyethylene with a special adhesive. Aluminum foil protects against penetration of oxygen into the pipe and inhibits linear expansion and contraction. The thickness of this layer is 0.2-0.25 mm, depending on the diameter.The foil is welded butt or lap, a sealed layer is obtained. On top of the foil is another adhesive layer that holds it together with an external protective layer of polyethylene.

A similar structure allows us to talk about numerous advantages of metal-plastic pipes:

- excellent flexibility and ability to keep a good shape after bending;

- thermal conductivity, which is provided by a layer of aluminum, and resistance to damage and overgrowth through the use of polymer;

- the installation of such pipes does not require the use of specific equipment, so it will be inexpensive;

- high durability;

- ability to withstand temperatures up to 1100With no change in basic performance;

- resistance to corrosion and aggressive environments;

- light weight;

- good soundproofing. The sound of the coolant moving through the system will be inaudible.

Among disadvantages inadmissibility of twisting pipes and bending about the axis, which must be remembered during installation. It is also important to consider the property of the aluminum layer to be damaged by repeated bending.

No. 3. XLPE pipes

The main competitor to plastic pipes is cross-linked polyethylene pipes. The main indicator of product quality is the quality of the weld, which can be judged by crosslink density. The recommended value is 60-85%, processing can occur in different ways:

- when cross-linked with peroxide, a density of 75% is achieved, this is the most preferred method. Such pipes are labeled as PE-Xa;

- when crosslinked by silane, a density of 65% is obtained;

- when irradiated with an electron flux in a magnetic field, the crosslink density reaches 60%.

The abbreviation may indicate crosslink density range: HDPE is the highest density pipe, MDPE is the medium density, LDPE is the lowest.

Benefits:

- ability to withstand the temperature of the coolant up to 1200FROM;

- resistance to temperature and pressure drops;

- light weight, sufficient internal cross section with a relatively small diameter;

- strength;

- sufficient flexibility. The minimum bending radius for such pipes is 5 diameters, and this is enough to install an effective system of underfloor heating;

- relative ease of installation;

- low price.

disadvantages:

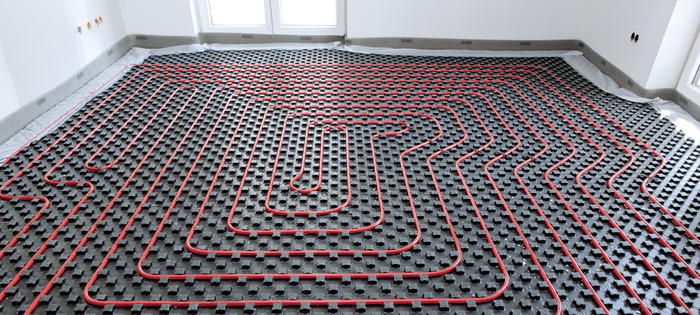

- the need to rigidly fix the pipe when laying, otherwise it may bend. For fixing, use reinforcement or a special substrate, you need a large number of fasteners to fix the pipes in the required shape;

- during installation it is not difficult to damage the pipe, therefore it is necessary to work with a certain degree of caution.

Pipes made of cross-linked polyethylene are produced with a diameter of 10 to 110 mm, the length reaches 200 m.

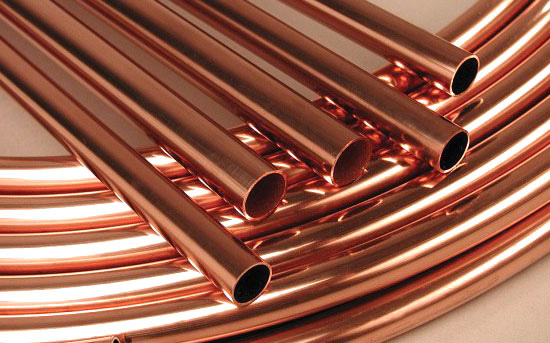

Number 4. Copper pipes for underfloor heating

In terms of performance, copper is an ideal material for arranging water heated floors. Not for nothing that in a number of European countries this material is mainly used today.

pros:

- high strength, not comparing with polymer analogues. The strength of copper pipes can even be called excessive in the context of underfloor heating;

- durability. The minimum service life is 50 years;

- excellent heat transfer, because it is metal;

- minimum bending radius among all pipes, so uniform heating is achieved;

- ability to withstand temperatures up to 3000C and system pressure up to 400 atm;

- complete impermeability of pipes for gases, resistance to corrosion, liming and rodents.

The widespread use of copper pipes in domestic spaces is restrained by some of their cons:

- high price;

- the need to use special equipment during installation, which you need to be able to handle. The connection is made only with brass fittings, which also raises the cost of installation.

No. 5. Corrugated Stainless Pipes

Corrosion-proof pipes are used even less often than copper pipes, even despite significant advantages. Such products have a long service life, have high thermal conductivity, are well bent, durable and resistant to corrosion, but cannot boast low cost. Biggest disadvantage - limited service life of sealing gum (only 30 years), which negates the durability of the pipes.

No. 6. Polypropylene pipes

Polypropylene pipes will cost several times cheaper than copper, steel and even metal-plastic, but still not widely distributed. For the system of underfloor heating use products marked PN25, which are reinforced with perforated aluminum foil. Outer diameter from 21 to 78 mm, wall thickness 4-13 mm.

Benefits:

- low price;

- ability to withstand the temperature of the coolant up to 950C at optimal 550C in the water floor heating system;

- high strength, service life not less than 25 years.

disadvantages:

- a small bending radius, because of which it is often impossible to equip a heating system with the necessary efficiency. The minimum bending radius of a polypropylene pipe is 8 diameters, which means that pipes with a diameter of, for example, 23 mm can be positioned 368 mm apart, which may not be enough for uniform heating. If the underfloor heating will be used as an additional source of heat, then the use of polypropylene pipes is justified;

- installation conditions for polypropylene pipes. Installation is carried out at a temperature above + 10 ... + 150C, which is not always possible.

Number 7. How many pipes are needed?

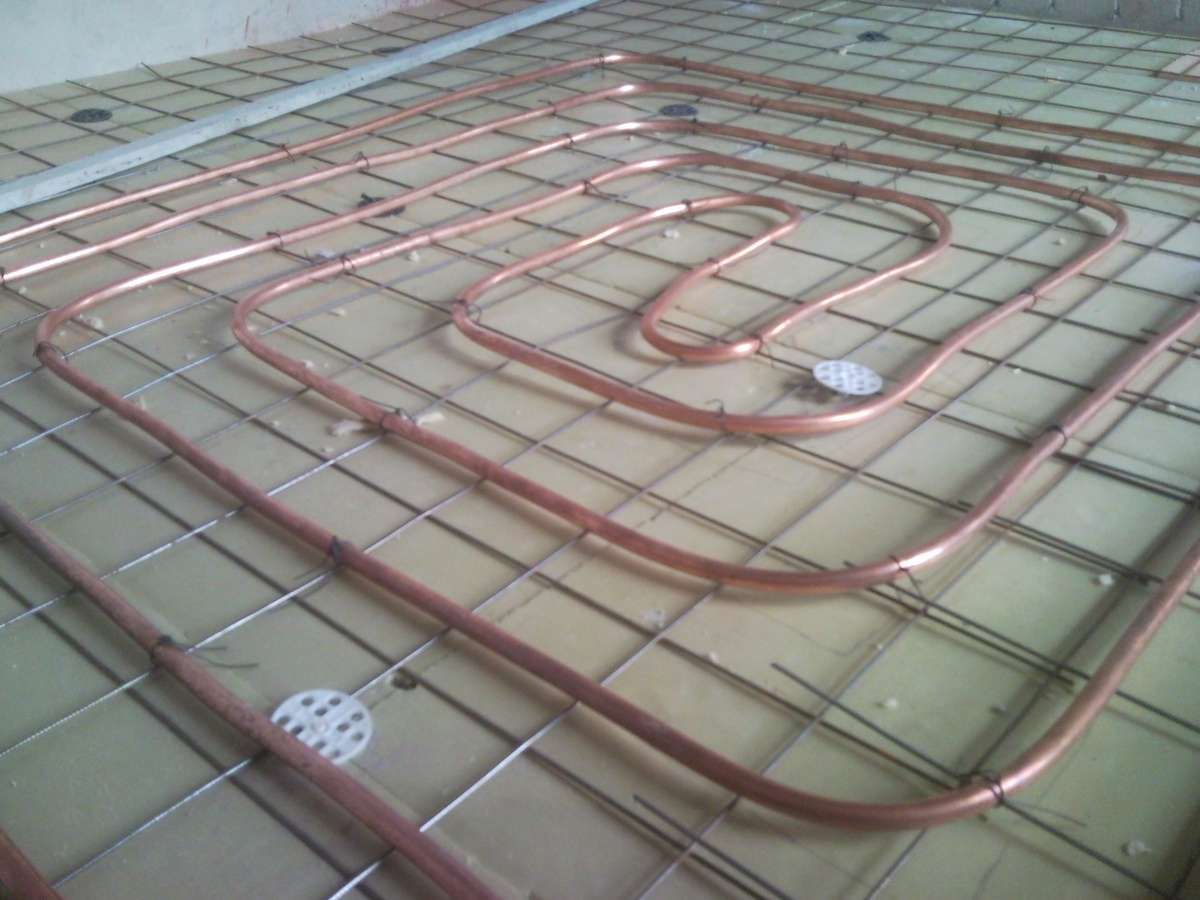

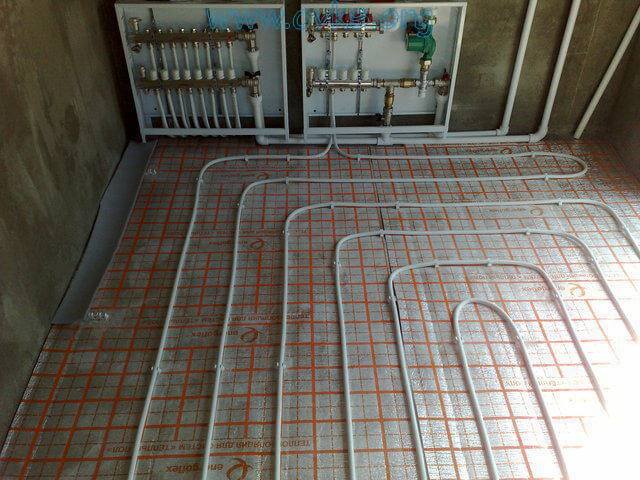

To more or less accurately calculate the required number of pipes, you can use software or arm yourself with graph paper, on which the scale of the floor plan is drawn. The diagram necessarily indicates all the large pieces of furniture that will stand motionless - you do not need to lay pipes under them: this is unprofitable and harmful to the furniture itself.

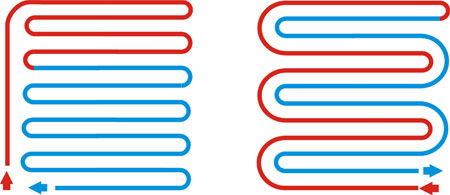

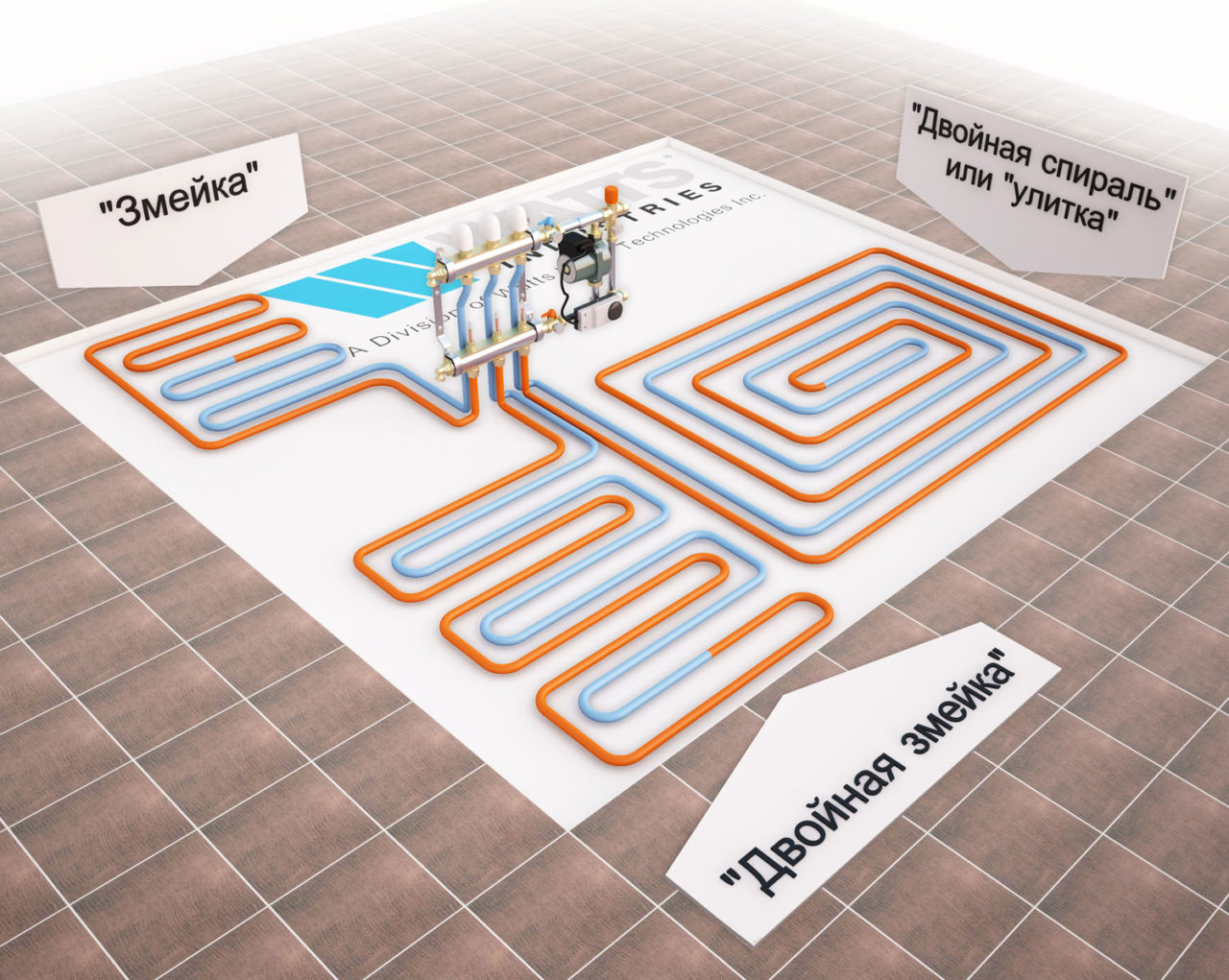

The layout of the pipes is applied to the plan. Laying is usually carried out in one of the following ways:

- "Snake". This is a simpler installation option, but has a significant drawback - uneven heating of the room, which is well understood from the figure. In the first case, one part of the room will be heated much less, since the coolant enters it already cooled, in the second - the distance between the sections with water that has not yet cooled is too large, so the floor will warm up unevenly, which will be felt when moving;

- "spiral" it is more complicated, it requires a more professional approach to calculation and installation, but heat will be distributed evenly on the floor, since zones with warm and cold water alternate. In addition, there are fewer rotation angles, which affects the speed of movement of the coolant in the pipes;

- combined system.

When creating a plan, keep in mind that pipes are laid at a distance of 15-20 cm from the walls, the step between them should be 20 cm, in extreme cases, no more than 35 cm. If a warm floor is the only source of heat, then the step should be minimal, that's why in houses where a warm floor plays only an auxiliary role, polypropylene pipes with a large bend radius are allowed.

A pipe with a diameter of 16 mm is able to heat 10-15 cm of the surface on both sides of itself. At external walls, it is advisable to take a step less to provide a reliable barrier to cold. The approximate number of pipes can be calculated using the created scheme, but it is better to take the material with a margin or ask to calculate the specialists who will carry out the installation.

The recommended length of one coolant circuit is not more than 60 m, otherwise the water will cool too much and you cannot build an effective heating system. If this is not enough to heat one room, it is better to equip several heating circuits. The data are given so that you can calculate the approximate amount of necessary materials and their costs - designing a system of underfloor heating, as well as their mounting, it is better to entrust to professionals.