Infrared film underfloor heating: 6 tips for choosing and installing

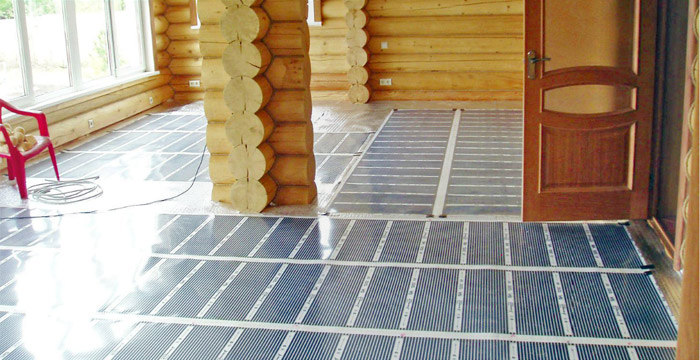

To install a warm floor in one day and do without screed work a dozen years ago seemed fantastic. Today warm film floors are widely used all over the world and conquer domestic spaces, but with their spread, many low-quality products have appeared. To take full advantage of the technology, it is necessary to make the right choice and installation of an infrared film warm floor, and for this it would be nice to know what you need to pay special attention to when buying, which manufacturers you can trust, and what the specifics of the connection are.

No. 1. Construction of a film heat-insulated floor

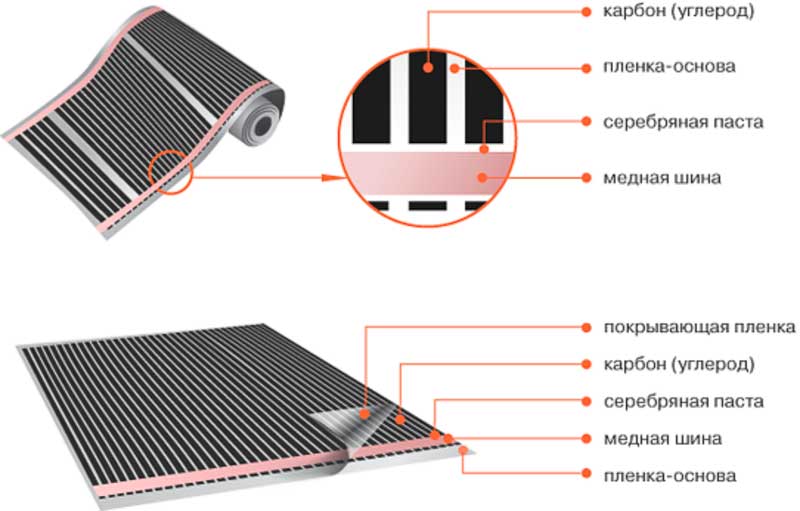

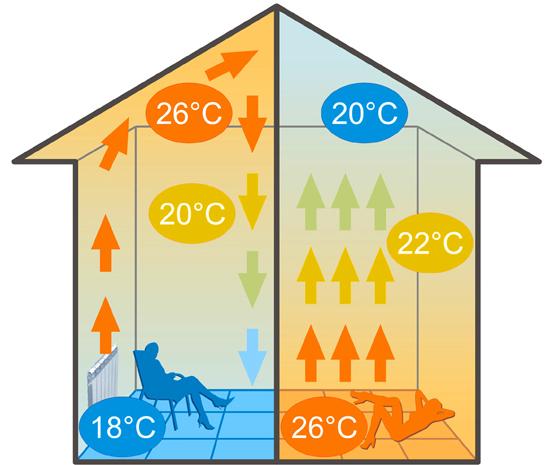

Film underfloor heating produces infrared radiation and does not heat air, like other systems warm floors, and surrounding objects. The heat obtained in this way can be compared with solar heat, so it is called the most harmless and even beneficial to human health. Infrared rays are emitted by carbon strips with a width of 16 mm, and the electric energy comes to them via copper busbars with a silver coating, due to which heating is carried out. The film is laminated on both sides with a polymer that protects the elements of the heating structure from moisture and mechanical stress and prevents possible fires.

Due to the design features and the dense arrangement of the heating elements heating is much more uniformthan using water or ordinary electric underfloor heating. Moreover, since the film consists of separate elements independent of each other, failure of one of the parts will not cause damage to the entire system - it will be enough to replace the damaged area, and even before it is replaced, the rest of the film will continue to radiate heat.

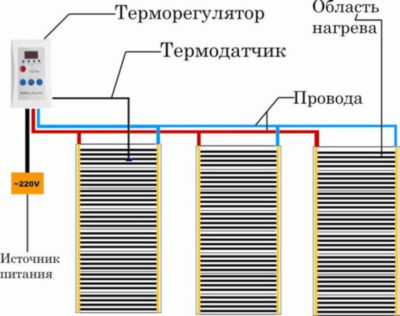

In addition to the film panels themselves, the infrared floor heating system also includes temperature sensors and thermostat. The purpose of these elements is clear from the name: the sensors fix the floor temperature, and the regulators, which come in a variety of modifications, allow you to track the readings of the sensors and adjust the degree of their heating. Thermostat is installed on the wall, and close to the switch or outlet, so that it is easier power up. If the power of the warm floor is above 2 kW, then it will be necessary to connect the system through a separate circuit breaker.

Carbon elements boast 98% efficiency they effectively turn electrical energy into heat. When organizing normal thermal insulation, electricity consumption will be at the level of 35-50 W / m2* h

No. 2. Pros and cons of warm film floors

Design features of the film warm floor allow us to talk about its mass the benefits:

- simplicity and high speed of installation, lack of need for arrangement cement screed, which allows you to install a warm floor in the shortest possible time even after all repairs have been completed;

- manufacturers say that dismantling the film is as simple as installing it, so you can literally take it with you when moving;

- minimum film thickness and no screed allows maintain the height of the room;

- the floor heats up almost instantly;

- uniform heating floor and room surfaces;

- the possibility of using any floor decorative coating, including linoleum and laminate flooring. Difficulties arise only when laying tiles, but more on that later;

- universality. The film can be mounted not only on the floor, but also on the walls and ceiling. Moreover, the characteristics of the material make it possible to use it in rooms with high loads on the floor covering, including in gyms, shopping centers, offices. The film can be heated garages, greenhouses, shedsand also use to prevent icing porch;

- complete harmlessness (and even usefulness) for the health of all inhabitants of the house.

disadvantages technology also has:

- it is still a fairly expensive system;

- susceptibility to mechanical damage, so you should be especially careful when installing;

- improper installation and use may result in fire of the film.

Heating elements cannot be laid in those places where bulky furniture will constantly stand. This recommendation applies to absolutely all systems of underfloor heating, but in the case of infrared film, we can deal with the failure of the whole fragment as a result of overheating due to insufficient heat transfer.

The film is heated to a temperature of 330C, which allows it to be used together with such a “delicate” coating as linoleum, but this imposes restrictions on the operation as main heat source: In this case, film must cover at least 70% of the floor area. Comfortable temperatures can only be achieved in regions with mild winters - otherwise such a warm floor can be used as an auxiliary heat sourceproviding comfortable barefoot movement on the floor and allowing warm the room in the autumn-spring period, when central heating already or does not work yet.

No. 3. Types of infrared film floor

According to the type of carbon coating, modern film floors are divided into two types:

- those coated with stripes;

- those that have continuous spraying.

The first are most widespread and show excellent performance in operation, but films with a continuous layer of carbon are more perfect. In striped films, individual bands are connected into groups, and cuts can be made between these groups. Since the strips are connected in parallel, if one of the parts is damaged, the rest continue to work. Inconvenience may occur if the damage area is large enough.

The first are most widespread and show excellent performance in operation, but films with a continuous layer of carbon are more perfect. In striped films, individual bands are connected into groups, and cuts can be made between these groups. Since the strips are connected in parallel, if one of the parts is damaged, the rest continue to work. Inconvenience may occur if the damage area is large enough.

A film with a continuous carbon coating is also divided into separate blocks, but if a separate section is damaged, the heating temperature will be lower only near a cut or hole - in the remaining zones the indicators will remain unchanged, and this is a big plus. Moreover, since carbon spraying is continuous, heating is even more uniform than when using a striped film, because there are no so-called dead zones. The service life of such a film is about 50 years, but the price is many times higher. Tests and comparisons in the video below.

Number 4. What to look for when choosing?

When buying film infrared heat-insulated floors, it is important to pay attention to the name of the manufacturer, the declared characteristics and appearance of the film. What should a high-quality film look like, and what operational qualities should it have? When choosing, pay attention to the following parameters:

- power, which directly depends on which flooring you can use the film. The power consumption of the system ranges from 130-450 W / m2. For laying under linoleum, carpet and other lightweight flooring there will be enough film with a power of up to 160 W / m2under tile and porcelain tile it is better to take a film more powerful - up to 220 W / m2, and all that is more intended for use in industrial environments and infrared saunas;

- film thickness depends on the thickness of the polymer and carbon layers, it ranges from several microns to several millimeters. The minimum allowable thickness is 0.3 mm, the generally accepted thickness is 0.338 mm. The greater the thickness, the protective shell will be more durable and resistant to deformations. Some manufacturers insist that the film should be as thin as possible so as not to take away the height of the room, but the difference in height when installing the film of 0.3 and 3 mm will be imperceptible, and the durability of the latter is several times higher;

- film width. The material is produced in rolls with a width of 50, 60, 80 and 100 cm. During installation, the film is mounted so that adjacent sections are as close to each other as possible, but do not overlap one another. Based on this rule and the room parameters, the most suitable roll width is selected to ensure the fastest installation and minimize waste;

- strips made of silver and copper alloys should have clear contours, not be visible, not have damage and no oxidation. The higher the silver content, the more reliable and less sparkling the film will be. The silver part may be 1.5-2 mm wider than the copper;

- preference should be given to those films where copper and silver tires are connected by a “dry” contact, which minimizes the thickness of the air gap and extends the life of the product;

- copper bus width must be at least 13-15 mm, otherwise we can talk about the low quality of the film. Through copper, carbon strips will not be visible and felt;

- the carbon layer should be applied evenly and not shine through. The thicker its layer, the longer the film will last;

- Some manufacturers add silver to the carbon paste to minimize its current resistance and improve tire contact. Over time, the cold tire may peel off from the constantly heated carbon part, and the result may be sparking and a decrease in heating power. Large companies that constantly improve their products come up with different ways to avoid sparking. The most effective development is the location of the grid of silver strips at the border of the carbon coating and the copper bus. A similar configuration is called an anti-spark mesh;

- the gaps between the carbon strips can be transparent or unclear - the difference in the features of production. The first option is obtained when applying adhesive technologysecond - during lamination. After several months of operation, the adhesive strips become brittle, and the laminated ones last for years, so give preference to them;

- the heating rate of a high-quality infrared film is 5-10 seconds.

No. 5. Large manufacturers of film infrared floor

The quality and compliance of the actual technical properties indicated on the package depends on manufacturer name. Today, there are more and more different companies producing warm film floors, but many of them, unfortunately, do not offer the most durable products. When buying, pay attention to the products of reputable manufacturers:

Caleo - the largest company in the industry, it owns numerous innovations and developments. A manufacturer from South Korea has been producing warm film floors since 2006, and has since become a true leader in the field. This company owns the development of floors with anti-spark mesh. Today the range includes several modifications of underfloor heating: from budget to luxury options. In any case, the quality is on top, a guarantee of 7 to 15 years, thermostats, cable underfloor heating and heating systems are also on sale the roof, pipes and drains;

Caleo - the largest company in the industry, it owns numerous innovations and developments. A manufacturer from South Korea has been producing warm film floors since 2006, and has since become a true leader in the field. This company owns the development of floors with anti-spark mesh. Today the range includes several modifications of underfloor heating: from budget to luxury options. In any case, the quality is on top, a guarantee of 7 to 15 years, thermostats, cable underfloor heating and heating systems are also on sale the roof, pipes and drains;- Heat plus - Another Korean company that over several years of activity in Russia was able to make the brand recognizable, establish sales and after-sales services in many large cities. The company produces striped and continuous infrared film with a power of 80 to 450 W;

Teplotex - A Korean company that produces only striped film, a minimum thickness of 0.37 mm. Subject to proper installation, the film can be used for 30 years. Width of rolls from 50 to 100 cm;

Teplotex - A Korean company that produces only striped film, a minimum thickness of 0.37 mm. Subject to proper installation, the film can be used for 30 years. Width of rolls from 50 to 100 cm;- Rexva - A major Korean manufacturer, whose share in the home market is about 60%. A domestic buyer recently got acquainted with the brand's products, but has already managed to appreciate its highest quality. The company is also one of the leaders in terms of innovation. Due to the double-sided lamination by electrotechnical polyester, full moisture resistance is ensured. In addition, the product withstands high temperatures, is difficult to ignite, does not emit caustic smoke. The width of the film is 50, 80 and 100 cm, the thickness is 0.338 mm;

- Eastec - The company is all from the same South Korea, where the technology of infrared underfloor heating was invented and where today most of such products are manufactured. The company offers a film with a width of 30 cm and a power of 65 W, therefore, its products will be interesting in cases where the offers of other manufacturers are not satisfied;

Monocrystal - Ukrainian company, which positions itself as the only manufacturer of film infrared floors in Europe and the CIS countries. In its activities, the company combines the best Korean developments and achievements of domestic scientists. The manufacturer has a lot of its own solutions, including a film without silver paste, but with an increased carbon layer, which suggests a more stable electrical contact. There is also a special film under the tile in the assortment, which is characterized by the presence of many holes, which improves the adhesion of the glue with the subfloor during tile laying. The company produces striped and continuous coating of 60 and 34 cm with a power of 135-600 watts. There is a film where the graphite coating is applied by a snake, as well as products with a width of 24, 20 and even 10 cm, which can be used on balconies, for mounting on the contour of doors, windows, etc.

Monocrystal - Ukrainian company, which positions itself as the only manufacturer of film infrared floors in Europe and the CIS countries. In its activities, the company combines the best Korean developments and achievements of domestic scientists. The manufacturer has a lot of its own solutions, including a film without silver paste, but with an increased carbon layer, which suggests a more stable electrical contact. There is also a special film under the tile in the assortment, which is characterized by the presence of many holes, which improves the adhesion of the glue with the subfloor during tile laying. The company produces striped and continuous coating of 60 and 34 cm with a power of 135-600 watts. There is a film where the graphite coating is applied by a snake, as well as products with a width of 24, 20 and even 10 cm, which can be used on balconies, for mounting on the contour of doors, windows, etc.

No. 6. Installation of a film heat-insulated floor + video

The process of laying a film underfloor heating is simple, all work takes one working day. Some people prefer to put the film on their own, and entrust their connection to the network to a professional. To evaluate your own strength, you need to know what you have to face, and for this we will study sequencing:

- installation of a temperature regulator in a convenient place;

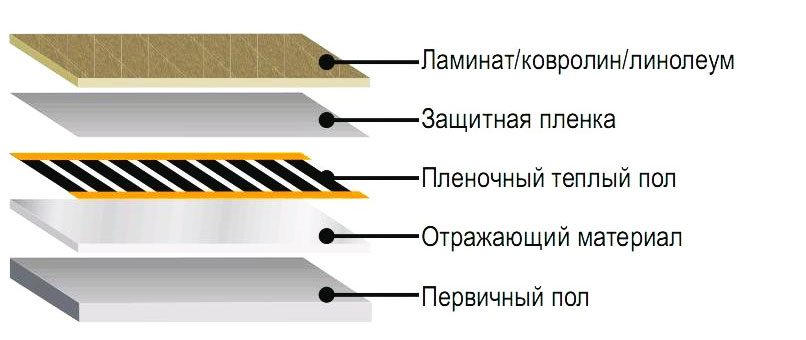

- cleaning the main floor from dust and dirt, leveling if necessary, laying thermal insulationso that the heat does not go down. As a heat insulator, you can use penofol, isolon or roll cork. The latter option is most convenient from the point of view that in the cork you can easily cut grooves for laying cables. When laying on concrete some masters advise to lay a plastic film as a waterproofing;

- cutting and unfolding the film. Before installation, it is necessary to clearly know where the overall pieces of furniture will be located (sofas, cabinets, beds, etc.) so as not to put film in these places. In any case, it is impossible to lay the film strictly under the wall - it should be 15-20 cm to retreat. The length of one segment of the film should not be more than 10 m, you can cut it in strictly marked places (these are white lines that are not coated with graphite). Experts use a film of different widths when working, but you can get by with a roll of only one width - the main thing is to arrange it correctly, for which it is sometimes better to pre-draw everything on paper so as not to spoil the expensive material;

- the cut film fragments are stacked with the matte side up, with copper bars down, taking into account the distance from the walls. Each fragment is fixed with ordinary tape so that the film does not move from its place during installation;

- the next fragment is laid butt to previousby not allowing one part to overlap another. The joint is also glued with tape for fixing.This is done until all fragments are decomposed. Do not forget that it will be necessary to install a temperature sensor close to the temperature regulator, so at this stage part of the film where the sensor will later be mounted is not fixed with tape. So the edges of the film are not fixed, to which the wires will later be connected;

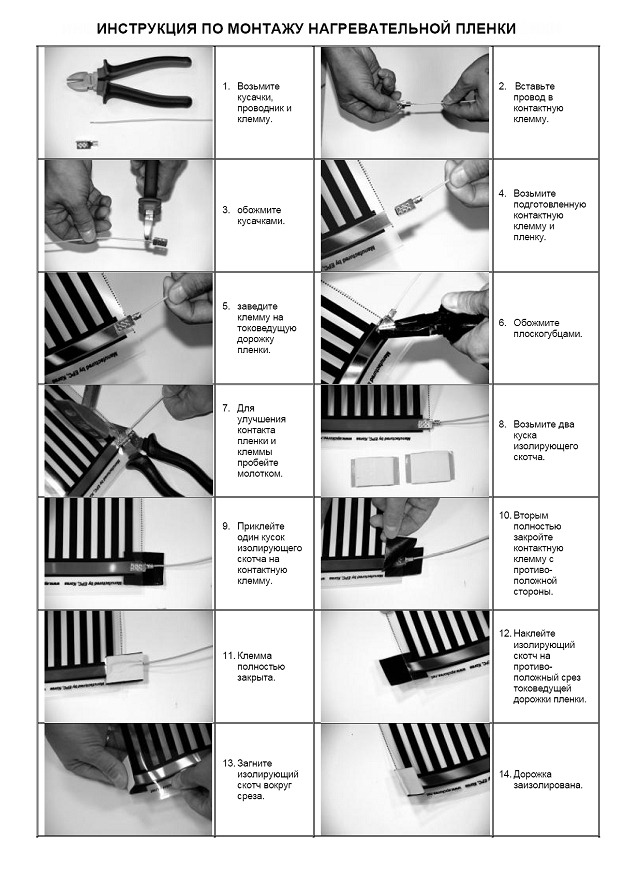

- when the film is laid out, the most crucial moment comes - connection to electricity. Do not overestimate your capabilities - if there are doubts about at least some stage of the work, it’s better call a specialist. The easiest way is to use special contact clamps that are included in the kit to connect the wires to the film. The clamp is inserted into the cavity between the film and the silver strip, after which it can be crimped with pliers;

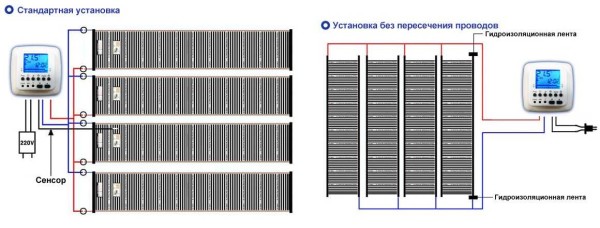

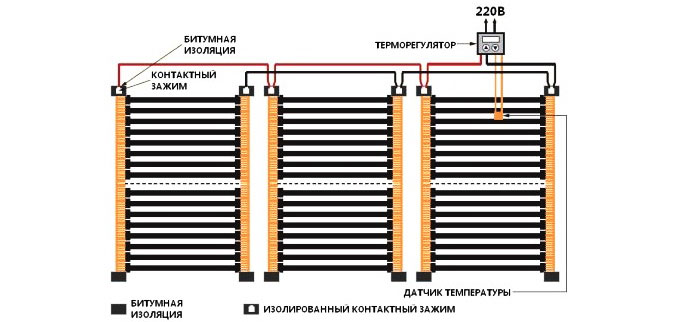

- the location of the clips on the film will depend on the connection scheme of the warm floor. Standard circuit involves connecting wires on one side of the film, with the upper busbars connected to the upper, the lower to the lower. there is installation diagram without crossing wires. In this case, the upper tires are connected by wire on one side, the lower ones on the other side (seen in the diagram);

- from the wire that will be used to connect the films to each other and from the thermostat, remove the insulation, insert it into an already installed clip, and gently fix the latter with pliers. Above and below, such a connection is closed by insulation. To ensure that the surface of the warm floor is smooth, and in the future no elements are damaged by the floor covering, holes for wires and clamps are cut out in the cork (see video);

- It is convenient to connect the lower and upper tires with wires of different colors. Cables and film are fixed to the cork by insulation. The wires are connected according to a pre-selected scheme, for them it is better to make the strobes and fix them later with bitumen insulation. She is recommended to close unused sections of tires. It remains only to lead the wires to the thermocirculator;

- mounting the temperature sensor near the location of the thermostat. It can be located at a distance of 15 cm from the edge of the film. It is necessary to fasten it to the graphite strip using aluminum tape. It remains to connect power to the sensor and check the operability of the entire system. If nothing sparks and does not smell, it evenly heats up, you can proceed with the installation of the flooring.

If as topcoat will be used laminate, its elements as a result of friction can damage carbon strips. To prevent this, some advise to lay on top a hard base (plywood or gypsum fiber board), but it will have to be fixed screws or nailsdamaging the coating, so it’s better to lay on top of the film ondulin, and fix the joints with tape. Somewhat more complicated things are with tiles. For it, either a special film with perforation is chosen, or a reinforcing mesh is used on top of the film, which will strengthen the structure. It will be possible to turn on the warm floor only after the glue has completely dried, and this is about 1 month.

Now it remains only to objectively evaluate your strengths, as well as the advantages and disadvantages of a film infrared heat-insulated floor and decide whether to use it and who to entrust the installation to yourself or to professionals.

I read that there is still a mobile version of the warm infrared floor .... very convenient for example when young children ... or do not want to disassemble the floor