9 tips on how to build a barn in the country, or choose material for the barn

Each summer resident understands well that one can’t do without a barn on a site. This building can become a place for storing garden tools or firewood, a small workshop, a chicken coop or rabbitry. Often, the barn becomes the first building that is being built on the newly purchased site, but the utility unit can be erected during building a house or after its completion. In any case, it will be necessary to choose the material for the barn, and here the summer resident will have a huge assortment: from the usual lightweight concrete blocks and boards to finished containers. We deal with the features of different materials, types of foundations and roofs and determine which barn to build in the country.

No. 1. We are looking for a place for a barn in the country

It is better to choose a place for a barn in advance at the planning stage of a summer cottage. On the diagram, it is necessary to identify the areas of the house, baths, greenhouses, playground, barbecue areas, the garage and other buildings to find the best place for the barn and understand how best to arrange all the buildings relative to each other.

Shed usually have:

- behind the apartment buildingso that it is not visible. Sometimes the barn is also masked with vertical landscaping;

- near homeso that all the tools and trifles necessary in the household are at hand;

- on the border of the site.

Often for house block choose a place that is not suitable for organizing other buildings or zones there, for example, shady areas, areas on the north side or with not very good soil. In principle, there are no special requirements regarding the location of the shed in the country house - it is important to observe only distance from the fence:

- if in the barn you are going to store garden tools, tools, carry out minor repairs, then the minimum distance from the fence - 1m;

- if the shed is used for growing animals or storing organic fertilizers, the distance from it to the fence should be at least 4 m;

- when using a barn for raising animals, it is important not only the distance to the fence, but also the distance to the neighboring apartment building. It should be at least 12 m.

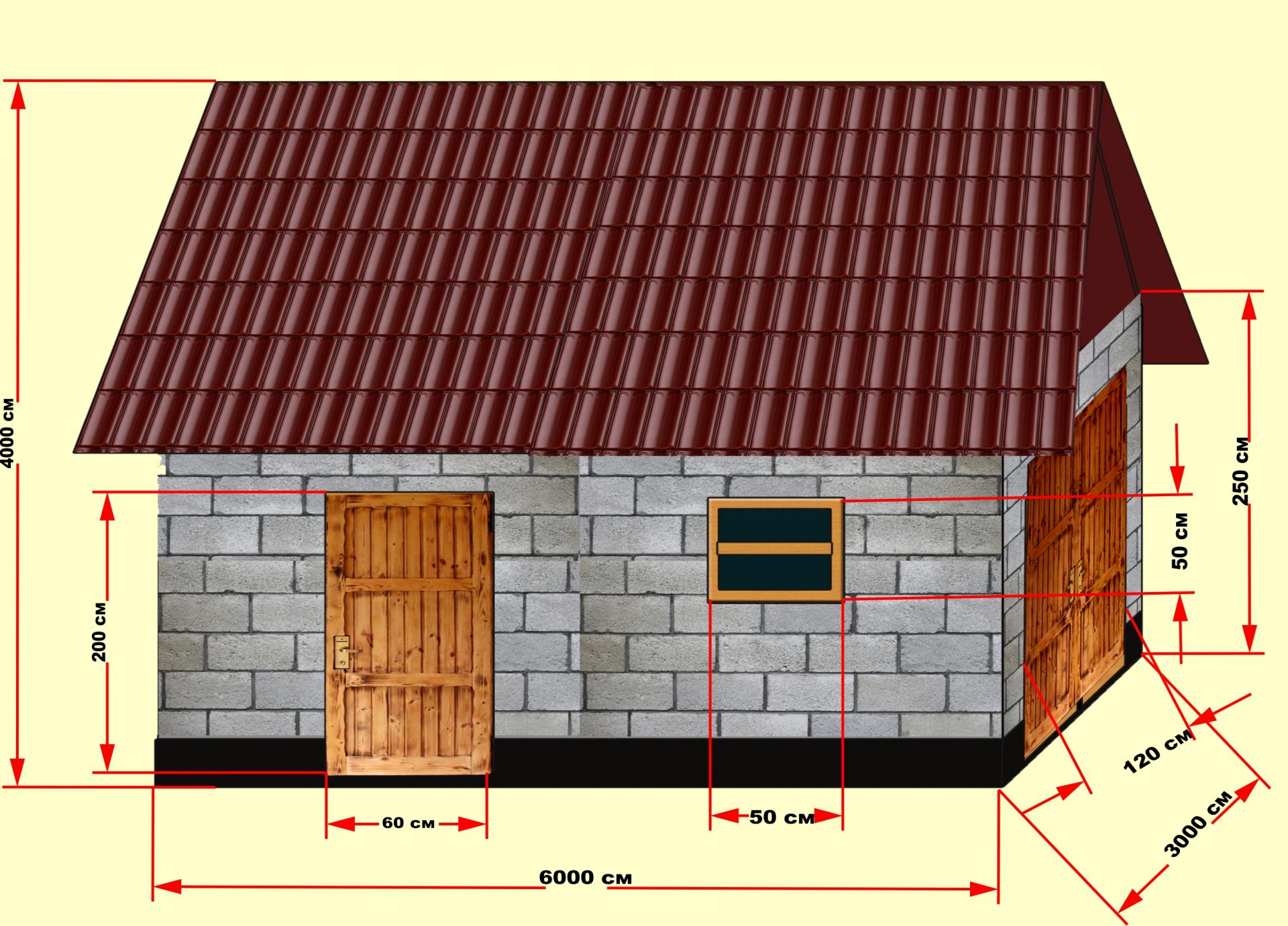

No. 2. Determine the size of the barn

The size of the barn is determined by the purpose of its use. The experience of numerous summer residents allows us to talk about the minimum necessary parameters for different purposes of use:

- for storage of garden equipment (rake, shovels, secateurs, etc.) a building with dimensions of 1.5 * 1.5 m is suitable, in it you can organize a system of hooks and shelves;

- if it is supposed to store not only garden tools, but also additional materials, such as paints, fertilizers and other things, then everything can be conveniently stored at sizes from 1.5 * 2 m;

- if you plan to store equipment such as a lawn mower or pump, it is better to expand the shed to a size of 2 * 3 m;

- when using a hozblok as a chicken coop or rabbitry, its size depends on how many animals you plan to raise. For example, for 10-20 hens a shed measuring 2 * 3 m is enough.

Often a barn is built with a margin, but its size is rarely more than 3 * 6 m.

No. 3. Shed Materials

Modern summer residents erect sheds from anything: they use both completely traditional materials and improvised ones. Conditionally According to the material and construction technology, sheds can be divided into:

Number 4. Frame shed for a summer residence

Wireframe technology Construction is one of the most popular today, it allows you to do with small investments, and it’s easy to build such a barn with your own hands. The technology is to create a strong, reliable frame of wooden beam or pipe. From above, the frame is sheathed with any sheet or piling material and, if necessary, insulated from the inside.

According to the material used for external cladding, sheds are:

- wooden sheds with sheathing from edged or unedged boards (slabs) are considered the simplest to implement and the cheapest designs, however, their durability is low. The construction begins with the construction of the foundation, then they mount the support frame from a wooden beam, the rafter racks are fastened to equip the roof. The resulting frame is sheathed with a regular board or croaker. Grooved material is ideal as it avoids crevices. Some resort to installing boards with herringbone. Wooden sheds can be used for any purpose, but if wintering of animals is provided for in them, it is better to use wind-protective films and insulation material. A wooden barn is cheap, simple and environmentally friendly. Cons are significant: low durability, susceptibility to decay, ignition, the appearance of insects, the need for constant protective treatment to extend the service life;

- OSB tiled sheds, show the best indicators of durability, because the material practically does not decay and does not warp. The basis is a wooden frame, but when it is erected, it is very accurate to mount the support posts so that the seam between the OSB plates falls precisely on them. At the cost of the OSB plate, they will cost more than boards, but the hassle in terms of installation and maintenance is less. Nevertheless, it is better to paint such a barn with paint not so much for aesthetic reasons as for providing additional protection;

- metal shed - already more reliable and durable construction. The frame is made of a profile pipe, some summer residents use old water pipes. They are concreted in the ground, fixed with bolts or welding vertical girders and fasten the lining, which sheets are suitable for corrugated board. The metal will have to be periodically protected from corrosion, then the barn will stand for a very long time. The metal hozblok leaves cold, and if it is necessary to organize a workshop or a place for keeping animals in it, it is better to hold internal insulation;

- polycarbonate traditionally used for the construction of greenhouses, but use it when arranging sheds for closed walking of poultry. If the barn will be used as a workshop or warehouse, transparent walls are useless for him, but due to the lack of other materials, polycarbonate may come in handy. It is possible to fasten sheets of material on a wooden and metal frame, special screws with a wide hat and a sealing washer;

- slate, remaining after replacing the roof at home, can also be used to create a barn. Flat or wavy sheets are best mounted on a wooden frame. Since the size of the sheets is large, installation is greatly accelerated. Such sheds do not look very attractive, but they are as economical as possible;

- sawdust shed erected using monolithic technology. You will need to create a frame and sheathe it with OSB plates, having received the formwork. A mixture of cement mortar and sawdust is poured into it. The result is sturdy walls with a good indicator of thermal insulation. In such a shed, you can equip a workshop, warehouse or chicken coop;

- pallets, they are pallets, can be used as an alternative to timber in the arrangement of the shed frame. It is not difficult to get wooden pallets: if not completely free, then for a minimal fee. Pallets are put on the foundation, pulled together by bolts, rafters are installed, and the finished frame is sheathed (usually OSB boards).

No. 5. Brick and cellular concrete sheds

Of course, much more durable structures come out of stone materials. Recall at least the tale of the three little pigs, which clearly shows that the stone building is not afraid of anything, but requires more time and effort to erect.

Brick Shed

Of bricks sheds are erected infrequently, and this is due several disadvantages:

- high price;

- high labor input;

- heavy weight and the need to lay a powerful foundation.

The brick shed boasts numerous the benefits:

- great appearance. In fact, this is almost the only option when the shed looks quite acceptable without additional cladding and does not spoil the site;

- high durability and reliability;

- fire and moisture resistance;

- resistance to rodents and mold.

Despite the high cost of building such a barn, some prefer to invest money once, so that later they do not know the problems with constant renovations and repairs.

Foam Block Shed

Barn from foam blocks - An ideal option when it is necessary to erect a durable building with a small budget. The foam blocks are large and have a porous structure, due to which numerous advantages:

- high speed of construction due to the low weight and large format of the blocks;

- low load on the foundation;

- excellent thermal insulation properties;

- resistance to fire and rodents;

- relatively low cost.

Of cons a similar solution, the possibility of shrinkage and not the most attractive appearance. Shrinkage is about 2-4 mm per linear meter, and the problem of appearance is solved by plastering, decorative brick or siding.

Block of gas blocks

Gas blocks are produced using a slightly different technology, but largely repeat the properties of foam blocks. They keep heat, weigh a little, are resistant to fire, are inexpensive, but are afraid of water. Water absorption can reach 35%, therefore reliable waterproofing. Not every summer resident is ready to bother so when building a shed, so aerated concrete is not used very often, unlike foam concrete.

Arbolite Shed

Arbolite blocks produced on the basis of concrete and wood chips. Not so long ago they began to be actively used in private low-rise construction. While sheds of arbolite are erected infrequently, but this is only a matter of time, since the material has mass pluses:

- high thermal insulation qualities;

- high vapor permeability;

- the large block size and light weight allow you to build quickly and with minimal load on the foundation;

- high strength;

- resistance to mold and rodents;

- hassle-free mounting of fasteners.

Arbolite is criticized for not the most accurate geometry, low frost resistance and moisture resistance, therefore, after erecting a shed, it is better to revet it. Finishing will not only make the shed more aesthetic, but will also extend its life.

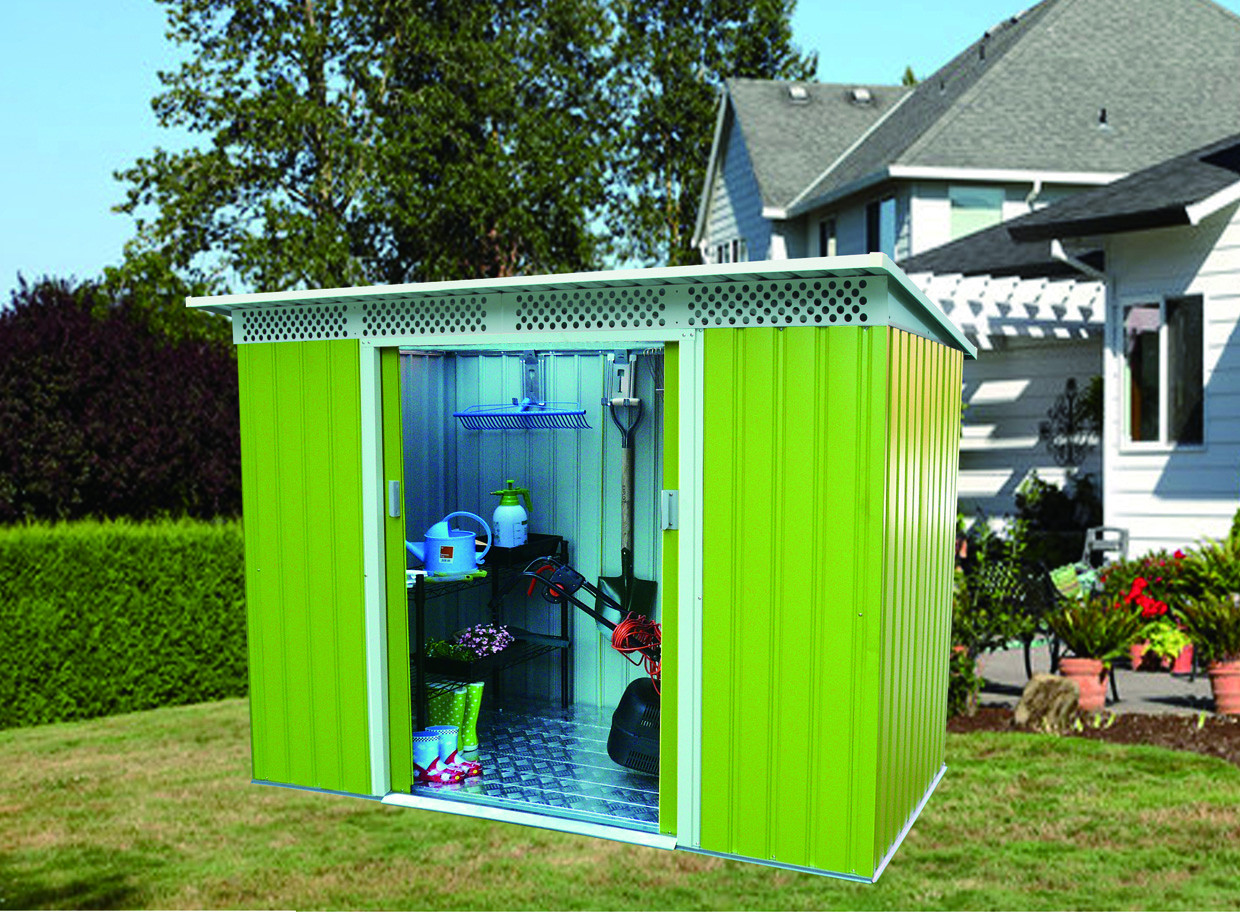

No. 6. Ready Container Shed

If the time for the construction of the hosblock is critically small, then you can greatly simplify your life by finished barn. The basis of such structures is a metal frame sheathed with metal with a layer of insulation. In the heater, all the necessary communications are laid. Outwardly such a barn looks like a container, and its equipment can be very different: from a small storage barn, then a full-fledged utility unit with a toilet and even a place for rest and a canopy for arrangement of the veranda. The most functional containers can be used as a small country house while the main one is under construction.

As a rule, such structures are brought to the site already assembled - all that remains is to connect all the necessary communications. These are durable constructions, the arrangement of which requires a minimum of time. You will only have to take care of the foundation, but an ordinary columnar or simple concrete slab will do. Such sheds are not cheap, they do not look very attractive, but due to their durability and strength, the structure can be sold if it is no longer needed.

Number 7. Prefabricated Sheds

Prefabricated sheds should be allocated as a separate group, despite the fact that they are actually a type of frame. They are based on the same technology, only the manufacturer simplifies the task to the summer resident so much that it turns the construction of the shed into a kind of assembly of the designer.

Prefabricated sheds are produced on the basis of:

The frame is initially created, and prefabricated typical elements are attached to it. It is enough for a summer resident to follow the instructions and mount one element after another to get a full-fledged barn. Time costs are significantly reduced, and the need for insulation or external decoration is eliminated due to the design of the panels. SIP panels consist of two layers of wood boards, between which is a layer of insulation, sandwich panels - the same, but on the sides of the insulation are sheets of metal. The cost of a finished prefabricated shed is more than that of a frame or block shed, but the speed of erection and mobility is higher.

Separately, it is worth highlighting plastic sheds. Elements for their construction are made of composite plastic. Such buildings cannot be called super-long-lived, but they cope with the tasks of storing garden tools, they look pretty, they assemble quickly, they do not require a reinforced foundation. For the maintenance of animals, this design is not suitable due to the lack of insulation.

Number 8. Foundation for the barn

No matter how light the building foundation under the barn is necessary in any case. If you save money or succumb to the persuasion of laziness, and miss this important stage of the construction of the barn in the country, then soon you can encounter the rickety walls. Of course, a powerful laborious foundation is not always necessary - it all depends on the material used in construction. As a rule, the following types of foundation are used:

- blocky - the basis for the lightest sheds, incl. wooden. It is equipped using concrete blocks that are installed on a sand cushion around the perimeter of the future barn with a step of 1-1.5 m. Financial and labor costs are minimal;

- monolithic slab foundation - A universal option that can be used even in areas with loose soil. The arrangement process is simple and consists in the preparation of a sand pillow with a thickness of 15-20 cm and pouring cement mortar 10 cm thick, to guarantee it can be further strengthened with fittings. A significant plus of such a solution is the lack of flooring;

- column foundation - A popular option for frame sheds, it is cheap and easy to arrange, but not suitable for terrain with difficult soil;

- pile foundation it can be used on any soil, quickly equips, but has a high cost, so resort to its arrangement in the absence of alternatives;

- strip foundation the most time-consuming, but the construction of heavy buildings (brick shed, for example) is difficult to imagine without it. The strip foundation is being erected using a monolithic technology of concrete and a precast technology of concrete blocks. Under the barn, you can use an intermittent strip foundation, it is not laid with a solid line.

No. 9. Arrangement of the roof of the shed in the country

The roof of the barn can be:

- single slope;

- gable.

Other options (tent, round, four-slope) are very rare. The cheapest is to equip pitched roofTherefore, this is the most common option.Its advantage lies in the best natural ventilation, which is especially important if the barn is used for breeding animals. When arranging a single-pitch roof, it is necessary to provide that its slope is not towards the door, otherwise puddles will accumulate in front of the entrance during rain.

Gable roof better only in appearance. Natural ventilation under it is worse, but there is an opportunity to equip a hayloft under a roof. In any case, it is necessary to provide a roof slope of at least 25 degrees.

To equip the roof of the shed, the following materials are usually used:

- slate - The most budget option, and after the construction or repair of other summer cottages, most summer residents have it. The material is characterized by durability, good strength, weather resistance, but it requires a reliable crate and is excessively fragile. Its low aesthetic properties in the construction of the barn are not so important;

- metal tile - lightweight inexpensive material, which also often remains after the roof of a country house or pergolas. The advantages include appearance, range and durability. The shed, covered with metal, can become part of the architectural ensemble of the site. The fear is the appearance of scratches during installation, as they start the corrosion process;

- professional sheet resembles metal tiles in properties, but costs less and looks much simpler;

- roofing material - soft roll material, characterized by low price and ease of installation. The aesthetics of such a roof are low, in addition, it is better to put roofing material in several layers;

- ondulin, it is soft slate, it weighs a little, looks good, flexible, easy to install, but is combustible;

- flexible tile possesses excellent aesthetic and operational qualities, but due to the high price for roofing sheds, it is used infrequently.

The external decor of the barn can be anything you like - if you wish, the outbuilding can be not just organically fit into landscape designbut also make it a highlight.