12 tips for warming wooden windows with your own hands

The windows account for one fifth to one third of all heat losses at home, so the comfort of all households depends on their thermal insulation. Despite the ubiquity of sealed plastic windows, old wooden windows have not yet left our apartments and are unlikely to do so in the next few years. Of course, they are good in many respects, but have low thermal insulation qualities, and therefore require modernization. Consider all possible ways to conduct insulation of wooden windows with your own hands, from the most budgetary to more expensive and most effective. The text of the article was prepared with the support of Moscow specialists. RemSila company specializing in the provision of insulation services for wooden windows of any type using high-quality consumables and European production (rubber sealant, adhesive sealant).

Why, with the frenzied popularity of modern eurowindows with hermetic double-glazed windows ordinary old wooden windows are still in use in thousands and millions of apartments? Among the main reasons:

- the cost of plastic windows, doubts about their harmlessness, in addition, sometimes plastic windows themselves need warming;

- the ability of wooden windows to provide natural ventilation;

- living in houses of high historical and architectural value, where replacement of old windows is not allowed;

- lack of desire and ability to carry out repairs, albeit small, after replacing windows;

- accommodation in a rented apartment.

With numerous advantages, old-style wooden windows do not provide adequate thermal insulation. This was noticed by our ancestors, who developed many ways to deal with their lack of tightness. More modern solutions have been added to grandfather's decisions, so we have plenty to choose from.

No. 1. How does warming of wooden windows begin?

Warming of old wooden windows begins with an examination of the structure for detect cold bridges, i.e. the main ways of getting cold air into the apartment. It is important to find all the weak points to spend complex insulation. The main cold bridges in wooden windows include:

- junction of the window frame and sash;

- the wood of which the frame is made;

- glass;

- slopes window sills and ebb.

It is better to insulate the slopes, the ebb and the windowsill from the outside, the rest of the elements require insulation from the inside, so you have to work hard to turn the old wooden window into a sealed one and meets the current comfort requirements.

If the inspection of the window and its insulation are performed qualitatively, you can count on an increase in temperature in the apartment by 3-40C if you are connected to a centralized heating, or significant cost savings if individual heating is used. In addition, it will be possible to get rid of drafts. The flip side of the coin is the cessation of natural air circulation.This problem is also characteristic of sealed plastic windows. Its solution is periodic ventilation or installation. special valves, which allow you to adjust the amount of fresh air entering the apartment.

Get ready for the fact that for effective insulation you will have to use several of the methods described below. Let's start with the technologies that are used for internal warming.

No. 2. Window insulation with paper

Most ancient, simple and inexpensive way. Today it is rarely used, but it is suitable if the budget is very limited. Exist several variations this method of insulation:

- newspapers, wallpapers, paper are torn into pieces, twisted into flagella, which clog the gaps between the sash and the window, use a ruler, knife to simplify the task, screwdriver or other sharp instruments. Some advise pre-wetting the flagella in water;

- paper waste is crushed, soaked in water and squeezed. To the resulting mass add 1 part of clay or 2 parts of crushed chalk. As a result, a plastic putty comes out, which penetrates well even into the smallest crevices.

The classic grandfather's recipe involves sticking a paper heater strips of fabric or paper. To keep them well, they were moistened with a solution of laundry soap or used homemade paste. The latter can be obtained by mixing water and flour in equal proportions, mix well and bring the mixture to a boil.

A more modern option is to use masking tape or special window tape. In this case, the task is simplified, but the costs still remain. Paper warmed window cannot be opened for airing if suddenly in the middle of winter it suddenly warms up. In the spring, you will have to remove strips of paper / fabric / adhesive tape and get insulation. Marked marks remain on the window frames, sometimes even part of the paint is removed, so alas, you can’t do without updating the decorative coating. However, fabric and self-adhesive paper are easier to remove total and leave a minimum of traces.

No. 3. Wadding insulation

Instead of paper, you can use cotton wool - there are fewer problems, and the insulating qualities are almost the same. All cracks are gently closed with cotton wool, strips of paper, fabric or adhesive tape are glued on top. The disadvantages of the method are the same as the previous one, but cotton wool is much easier to get out of the cracks.

Number 4. Cord insulation

Slots can be filled with a linen cotton cord. Fix it with small cloves or glue, while achieving a fairly good level of sealing, but in the spring you will have to devote a lot of time to dismantling the insulation.

No. 5. Insulation of a wooden window with foam and sealant

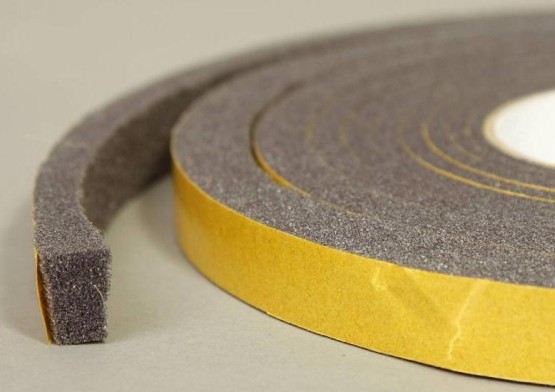

A much more modern, reliable and effective way of warming is to use foam tape and sealing cords.

Foam tape will cost inexpensively, but its service life is only about 2 years. This method of insulation is optimal when sufficiently large gaps have formed between the wings and the frame. The installation process itself is simple, but time-consuming, since everything must be accurately measured and carefully glued so that the window is well insulated, but it does not stop closing normally. The main advantage of the method - the ability to open a window.

The process of insulation with foam tape is as follows:

- measuring the required length and width of the tape. The length should correspond to the perimeter of the valves, and the width in a compressed form - the width of the voids;

- places on the wings where the tape will be glued must first be cleaned of dust and degreased with alcohol or acetone;

- foam rubber tapes are produced, as a rule, with a self-adhesive base, therefore the task is simplified and comes down only to removing the protective layer and carefully sticking the foam to the designated places;

- some experts advise additionally sealing the window with paper tape, but at the same time, the main advantage of the method is lost - the ability to open the window when it pleases. An alternative solution is to glue the foam rubber in several rows.

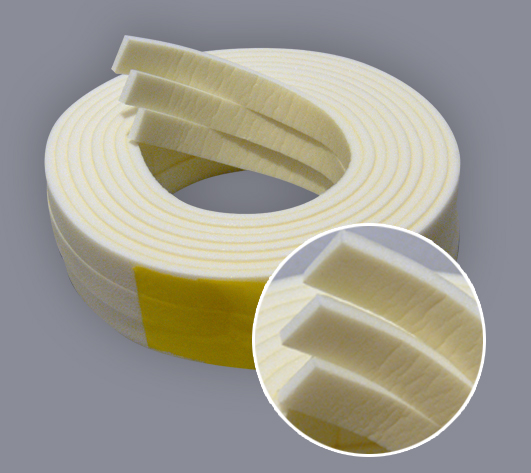

The insulation made with sealing cords. They are made of different materials:

- rubber;

- polyvinyl chloride;

- polyethylene foam;

- polyurethane.

Main advantage rubber seal - the price, but with a decrease in temperature it is able to double and break. In addition, rubber has high wear resistance, so it is better to choose it for windows that constantly open and close. Other types of cords, although they are more expensive, but in terms of operation, they show themselves much better.

Sealing cords are made different shapes - the choice depends on the size of the slots in the window structure:

- a sealant whose profile resembles the letter P is suitable for windows with medium-sized slots;

- a sealant with a D-shaped profile - for sealing large enough cracks;

- type E sealant - for windows with small gaps.

Tubular seals can achieve a sufficiently high level of sealing, do not interfere with the free opening of the window, can remain for the summer and serve for several seasons in a row. The sealant may have self-adhesive backing and then its installation will be identical to the installation of foam rubber tapes described above. If you take such a sealant, pay attention to the expiration date of the glue: if it comes to an end, the cord may either not stick at all or peel off quickly.

It is most reliable to take separately the seal and separately the glue for it, for which you can use silicone sealant. In this case, the durability of insulation reaches 5 years.

There is one more nuance. All work with tubular profiles is carried out at a temperature above +100C, so it’s better not to delay it before the cold. The sealant must be glued very carefully so as not to disturb the sash opening system.

No. 6. Insulation of wooden windows according to Swedish technology

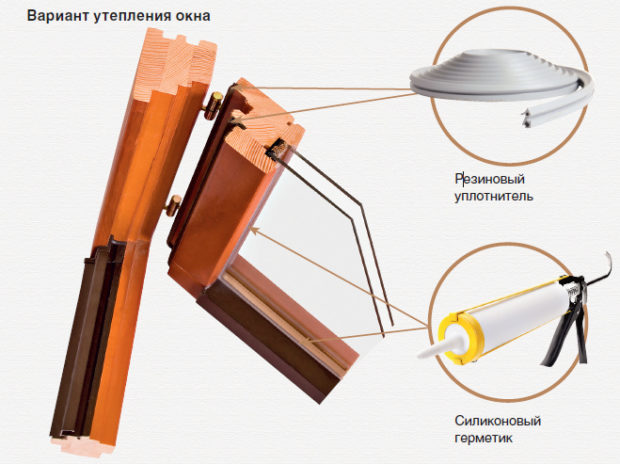

it the most progressive, modern and effective way. The windows insulated by Swedish technology are actually are equal in level of tightness to modern plastic windows. This method also involves the use of a sealant, only for it special grooves are prepared in the casement windows.

Swedish insulation technology involves the following procedure:

- dismantlement of shutters;

- cutting thin grooves around the perimeter of the wings, which is carried out by a special cutter, the size of the groove should correspond to the size of the selected seal;

- installation in grooves of a sealant (polyurethane, PVC, polyethylene foam, foam rubber is less often used). No glue is used at the same time - the sealant holds well due to the thickenings existing in its design;

- applying silicone sealant to the junction of the sash and glass;

- if necessary, fittings and glass are replaced;

- installation of the leaves in place.

The durability of such insulation is 15-20 years.Therefore, the complexity and high cost of the method are justified. It is worthwhile to independently carry out such work only if there is at least a little experience in the carpentry, otherwise it can only be done worse. The easiest way, of course, is to entrust all the work to specialists.

Windows insulated by Swedish technology can be opened at any time of the year, their appearance does not deteriorate, but An additional bonus is sound insulation.

Number 7. Insulation of a wooden window with sealant

This method is aimed at thermal insulation of the junction of glass and sash, can be done with your own hands, but will require a high degree of caution and accuracy. The procedure is as follows:

- extraction of glazing beads, thin rails that hold the glass around the perimeter. When dismantling, almost all glazing beads break, so it is better to buy new ones in advance, and with a margin.Extraction begins with the lower glazing bead, then the side ones are removed and only then the upper one is removed, for this it is convenient to use a small knife or a screwdriver;

- the seat inside the sash is thoroughly cleaned of dirt and dust;

- application of silicone sealant and installation of glass in place. All glass dismantling and installation work is carried out with thick gloves;

- installation of new glazing beads.

Instead of sealant, you can use putty for windows. The procedure remains the same, only after installing the glass, the excess putty must be immediately removed with a knife. In terms of aesthetics, this method is no worse, since subsequently the junction will still be closed with a new glazing bead.

Number 8. Insulation of a wooden window with foam

Polyurethane foam use for internal and external insulation, it fills large slots well and is used to seal joints between the frame and the slope, between the slope and the windowsill, under the windowsill, and between the frame and the upper beam.

It is not difficult to work with polyurethane foam, but you should know some nuances:

- filling is best done from the bottom up;

- the foam, solidifying, increases in volume, so filling the slots is about 1/3;

- works are performed at air temperature not lower than +5 and not higher than +300FROM;

- polyurethane foam collapses under the influence of sunlight, therefore it is necessary to cover it with a layer of finishing material. However, it is unlikely that anyone will leave this material without decoration - it does not look very good.

Instead of foam, you can use homemade putty. It is prepared from chalk and gypsum, which are mixed in a ratio of 1: 2, and then water is added to obtain a solution of viscous consistency. All slots are easily filled with this mixture, and outwardly it looks much more aesthetically pleasing foam.

No. 9. Heat-saving film for a wooden window

This method is aimed at improving the insulating qualities of glassbut today heat-saving film is also glued to wooden frame. It works like energy-saving stelopaketam, i.e. allows daylight into the apartment but does not release heat. They make such a film based on polyester, and it receives unique properties to reflect thermal radiation due to metal spraying. This is a transparent material that does not violate the optical properties of window glass, can withstand detergents, has high strength and makes the window safe, because in case of damage to the glass all the pieces will remain on the film.

The process of mounting the film is simple, but requires accuracy, because it is important to stick it evenly, without bubbles, with the metallized side out. It is best to work with gloves so as not to leave greasy marks on the surface.

The heat-insulating film is able to make the window more “warm”, but cannot be used as an independent heater.

No. 10. Eliminate gaps in the wings and frame

It is not enough to seal the gaps between the frame and the sashes, and between the sashes and the glass - the window will still let in cold air if there are cracks on the wooden elements. They certainly appear on wood as a result of temperature changes. It is not difficult to eliminate them; for this, the following materials are used:

- paraffin. It is heated in a water bath to a temperature of about 700C, they draw a syringe without a needle and fill all the cracks with it. In an hour, it will harden and turn into a serious barrier to drafts;

- special putty on wood;

- sealant, and you can choose the material in the color of wood;

- home-made plaster and chalk putty, the recipe of which was described above.

Naturally, such thermal insulation measures will be most effective if you first remove the old decorative coating, then fill in the cracks, and after that apply a new coat of finish. Keep in mind that the paint lays worse on paraffin and sealant, so it is better to carefully remove their excess.

No. 11. How to insulate wooden windows outside?

Internal insulation is sometimes not enough. Additional thermal insulation is often needed slopes. Work on their insulation begins with the dismantling of the old finish, after which it is performed surface priming. Slots can be filled with mounting foam, another option is to close the slopes polystyrene. Excess foam after hardening is cut off, the surface is treated stucco. A polymer mesh is attached to the foam on top, a perforated tape is in the corners, after which plastering is performed. It remains only to prime and paint the slopes.

A place window tide also seal with foam. A mandatory requirement is the installation of a special bar for the drainage of rainwater. It should be inclined and have curled edges so that moisture does not get on the walls and the window. It is desirable to seal the joints of the bar and frame or slope with sealant.

It is better to insulate the area outside the window sill with foam plastic, because in a third of cases, most of the heat flows through this zone.

Finishing touch external thermal insulation - updating the paintwork. The old peeling paint can be removed with a spatula and building hair dryerand instead apply fresh paint or varnish.

No. 12. Insulation of wooden windows in a wooden house

Wooden house puts forward high demands on the aesthetics of all ongoing work. In principle, you can apply any insulation technology, but be extremely careful. It is best to use a transparent sealant to insulate the junction of the glass and the frame, heat-saving films, fill large gaps with mounting foam, followed by casing. A great way to additionally insulate windows in a wooden house is installation of shutters.

In conclusion

High-quality warming of a wooden window using modern materials will not cost so much, but it will ensure tightness at the level of eurowindows and will preserve the original appearance of the window structure. Of course, investing time and financial resources makes sense, if the window is still strong enough - if it already barely breathes, as they say, then it's easier replace it with a new one.

Good afternoon! To date, the best way to insulate windows is insulation according to Swedish technology or, as indicated in method 6. This method is good because it really works and, in addition, improves sound insulation. Plus, you can use windows year-round. The constant use of wooden windows increases their service life as well as timely repairs. Closing windows for a long period of time, you may be faced with the fact that they will lead, and they are deformed, which will increase your costs for their repair and restoration. Do not rush and part with the old windows, because the old ones are only outside!