8 Tips for Choosing and Sticking Styrofoam Ceiling Tiles

Is a beautiful, inexpensive and easy-to-install finishing material for the ceiling - is it a myth or a reality? All these qualities boast a ceiling tile made of polystyrene foam, a material that captivates with its variety and low price. We deal with the advantages and features of the choice of ceiling polystyrene foam, and also study the basic principles of installation.

No. 1. What is a ceiling polystyrene foam?

Decorative tiles are made of polystyrene, which foams during heating. During production, they add to the material flame retardants and carbon dioxide, substances that can increase resistance to high temperatures. A styrofoam tile made in this way, although it melts when exposed to fire, still shows better performance than regular polystyrene foam. By the way, on sale you can find ceiling tiles from polystyrene foam: they are not only less safe, but also more rude in appearance. The presence of flame retardants in the composition of the plates indicates marking: domestic manufacturers add the letter C, foreign - F.

The size, shape, color and appearance of the material can vary greatly. On sale you can find square, rectangular and designer tiles. Surface can simulate decorative plaster country style or exquisite stucco molding in style baroque. The classic color of the tile is white, but color options and products with a mirror and laminated surface are also sold. The standard sizes are 50 * 50 and 100 * 16.5 cm, but other formats are also found.

No. 2. Advantages and disadvantages

Styrofoam ceiling tiles are among the most popular decoration materials. Buyers appreciate her for numerous benefits:

- affordable price. In this regard, tile can become a competitor even to ordinary painting. The most expensive samples with an exquisite design, which generally will not allow at first glance to determine what the ceiling is made of, will cost much cheaper than, for example, a system of suspended or suspended ceilings;

- ease of installation. You can cope with sticking the ceiling tiles on your own, without having any special skills. Given the low price of the material, it can be called an ideal choice if the budget for repairs is limited;

- big variety. On sale you can find both the simplest white tile with an uncomplicated pattern, and material that very closely repeats the structure of a tree or stoneTherefore, with the help of ceiling tiles you can equip any interior. White tiles can be painted in any desired shade;

- additional heat and sound insulation premises;

- resistance to temperature extremes and high humidity, so the tile can be used even in the bathroom;

- tile does not steal height, in contrast to suspended and suspended ceilings. In addition, it hides small irregularities and cracks that would have to be removed when painting;

- polystyrene foam - although an unnatural material, but is not particularly dangerous.It does not emit harmful substances under normal operating conditions, unless, of course, it is made with high quality and has all the safety certificates. Dangerous tiles become at high temperatures, i.e. during a fire;

- it’s easy to take care of the material, it can be cleaned with a vacuum cleaner or a damp sponge;

- high maintainability. If part of the ceiling is damaged, then a few old elements are easy to replace with new ones, so always take the tile with a margin.

Now about disadvantages:

- low durability and the ability to turn yellow over time, and the process is accelerated if direct sunlight is constantly falling on the surface;

- tiles are easily damaged by tobacco smoke, grease and soot, therefore on the kitchen do not recommend using it;

- constant temperature changes can cause some elements to fall off, but this is only if poor-quality glue was chosen for installation;

- polystyrene foam is a rather delicate material, so you should be careful when transporting and installing it;

- polystyrene foam tile is not very resistant to fire, and even when impregnated with flame retardants, it can ignite, releasing toxic substances. To be safe, it is better not to place the lamp very close to the ceiling. Such precautions, in addition, will prevent the appearance of yellow spots on the material from the lamp;

- when cleaning the surface, you should be extremely careful - a sponge that is too wet or using a rough brush can cause the tile to peel off.

Experts convince that truly quality ceiling tiles thanks to the additives used long does not turn yellow and almost does not support combustion. Conscientious manufacturers claim that all the myths that exist among the people are caused by the abundance of low-quality products on the counter, and are advised to always ask for a certificate of conformity. Sometimes we ourselves are to blame for the fact that the experience of using expanded polystyrene is negative. It is not only the choice of low-quality tiles, but also the wrong selection of glue, on which a lot also depends.

Expanded polystyrene ceiling tiles can be used in almost any room. It is undesirable only to glue it in the kitchen, and for children you can still find other material.

No. 3. The main types of polystyrene tiles

By type of production, ceiling polystyrene foam is of the following types:

- stamped, or pressed;

- extruded;

- injection.

Stamped plates produced by placing polystyrene foam blocks in special forms and their subsequent compression. The result is products with the simplest and not very embossed patterns, small thickness (about 6-8 mm) and very fragile. Since such plates are not covered with a protective layer, they absorb dirt well and are difficult to clean. The main advantage is the price.

Extruded panels are considered the most durable, durable, reliable and moisture resistant. The material is produced by hot extrusion of raw material bands. As a result, tiles with a slight grit and an almost smooth dense surface come out, due to which it becomes possible to apply a decorative coating. Such panels can be simply white and have complex patterns, or they can imitate the surface of a tree of any breed or stone. Due to its high density, minimal porosity and impregnation with water-repellent compositions, the material receives sufficient moisture resistance. It is the extruded tile that can be seamless, which we will discuss below.

Injection polystyrene foam produced by filling the raw material into a mold and sintering it under the influence of high temperatures. The result is a product with precise geometry and a clear relief pattern, the thickness of the plates is 9-14 mm. Such panels are well tolerated by moisture, perfectly retain noise and heat, they are quite durable and have a wide variety of patterns.Due to the intricate ornament and good performance, such plates are sometimes even used for wall decoration. Injection panels are often produced with imitation of leather, wood, fabric, and ceramics.

Number 4. Surface type

In terms of diversity, expanded polystyrene ceiling tiles eclipse many other finishing materials. By surface type, the entire range of products presented can be divided into the following types:

- plain white tilewhich, if desired, can be painted in any suitable shade;

- plain colored tile;

- laminated tile. Due to the thin film that is applied on top of the polystyrene foam, you can simulate any type of wood, stone and other noble materials. The film allows you to make the tile more resistant to moisture and dirt, as well as simplify the process of cleaning it;

- mirror tile characterized by the presence of a thin mirror layer. Such products belong to exclusive design options and are great for arranging small rooms, as they will visually expand the space. The only exception is the bedroom, where the mirror ceiling is inappropriate.

The shape of the tile can be square, rectangular, diamond-shaped, there is also a tile of the wrong so-called design form.

No. 5. Seamless Ceiling Tile

Seamless tiles should be highlighted separately. Many are embarrassed that seams form during installation. If you glue ordinary tiles and act carefully, they will be almost invisible, but if you are a perfectionist who wants to get a monolithic surface, then you will like seamless tiles.

The main feature of the material is a special edge treatment, due to which the seams will be minimally noticeable. As a rule, the manufacturer encloses the installation diagram on the packaging, and if you follow it exactly, you can get the perfect integral ceiling surface.

No. 6. What else to consider when choosing?

When choosing polystyrene foam tiles, it is very important to personally see and evaluate the quality of the material:

- the edges of the tile should be flat and not crumble. If you choose a square or rectangular tile, then the corners should be clearly straight;

- all tile grains should be the same;

- all tiles must be of the same size, because discrepancies of several millimeters will no longer allow a good joining of the elements and the integrity of the surface;

- High-quality tiles must be strong enough to support their weight. Check it out easily. You should take the tile at one corner: this operation should not lead to cracks.

By shape and size tile can be any. The most popular are square tiles measuring 50 * 50 cm, 30 * 30 cm and rectangular 100 * 16.5 cm. Calculate the required amount of material not difficult. First of all, you need to know the surface area to be trimmed. It should be divided by the area of the material in the package. For example, if you take a large square tile, then in the packaging it is usually 8 pieces or 2m2. If the ceiling area is 17 m2, then it costs 9 packs, it’s better to take 10-11: a small supply will not be superfluous, it will come in handy during repairs, especially when installing and trimming part of the tiles can be damaged. It is better to take a stock of material 15-20%.

Number 7. The best manufacturers of expanded polystyrene boards

The best quality guarantee is the name of the manufacturer. In order to protect yourself, you should look in the direction of the products of eminent companies that value their reputation. Among the largest manufacturers it is worth noting:

- Armstrong is a company that produces both the most ordinary and rather non-standard tiles. Performance in any case at a height;

- Ormit is a German-made tile characterized by high moisture resistant qualities, a wide range of sizes and colors;

- Antares - lets in all kinds of plates, the color scheme is varied. Also produces baseboards and corners;

- Matrix - Chinese-made tiles of small thickness. The main advantage is the low price;

- Angara is another Chinese manufacturer with an attractive pricing policy; it produces panels no more than 8 mm thick.

When buying tiles, in any case, it is better to make sure that there are quality certificates.

Number 8. Do-it-yourself installation of polystyrene foam tiles

One of the main and most important advantages of the material is the ease of installation, but preparatory work should be given maximum attention.

Ceiling preparation performed as follows:

- the old finish is removed. Wallpaper can be pre-soaked, then they can easily be removed with a spatula. It’s more difficult with the paint - you have to warm it construction hairdryer or handle special solvent. If the ceiling was plastered, then you do not have to remove the finish. True, it is worth identifying weaknesses with the help of light taps. a hammer and at the next stage close them up;

- the cleaned ceiling is cleaned of dust and dirt;

- surface primer and sealing cracks, pits and other defects, if any. Ideal for these purposes puttywhich, after drying, is sanded with sandpaper. The smoother the surface, the more accurate the resulting ceiling. In the presence of strong irregularities, the tile will deform, weakly hold and will soon peel off;

- when the ceiling dries, you can start gluing.

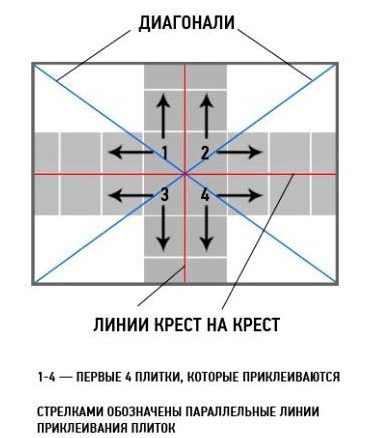

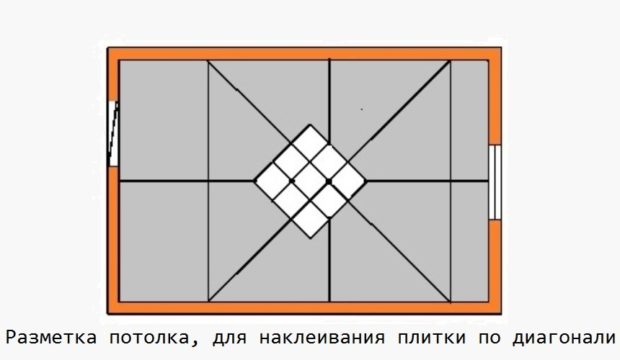

Another difficulty when sticking polystyrene tiles is mark up and correctly install the first elements. Exist two markup options:

- straight. It involves the installation of tiles parallel to the walls. Since the geometry of the room can be imperfect, and it is better to install non-integral parts of the tiles around the edges, special markings are performed, and installation is done from the center of the room. Diagonals are drawn from the opposite corners of the room, for this you can use the cords. The place of their intersection will be the center. From this point, with a pencil, using a level, draw two lines crosswise, each of which is parallel to the wall. The first plates are mounted in the corners of the intersection, then you can focus on the already installed elements. If a chandelier hangs in the center of the room, then it will become the center point. This installation option allows you to avoid distortions, even if the walls in the apartment are far from ideal. Variation of direct mounting - mounting of each new row with a shift relative to the previous;

- diagonal. For starters, you also have to stretch the diagonals from the cords. The tiles will be mounted along the formed diagonal lines, also from the center. The result is an interesting layout, and the oblique lines will visually expand the space.

Installation process itself looks like this:

- glue is applied to the tile, it is best to use liquid Nails and apply them dotted or in strips. In this way, glue can be saved and the tile maximized breathability. You can apply a little glue to the end to guarantee;

- the tile is pressed against the surface of the ceiling to a previously designated place quite tightly, but without excessive force. After a few minutes, the tile should already be glued if a high-quality, quick-setting adhesive has been selected;

- if part of the glue is on the front side, it is better to immediately wipe it with a damp sponge, otherwise traces may remain;

- in a similar manner, the remaining elements are mounted, if necessary, they are cut with a paint knife. Trimming is needed for the extreme elements, as well as for the central ones, if a chandelier is located in the center of the ceiling;

- setting skirting boards. It is also attached to glue. Masters recommend fixing it additionally with small cloves in several places, since it will be difficult to keep a long baseboard pressed to the surface. The next day, the cloves are removed, and the holes from them are sealed with acrylic putty;

- if there are discrepancies or seams between the tiles, they can be repaired sealant white color.

All work is carried out in the absence of drafts.After the glue and sealant have dried, the tile can be painted if desired, and it is not necessary to use only one shade: the relief sections can be highlighted in a different color.

If you pay attention to the choice of ceiling polystyrene foam tiles and carefully install it, then the result will please you for many years.