6 Tips for Choosing and Installing an Aluminum Slatted Ceiling

A variety of ceiling decoration materials knows no boundaries. If our parents chose only between whitewashing and wallpaperthen we can use today stretch ceilinglining polystyrene plates, mirror and even metal. The latter option requires more detailed consideration. Metal rack ceiling allows you to realize bold design fantasies, create interesting lighting and at the same time it is resistant to moisture, strong and durable. At first glance, such a solution may seem ideal. Is it so? We will consider how to select and install an aluminum rack ceiling, get acquainted with the main advantages, disadvantages and types of such a design.

Metal is widely used in the design of ceilings, because it is a durable material that easily takes and maintains the necessary shape. Thanks to coloring, corrugation and perforation, it allows you to create very interesting ceilings. Modules of various shapes are made of metal: slats, panels, cassettes and grilles. All of them are mounted according to the principle of suspension design. Mostly only flats are used in apartments - the other options are used in public and office premises.

No. 1. What is a metal rack ceiling?

By name, it is easy to guess that the basis of such ceilings are metal battens. Them length usually ranges from 2 to 4 mbut some companies produce rails up to 6 m in length. However, for a spacious living room, for example, this will not be enough, so some large manufacturers offer special connectors to the rails, which make the junction unnoticed, turning several rails into a monolithic element.

By rail width can be from 30 mm to 400 mm, but more often found elements in the range of 50-200 mm. Here the choice depends on personal preferences, the desired effect and the characteristics of the room. If you need to arrange a ceiling of a large area, it is better to take wider slats and vice versa. The choice of thickness is also based on minimizing trimmings.

As for the material of manufacture, the rails can be performed aluminum and steel. The second option is less practical and popular, so we will only talk about aluminum rack ceilings.

A decorative coating is applied to aluminum:

- powder coating;

- polymer protective layer;

- anodized aluminum;

- laminate layer.

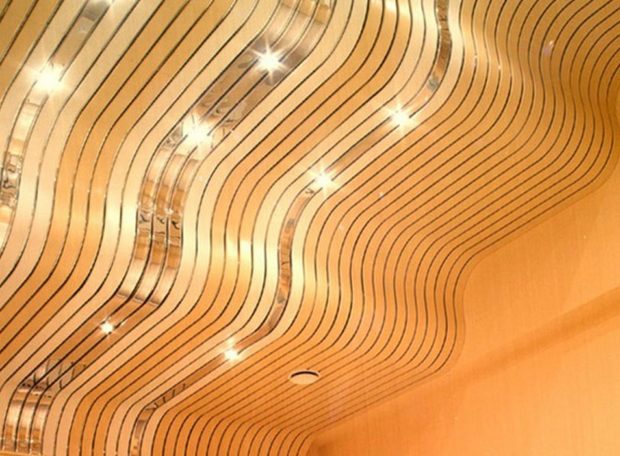

If we add that the slats can be smooth, matte, mirror, perforated, imitate wood and take almost any shape, then they can be called a source of inspiration for the designer and a way to bring any interior idea to life.

No. 2. Advantages and disadvantages

Aluminum rack ceiling is not yet so popular, but it seems that the period of its glory is not far off. This is the perfect solution for your home improvement. ceiling in the bathroom or on the kitchen, and with a certain approach, it can be used in other rooms.

Main advantages metal rack ceiling:

- high durability, measured over decades;

- high strength;

- excellent moisture resistance, the ability to maintain the original appearance even in rooms with a constantly high level of humidity, therefore often such ceilings are installed in bathrooms and in kitchens;

- antistatic properties and simplicity in leaving. Not only does the metal accumulate dust poorly, it is also easy to clean. It is enough to wash the surface and wipe it with a disinfectant solution sometimes;

- the ability to hide communications between the rails and the surface of the main ceiling, so it will be possible to create any lighting system - most importantly, think through everything in advance;

- no need to prepare for a long time and level the main surface;

- fire safety;

- low weight of the structure, so the additional load on the ceiling will be low. To equip the rack ceiling, metal is used with a thickness of about 0.5 mm;

- simple installation, which is quite possible to do it yourself. Mountains of dirt after installation of such a design will not be required to be taken out. Moreover, it is also very easy to disassemble a metal rack ceiling; a special tool is not needed;

- huge scope for design decisions, and it is not only the color and type of surface of the panel. The rack ceiling can be multi-level, complemented by interesting lighting system, combine panels of different thicknesses and textures. By the way, the ability of a metal surface to reflect will not only create interesting visual effects, but also save energy.

Now about cons:

- like all suspended structures, a rack ceiling takes away the height of the room. After its installation, the room will become 5-15 cm lower. If the ceilings are already low, then it is better to look at other finishes;

- during installation, rails should be handled carefully, since they can be deformed from impact;

- installation of a multi-level construction requires certain skills, therefore, perhaps the help of specialists is needed;

- metal does not absorb sound, and with a large ceiling area it can create a resonance, which is not very nice;

- cost. The rack ceiling will cost a little more than the more common options for finishing the ceiling, but at the same time it is still cheaper than the tension structures.

No. 3. Open and closed rack ceilings

The fundamental difference in aluminum rack ceiling designs - this is the presence of a gap between the individual rails:

- open type assumes a small gap between the rails. Such ceilings are mounted in high rooms. The gaps can be installed decorative inserts made of aluminum of a different color, resulting in interesting visual effects. Designers do not recommend using more than three colors at once;

- closed type the ceiling is assembled according to the principle wooden lining, all panels are butt-mounted to each other.

Both options look good, but the second is more strict and classic, and decorative inserts in an open design allow you to create a unique ceiling.

Number 4. Metal rack ceiling design

Reiki can be painted in any color or stylized for any material. The most commonly used options today are:

- matt white slats with enamel coating, which can be called a real classic. They fit perfectly into any interior, do not attract attention, but at the same time allow you to quickly and easily create a beautiful even ceiling;

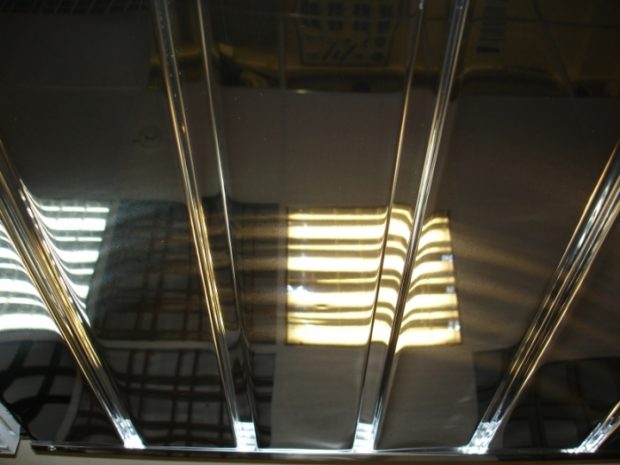

- mirror slats, which can additionally be painted in gold, bronze, copper. Such material perfectly reflects the light, therefore, with the proper selection and location of the fixtures, it will be possible to achieve interesting effects. The chrome planks will complement the interior in high tech style;

- Reiki laminated with veneer natural wood, allow you to create a ceiling that looks practically indistinguishable from what is done using wooden lining. This is a good option for rooms decorated in a classic style.

No. 5. What else to consider when choosing?

When buying aluminum rails directly, pay attention to such nuances:

- quality slats are supplied in protective film, which significantly reduces the risk of deformation and damage during transportation;

- if you want to create the most durable and strong construction, it is better to take rails with enthusiastic thickness;

- poor soundproofing qualities can greatly spoil the impression of the entire system of slatted ceilings. If the design will be mounted in a living room, it is better to take the so-called acoustic ceilings, i.e. slats glued to the back soundproofing material.

Please note that the metal ceiling does not allow air to pass through. If other finishing materials in the room also do not “breathe”, or if powerful ventilation, then in the ceiling space it is possible to equip an exhaust channel, and in order for air to approach it, use several perforated rails. An alternative for proper ventilation is the use of an open type design without decorative inserts.

Now for ceiling ceilings manufacturers. If you need a solid quality guarantee, it is better to take the products of foreign companies. You can recommend the American manufacturer Ceiling Group USA Corporation, the German Geipel and the Dutch Luxalon. Domestic manufacturers recently also offer products of good quality, in addition, it is somewhat cheaper. It is worth noting the rack ceilings of the Bard, Albes and Lyumsvet companies.

No. 6. Features of installation of aluminum rack ceilings

It is not very difficult to install a metal rack ceiling with your own hands, but it is better to take an assistant and be very careful at all stages. Installation technology is as follows:

- installation of a guide profile around the perimeter of the ceiling. A marker on the walls mark a line that corresponds to the level of the future suspension structure. The distance from the main ceiling to the rack should be at least 5 cm and sufficient to hide all the necessary communications. When determining the level and drawing the line, it is best to use the laser level, but you can do everything with ordinary water, only a little more tinkering. Now you should cut off a fragment of the angular profile, the length should correspond to the length of the wall. The procedure is repeated for all walls. Profiles are fastened along the drawn line with screws and dowels, holes are prepared in the wall and profile first, for which you can use drill or hammer drill. Fasten a profile with a step of 50-60 cm;

- installation of suspensions for stringers. The stringer is the structural support bus; it is to it that all the ceiling rails will be attached. This is a U-shaped profile with reeds carved on the edges, which are used to fasten the rails. Stringers are made of steel and aluminum: the first option is suitable only for dry rooms, the second is universal. Stringers are mounted on the ceiling with adjustable suspensions, thanks to which you can adjust the position of the tire to get a precisely horizontal surface. Suspensions consist of a rod that is mounted on the ceiling, and brackets to which the tires are attached. Stringers are mounted with a step of 1 m, the first tire is placed at a distance of 30-40 cm from the supporting profile. On the ceiling, it is better to mark the places where the tires will be installed. Suspensions are fixed along the applied lines, given the location of the mounting holes in the stringer. Suspension rods are installed on the ceiling using anchors, all suspensions must be located on the same level - they are easily adjustable in height. It is better to control this stage of work with the help of a laser level;

- tire installation carried out using screwdriver through a specially provided hole. It is very important to fix the stringers at the same level with the supporting profile;

- installation of rails. Remove the protective film from the rails and cut the elements of the required length. Experts advise cutting fragments 3-5 cm shorter than the distance from wall to wall. The slats are inserted into the stringers and snap along the entire length on the tire clips. Elements are installed sequentially, one after another. If necessary, the height of the tire can be adjusted thanks to the suspension. The last rail may need to be cut. First, a line is marked on the element, and then the rail is bent and unbent along it until it breaks. On long rails, it is better to make transverse cuts. The cut rail is fixed with corner profile scraps or wooden struts;

- skirting installationwhich masks the gaps and makes the ceiling look complete.

If it is planned to install spotlights in the ceiling, then a circle should be drawn in the required place on the panel, and radial cuts should be made with metal scissors from the center to the outside line. The petals bend into the slats. If you do not feel confident that you can complete the installation yourself, it is better to immediately contact specialists and not spoil the expensive material. A properly installed metal rack ceiling will delight you with its appearance for a very long time.