7 tips for choosing a corrugated pipe for electrical wiring (cable line)

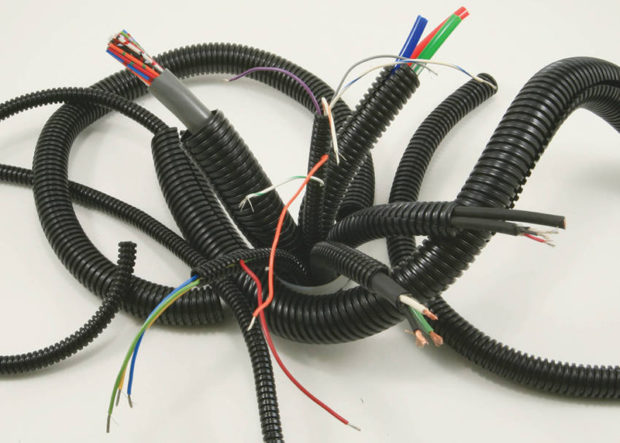

The times when the wiring was simply walled into the wall have long passed. This is very inconvenient, because in which case access to the cable will be difficult. Probably, one should not even talk about the insecurity of such a decision. Corrugated pipe helps to improve convenience and safety, which protects the cable from mechanical stress, moisture and acts as a dielectric. In some cases, a corrugated pipe cannot be dispensed with, at least, this is stated in the rules for the installation of electrical equipment (PUE). There are a lot of different options for its execution, so before buying it is important to figure out how to choose a corrugated pipe for electrical wiring, get acquainted with the assortment and all possible variations.

No. 1. What is a corrugated pipe and why is it needed?

Corrugated pipe can be made of different materials, but its structure remains unchanged. It consists of sections with different cross sections, which naturally alternate with each other. Smaller diameter sections have thinner walls and provide excellent flexibility and stretchability to the pipe: you can bend the corrugated pipe at almost any angle. Sections of a slightly larger diameter are characterized by increased thickness and play the role of stiffeners, all loads and impacts are assigned to them.

The use of plastic corrugated pipes for electrical wiring allows you to get a number additional benefits:

- protection of wires from mechanical damage and the negative effects of the environment;

- additional moisture insulation, which is especially important for rooms with a constantly high level of humidity;

- ensuring fire safety. Corrugated pipe made of self-extinguishing PVC does not burn and prevents the spread of fire;

- no need to perform additional insulation such as shielding and braids;

- the ability to diagnose and quickly replace wiring or parts thereof;

- longevity, which can reach 50 years.

No. 2. Corrugated Pipe Material

For rooms of different types and purposes, with different conditions of temperature and humidity, corrugated pipes are chosen from different materials. At the moment, the most popular solutions are:

- polyvinyl chloride (PVC), which, thanks to special additives, has the ability to self-extinguish;

- polyethylene low pressure (PND) allows you to get the most flexible pipes;

- high pressure polyethylene (LDPE) is used to organize hidden wiring in structures that are not subject to fire (brick, foam block, concrete etc.). The material can also be used to create the outer layer of two-layer corrugated tubes;

- polypropylene (PP) is used in rare cases and is indispensable when wiring is arranged during construction using monolithic technology;

- polyamide (PA) has increased waterproofing, so it will be useful in rooms with high humidity.

The most popular option is PVC., also pipes from PND and PVD are often used, their operational characteristics differ slightly. All of them are resistant to moisture, corrosion, do not rot, withstand temperatures from -25 to +950FROM.

Note that PVC pipes - The best option in terms of fire safety, but such a corrugation has a minus - low resistance to ultraviolet rays, so it is better to use PVC pipes to organize hidden electrical wiring or placed inside buildings. Pipes from PND They are not so afraid of ultraviolet radiation, therefore they can be used outside buildings. They are more resistant to cold and heat, but less resistant to fire.

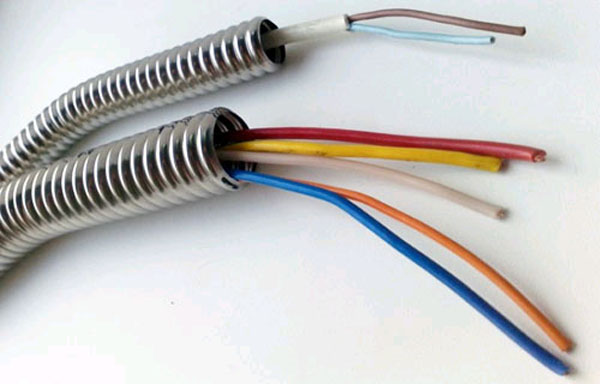

If we are talking about laying electrical wiring in a combustible material (a striking example is wood), then it is best to use corrugated metal pipe. It costs more than all plastic analogues, so in other cases it is not used.

No. 3. Design features of a corrugated pipe

Corrugated pipes are divided into:

- single layer;

- two-layer.

FROM single layer pipes everything is clear only by one name.Double layersuggest the presence of an outer corrugated layer and an inner smooth one. The latter are used less often, but allow the cable to provide even higher resistance to mechanical stress.

Inside the corrugated pipe can be located probe. This is a steel wire that runs along the entire pipe. The probe greatly facilitates the process of tightening the wires into the corrugation. On sale can be found corrugated pipe and without probe. It costs less, but pulling the cable into it will have to torment.

Number 4. Light and heavy corrugated tubes

Depending on the conditions of installation and further operation, it may be necessary to use corrugated pipes of various designs, according to which they are divided into the following types:

- lungs;

- heavy;

- super heavy.

Light corrugated tubes They are distinguished by small thickness, light weight, they bend very well, perfectly take the necessary shape, therefore they are as simple as possible in installation. Minus - low resistance to mechanical stress. Such pipes are used mainly for internal wiring, but they can also be used to organize external wiring if strong pressure is not applied to the corrugation. Lightweight pipes can be used under structures made of drywall, above traction and false ceilingsas well as in the car.

Heavy pipes have thicker walls that can withstand already more serious loads of both mechanical and climatic nature. Such corrugated pipes are used for cement-concrete screed, plaster, for laying highways underground.

Is there some more super heavy pipesthat can provide the highest level of protection for wiring. Such products are recommended for use in medical and educational institutions, where safety comes first.

No. 5. Diameter of corrugated tubes for electrical wiring and their color

The corrugated pipe is produced in bays, length may be 50-100 m for light corrugations and 2-25 m for heavy ones. The bays are packed in a shrink film made of polyethylene for ease of transportation and better preservation of the pipe itself. The outer diameter of the corrugated pipe ranges from 16 to 50 mm, internal - from 11 to 40 mm, much depends on the type of material used.

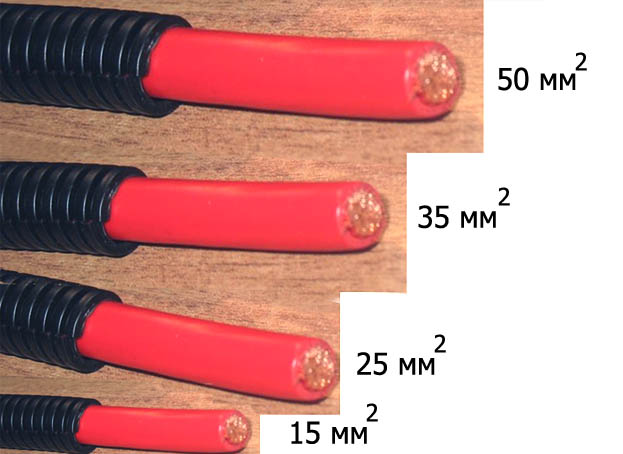

Pick up corrugation diameter It follows, based on what section the wire is used, and how many wires will be simultaneously in the corrugation. Based on vast experience, specialists formed the following recommendations:

- for bringing thin cables to outlets, installing computer and telephone networks, alarms and lighting devices, a pipe with an external diameter of 16 mm is suitable;

- to connect electrical appliances use a corrugation of 20 mm;

- between junction boxes, wiring is mounted in a corrugation with a diameter of 25 mm;

- to connect electrical panels it is better to use a pipe of 32 mm;

- it is better to hide the wiring between floors in a pipe with a diameter of 40-50 mm.

For laying underground wiring use double-walled heavy corrugation, the diameter of which can reach 200 mm

If one piece of corrugation was not enough, the connection of different parts is carried out using special couplings, split tees, bends and elbows.

In the production of plastic corrugations, the use of special additives is allowed, which allow paint the material in a specific color, but at the same time do not affect its performance. For convenience, can be used for laying various cables corrugation of a certain color. In order not to get confused, you can focus on a single European standard, according to which:

- gray corrugation is used for laying general wiring;

- white - for computer networks;

- black and brown - for connecting electrical appliances;

- blue - for a warm floor;

- red - for external wiring.

Practice suggests that commonly used standard gray corrugation. Regardless of whether the pipe is painted in some color or not, there should be no foreign inclusions in the material, as well as cracks and chips.

No. 6. Electrical Corrugated Pipe Manufacturers

When buying a corrugated pipe, it does not hurt to inquire about the availability of quality certificates. This is not a simple formality, but an important security requirement. It does not bother to look at the name of the manufacturer, as large companies will not risk their reputation and produce products of inadequate quality. Among the largest manufacturers corrugated pipe, whose products are presented in domestic stores, it is worth noting:

- LLC "Company"Ecoplast"- a domestic company that produces and sells a wide range of materials for electrical wiring, including produces a corrugated pipe. The assortment includes PVC, HDPE and PP products, light and heavy pipes, with and without a probe, of different diameters. Production is standardized according to ISO 9001, and the products comply with all European requirements;

- COMPANY "RUVINIL”- one of the largest Russian manufacturers of electrical products. Since 1998, the company has mastered the production of a huge type of product, uses modern technology and high-quality raw materials. The company produces corrugated pipes made of PVC, HDPE and LDPE with a diameter of 16 to 63 mm;

- company "MosElectroPlast"- another fairly large domestic company that produces a solid list of electrical products. The corrugated pipe here is produced only from PVC, diameter from 16 to 55 mm, there are products with and without a probe, light and heavy;

- LTD "Delta»Manufactures products under the EnergoPlast trademark. The assortment includes PVC and HDPE pipes, light and heavy, with and without a probe;

- The Tyumen Corrugated Pipe Plant produces PVC pipes of various diameters;

- NASHORN - The company, which today is called one of the largest manufacturers of plastic pipes. For the installation of electrical wiring, they produce a corrugated pipe only from PVC, the assortment is not very large.

Number 7. Features of working with corrugated pipe

Laying the cable in the corrugation is not difficult, at least for those who have at least minimal electrical installation skills. Connecting and organizing the power grid is already a more complicated issue, so it is better to use the help of professionals if you are not confident in your abilities.

General principles of work in a corrugated pipe:

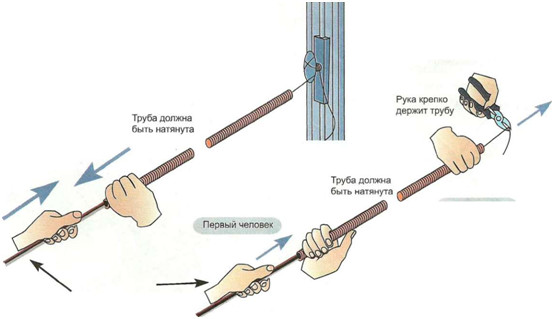

- tighten the cable or a bundle of cables in the corrugation is better with someone. First cut the required length of the pipe fragment. The plastic corrugation can be cut with an ordinary knife, and the probe in it with nippers or side cutters. After cutting, the steel wire should be held, otherwise it may pop in. The wire is bent. If it is necessary to tighten the bundle of wires, then it is better to pull them in several places with electrical tape. The resulting harness is attached to the probe using the same electrical tape or by winding with wire. If one cable is laid, it can simply be punctured in the insulation. Before pulling, the end of the twist is wrapped with electrical tape. It is easier to get the cable into the corrugation together;

- with external corrugation fixed special clips. When mounting in a shtrob, special clamps can be used, fastening to quick-hardening mortars (alabaster) is also allowed;

- it is necessary to bring the corrugation to the switches, sockets and boxes so that the edge of the pipe enters the housing, and bare wires do not remain outside;

- between the corrugation with electrical wiring and the elements of the heating system should be at least 10 cm;

- if the corrugation is carried out in a room with a high level of humidity, the joints must be equipped with gaskets.

The corrugated pipe is able to make the wiring system in the apartment more secure, reduce the influence of external factors on it, but for this the pipe must be selected and installed correctly.