6 tips for installing electrical wiring in a wooden house

Nowadays, wooden houses - this is the norm. Everyone wants to live in an environmentally friendly house, but at the same time, modern people do not want to give up the conveniences of modernity. We are talking about lighting, the use of household appliances, computers, etc. All this will become possible only if electric wires are laid inside the house, switches and sockets, distribution boards are installed. When it comes to a wooden house, which is easily ignited and burns, special requirements are put forward for wiring, compliance with which is the guarantee of safety for all residents. We will figure out how to correctly install the wiring in a wooden house and what should be taken into account. The material will help assess your strengths and determine whether it is possible to do all the work yourself or if you have to call for professional help.

No. 1. Wiring requirements in a wooden house

Wood belongs to those types of materials that are easy to light up and burn well. Wooden house It can easily catch fire from a normal short circuit in an electrical circuit, so the process wiring installation It is to minimize the likelihood of a short circuit, and in case of its occurrence, to minimize the consequences. For wiring in a wooden house, such requirements are put forward:

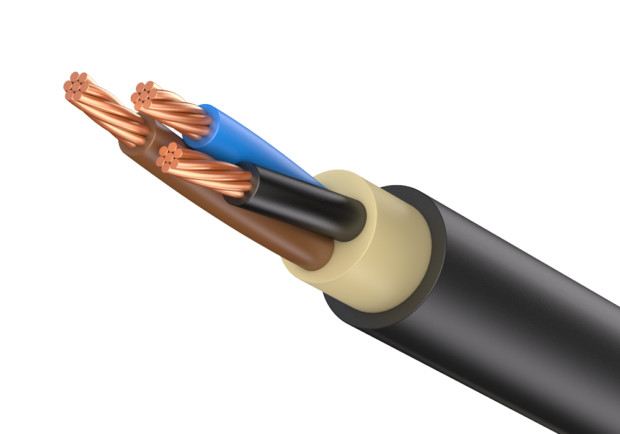

- use only copper conductors with fireproof sheath;

- insulate conductors in non-combustible material;

- perform the correct calculation of the cross section of the electric cable so that the current load does not exceed its capabilities;

- it is better to use open type wiring;

- hidden wiring must be in a metal pipe - use a metal hose and even PVC corrugation with self-extinguishing effect is not recommended;

- there must be an RCD and a circuit breaker in the shield;

- it is better to use quality materials from trusted manufacturers, as the savings associated with buying cheap Chinese products can result in big problems.

No. 2. Hidden wiring in a wooden house

Electrical wiring in wooden buildings can be performed in two ways:

- hidden;

- open.

Hidden wiring in a wooden house it is more complicated and has a lot of risks. Such work is best trusted by specialists. Internal wiring is equipped when the wooden walls of the house are sheathed from above decoration material, eg, clapboard or drywall. In this case, the wires are placed between the main wall and the cladding layer. Naturally, you cannot leave wires unprotected - they must be hide in a metal pipe. Many masters make a mistake and use plastic sleeves, PVC corrugation or metal hose for these purposes. This can not be done for several reasons:

- there is no guarantee that the cable insulation will not be violated and there will be no short circuit, and the walls of the ducts and pipes will not be able to withstand such a load. The result is a fire. Insulation can be violated not only due to installation errors, but also as a result of manufacturing defects, improper storage and transportation.Most measuring instruments do not fix microcracks in isolation, and over time, when exposed to constant loads, the insulation weakens more and more;

- plastic corrugation and box - weak barrier for rodents, which can easily damage it by exposing the wires;

- voids are prepared for the installation of hidden wiring in wooden walls, and over time, wood dust tends to accumulate in them, for which a small spark is enough to ignite. It is problematic to localize such a fire source.

That is why hidden electrical wiring in a wooden house must be mounted with metal pipes. They can provide reliable protection against short circuits, but number of conditions:

- inside and outside such pipes should have anticorrosive layer;

- it is better to mount the pipes at a slight slope to allow the condensate to flow freely;

- pipes must be connected to the ground loop;

- sharp edges that are formed when cutting pipes can damage the wire, they must wear plastic sleeves;

- the pipe connection must be tight;

- in the walls you need to cut out the channels.

The best option is copper pipes, but it will cost a lot.

Safety does not violate the option with using plaster, although, at first glance, it does not seem quite suitable. To ensure proper protection, the cable should be surrounded on all sides by a layer plasters at least 10 mm thick, but to be able to replace the cable, it must be placed in a metal hose. In fact, it turns out that replacing the cable is very difficult, and the plaster over time, under the influence of the "breath" of the tree, begins to crack.

No. 3. Open wiring in a wooden house

Laying electrical wires inside wooden walls is not only very dangerous, but also technically difficult. With the open method, the owner can fix the problem at any time, since access to the wires is always open, so this installation option has become more popular. Of the shortcomings, only unaesthetic is called due to the visibility of the wires, but today this minus can be dealt with.

For open wiring in wooden houses use:

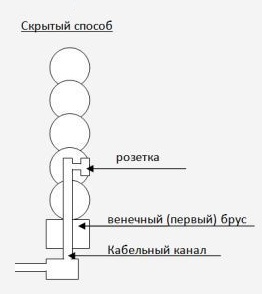

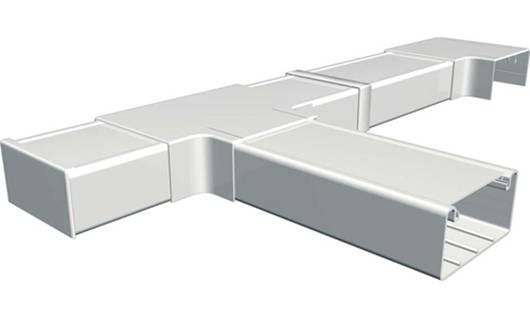

- cable channels, or electrical boxes. This is the most convenient and popular way. Such channels are relatively easy to mount to a wooden surface, and if you choose the right color, they will be minimally noticeable. Manufacturers produce boxes with color and pattern for different types of wood. In terms of aesthetics, cost and ease of access to wires, this is the best option, but correctly calculating the number of necessary elements, turns, angles and plugs is not always easy;

- electrical skirting board - The most modern option that allows you to achieve the most aesthetic results. It provides for clamps;

- insulation rollers. These are small ceramic elements that are mounted on the surface and hold the wiring. All wires will be visible, therefore, in terms of aesthetics, the option is not the best, but it allows you to create retro style interior. A similar method of installation is usually used in houses built of logs;

- special staples. This is the cheapest and easiest option, but looks not very good;

- metal hose It is used for open wiring only in non-residential buildings, as the room becomes similar to a production one. The corrugation, no matter how hard you try, will not lie perfectly, it will sag, and, moreover, it collects dust.

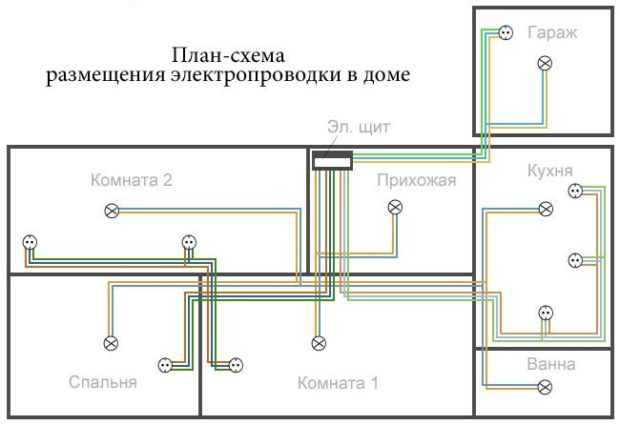

Number 4. Creating a wiring diagram

Installation of electrical wiring in a wooden house begins with the creation of a scheme that is agreed with Gosenergonadzor. On it is necessary indicate the places where all sockets, switches, as well as the shield and counter will be located. The diagram also shows the future location of the cable, indicating the distance from the floor, ceiling, window and door openings. As a basis, it is better to take a house plan, where the exact parameters of all rooms are indicated.

To correctly draw up a diagram, follow these rules:

- in advance, you need to think about the location of large household appliances, as well as the lighting scheme. This will eliminate the problems with extension cords in the future;

- determine the maximum power of devices;

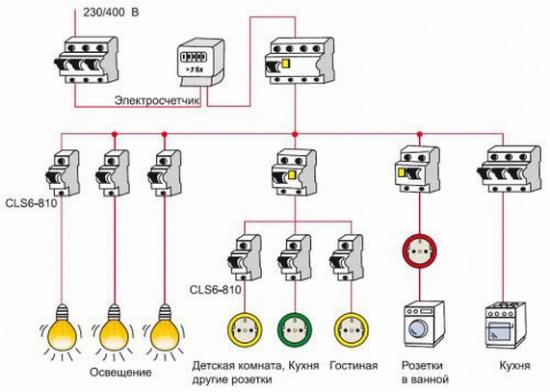

- form connection groups. The rules dictate that each room has two branches of wiring: one for sockets, the second for lighting. Each powerful appliance (washing machine, boiler etc.) - for them it is necessary to lay a separate cable. House lighting - This is another group, but it is often connected to a separate circuit breaker in order to be able to turn on the lights when no one is at home. For each group, the maximum load is considered;

- Outlets can be located at any height. The main thing is that it is convenient to use them, so think about the type and number of electrical appliances;

- circuit breakers, as a rule, are located at a height of 80 or 150 cm. It is desirable that all are not at the same height;

- the distribution panel is mounted at a height of 150 cm so that small children do not reach it;

- wiring can only go vertically and horizontally, rotate at right angles.

When the scheme is agreed, and the necessary power is allocated, you can move on.

No. 5. Laying the cable to the house

There are two ways to carry a power cable into a house:

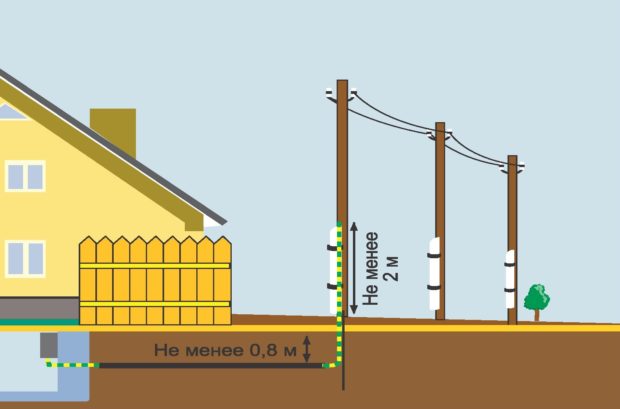

- underground;

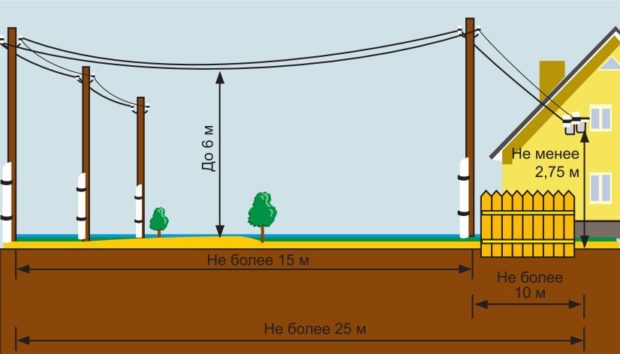

- air.

Underground installation - This is a more reliable and modern technology, but also more difficult to implement. It is justified to use it in the construction of a new house. Under the ground, the cable experiences much less stress than the one that hangs in the air and lasts longer: it will not tear from the wind or a tree falling on it. In addition, the house, around which no wires hang, looks much better. Installation is complicated, time consuming and expensive. It will be necessary to dig a trench with a depth of at least 80 cm, the entrance to the house is carried out by installing metal sleeves from thick-walled pipes. Used power copper wire.

Aerial installation it will be cheaper and faster, but be prepared in case of bad weather to remain without electricity. Carrying out such work is possible if the distance to the object is not more than 25 m - otherwise you will have to put additional support, and this is money. For connection use a self-supporting insulated wire with a sheath of crosslinked polyethylene, cross section and number of cores depends on the power of the connection.

Inside the house, the aluminum wiring does not start - only copper is used, therefore, from the connection point to the input distribution panel, the VVGng cable is used. For connection, tight clamps are used, and VVGng cable, according to the rules, must be enclosed in a metal sleeve from a thick-walled pipe. In the same sleeve, the cable leads to the distribution panel, if the latter is not taken out to the street or is not located at the entrance to the house.

The shield is installed in a safe place, guaranteeing free access to it. Circuit breakers and RCDs are mounted in the shield.

No. 6. Cable routing in rooms

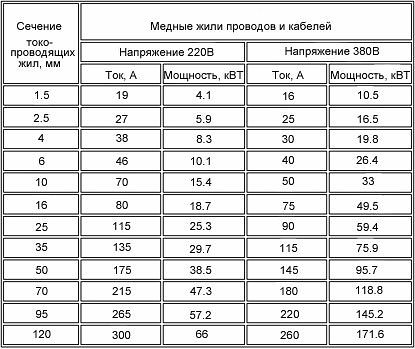

Cable section wiring depends on what kind of load they will be assigned. This is the subject of serious calculations, but you can also use tables in which the cross-section of the wires has already been calculated, depending on the current, power and voltage.

Open wiring in cable channels

Before starting work best mark out future locations for outlets and switches. For safety and aesthetics, it is best to mount open wiring in cable channels in a wooden house. They are made of self-extinguishing plastic, they are a box with a latch, the size and color may vary. The wiring process in this case is as follows:

- choose a cable channel, which corresponds to the number of wires and their cross section;

- remove the lid and attach the channel box to the surface on screws;

- at the junction of the cables they put junction boxes;

- the base of sockets and switches (only those that are intended for external wiring are used) are mounted on designated places;

- the cable is laid in the channel, closed with a lid;

- cable ends will be connected in junction boxes. Connect the cable to sockets, switches and circuit breakers.

Internal wiring in a metal pipe

If you decide to mount hidden wiring in a wooden house, then the procedure will be as follows:

- preparation of the gate and installation of open junction boxes, they should be freely available even after wall cladding;

- passage through the walls make using metal pipes, which are called bushings. First, a hole of the required diameter is prepared in the wall, then a sleeve is placed, along the edges it should have a plastic sleeve. Special metal sleeves are placed under sockets and switches;

- the diameter of the pipe is chosen so that after winding up all the cables, 60% of free space remains in it. Preference is given to copper pipes, which are well bent and easily cut. After cutting, the ends of the pipes are well ground or they are provided with plastic rims. Pipes are attached to the wooden surface with clamps, to metal sleeves - thanks to the expansion of the pipe inside the sleeve;

- pull the cable through the pipe and check the insulation;

- connection of cables in junction boxes and connection to sockets, switches.

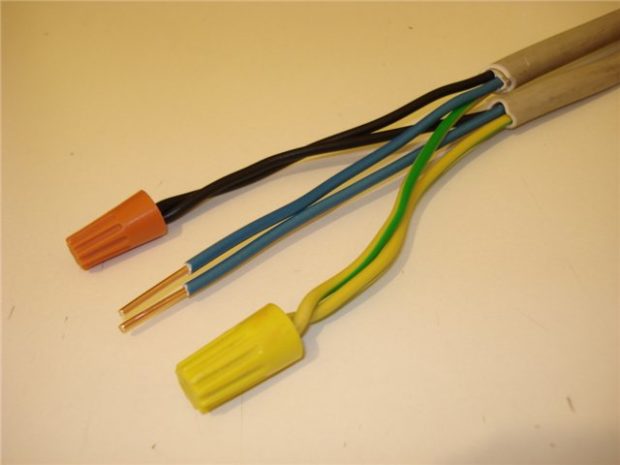

Wire connection

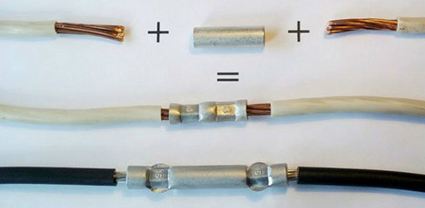

In junction boxes wires can be connected in one of the following ways:

- junction. These are special insulating caps that allow you to connect two previously smoothed 2-3 cm and twisted wires together. Caps are very easy to put on and are inexpensive;

- wagging no less simple, but more reliable. A wagon with an appropriate number of holes for wires is selected, cables are inserted into them until they click;

- crimping with sleeves - One of the most modern methods, but special equipment will be needed;

- grandfather way of twisting with subsequent isolation electrical tape in a wooden house it is better not to use it.

It remains only to install sockets and switches. For a wooden house, fittings made under a tree are best suited, but this is not necessary. This is followed by work on connecting all groups of wires to the shield, installing a meter, RCD and automatic devices.

Also need ground. To do this, they dig a hole in the shape of an equilateral triangle near the house with a side of 1 m. The depth is at least 30 cm. A metal corner or a pin 3 m long is driven into the vertices of the triangle, they are connected to each other by a 1 m long corner using welding. A hole is made in one of the corners and the grounding conductor is fastened in it with the help of a bolt and nut, it is brought out to the distribution panel and connected to the grounding bus, grounding wires of the cables are also connected to it.

After completing all installation work, specialists from the electric laboratory are called up who carry out all the necessary tests and issue a protocol confirming the correctness of the wiring and its safety. The wiring diagram is recommended to be glued to the inner surface of the flap door - it will be much more convenient to navigate in the event of an accident.

Perform all installation work in the wooden house is necessary only with the appropriate knowledge and experience. At the slightest doubt, it is better to call specialists - the safety of the house and its residents depends on the quality and correctness of the implementation of all stages of work.

Hello! Very useful and interesting article! Thanks!

Good afternoon.

KINETIC SWITCH

Works WITHOUT BATTERIES and WITHOUT CABLE GASKET.

Avoids cabling to current consumers, speeds up repair time.

Ideal for electrical work in wooden houses (due to the high cost and complexity of ordinary work) and in cases where expensive repairs have already been completed and the customer does not want to lay the cable and finish the walls again.

Remote (up to 120 meters in a straight line) on / off. fixtures, gates, shutters, pumps, boilers, etc.

The switch is IP67, which allows installation in showers and in the rain.