10 tips on which solid fuel boiler is better to choose for a private house

Access to electricity and gas is far from everywhere, but somehow it is necessary to bask. An excellent solution would be the installation of a solid fuel boiler. Not only does it allow you to create completely autonomous heat supply systemso still in operation very economical. Solid fuel boilers are used as the main and backup heat source, and burned to produce thermal energy firewood, sawdust, coal or pellets. These are rather bulky units, and the fuel has to be thrown up regularly, but the low cost of the energy received allows solid fuel boilers to still compete with more modern gas and electric. We will figure out which solid fuel boiler is better to choose for a private house, determine the power, type of heat exchanger and other nuances.

No. 1. Briefly about the principles of work

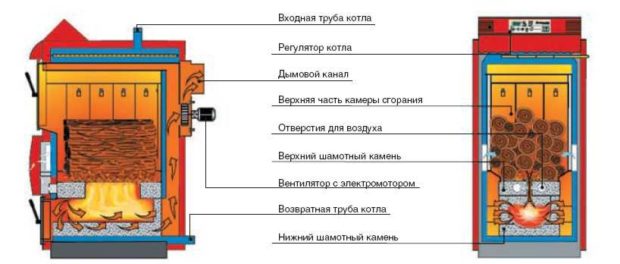

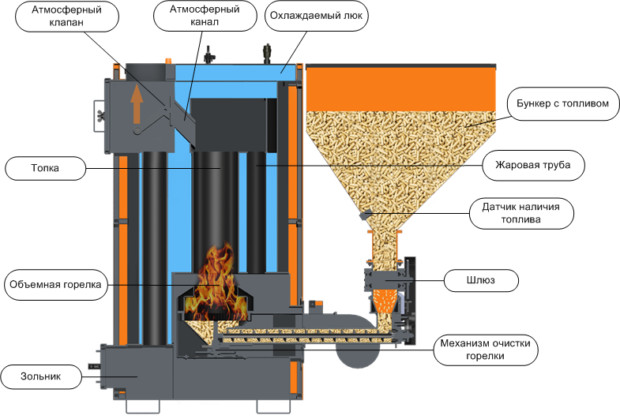

It would seem that complicated in a solid fuel boiler? He threw firewood or coal into the furnace, they burned down, heated water, and the house was filled with heat. In general, everything is so, but the principle of operation of the device is somewhat more complicated. The design of a modern solid fuel boiler can distinguish the following main elements:

- firebox;

- coolant circulation system;

- smoke removal system;

- safety system;

- heat storage system.

IN firebox fuel is supplied and burned for heat. This is a classic version. There are pyrolysis boilers in which solid fuel (firewood) smolders, releasing gas, which then burns, providing heat. The efficiency in this case increases somewhat, but we will deal with the features of the operation of classical and pyrolysis boilers later.

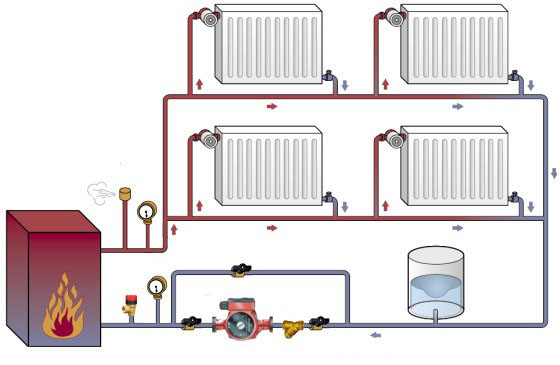

The firebox is a large capacity with double walls, between which is located coolant. This is in most cases water, less often an anti-freezing liquid or a mixture of water and antifreeze is used. The heat carrier receives heat from the burned fuel, circulates through pipes and radiatorsheating the air in the house. Cooling down, the water returns to the boiler and everything repeats. Often, special pumps are used to improve circulation.

When burning fuel, not only heat is generated, but also gases that must be removed. The system is intended for this smoke removal. Chimney removes gases from the boiler to the street, sometimes a forced system is used to increase the efficiency of this process ventilation.

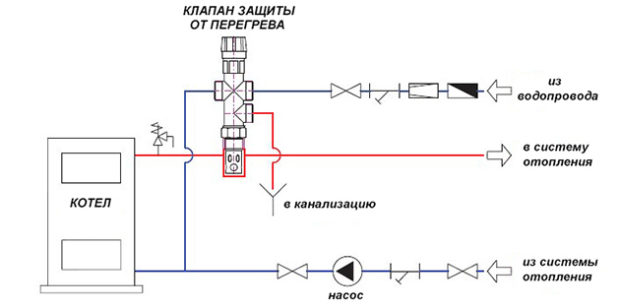

The most great dangerthat can happen during operation of a solid fuel boiler is coolant overheating. Water can already be sufficiently heated, and the boiler will continue to generate heat. If the water boils, the heating system may not stand it, especially if the house is set sufficiently sensitive to high temperatures plastic pipes. It is practically impossible to stop the combustion of firewood or coal - it remains only to reduce the intensity, and so that an overheated coolant does not get into the system, use cooling heat exchanger. It receives cold water from water supply, but in case of a blackout, it is better to always have a sufficient supply of it.

The cooling heat exchanger may be built into the boiler or located between the boiler and the rest of the heating system. It can only be integrated into the design of a steel boiler. It works in one of two possible ways:

- first option - cooling of the heated coolantthat passes through a cooling heat exchanger. Cold water is supplied to the cooling heat exchanger through a thermal valve, which opens when the coolant temperature reaches +950C. The process continues until the coolant has cooled to a safe temperature;

- the second option provides for shut off valve. If the water temperature rises to critical values, the valve prevents it from entering the pipes. Cold water from the water supply system is supplied to the heat supply system, and the superheated coolant is drained into sewer. True, the water pressure should be sufficient, and its composition should not be high salt contentthat provoke the formation of scale.

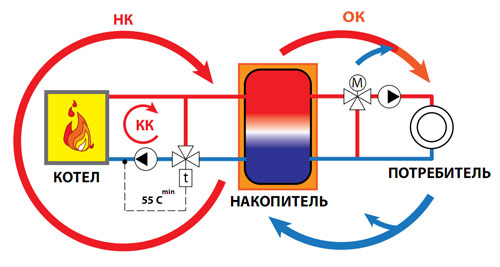

It is not very smart and economical to drain heated water into the sewers, therefore it is better to supplement the design of a solid fuel boiler storage tank. This is a buffer between the boiler and the rest of the heating system, thanks to which it is implemented a number of important functions:

It is not very smart and economical to drain heated water into the sewers, therefore it is better to supplement the design of a solid fuel boiler storage tank. This is a buffer between the boiler and the rest of the heating system, thanks to which it is implemented a number of important functions:

- accumulation of warm water for its further use, and this is fuel economy, comfort, stability in maintaining the temperature and reducing the number of trips to the furnace for topping up fuel;

- accident protection. In the tank, superheated water is mixed with warm;

- the ability to use different types of boilers. The storage tank will be common to solid fuel and, for example, gas or electric boiler, will allow you to simply organize a unified heat supply system at home and insure yourself with several heat sources.

The heat accumulators are made of cast iron or steel and receive powerful thermal insulation. Buffer volumeFirst of all, it depends on the boiler power: for every 1 kW it is necessary to provide 25 liters of tank volume. The quality of this element of the heating system should be the highest, therefore, it is better to trust the products of well-known manufacturers.

No. 2. Types of solid fuel boilers according to the principle of operation

With a similar general scheme of the device, different types of solid fuel boilers have some nuances in design. The entire existing assortment can be divided into the following types:

- classic or traditional boilers;

- pyrolysis or gas generating boilers;

- long burning boilers;

- pellet boilers.

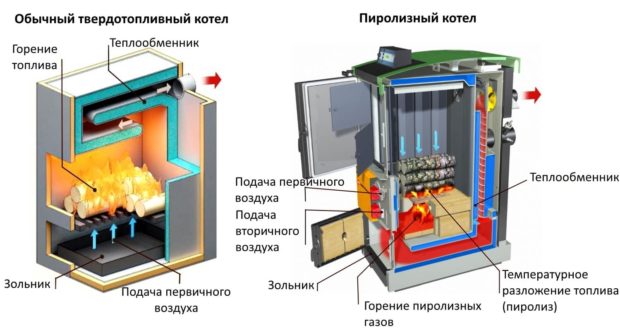

Classic solid fuel boilers

Such boilers are much like ordinary furnace. Heat is obtained as a result flame burning fuel. As a last use, as a rule, firewood or coal. Fuel is supplied through one door, and through another - the boiler is cleaned of ash and other products of incomplete combustion. Traditional boilers can have both cast iron and steel heat exchangers, they are usually used in systems with natural circulation.

Although the efficiency of this kind of device is not the highest, they are appreciated for reliability, because in the design of the boiler there is a minimum of electronic elements that can fail. The only automation element is a temperature controller, but it also works on a mechanical basis. Classic boilers are durable and rarely require repair.

Pyrolysis Boilers

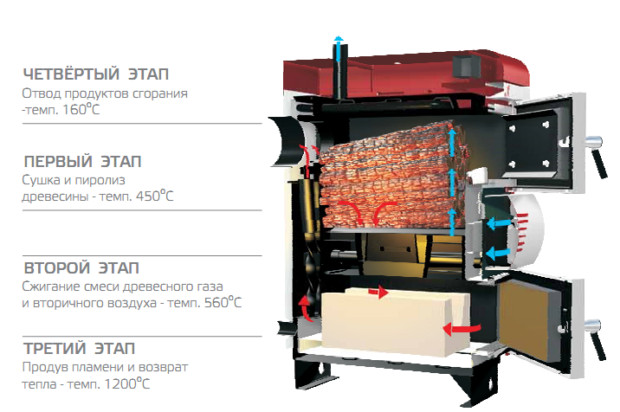

Pyrolysis (gas-generating) boilers are arranged somewhat more complicated. Present in their design two combustion chambers. In the first put solid fuel (firewood), at high temperature and oxygen deficiency occurs pyrolysis process with the release of pyrolysis gas. It goes into the second chamber, where it burns out and gives off heat to the heat carrier. Only charcoal remains from firewood.

The combustion temperature of pyrolysis gas is higher than that of firewood, which ensures an increase in boiler efficiency up to 90%.If we take into account the fact that the process of wood decay is slower than its burning, then we can talk about another advantage - one bookmark of fuel is enough for 10-13 hours (for classic boilers, this figure is 5-7 hours). Hardwood and low humidity (not more than 20%) are used as fuel.

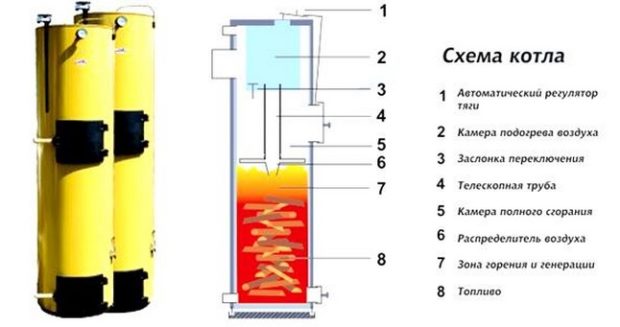

Long burning boilers

This type of boiler is largely reminiscent of pyrolysis, but differs in some technical features. Solid fuel smolders in the first chamber, forms gases that burn out in the second furnace. In this case, only the upper part of the fuel is involved in the process of smoldering and burning. Due to this, it is necessary to load it less often, and the efficiency increases. One load of firewood is enough for the boiler to work two days. The main disadvantage is the high cost of equipment.

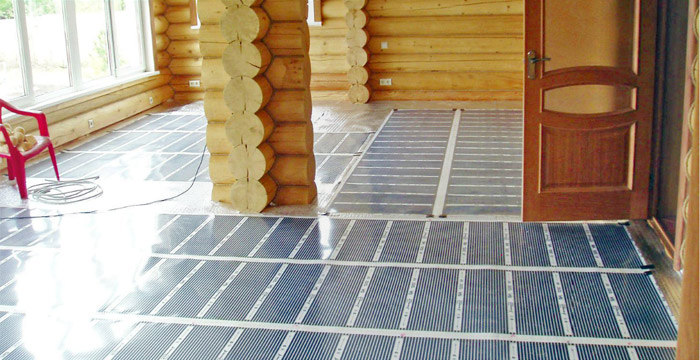

Pellet boilers

They are often also called automatic boilers. According to the principle of action, they are not much different from traditional ones, but in addition to the furnace, they have bunker for storing fuel stock. This means that it will be unnecessary to often come up and throw fuel into the furnace manually - everything will be done by automation. Between downloads, the fuel supply may take about 7 days. In addition, such a system can be very precisely adjusted for yourself. Fuel is considered one of the most environmentally friendly at the moment. Pellets are granules that are made from wood waste (sawdust, shavings, etc.). Efficiency of such systems 91-95%, the only negative is the high price of boilers.

No. 3. Heat exchanger fabrication material

There are few options. Heat exchangers can be:

- steel;

- cast iron.

It is difficult to say unequivocally which solid fuel boiler is best - it all depends on the budget, operating conditions and personal requirements. Manufacturers produce both boilers.

Cast iron heat exchangers have the following advantages:

- they are going to from individual sectionstherefore their transportation and installation is easier. Moreover, if one of its sections is damaged can be replaced, so durability such boilers at a height of up to 20 years or more;

- cast iron during operation is covered with a film of iron oxide. This is dry rust, which hardly progresses, protecting the rest of the material from the negative effects. Cast iron more resistant to corrosion, therefore, it’s less necessary to clean the heat exchanger;

- cast iron keeps warm longeris a plus. Reverse side - it warms up more slowly.

Among cons high weight, higher than steel, brittleness, and poor resistance to thermal shocks. With a sharp change in temperature, the cast-iron heat exchanger can easily crack, so avoid getting cold water into the still-cooled heat exchanger.

The advantages of a steel heat exchanger include:

- higher strength, and since such a heat exchanger is brewed in the factory and is solid, it becomes possible to produce combustion chambers of complex configurations, due to which the efficiency increases;

- high resistance to sudden changes in temperature. Boilers with such heat exchangers, as a rule, receive more advanced automation, since you can freely control the temperature without fear of damaging the structure;

- not as high as cast iron;

- faster heating, but also faster cooling.

Steel, on the other hand, is more susceptible to development corrosion processes. Despite the resistance to temperature changes, with frequent such fluctuations, cracks may appear in the weld areas. In which case it will be impossible to repair the steel boiler - you have to buy a new one, therefore the durability of such structures is lower.

Number 4. Traction and energy consumption

Solid fuel boilers can be divided into two types:

- non-volatile with natural draft. They do without special pumps, so they do not consume electricity. In this design, classic boilers and some long-burning boilers function.Good for frequent areas power outagescan be used as a backup heat source;

- volatile with additional traction. The design provides for a fan that helps air to enter the combustion chamber. In this design, most long-burning boilers, pellet and pyrolysis boilers are produced. Thanks to the control panel, you can make some settings.

No. 5. Number of circuits

Single-circuit boilers responsible only for the heating system. There are also double-circuit boilersthat allow you to provide a hot water system private home. This is very convenient, but when calculating the required power, you should definitely consider this feature. In addition, there are boilers equipped cooking hobs.

Pay attention to the fact that solid fuel boilers are installed on the floor - there are no wall-mounted models.

No. 6. Calculation of the power of a solid fuel boiler

One of the main indicators that you should first of all pay attention to when choosing a solid fuel boiler is its power, which determines how much heat it can provide. It should come from just the same the area of the heated room. You can use the generally accepted rule: for every 10 m2 The area requires 1 kW of boiler power. This is subject to normal thermal insulation and ceiling height not more than 3 m.

It turns out that for heating a house with an area of 150 m2 a boiler of 15 kW will be enough. It is even at an external temperature of -360C will ensure that the temperature in the house is +180C. In case of insufficient thermal insulation at home, as well as in harsh climates, it is better to take a boiler with a small margin of power.

If the boiler will be used in a hot water supply system, this must be taken into account when calculating the capacity of the heat exchanger. Experts say that in order to ensure comfort in the house, the power of a double-circuit boiler in any case should not be lower than 24 kW. It is better to entrust more accurate calculations to professionals who will take into account all the features of a particular house and heating system.

Number 7. Fuel type

Solid fuel boiler can be thrown into the furnace firewood, coal, pellets and sawdust. It is a mistake to assume that the boiler capacity will remain unchanged, no matter what fuel is used. Many boiler models can work with different types fuelbut at the same time, maximum power will be achieved only when using the fuel that the manufacturer indicated as the main one. When using less caloric fuel, the power will drop by 25-30%, and if it is excessively wet, then the power drop can be up to 40%.

Average heat transfer parameters of different types of fuel:

- firewood - 2500 kcal / kg. Logs of wood usually have a length of 25-30 cm, can be sawn or chopped. It is important that the wood is dry;

- coal anthracite - 7400 kcal / kg;

- coal - 7000 kcal / kg;

- brown coal - 3500 kcal / kg;

- pellets - 4500 kcal / kg.

Number 8. Combustion chamber volume

The larger the volume of the combustion chamber, the more fuel can be loaded, and the less often run to the furnace and toss up a new portion. In the characteristics of the boiler, it is customary to indicate such an indicator as the ratio of the volume of fuel loading to the power of the boiler, measured in l / kW. Since a steel boiler with the same power as a cast-iron one will have slightly more compact parameters, for it this ratio is 1.6-2.6 l / kW. For cast-iron boilers - 1.1-1.4 l / kW. The higher this indicator, the less often you will have to run to the boiler.

In boilers with top loading fuel the usable volume is greater, and the fuel in this case is distributed more evenly. With front loading, especially when it comes to a cast-iron multi-section heat exchanger, it will be necessary to make some efforts to evenly distribute fuel.

No. 9. What else to consider when choosing a solid fuel boiler?

Obviously, even before the purchase of the boiler, it is worth determining whether the boiler will be the main source of heat or backup. In the latter case, it is necessary to install an expansion tank or a heat accumulator - this is easier to do right away than to upgrade an existing system later.

If in the future there will be an opportunity switch to gaseous fuel, when choosing, pay attention to the possibility of transformation of the boiler. Many traditional boilers can switch to gas by installing an inflatable burner. It is convenient, but it is worth considering that the efficiency of the converted boiler will be lower than that which was originally designed for gas.

No. 10. Solid fuel boiler manufacturers

We will not discover America if we say that quality largely depends on the reputation of the manufacturer. Large companies will not spoil their name with products of inadequate quality, so when choosing a solid fuel cat it is better to pay attention to models from trusted manufacturers. This is the case when it is better not to save.

You can mark boilers of these brands:

- Buderus - A German company that specializes in the production of boilers of various types and purposes. Solid fuel models run on different types of fuel, there are classic and pyrolysis boilers, there is enough power to heat large private houses;

- Bosch produces traditional non-volatile boilers;

- Ferroli - A large Italian company, produces domestic and private boilers. Among solid fuel boilers there are coal-fired boilers, wood and pellets. The assortment is wide, the quality is on top;

- SIME - Another Italian company that made a name in just 35 years. Products are exported to 50 countries of the world, the range is represented by boilers for coal and wood;

- VIADRUS - Czech boilers. Represented in a fairly wide range, reliable, safe, have a pleasant cost;

- Stropuva - Lithuanian manufacturer, which often presents new solutions in the field. The latest development is a 40 kW boiler with the ability to work from one load for 30 hours;

- Protherm - high-quality Slovak cast-iron boilers with high efficiency.

You can also note the products of domestic enterprises manufactured under the brands "Prometheus" (for houses up to 450 m2), "Hearth" (there are double-circuit boilers), Zota and "Smoke".

Finally

Solid fuel boilers are available, can be used in the most remote places from civilization, are relatively cheap to operate and autonomous. Nevertheless, it will be necessary to put up with such shortcomings as the need for constant maintenance and control, transportation and manual loading of fuel. Safety is in the hands of each of us, so do not forget to check the pressure level in the expansion tank and the condition of the chimney.