11 tips on which metal-plastic pipes for heating and water supply is better to choose

It seems that the era of the dominance of metal pipes in the arrangement of various kinds of pipelines is slowly coming to an end. From many areas of use they were superseded by more flexible and cheaper metal-plastic pipes. Today they are successfully used in residential and industrial construction, with the organization of water supply, heating and sewage systems. What properties do they bribe, and can such pipes be called universal? We figure out which metal-plastic pipes for heating and water supply are better to choose, and determine the best manufacturers.

No. 1. Performance

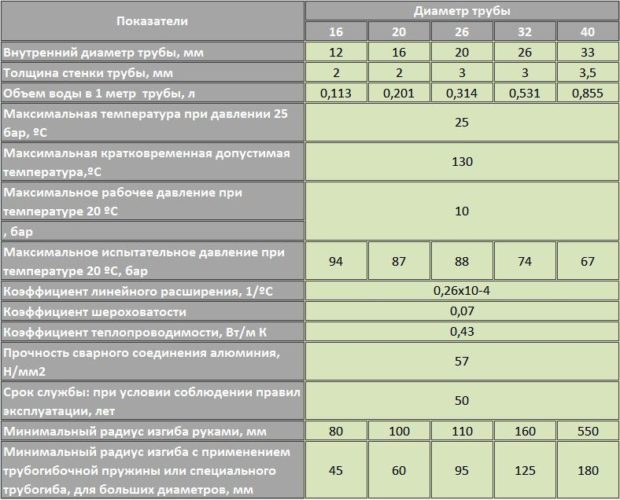

Of course, some of the performance of metal-plastic pipes may differ depending on the materials used in the production and their thickness, but for most products sold today, these characteristics are characteristic:

- maximum water temperature inside the pipe +950FROM;

- at a temperature of about +950C the maximum pressure that the pipe can withstand is 10 atm;

- at water temperature up to +250With the maximum working pressure can reach 25 atm;

- the pipe can withstand a short-term increase in temperature inside it to + 110 ... + 1300FROM.

No. 2. Scope of metal-plastic pipes

The properties of metal-plastic pipes allow almost everywhere to use them in civil and industrial construction. Without fear, you can apply in such areas:

- cold and hot water supply in apartments and private houses;

- heating systems;

- sewage systems;

- arrangement watering systems;

- water intake systems wells and wells;

- compressed air supply;

- transportation of some chemically aggressive liquids

Since installation is carried out without welding, such pipes are installed in places where welding is prohibited.

Do not use such pipes in rooms where objects located nearby can heat up to a temperature of 1500C and above, as well as in rooms with a high level of fire hazard.

No. 3. Advantages and disadvantages of metal-plastic pipes

In terms of performance, it is clear why pipes made of metal-plastic have gained such popularity. The ability to withstand relatively high temperatures and pressure surges is basic, but not the only advantages of metal-plastic pipes:

- low price;

- excellent flexibility, the ability to maintain shape along with low weight greatly simplify the installation of pipes. Dismantling, by the way, is also simple;

- no welding machine is required for installation - all connections are made by special fittings;

- corrosion resistance, since the outer and inner layers of the pipe are made of polymer;

- lime deposits do not accumulate on the smooth inner layer;

- high level of tightness. The pipe will not let out the liquid and will not let in oxygen, which leads to the start of the corrosion process of the metal elements of the pipeline;

- durability subject to installation and operation technology - about 50 years or more;

- fluid flow passes silently through such pipes;

- aesthetics;

- low thermal conductivity.

The main disadvantages:

- low resistance to mechanical damage;

- when compared with metal pipes, metal-plastic is inferior in maximum and minimum operating temperatures, resistance to water hammer;

- with a temperature difference, aluminum shrinks slightly more than plastic, which gradually leads to weakening of pipe joints and leaks, so threaded connections will have to be tightened periodically. Access to them should be free;

- with constant use at low temperatures or exposure to ultraviolet rays, the service life is greatly reduced.

Number 4. The construction of plastic pipes

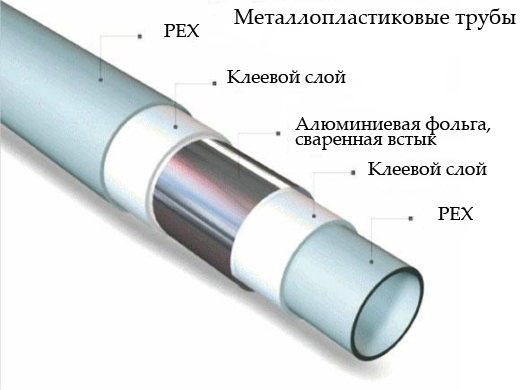

From the name of this type of pipe it is easy to guess about the features of the structure. Obviously, plastic and metal are used for the production, which are combined in a special way. Plastic pipe consists of five layers, three main and two binders:

- the first (inner) layer is made of polymer;

- the second layer (binder) is glue;

- third layer (reinforcing) - aluminum;

- the fourth layer (binder) is glue;

- the fifth layer (outer) is made of polymer.

To simplify, the pipe consists of two layers of plastic, between which is a layer of aluminum foil. The latter is necessary to give the product strength and wear resistance. Plastic inside and out protects aluminum. In addition, the inner polymer layer creates a smooth surface over which water (or other liquids) can move freely. Rust does not form on the plastic and limescale does not linger, therefore pipe capacity does not drop over the years. The outer polymer layer protects the product from mechanical damage and prevents condensation. To connect the three main layers using special adhesives with a high level of adhesion to polymers and metal.

To simplify, the pipe consists of two layers of plastic, between which is a layer of aluminum foil. The latter is necessary to give the product strength and wear resistance. Plastic inside and out protects aluminum. In addition, the inner polymer layer creates a smooth surface over which water (or other liquids) can move freely. Rust does not form on the plastic and limescale does not linger, therefore pipe capacity does not drop over the years. The outer polymer layer protects the product from mechanical damage and prevents condensation. To connect the three main layers using special adhesives with a high level of adhesion to polymers and metal.

The durability and scope of operation of the plastic pipe depend on the quality of the performance of each layer.

Number 4. Aluminum layer: thickness and method of connection

The following functions are assigned to the aluminum layer:

- protection against various kinds of damage, including mechanical stress, bending during installation, water pressure drops inside the pipe;

- protection against linear extensions;

- oxygen barrier.

Today, pipes with different thick aluminum layer. As a rule, it fluctuates within from 0.15 to 0.6 mm. To take pipes where the aluminum layer is up to 0.3 mm thick is undesirable, since they can be broken even during the installation process. The optimum thickness indicator is 0.3-0.55 mm: while maintaining sufficient strength, such pipes remain flexible and easy to install. If the aluminum layer exceeds 0.55 mm, then you will have to make a lot of effort during the installation process. Such pipes are more expensive, but in terms of strength, of course, prove themselves best.

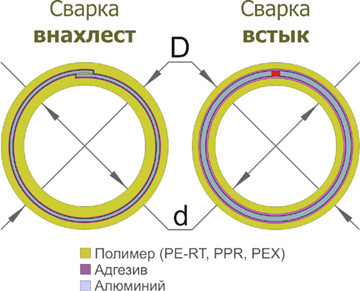

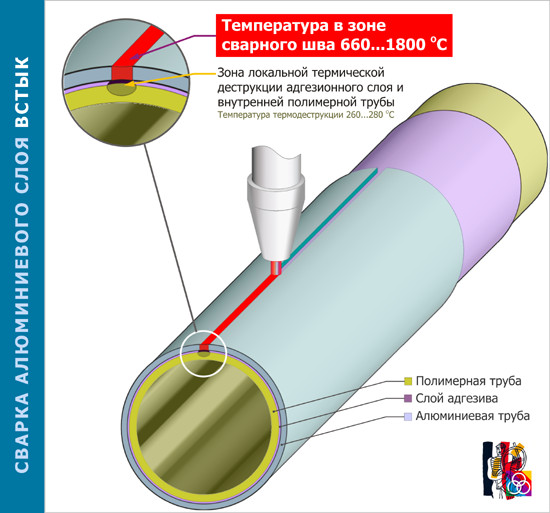

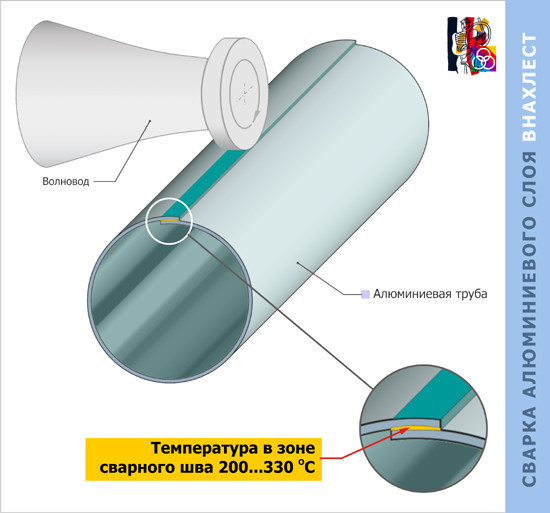

Layer aluminum foil turns into a solid tube by weldingbut it runs different ways:

- laser welding allows you to create seamless butt joint. The result is a pipe with smooth walls and excellent performance. The thickness of the aluminum layer can be anything;

- ultrasonic welding involves connecting the ends of the foil lap. In order to avoid significant thickening in the overlap area, it is necessary to slightly reduce the thickness of aluminum at the junction, which is why it is difficult to achieve perfect evenness of the walls along the entire length. Such pipes are cheaper, but inferior to seamless pipes in strength, durability, wear resistance and ease of installation.

Which plastic pipes are better to choose? Of course, seamless, especially when it comes to installing critical systems.

No. 5. Type of plastic in the inner and outer layer

For the production of metal pipes use such types of plastic:

- crosslinked PEX polyethylene and linear PE-RT polyethylene. They provide pipes with maximum strength, reliability and resistance to various kinds of loads. Such products better tolerate mechanical stress, jumps in temperature and pressure in the system, and have a long service life. To equip a hot water supply or heating system, it is better to take such pipes;

- low-pressure polyethylene (in the pipe marking it can be indicated by abbreviations such as PEHD, PE-RS, PE or HDPE) is also used in the production of metal-plastic pipes, but significantly reduces the scope of their use. This polymer is not able to withstand temperatures above +750C, therefore it is used exclusively for transporting cold water. In addition, it quickly wears out under the influence of direct ultraviolet rays, so it is advisable to protect the pipes from sunlight. Pipes made of low-pressure polyethylene are cheaper, but, subject to operating conditions, can last for decades.

No. 6. Tie layer

To connect plastic and metal with each other, special compositions are used whose properties make it possible to turn a multilayer structure into a single whole. What kind of glue is used by manufacturers, and what components are included in its composition, is difficult to say, since companies keep the glue formulas in secret. We can only check the safety certificates and make sure that the product is not toxic.

Glue not only binds all layers of the pipe to each other, but also is responsible for the elasticity of the product. The bonding layer is the most vulnerable spot in plastic pipes. With a loss of elasticity of the adhesive, the product begins to delaminate and flow.

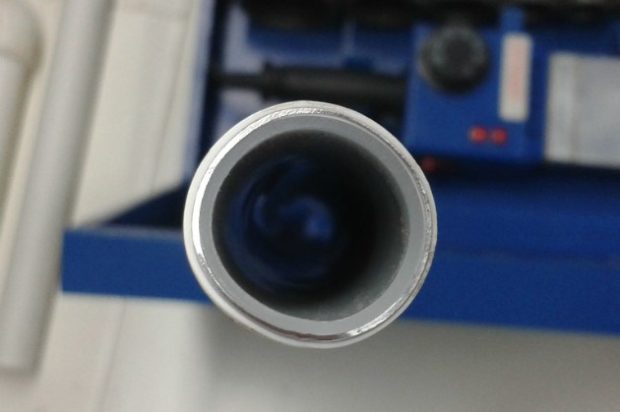

The metal-plastic pipe for heating and the pipeline must have a high-quality bonding layer: no delamination should be visible on the cut. If you notice that the layers are not bonded together tightly enough, it is unlikely that such a pipe can last a long time.

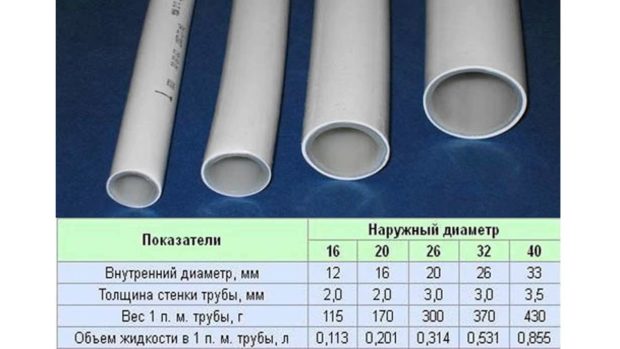

Number 7. Diameter of metal-plastic pipes

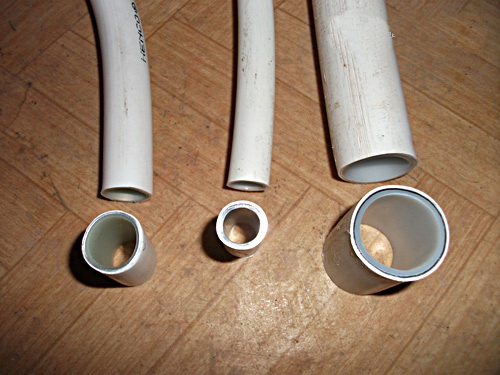

When choosing metal-plastic pipes, it is important to focus on such important product parameters:

- inner diameter - the main characteristic that determines the throughput of the pipe;

- the outer diameter is also indicated upon sale and ranges from 16 to 63 mm;

- wall thickness ranges from 2 to 3.5 mm, increases with increasing diameter.

The most popular sizes of metal-plastic pipes:

- outer diameter 16 mm, inner diameter 12 mm, wall 2 mm (16*12). Such pipes are used when supplying water to faucets and water meters, can be used to organize the entire water supply or heating system, but the latter, as a rule, are created from pipes of larger diameter. 16 mm pipe fittings are the cheapest;

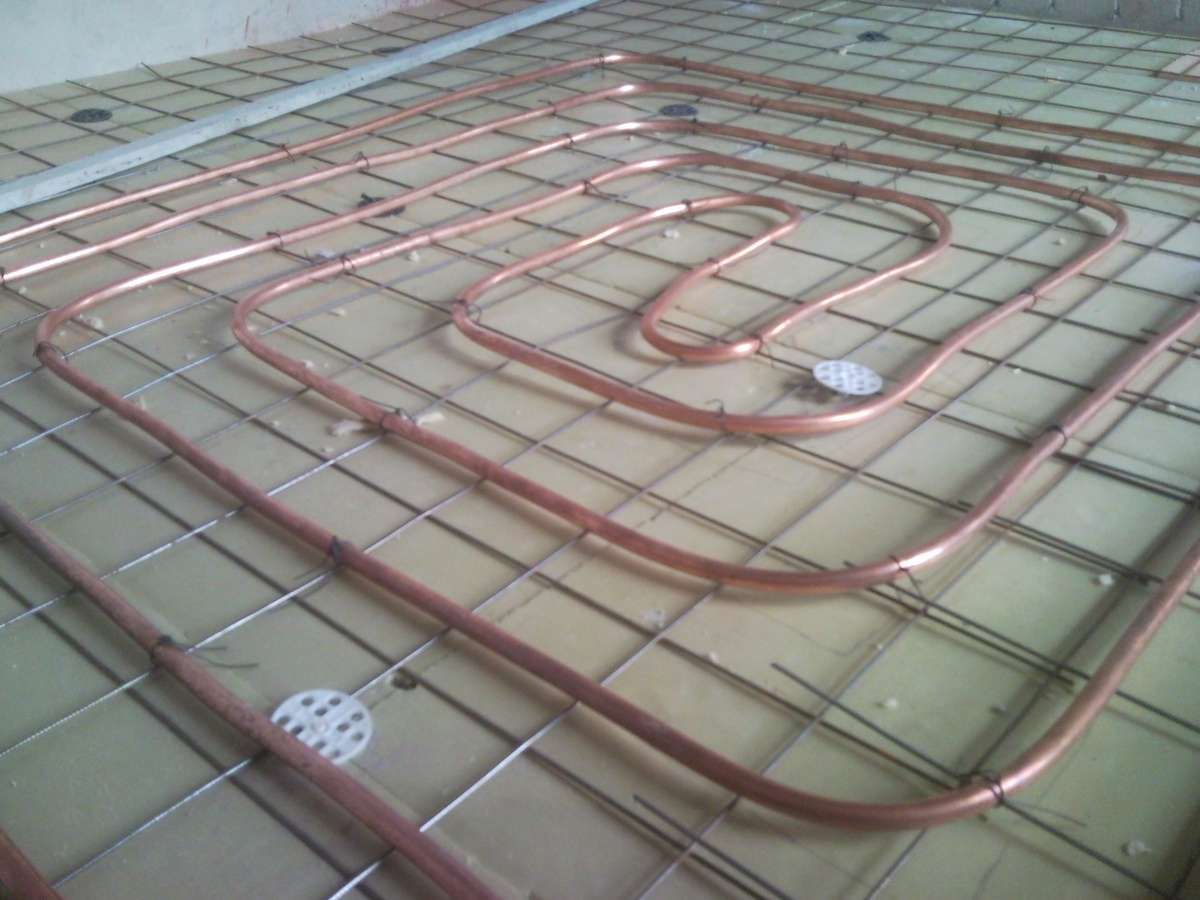

- pipes 20 * 16 with a wall thickness of 2 mm provide higher throughput and are used for installation warm floor, as well as for the construction of a water supply system in cases where the water pressure is unstable;

- pipes 26 * 20 with a wall thickness of 3 mm are suitable for organizing plumbing and systems heating in a private houserisers and underfloor heating;

- pipes 32 * 26 with a wall thickness of 3 mm are suitable for organizing the main water supply, riser. Such pipes are installed in houses with low water pressure;

- pipes 40 * 32 with a wall of 3.9 mm are suitable for the construction of central heating and water supply systems, can also be used in autonomous systems, water treatment systems. Typically, such pipes are not used in private construction - they are more suitable for creating extensive urban and industrial engineering networks;

- pipes 50 * 40 with a wall of 4 mm are applicable for the installation of technological pipelines, for the construction of water supply and heating systems for large industrial facilities. Also, such large pipes are suitable for transporting compressed air, aggressive substances;

- pipes with outside diameter 63 mm and more have a specific scope of use.

Number 8. Metal-plastic pipes for heating

In centralized heating systems, pressure can rise up to 4 atm, in autonomous ones it rarely exceeds 1-1.5 atm. The temperature of the coolant is about +700C, sometimes rises to +900C (if you use boiler, then this parameter can easily be adjusted). This once again convinces us that metal-plastic pipes can be used to organize a heating system.

The only thing restriction, which is present in this case, is the need to maintain positive temperatures in the house. The linear expansion of such pipes is minimal, so if the water freezes in them, the metal plastic will tear. That is why it is used to organize heating in constantly heated rooms.

If used solid fuel boiler, where possible overheating of the coolant, it is better to install a heat accumulator, otherwise with frequent temperature increases above +1000They may leak from the pipe.

No. 9. Metal-plastic pipes for water supply

For the transportation of cold water, any metal-plastic pipes are suitable. If we are talking about hot water supply (this also applies to heating), then it is necessary to take only pipes from cross-linked and linear polyethylene. Be sure to pay attention to the marking of the pipes, in which data such as working pressure and temperature, type of material of manufacture, plant name and batch number should be reflected. Before buying, specify what nominal and peak pressure indicators are typical for your water supply.

Since we are talking about transporting water, which will be used incl. for drinking, it does not interfere with making sure the product is safe and see hygiene certificates. Of course, the pipe itself should not have foreign inclusions, scratches, dents or other defects.

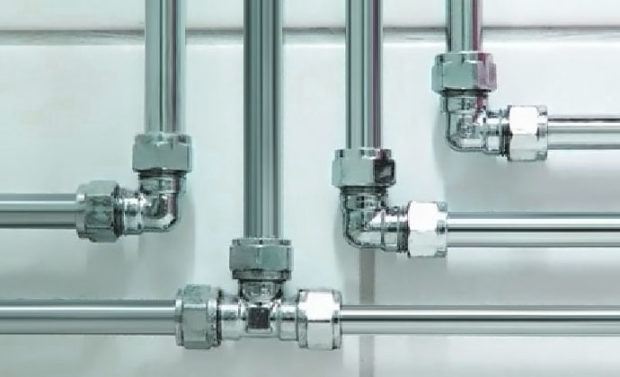

No. 10. Fittings for plastic pipes

The connection of individual sections of the pipeline is ensured through the use of special fittings. Of course, the topic of choosing suitable fittings requires a more detailed consideration, but we will focus on the main types of joints and their features.

So, fittings for metal pipes are of the following types:

- split fittings also called collapsible, threaded and collet. They cost more than others, they can be assembled and disassembled several times. The body of such a fitting is made of brass, fixing is ensured by a crimp ring and gasket. In general terms, the installation process looks like this. Marking is applied to the pipe, cutting is carried out with a special device and the pipe is calibrated (necessary to restore the shape). Then, a union nut and fitting collet are put on the pipe, the fitting body is inserted into the pipe until it stops. It remains only to tighten the union nut on the fitting, put the union nut on another pipe and connect the elements (clearly shown in the video). Such a connection is used to organize systems. cold water supply, for heating and hot water this is not the most suitable option - after 2-3 years you can notice a leak. Of course, the connection can be tightened, but all this for the time being, i.e. until the thread resource is exhausted;

- compression (crimp) fitting much easier to install, consists of a fitting and a union nut, which are fixed by a crimp ring. Such connections are suitable for systems cold water supply, but can be used for water pipes with hot water;

- press fittings - the best option for building heating systems. Such fittings have a complex design, but allow you to create the most reliable connection that can easily withstand pressure and temperature shocks. Installation of such fittings is carried out using special press machines, which are expensive.

No. 11. The main manufacturers of plastic pipes

The best quality guarantee is the name of the manufacturer.Today, such large manufacturers compete in the market for metal-plastic pipes:

- Valtec - An Italian company, a leader in the field. The production uses high-quality polyethylene, pure aluminum foil (butt-welded) and reliable adhesives that do not lose their elasticity under repeated pressure and temperature drops. Pipes of different diameters are produced, suitable for use in various fields, from water supply to the transportation of carbon fuel;

- Henco - A Belgian company that produces pipes, various fittings, manifolds and other equipment. The company carries out serious quality control, so the products have found worldwide recognition;

- OVENTROP - A large German company, produces pipes of all possible diameters, supplies them with appropriate press fittings;

- Kermi - Another German manufacturer who introduced the practice of using an additional layer of waterproofing in his pipes to completely prevent the passage of oxygen into the product;

- Uponor - German pipes, which are used in 60 countries of the world. The company produces pipes with a diameter of 26 to 110 mm;

- Rehau - German pipes and fittings. The layer of aluminum is joined end-to-end, polyethylene is characterized by the highest degree of crosslinking. A unique feature of the manufacturer's pipes is the ability to bend without special tools;

- pipes PRANDELLI and Ape Italian production is also of high quality, but inferior in popularity to other manufacturers in our market;

- Sanha - A German company that is characterized by the active use of the latest developments. Manufacturer pipes - an ideal of quality;

- Hydrosta - good pipes made in Korea;

- Nanoplast - pipes of domestic production that meet all hygiene requirements.

In order not to run into a fake, before buying, look on the Internet what pipes of a certain manufacturer should look like, what color should be the inner and outer plastic, what texture the product has, how it is marked. Labels on original products will always be clear. From the internal cut you can easily find out how aluminum is welded: remember, the advantage is on the side of a seamless, butt welded joint. The thickness of the outer and inner plastic layers should be the same throughout the pipe, defects, scratches, bumps and depressions are not permissible.

Excellent analysis of products from different manufacturers, thanks to the author!

Great article.