7 tips on which pipes made of cross-linked polyethylene for a warm floor, heating and water supply is better to choose

Flexibility, strength, durability, the ability to restore shape after damage are the main, but far from the only, advantages of pipes made of cross-linked polyethylene. They surely displace other types of pipes from the market, are actively used in the installation of underfloor heating, water supply (hot and cold) and heating systems. Are they so universal? Let's put all the dots on “i” and try to figure out which pipes made of cross-linked polyethylene for underfloor heating, heating and water supply are better to choose what to look for when buying and which manufacturers you can trust.

No. 1. Production Features

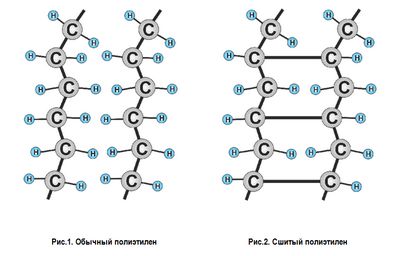

If we act in a special way on ordinary polyethylene (a polymer consisting of carbon and hydrogen atoms), then some hydrogen atoms are separated, leading to the formation of a new bond between carbon molecules. The process for producing these additional carbon bonds is called stitching. They affect polyethylene by various substances and methods, so the degree of crosslinking may vary. The optimal indicator is 65-85%.

Cross-linking allows you to improve the properties of polyethylene: increased resistance to high temperatures, improved flexibility, wear resistance, there is the possibility of self-healing after mechanical stress. The crosslinking process was developed in 1968 by the Swedish chemist T. Engel, but underestimated his invention, considering it uncompetitive. The patent was acquired by WIRSBO, which was the first in the world to begin industrial production of cross-linked polyethylene pipes (PEX) and is still a leader in this field. Such products did not immediately hit the domestic market, but now they are very popular.

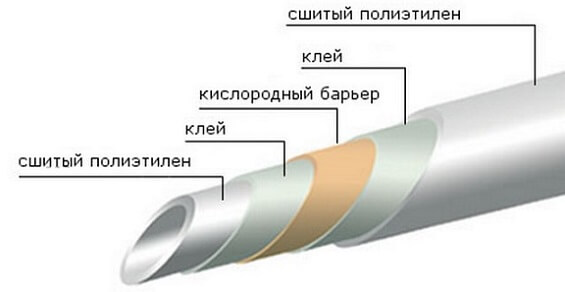

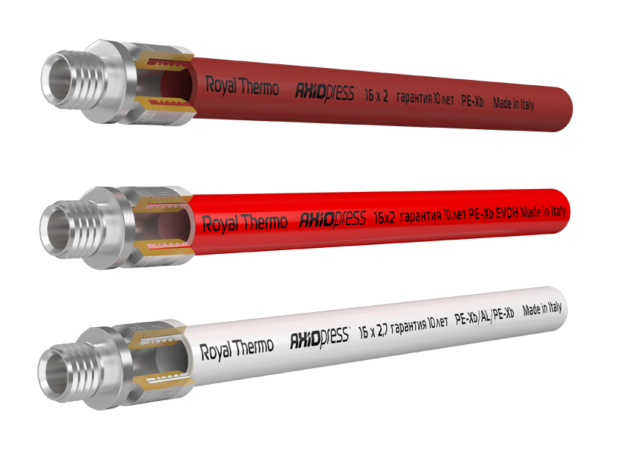

Pex pipe usually consists of three layers: inside - cross-linked polyethylene, outside - an oxygen-protective layer, they are connected with glue. On sale are found and 5-layer pipes. They have on top of the oxygen-protective layer another layer of glue and cross-linked polyethylene.

No. 2. PEX pipe crosslinking method

The most important parameter when choosing pipes made of cross-linked polyethylene is the cross-linking method used by the manufacturer. The quantity of formed additional bonds depends on it, and, consequently, the performance of the product.

To form additional bonds (bridges) in polyethylene, the following stitching methods are used:

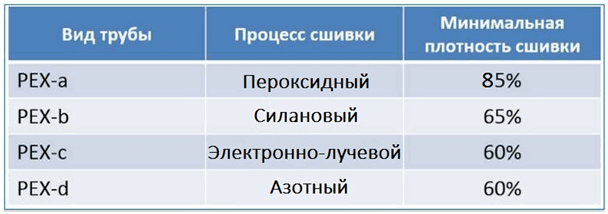

- crosslinking with peroxide, such pipes are marked PEX-A;

- silane crosslinking, PEX-B;

- radiation crosslinking, PEX-C;

- nitrogen crosslinking, PEX-D.

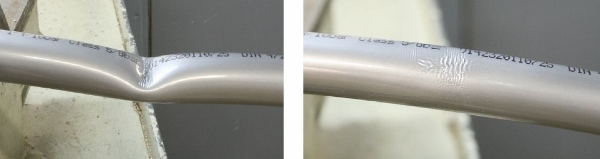

Pipes PexA obtained by heating the raw materials with the addition of peroxides. The crosslink density of this method is maximum and reaches 70-75%. This allows us to talk about such the benefitsas excellent flexibility (maximum among analogs) and the memory effect (when unwinding a bay, a pipe almost immediately takes its initial straight form). Kinks and creases that may appear during installation can be corrected if the pipe is slightly heated. construction hairdryer. Main minus - This is a high price, since peroxide crosslinking technology is considered the most expensive.In addition, during operation, the leaching of chemicals takes place, and it is somewhat more intense than in other PEX pipes.

Pipes PexB produce in two stages. First, organic silanides are added to the feed, resulting in an undersized pipe at the outlet. After that, the product is hydrated, and in the end crosslink density reaches 65%. Such pipes have a low price, they are resistant to oxidation, have high pressure values at which the pipe breaks. In terms of reliability, they are practically not inferior to PEX-A pipes: although the percentage of crosslinking is lower here, but the bond strength is higher than with peroxide crosslinking. Of cons note stiffness, so bending them will be problematic. In addition, there is no memory effect, so the original shape of the pipe will be restored poorly. When creases appear, only couplings will help.

Pipes PexC obtained with the so-called radiation crosslinking: polyethylene is affected by electrons or gamma rays. The production process requires careful monitoring, because the uniformity of crosslinking depends on the location of the electrode relative to the pipe. The degree of crosslinking reaches 60%, such pipes have a good molecular memory, they are more flexible than PEX-B, but cracks can form on them during operation. Halls can only be fixed with couplings. In Russia, such pipes are not widely used.

Pipes PexD produced by treating polyethylene with nitrogen compounds. The degree of crosslinking is low, about 60%, therefore, in terms of performance, such products are significantly inferior to analogues. Technology has actually become a thing of the past and is hardly ever used today.

On sale you can meet PEX-EVOH pipes. They differ not in the way of crosslinking, but in the presence of an external additional anti-diffusion layer of polyvinylethylene, which further protects the product from oxygen entering the pipe. By the method of stitching, they can be any.

The pipes are considered the highest quality. PexAbut their high cost forces many to use PEX-B pipes. These two types of products are most prevalent in the market, and the choice between them depends on the budget, personal preferences and features of the pipeline, which must be built with their help.

Do not confuse XLPE pipes with:

- pipes made of low pressure polyethylenethey withstand temperatures of no more than +400C and suitable only for cold water supply systems;

- pipes from undersized polyethylene Pert, in them there are no intermolecular bonds, instead of them there is an interweaving of polymer chains and their adhesion. Such pipes have recently appeared on the market, withstand temperatures up to +700FROM;

- pipes made of heat-resistant polyethylene. They are also able to withstand the effects of high temperatures (due to the introduction of heat-resistant additives into the polymer), but they will not be able to work at high temperature and other loads as long as PEX pipes.

No. 3. Advantages and disadvantages of PEX pipes

It is difficult to call XLPE pipes a unique and revolutionary product, but the material has, indeed, many advantages:

- maintaining performance over a wide temperature range. The pipe can withstand short-term temperature drops. up to 500FROM and increase to +1200FROM, melts the material only at a temperature of +1500C. Remember that optimally operate the pipes at a temperature of 0 ... + 950FROM - if the product is often exposed to critically high or low temperatures, this will affect its durability;

- resistance to pressure drops, ability to withstand pressure of 4-10 atm (the specific value of the limiting pressure depends on the type of pipe);

- flexibility. In pipes with a different method of cross-linking, the flexibility indicators differ, but, in general, remain at their best;

- high strength, wear resistance;

- longevity up to 50 years, subject to proper installation and operation;

- corrosion resistancebacteria fungusaggressive chemicals, therefore, the effect of alkalis and acids dissolved in water, the material will easily transfer;

- smooth walls provides excellent hydraulic performance, which does not deteriorate over time, since growths on the walls practically do not form;

- security. PEX-A and PEX-B pipes do not emit any toxic substances, but PEX-C pipes are not allowed to be used in some European countries;

- elasticity. If the water inside the pipe will freezeshe won't be torn;

- molecular memory (in some types of PEX pipes), which allows the material to restore its original shape;

- the material perfectly absorbs noise, which ensures comfort during operation;

- light weight (running meter weighs 0.1-0.15 kg);

- relatively simple installation.

Among the cons:

- sensitivity to prolonged exposure to sunlight, so it is better to hide the pipes. When it comes to system installation warm water floors, then this disadvantage is insignificant;

- The protective anti-diffusion layer must be handled with extreme care during transport. It is easy to guess that its damage will let oxygen into the system and reduce its durability;

- the ability to pass oxygen, which leads to corrosion of the metal elements of the pipeline. To level this minus, manufacturers make a protective spraying;

- cross-linked polyethylene pipe diameters are limited. It is impossible to find large-diameter products on sale - their production is very expensive, so the products are inferior in competition to metal-plastic or metal pipes. That is why PEX pipes cannot be called universal;

- if water has an increased degree of mineralization, then there is still a risk of the formation of growths. In this case, it is appropriate to use trunk filtersotherwise the pipes will quickly become clogged;

- fixing the pipe and retaining the shape given to it will require a little more effort than when working with metal-plastic pipes.

Pipes made of cross-linked polyethylene are, of course, more expensive than cast-iron or ordinary polyethylene pipes, but still quite affordable, however, you will have to spend money on the corresponding fittings. Installation is carried out using a special hand tool. It is very, very important not to damage the protective layer. We can say that the durability of the pipeline will depend on care during operation, which is why it makes sense to entrust the installation to certified craftsmen.

Number 4. Scope of use

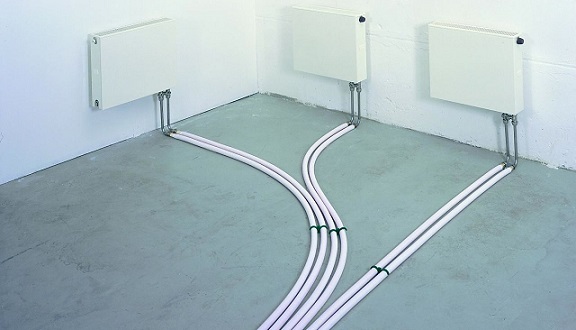

The performance characteristics of cross-linked polyethylene pipes allow them to be used for building the following engineering networks:

For industrial purposes, PEX pipes are not used - large-diameter material (for example, for main water supply) is expensive.

No. 5. Crosslinked polyethylene or metal plastic?

Cross-linked polyethylene pipes and metal-plastic pipes are the main competitors when it comes to arranging a water supply system, heating system or underfloor heating. They have a lot in common. Both types of pipes are quite flexible, durable, resistant to corrosion and relatively easy to install - there is no need to weld anything. True, mount plastic pipes still lighter than pex pipes with which to be extremely careful

Metal-plastic pipes have a slightly higher coefficient of thermal conductivity (0.45 versus 0.38), but they will not survive freezing inside the coolant. PEX pipes, after the water in the system has melted, can be operated as before. Moreover, some types of PEX pipes easily restore their shape. Resistance to high temperatures and pressure is high for both types of pipes: metal-plastic withstands pressure up to 25 atm at a temperature of 250C, can be operated at coolant temperatures up to +950C with short-term increase to +1200C, however, the maximum pressure is 10 atm.Thus, the operational characteristics are quite comparable with the similar parameters of pipes made of cross-linked polyethylene, which we presented above.

The choice depends mainly on the characteristics of the operation of the water supply and budget. The price spread among pipes, even within the same group, is significant, but PEX pipes are often cheaper than metal-plastic ones.

No. 5. Diameter and length

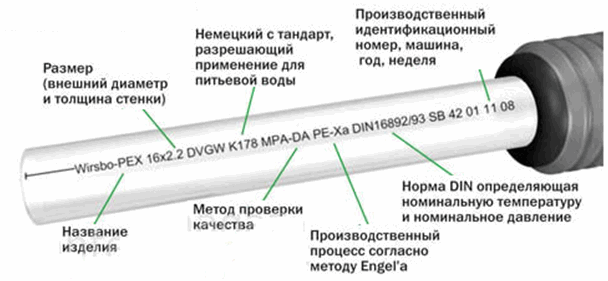

Cross-linked polyethylene pipes are sold in bays of 50, 100 and 200 m. Pipes with a diameter of 40 mm or more are sold in sections of up to 12 m. On the pipe along its entire length information on material of manufacture (type of crosslinking), operating temperature, pressure, diameter, date and place of production. For added convenience, some manufacturers apply risks to the product exactly every meter.

The choice of pipe diameter depends on the type of pipeline, the water pressure in it, the number of consumers and other parameters. General recommendations for selecting the diameter are as follows:

- pipes with a diameter of up to 15 mm (10.1 * 1.1, 14 * 1.5 and others) are suitable for supplying water from the main water pipe to the taps;

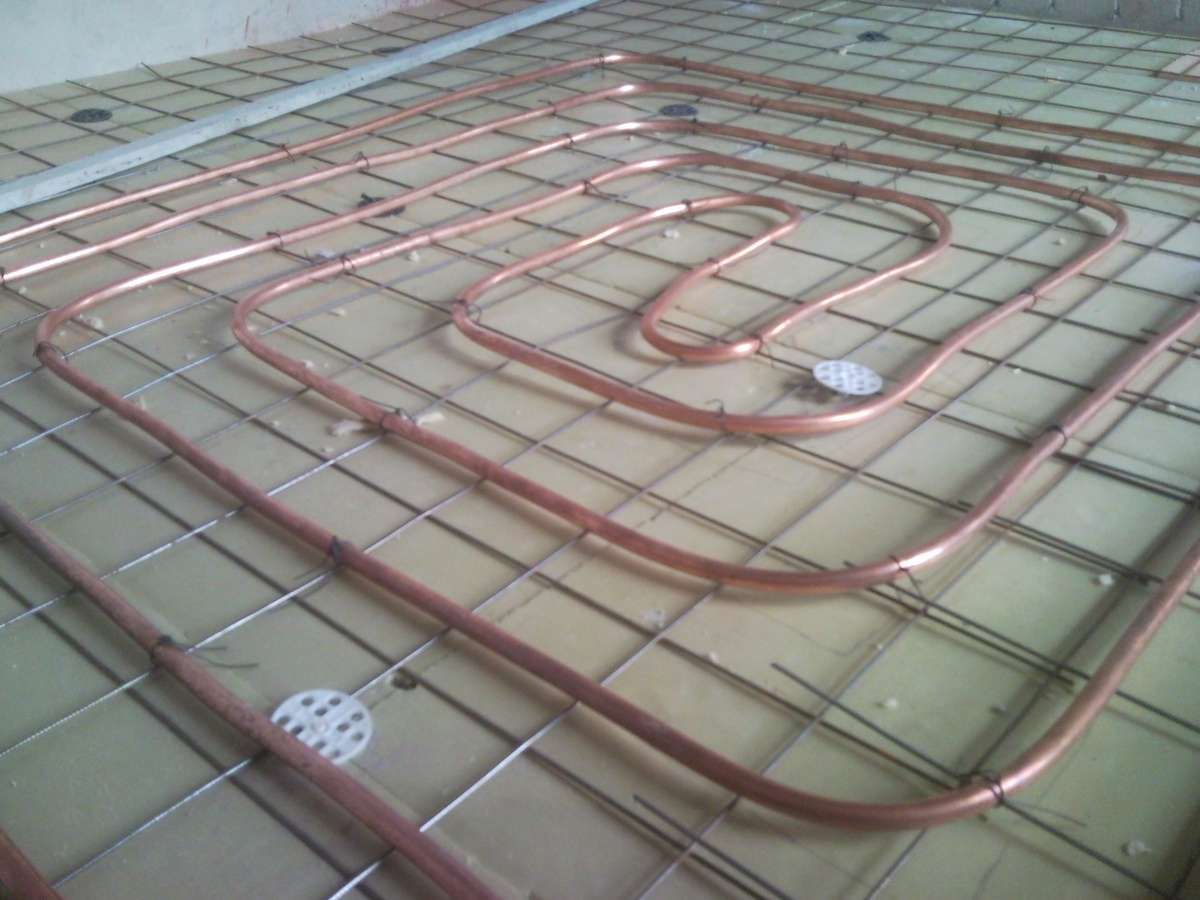

- 16 * 2 pipes are used to organize underfloor heating, 16 * 2.2 are suitable for hot water supply and radiator heating. Pipes with a diameter of 16-20 mm can be used as the main pipe for cold and hot water supply of apartments and small private houses;

- pipes of 20-32 mm are suitable for organizing water supply in cottages, are also used for heating, pipes with a diameter of more than 20 mm are usually not used for underfloor heating;

- 40-50 mm pipes are suitable for risers in apartment buildings;

- pipes with a diameter of 50-63 mm are used both in heating systems and water supply.

Typically, the manufacturer indicates for what purposes this or that pipe is best suited, for example, for heating, hot water, or is it universal in use.

Calculate the length not difficult, but for this there must be an accurate plan of the water supply system, radiator or floor heating. We measure the length of the proposed pipeline and multiply the resulting value by 1.2 - this is the margin for unforeseen situations that can happen during installation.

No. 6. XLPE pipe fittings

Looking ahead, we note that it is better to take fittings from the same manufacturer as the pipes. Even with the same declared dimensions, the difference in diameter of products from different manufacturers can reach 0.5 mm. In this case, it is difficult to talk about the absolute tightness and reliability of the system.

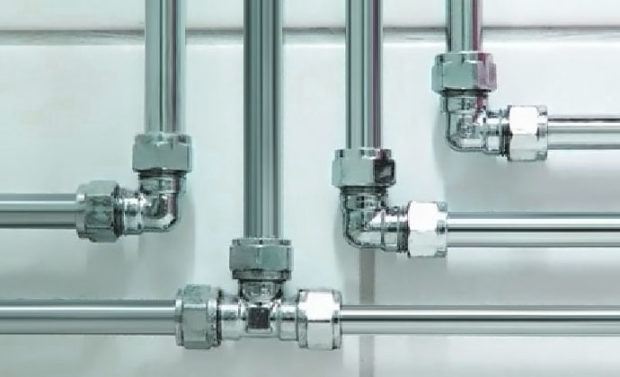

For connecting individual segments PEX pipes use the following types of fittings:

- compression plastic fittings. Consist of a housing, a connecting ring and a sealing ring, a clamping nut and a clamping ring. Installation is very simple: the pipe is cut at an angle of 90 degrees, all burrs are removed, the clamping nut and ring are put on, the sealing and compression ring are inserted into the body, they are inserted into the pipe until they stop, the clamping ring is pulled and the nut is tightened. You can tighten it by hand or tool - most importantly, tighten the nut tightly. Such fittings do not require any additional tools, but you will have to check the tightening of the nuts once every 3-5 months;

- compression metal fittings stronger and more durable than plastic, cost a little more, consist of the same elements. The installation principle is similar, no special tools, except for an adjustable wrench, are needed. Compression fittings can be removed and reused;

- press fittings consist of a housing and a crimp coupling, provide maximum bond strength. When installing a heating system (floor and radiator) and hot water supply, it is recommended to use just this type of fitting. Such products cost more, and their installation requires special expensive equipment ($ 1-2 thousand), so you have to turn to professionals for help.An alternative solution is to rent equipment, unless, of course, there is confidence that you can handle the installation on your own;

- compression fittings consist of a body and a press-in ring. Installation technology is simple, but specific equipment is also required. It costs several times less than what is necessary for a press fitting ($ 200-300), but at the same time, the strength of the connection is almost the same. Press fittings are even a little more expensive than press fittings.

It is impossible to weld, solder and glue the joints of pipes made of cross-linked polyethylene.

Number 7. Cross-linked polyethylene pipe manufacturers

To be 100% sure that in a couple of years the pipeline will not have to be repaired, or altogether changed, it is better to take pipes from a trusted manufacturer, which gives a guarantee for all products. Large companies will not risk their reputation and produce low-quality products. So, today in the market of pipes made of cross-linked polyethylene such major manufacturers:

- Rehau, Germany. These pipes are considered a quality standard, but they are also expensive. The manufacturer offers a wide range of pipes of different diameters, a huge selection of fittings. In this regard, the company's products are confidently ahead of the competition. All pipes are made of cross-linked polyethylene of the PEX-A type, and on top are coated with an oxygen-protective layer of ethylene vinyl alcohol (EVAL). The company produces pipes of several series, they can be distinguished by color. In the assortment there are products suitable for organizing cold and hot water supply, heating. The manufacturer speaks of special strength and reliability, declares that the service life of the pipes is about 50 years, and they can be laid without fear under the screed and plaster;

- Uponor, Germany. Pipes are made from cross-linked polyethylene of the PEX-A type, products are characterized by increased flexibility and durability (about 50 years). Suitable for installation of any type of piping, incl. for hidden laying;

- BIR PEKS, Russia. It produces PEX-B type pipes. The products are notable for their affordable price and high quality, the company takes into account the peculiarities of domestic conditions, so the pipes are ideal for arranging heating and water systems. The manufacturer uses high-quality English equipment;

- Valtec, Italy. The company produces pipes from cross-linked polyethylene type PEX-B. According to the company, this type of crosslinking is optimal, since a reliable uniform connection of the individual polymer chains is ensured, while the cost of production remains affordable for most consumers. Pipes are suitable for arranging underfloor heating, hot and cold water supply, radiator heating;

- Frankische, Germany. It produces PEX-A pipes with excellent performance, but the company's products have not found much distribution in the domestic market;

- Sanxt, Russia. A large company produces everything necessary for a heating system. PEX-A pipes with a protective anti-diffusion barrier EVOH are also available. The products are universal, suitable for heating and water supply, diameter from 16 to 63 mm;

- Rosterm, Russia. It produces universal pipes of the PEX-B type, as well as fittings and a huge assortment of equipment for heating and water supply systems;

- Kan-therm, Germany. It produces pipes of the PEX-C and Pert type, all products receive a protective coating to withstand the passage of oxygen;

- Watts, Germany. The company produces PEX-B pipes of various diameters. Products can be used in various systems;

- Tiemme, Italy. The manufacturer makes PEX-B pipes of different diameters, declares durability at the level of 50 years.

Most manufacturers indicate sky-high warranty periods, it’s 20-30 years, and somewhere even all 50. The conditions of this warranty must be studied carefully so as not to violate them during installation and operation, otherwise the manufacturer will have the right not to fulfill its obligations.