8 tips for choosing a clinker brick

The unique properties of clinker brick are indicated only by the fact that after dismantling the buildings in the construction of which it was used, it is cleaned and used again. Clinker brick is characterized by high strength, moisture resistance, durability and chic appearance. It is used in construction, for paving sidewalks, in finishing works, as well as in the arrangement of furnaces. Brick available on the market may vary in size, shade, surface type, shape and some performance characteristics. We figure out how to choose the clinker brick correctly so that for decades it has pleased you with its impeccable appearance.

No. 1. Clinker brick production features

The production process of clinker bricks is largely reminiscent of the manufacturing technology of the familiar to all of us ceramic: the clay mass is molded and then fired in an oven. By and large, clinker brick can be considered a type of ceramic, the differences lie only in the characteristics of the raw materials and the temperatures of its processing.

For the manufacture of clinker bricks use special refractory clay grades. In kilns, the temperature rises to 1200-13000C (for ceramic bricks, temperature indicators 800-9000C) that provides complete sintering pre-carefully pressed raw materials. All voids are filled, and in the end it turns out solid brick with unique properties. Due to its structure, it has high strength and wear resistance, ahead of all the others in these parameters types of bricks. The absence of pores inside the product allows us to talk about minimal hygroscopicity. The moisture absorption index of clinker brick is not more than 4-6%, and for the nearest competitor, ceramic brick, this parameter reaches 15-20%. It is not surprising that buildings that were built in the 19th century using this material still retain their original appearance.

To get a really strong and durable material, you need to be very careful about the choice of raw materials and production technology. Deposits of suitable grades of clay are present in Germany, Poland, Austria and the Netherlands. In Russia, there are very few of them, so almost all of the brick brick on the market is imported, which affects the cost of an already expensive product.

Today, almost all clinker brick factories are used machine moldingwhich provides high operational qualities of material. Brick hand molding gets much less strength and higher moisture absorption.

No. 2. Advantages and disadvantages of clinker brick

Features of raw materials and production technologies make it possible to obtain a brick with a unique structure, which has many advantages:

- durability. The material retains its original qualities for 100 years or more;

- strength. If we compare different types of bricks in terms of compressive strength, then clinker confidently takes the lead.The parameter, of course, can fluctuate within certain limits, but will never be lower than 250-300 kg / cm2, which corresponds to the brand strength M250-M300. By the way, in the construction business, brick of such brands is used for laying foundations apartment buildings;

- low moisture absorption (4-6%) due to the almost complete absence of pores in the structure of the material, because the raw materials in the process of pressing and sintering turns into a monolith. That is why clinker brick is used for the construction of critical structures, especially those whose operation will take place in difficult conditions (aggressive environment with a high level of humidity). No efflorescence on the material. By the way, clinker brick covered with glaze does not absorb moisture at all;

- frost resistance, which is due to the high density of the material and minimal moisture absorption. Even the simplest clinker brick can withstand 75-100 freeze / thaw cycles, and some types can easily tolerate up to 300 cycles. Excellent frost resistance made the material popular in areas with harsh climates. The most frost-resistant products create for paving paths;

- resistance to temperature extremes;

- fire resistance. The presence of refractory components in the material and high firing temperatures provide clinker brick record resistance to fire. The experiments showed that the material can withstand temperatures up to 18000C, and structures after a fire do not deform and do not collapse;

- environmental friendliness. The product is based on natural raw materials, so there is no need to talk about health hazards and the emission of toxic substances. All major manufacturers of clinker bricks check the raw materials and the finished product for radioactivity, so you can be 100% sure of your own safety;

- excellent appearance. Clinker brick looks natural and noble. The shade depends on the characteristics of the composition of the raw materials, so each brick is unique in its own way. If you take into account the variety of sizes and shapes, then you can choose the material for every taste;

- versatility and wide scope. Clinker brick is used in cladding, full-scale construction, with furnishing furnaces and sidewalks.

Among the main disadvantages of clinker brick it is worth noting:

- high price, because a material with such impressive performance, as you might guess, cannot be cheap. However, if you correlate the cost of the material and its durability, then the purchase can be considered investing in your unremovable future. Clinker brick is twice as expensive as ceramic, but by durability and resistance to negative external factors, it bypasses it at times. On the other hand, it is worth noting that it is because of the high price that clinker brick is rarely used as a building material - it is preferred to use it for cladding;

- high thermal conductivity as a result of an almost complete absence of air pores. For high strength and moisture resistance will have to pay with quality warming;

- low soundproof qualities, which again emerges from the absence of pores, therefore, enclosing structures made of this material will also need good soundproofing;

- brickwork should be done by professionals. In addition, it is necessary to use special solutions - The usual masonry composition will not work, as the material is characterized by low moisture absorption.

Separately, it is worth noting low vapor permeability. The minimum number of pores gives the clinker brick resistance to moisture, but at the same time prevents air from passing through the material. That is why when using the material as a building or facing material, it is necessary to take care of quality ventilation.

No. 3. Types of clinker brick and scope of use

All brick brick on the market, depending on the purpose, can be divided into kinds:

- building, or ordinary brick. This is a solid solid brick, which is used for the construction of critical structural elements, including foundations, socles, columns, stairs and pillars. Sometimes this type of brick is used to build some parts of the kiln. Starting rows of heavy furnaces and internal channels are made of it. chimney;

- facing, or front. From the name it is clear that this type of material is used exclusively for decoration. The chic appearance of clinker bricks can decorate the facade of any house. In addition, the material will protect the load-bearing walls from negative external influences. To save money, clinker in decoration is combined with other materials. Clinker bricks are often used to clad the basement. The material will retain its original appearance for decades, so the repair of the facade will not take a long time to remember. Clinker tiles, which are much thinner than bricks, also appeared on sale today, but after installation outwardly there will be no differences. This solution allows not only to save, but also to ease the load on the foundation;

- paving brick used for paving paths, alleys and pavements. The material is characterized by increased wear and frost resistance, excellent resistance to mechanical and shock loads. Streets in Europe are often paved precisely clinker, knowing that he will last at least half a century.

For interior decoration clinker brick is used very rarely - such cladding hits the pocket and loads the foundation. However, today, designers have already begun to use clinker tiles to decorate individual areas. Good material for decorating stoves and fireplaces.

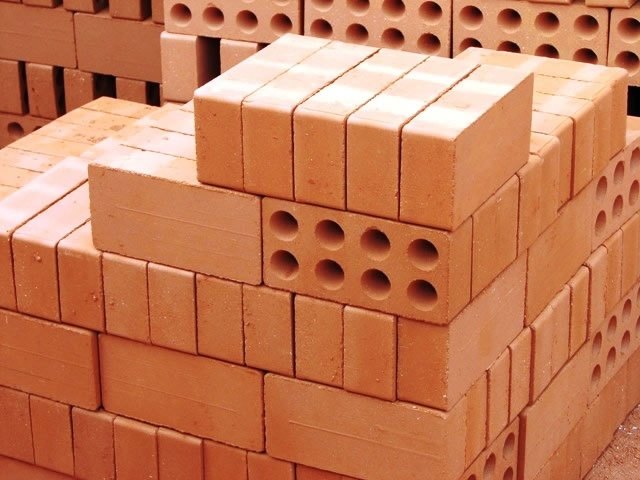

Number 4. Hollow and corpulent brick brick

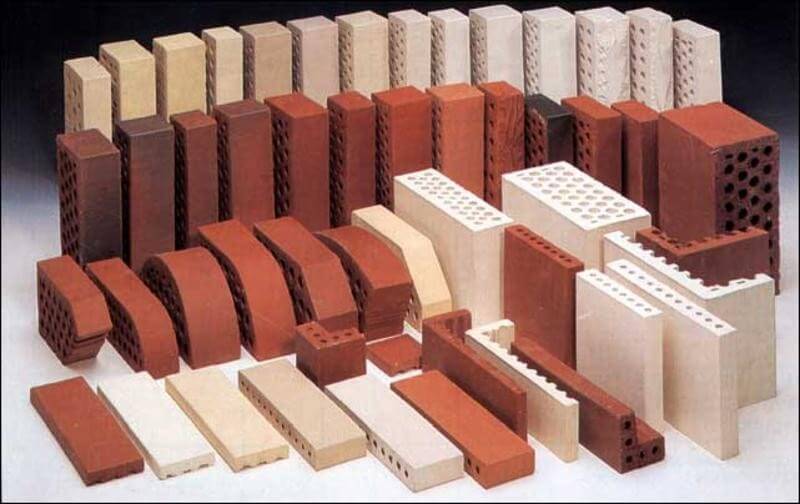

Like other types of bricks, clinker may vary by the nature of the filling:

- solid brick different holistic structure without holes. These are durable but heavy products that are used in the construction of important structural elements, as well as in the arrangement of chimneys of furnaces;

- hollow brick may have a different number of through holes or recesses of a round, rectangular or other shape. Holes are formed at the stage of pressing, for this special forms are used. Voidness in some cases can reach 35-40%. Such a brick copes with the loads worse, but it weighs much less than a full-bodied one. Moreover, the appearance of holes filled with air has a positive effect on the heat and sound insulating qualities of the material. Such a brick has found application in facade cladding.

No. 5. Dimensions and shape of clinker brick

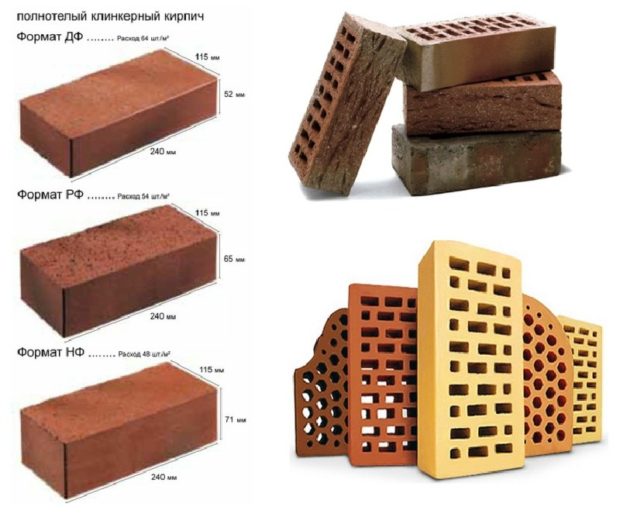

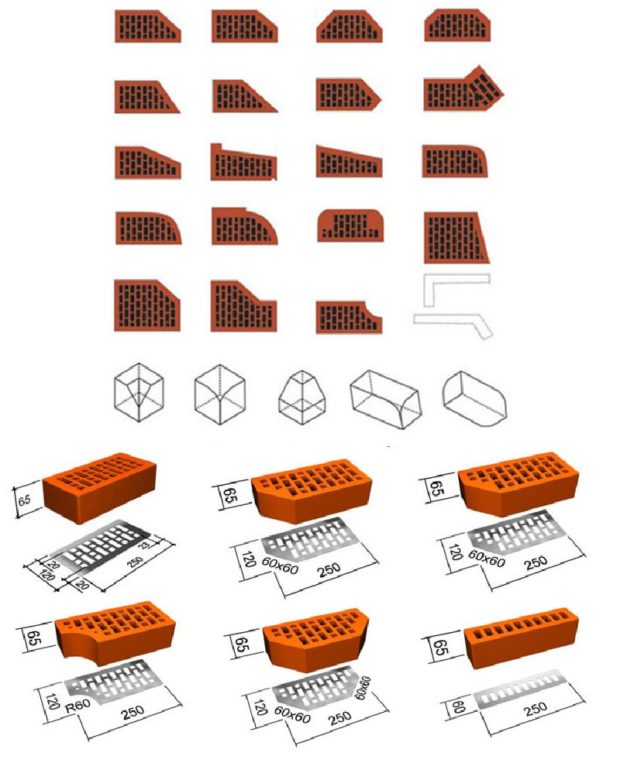

Clinker brick happens:

- standard in the form of a parallelepiped, the most common;

- curly, or shaped differs in an unusual form.

The world of brick production has long been established single standardwhich all manufacturers are guided by. Single brick, and this applies to clinker products, has parameters 250 * 120 * 65 mm and designated 1 NF (the so-called normal format). Such products can be solid or hollow, and are used in construction and in cladding - in general, they have found the widest application.

Standard bricks are also available in other sizes:

- one and a half brick, 1.4 NF, 250 * 120 * 88 mm. It is used in the construction of critical structures when it is necessary to save time;

- double brick, 2.1 NF, 250 * 120 * 140 mm. It is usually produced hollow and used in lightweight masonry;

- "Euro", or 0.7 NF, 250 * 85 * 65 mm, found application in facing;

- half, 0.5 NF, 250 * 60 * 65 mm, also used in finishing work;

- single modular block, 1.3 NF, 288 * 138 * 65 mm, is used extremely rarely.

There are other less common clinker brick formats, for example, 240 * 90 * 52 mm or 240 * 115 * 174 mm.The weight of one brick, depending on the size and fullness, ranges from 1.6 to 3.3 kg.

There are some requirements for the finished product, or rather its geometry. So, the maximum permissible deviation from the declared value in length is 4 mm, in height - 2 mm, in width - 3 mm. The product must have the shape of a regular parallelepiped, and the maximum divergence of parallel faces is 3 mm.

In cladding, a brick of an irregular shape is often used. Curly products can have a wedge-shaped, triangular, rounded and other complex shape. With the help of such elements, window openings are usually decorated, window sills, corners of the house and other architectural elements. Shaped brick allows you to create a unique appearance of the house and maximize your imagination.

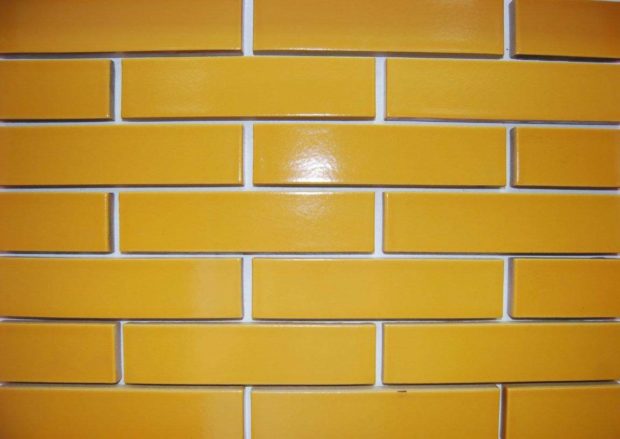

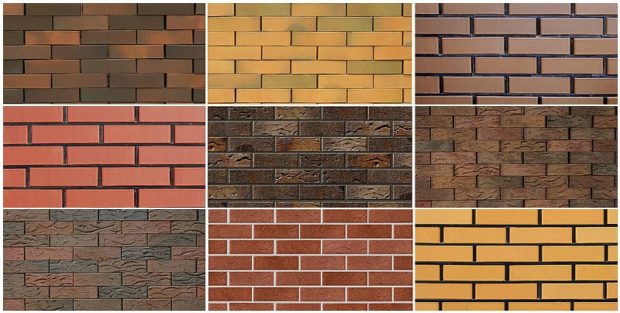

No. 6. Clinker Brick Color

The hue of clinker brick depends primarily on the type of clay. Corrections are also made by the firing procedure, after which products made from the same raw material may have slightly different tones. New shades are obtained by mixing different grades of clayNo third-party coloring pigments are commonly used. Has a huge effect on the shade mineralogical composition of clay. So, for example, clays that are located near iron ores get a terracotta hue, clays lying near limestone - a white hue, and near coal - gray. Each field is distinguished by its unique color - two are not the same.

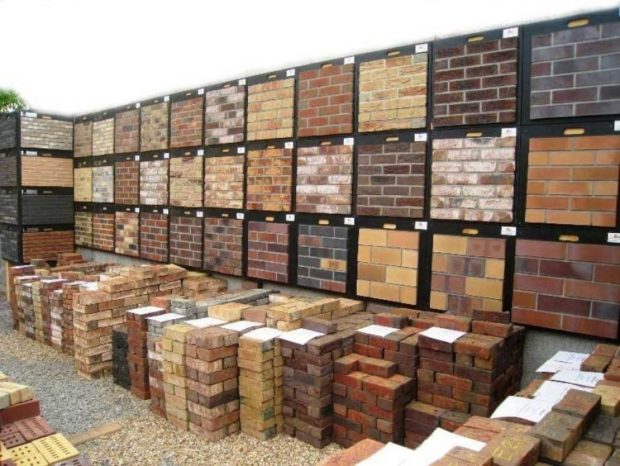

By mixing different varieties of clay, it was possible to obtain dozens of different shades clinker bricks, but all of them can be combine in three groups:

- natural terracotta and brick tones;

- light cream shades with a transition to a peach color;

- dark colors.

The rarest is considered white brick brick, which is made from the best grades of clay, which are fired before sintering. The result is beautiful products that retain their original shade throughout the life of the product, are characterized by almost complete waterproofness and excellent dirt-repellent properties.

Decent products that have undergone the procedure of artificial aging, or which in the factory created an imitation of efflorescence or soot, are in good demand. Such a brick allows you to create a unique architectural appearance of the house.

Before choose a specific shade, it is necessary to clearly visualize, but it is better to depict on the layout how this color will be combined with color the roof, the fence and other elements of the site. It is also important how well-chosen color will fit into the environment and landscape design style.

If you want to get a special result, you can combine several shades in the facade cladding. For example, window and door openings are distinguished by darker bricks. You can use bricks of two or three different colors in a chaotic manner. Any experiments are welcome, but the main thing is to think well in advance what result you want to get. It is advisable to buy a brick in the amount that is enough to complete the entire amount of work. Otherwise, you may encounter the fact that products from different parties will vary in shade. The difference, of course, will seem almost imperceptible, but after all the cladding works are completed, you will see an obvious color transition.

Pay attention to the color of decorative grouting. It can be in the color of a brick or, conversely, be contrasted. The hue of the grout dramatically affects the perception of the bricked surface.

Number 7. Clinker Brick Texture

The classic and easiest option is smooth matte surface. In this case, nothing special needs to be done in the production process. To diversify the appearance of the brick, to give it a relief or gloss, the following technologies are used:

- standard way involves applying a specific pattern to the molded, but not yet burnt, mass. After the processing of the product in the furnace, the drawing is saved, and as a result, a brick with the necessary relief is obtained. Such manipulations are not reflected in strength;

- shotcrete - A popular way to decorate clinker bricks. Before firing, mineral crumb is applied to one or more faces. Under the influence of high temperatures, it melts and sinter with clinker, forming interesting color transitions and a unique pattern;

- engobing involves applying a thin layer of ceramics called engobe to the molded dried brick. This is a mixture of clay and metal oxides. In the furnace, the engobe is melted, sintered with clinker and allows you to get the product with an interesting shade, and the color depends on the composition of the engobe. If engobe is applied only to a part of the brick surface, then you can get a material with a smooth transition of color. It is in this way that artificially aged brick is produced;

- glazing allows you to get a brick with a glossy slippery surface. The production technology resembles that described above, only the ceramic layer in this case is replaced by a layer of glaze. We emphasize once again that glazed clinker brick does not absorb moisture at all, and it is less polluted.

Any kind of clinker brick is suitable for facing the facade - it all depends on personal preferences and tastes. To pave the tracks, it is better to take a product with a noticeable relief - they will be less slippery.

Number 8. Large manufacturers of clinker bricks

The birthplace of clinker brick is Germany. All major industries are still concentrated in this country. Here they honor traditions, develop new solutions and are very scrupulous about the quality of products. There are more than a dozen manufacturers in the country. In the domestic market, you can purchase products of such large German companies:

- ABC Klinkergruppe produces facade, paving clinker, as well as clinker tiles and floor tiles from clinker. As a raw material, local shale clay is used. Finished products are used in the domestic market, exported to a number of European countries, to Russia and the UAE. Due to the composition of clay and the special technology of firing, unique products are obtained. The product range is wide, but I want to highlight a brick 490 mm long;

- Roben - These are 7 factories in Germany and 7 more in Europe and the USA. All are equipped with modern facilities. The assortment of products is colossal. It produces clinker cladding brick, facade and floor tiles, tile, porous and paving clinker, as well as finished facade elements;

- A-K-A Ziegelgruppe - a large enterprise with almost the most extensive range of clinker bricks

- Wittmunder klinker uses the ancient technology of firing, which in combination with modern technologies allows you to get a beautiful and durable material;

- Wienerberger - A German-Austrian company with 12 plants at its disposal. It produces facing and paving clinker bricks, tiles, tiles, finished facade elements;

- Hagemeister produces 100 million units of bricks per year, produces 300 different products, including paving and facing clinker

- Glueckstaedter klinker has unique clay deposits, and the use of glazing and engobing in the production process allows you to get a wide range of products;

- Klinkerziegelei uhlhorn - a small enterprise that produces several types of facing bricks, paving and molded bricks;

- Egernsund Ziegel produces construction and facing clinker, shades of mass, there are glazed samples;

- Janinhof - clinker brick 350 different types, there are non-standard sizes.

Separately, note the products Feldhaus klinker. Among Chinese manufacturers can distinguish a company Houson, which is one of the few that produces really high-quality bricks and sells it at very competitive prices.

Clinker brick appeared on the market not so long ago domestic production:

- Plant "Eco clinker"In Novocheboksarsk since 2014 produces facade, furnace and paving clinker, as well as tiles for the floor, steps and facade elements. This is our only manufacturer that offers a full range of clinker products. The range of facing bricks is constantly expanding;

- Nikolsky Brick Plant (Leningrad Region) has been producing facade and paving clinker bricks since 2013;

- LLC Dubensky brick factory (Republic of Mordovia) in 2015 launched the production of paving clinker bricks.

Of course, domestic-made brick is cheaper than imported products, but when buying, do not forget that clinker can not be very cheap - raw materials and production technology are quite expensive. Carefully inspect the brick for defects and geometry accuracy. Quality products will always have the relevant documents. First of all, this is a certificate of compliance with regulatory requirements.