8 tips on which sewer pipes to choose for internal sewage in an apartment and a private house

We don’t see them, but we use them every day. We are talking about internal sewer pipes that connect all objects plumbers with a vertical in-house riser. The durability and reliability of the entire drainage system depends on the quality of the pipes, the right material, diameter and angle of inclination. To determine which sewer pipes to choose for internal sewage in an apartment and a private house, for a start it is better to draw up a project for the wiring of the system, evaluate the geometry of the room, the height of the plumbing installation and other features.

No. 1. Material of internal sewer pipes

Internal sewer wiring can be performed using these pipes:

- cast iron. Previously installed everywhere, today they are almost never used;

- polyvinyl chloride (PVC);

- polypropylene. Looking ahead, we note that this is the most optimal option;

- polyethylene. Used infrequently;

- steel and copper. Expensive pipes that have not found application, but are sometimes still used due to their appearance.

Despite the fact that polypropylene and PVC pipes are most widely used, when choosing, do not rush to immediately discard the other options, as in some cases cast iron and even copper pipes can come in handy.

No. 2. Cast iron pipes for domestic sewage

Several decades ago, there was no special alternative to cast-iron pipes, so they are found in large numbers in houses of the old construction. Today, cast iron is being superseded by plastic, but is still in use. Such pipes are made of gray cast iron by centrifugal casting. To protect the material from corrosion and give the inner surface smoothness, the pipes inside and out are coated with a bituminous composition. The diameter of the cast-iron pipes ranges from 5-15 cm, the wall thickness is 10-12 mm.

The advantages of cast iron pipes:

- durability. The service life reaches 50 years and often exceeds this threshold. Some data indicate a longevity of 90-100 years;

- high strength and resistance to deformation. On the other hand, the material does not tolerate shock loads;

- the ability to withstand the long-term effects of hot drains (from a washing machine or dishwasher, for example);

- resistance to temperature extremes;

- resistance to fire;

- environmental Safety;

- good soundproofing.

Surely, cast-iron pipes would have remained in the lead, if not significant disadvantages:

- the walls become overgrown with deposits over time. The whole fault is the roughness of the material, which even with a bitumen coating cannot be completely eliminated. The overgrowing process leads to a narrowing of the lumen of the pipe and a decrease in its throughput. Anyone who has seen what a pipe looks like after many years of operation will never forget this terrible sight;

- high weight of pipes, which complicates transportation;

- complex installation, which is explained not only by the large weight, but also by the features of the connection of pipe sections. In order for the sewer system to be sealed, it is necessary to correctly connect the elements.Usually use the caulking or caulking method with a heel;

- susceptibility to corrosion processes;

- high price.

Cast iron pipes are not used today to build a new sewer system, but they may be needed when reconstruction of existing systems takes place. At the moment, the use of cast-iron pipes is also justified in the arrangement outdoor areas of private sewers and intra-house risers.

When choosing, it does not interfere with carefully inspecting the products and tapping each of them. Thus, it is easy to detect cracks and other defects that form when the manufacturing process is disturbed. A defective pipe does not have a long service life. For connecting cast iron pipes, various fittings, plugs and sockets are produced.

No. 3. Polyvinyl Chloride (PVC) Sewer Pipes

For arrangement of the internal sewerage PVC pipes considered almost the most suitable option. In the manufacturing process, some other substances are added to polyvinyl chloride, including stabilizers and polymers. Elements of the required form are formed from the heated mass.

PVC pipes can be of two types:

- pipes made of plasticized PVC (PVC) have good elasticity and low strength;

- unplasticized PVC pipes (PVC-U) are made more rigid and resistant to aggressive effects.

Of course, it is better to use unplasticized PVC, but in practice both types of pipes are used. The diameter of the product ranges from 2 to 20 cm.

Main advantages:

- affordable price;

- light weight;

- ease of installation. Separate sections of pipes are connected by couplings and connecting rings - everything is dispensed with without welding;

- low temperature coefficient of expansion. With a short-term or constant increase in the temperature of the effluent, the pipes will not sag;

- sufficient strength and durability up to 50 years;

- sufficient resistance to ultraviolet rays, so that some sections of the pipes can not be afraid to let on an open surface;

- resistance to corrosion and some aggressive substances;

- Due to the smooth inner surface, the walls do not silt over time.

Minuses:

- limited temperature range of operation. With constant exposure to negative temperatures, pipes become brittle and lose their tightness, and with constant exposure to temperatures above + 60 ... + 700With the material is able to deform and also loses its integrity;

- insufficient fire resistance;

- the inner walls of the PVC pipes are smoother than those of cast iron, but over time they will still appear on them. In addition, the inner diameter changes over the years. As a result of exposure to high temperatures, the circular cross section transforms into an ellipsoidal section, and this worsens the throughput and contributes to the occurrence of a leak;

- some aggressive substances contained in drains can still lead to the gradual destruction of pipes.

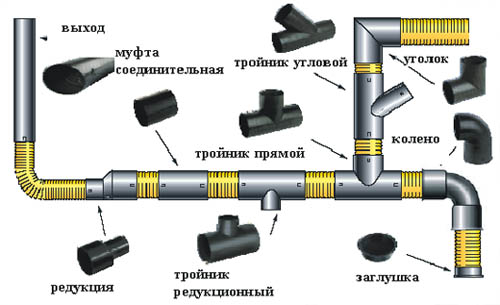

For the arrangement of internal sewage from PVC pipes, appropriate connecting elements are used. Among them kneedesigned to rotate the pipeline at an angle of 20 to 87 degrees, tee for arranging branches cross to connect the four pipes, and reduction for connecting pipe sections of different diameters.

Number 4. Polypropylene Sewer Pipes

Polypropylene pipes today are actively used in the arrangement heating systems, cold and hot water supply. Material properties are highly dependent on its structure. Pipes made from a copolymer of propylene and ethylene (Ppr), they withstand temperatures up to +700C. Pipe type behave even better PPsthat calmly withstand temperatures up to +950C and short-term exposure to even higher temperatures. Reinforced pipes will be more durable, and fiberglass reinforcement is considered optimal.In the product labeling, the working pressure is also indicated: there will be enough pipes for internal sewage PN10 (withstand 1MPa), but more often take PN20.

Advantages:

- durability up to 50 years;

- resistance to corrosion and almost all aggressive substances (acids, alkalis and salts will not damage the material);

- high strength pipes and joints. Polypropylene bypasses polyethylene and PVC in strength, it is more resistant to cracking, and joints are less likely to be depressurized;

- light weight;

- Absolute smooth inner surface, so that problems with pipe overgrowing will not arise;

- resistance to high and low temperatures, which allows the use of pipes in almost any conditions. The pipes are not deformed;

- relative ease of installation. The connection of individual sections is made by special welding machine, learn to work with which almost everyone can;

- relatively low price, but polypropylene pipes will cost more than polyvinyl chloride;

- PPs type polypropylene belongs to the group of non-flammable materials.

Among cons polypropylene pipes can be noted only temperature deformation, so they will either have to be insulated or equipped with compensators.

No. 5. Polyethylene sewer pipes

Polyethylene pipes are used infrequently in the arrangement of internal sewage. Usually used either low-pressure polyethylene or cross-linked polyethylene. The first option can withstand a maximum of +400C, so it makes sense to use it only in places with cold drains. Crosslinked Polyethylene it is intended for work at temperatures 0 ... + 950C, can withstand temperatures from -50 to +120 for a short time0C, therefore it is usually used. The material has such the benefits:

- high strength, wear resistance and flexibility;

- resistance to corrosion;

- smooth walls and almost complete resistance to the formation of growths;

- light weight;

- resistance to pressure drops;

- durability;

- flexibility and easy installation;

- relative affordability in terms of price.

Minuses:

- fear of ultraviolet rays;

- oxygen can pass through the material, which will damage the metal elements in the system. The manufacturer applies a special coating, but it is quite gentle, so during installation it is necessary to behave very carefully so as not to damage it;

- low resistance to abrasion.

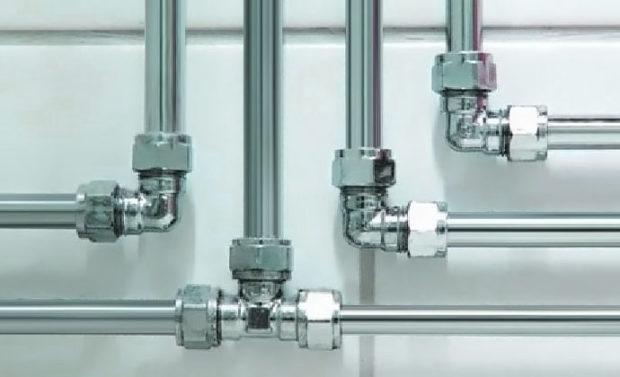

No. 6. Copper and steel sewer pipes

Copper and steel pipes can be called ideal in terms of durability, strength and corrosion resistance. They withstand any temperature and pressure indicators, are characterized by minimal thermal expansion, and have a smooth, non-fouling inner surface.

The main minus - high price. In addition, copper pipes require a specific installation, which only a professional can handle.

It is justified to use such an extravagant version of sewer pipes when outdoor installation is carried out, and plastic pipes will look ridiculous. Often they resort to copper pipes when they create retro interior with a bathtub on the legs.

Number 7. Size and diameter of sewer pipes

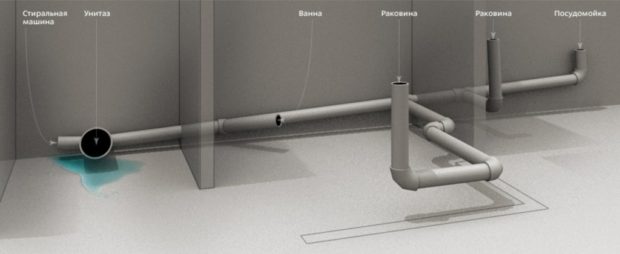

Before proceeding with the purchase and installation of sewer pipes, it is best to draw up a project where you specify all the drain points and the type of sanitary equipment. This will help you figure out what diameter and length of pipe you need. At this stage, it does not interfere with determining the number of auxiliary parts, which will depend on the number of turns and branches. Consider also the change in the diameter of the pipeline in individual sections.

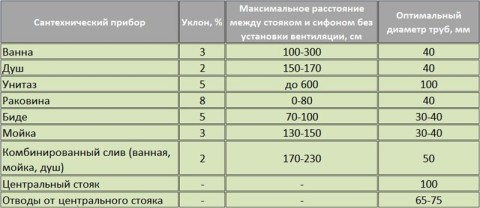

Depending on the type of plumbing fixture to be connected, pipes with different diameters:

- for a dishwasher and washing machine, a sewer pipe with a diameter of 25 mm is suitable;

- for bath, shower stall and kitchen sink - 40-50 mm;

- for washbasin and bidet - 30-40 mm;

- for piping - 40-50 mm;

- bends from the riser - 65-75 mm;

- central riser and pipe from toilet bowl - 100-110 mm.

It is better to add a margin of 10% to the calculated length.

Also consider the distance from the riser to each drain point: if it is larger than allowed, then ventilation taps and connectors will have to be provided.

Remember to also purchase siphons. It is desirable that they be from the same material as the pipes, then there will be a minimum of problems with the connection. After creating a project for the location of pipes, consider places where the pipe changes direction and branches, as well as places where several bends are connected. Based on this, we can understand how much reducing connectors (for the junction of pipes with different diameters), bends (aka knee, an element to create a bend) tees and crosses need it.

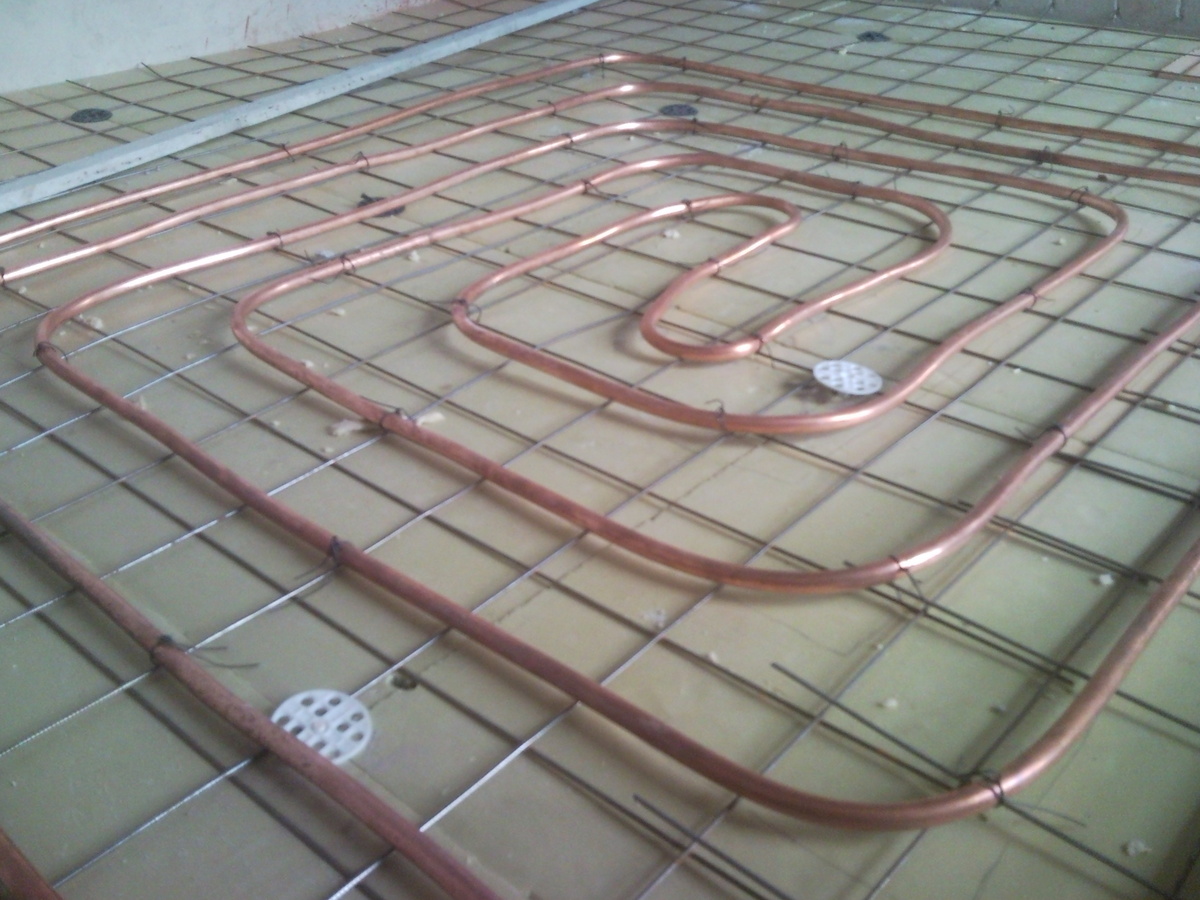

Number 8. Slope of the internal sewer pipe

Sewer pipeline can be divided into two sections, vertical and horizontal. Vertical is a riser to which all horizontal pipes are connected, but they can be called horizontal with a stretch. Sewer pipes must be laid with a slight slope to the riser. This is necessary in order to:

- drains quickly went into the general sewer under the influence of gravity;

- siltation of pipes did not occur, which occurs when stagnation of sewage in areas without the necessary slope;

- no unpleasant odors or breakthroughs occurred as a result of siltation.

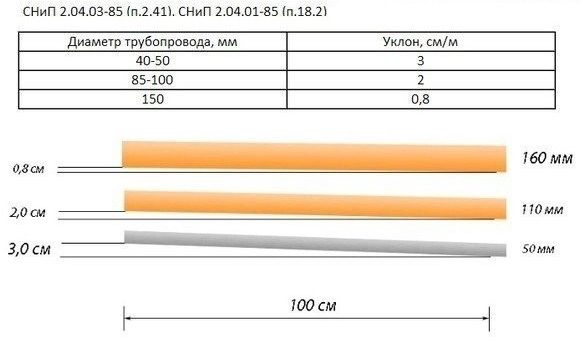

The larger the diameter of the sewer pipe, the smaller the slope is needed:

- for internal sewer pipes with a diameter of 40 mm, a slope of 3.5 cm per linear meter will be sufficient;

- for pipes with a diameter of 50 mm - 3 cm;

- for pipes 80 mm - 2 cm;

- for pipes 100 mm - 1.5 cm.

Subject to these values, the optimal speed of the effluent is provided, 0.7-1 m / s.

You should resist the temptation to make a bias more than required. The larger the angle, the faster the drains will leave the apartment. It’s kind of good, but this speed brings a lot of problems:

- particles of sewage, solid food debris and other debris remain in the pipe under the influence of a high flow rate;

- siltation of the pipes and their complete clogging occurs. The service life of such a system is several times shorter than the one built in accordance with all the rules.

The slope should not exceed 15 cm per 1 meter. It is formed by means of fastenings on which the pipe will hold, or by creating a strob in the wall.

Concluding, we note that the breakthrough of sewer pipes is one of the most unpleasant accidents that can happen in an apartment. That is why it is not worth saving on the purchase of pipes and their installation.

Yes. The article is not bad; everything is chewed and laid out on shelves, a lot of useful information. But everything is exactly I, as a self-taught person, I would not take up such a robot as there are many nuances that you need to know and not to miss during installation. Otherwise, the result will be negative.