9 tips on which cast iron bath to choose: advantages, disadvantages, size

At the mention of cast-iron baths, many people associate with the Soviet times, when there was no particular choice, and cast iron was the only material for creating a font. Times passed, steel and acrylic bathtubs appeared, kvarilovye and stone samples, but the good old cast-iron baths are too early to write off and retire. In many ways, they bypass analogs, so they are worthy of being installed in a modern bathroom. It remains only to figure out which cast-iron bath to choose. We will stop on this issue, having studied the current assortment of these products.

No. 1. Features of the production of cast-iron bathtubs

All responsible manufacturers of cast iron bathtubs use the same technology, which consists in placing cast iron in a pre-prepared form. Enamel is applied to the workpiece and the product is sent to the furnace, where the temperature is at least 1200C. Under such conditions, the enamel is sintered and firmly bonded to cast iron. The result is a durable and reliable corrosion-resistant product. The thickness of cast iron is 6-8 mm. Looking ahead, we note that with such an alloy thickness it is difficult to create a bath of sophisticated shapes, but manufacturers are trying, so there really is plenty to choose from.

Unscrupulous manufacturers can save on metal by making the walls of the bathtub thinner. This is easy to determine by the weight of the bath, which will be discussed later. For now, we confine ourselves to the fact that even the most small bath cannot weigh less than 70-80 kg. The second point of saving is the quality of enamel. Instead of sintering enamel, some manufacturers use painting, so soon the coating begins to peel off and literally fall off the surface of the bathtub, forcing it to resort to the reconstruction process several decades ahead of schedule.

No. 2. Cast-iron bathtubs: advantages and disadvantages

What is a cast-iron bath, for sure, every resident of our country knows well, because in some apartments still made and installed products made and installed back in Soviet times. Despite the emergence of steel and acrylic bathtubs, cast-iron products are still being produced, not only by domestic but also by foreign companies. What made cast iron bathtubs so popular and competitive? Everything is simple - a wagon the benefits:

- durability. Thick walls, robust construction, protective enamel - all this with proper care makes the cast-iron bathtub almost immortal. A high-quality product will last at least 30 years, but usually cast-iron bathtubs show themselves more durable and can withstand more than 50 years of operation;

- strength and stability. It is difficult to damage or deform the thick walls of the product. A cast-iron bathtub does an excellent job both with the weight of water and with the load from a bathing person. No additional reinforcing structures, as is the case with acrylic bathtubs, Not needed. Only enamel can be damaged, but today they have learned to easily restore it;

- heat and sound insulating properties. A cast-iron bathtub does not ring in a collision with water drops, as steel analogues do. In addition, cast iron retains heat well, so water procedures will be as comfortable as possible. According to these parameters, only acrylic can be compared with cast iron;

- hygiene and ease of care. The enamel sintering process allows you to create a smooth coating with a minimum pore content, so that dirt on the coating will not be delayed. Moreover, almost any cleaning agent can be used to care for enamel.

Among cons of cast-iron bathtubs distinguish:

- heavy weight. It guarantees the strength and stability of the bath, but complicates the process of transportation and installation. Problems with ceilings can even make you refuse to use this kind of plumbing. A bath 160 cm long and 75 cm wide weighs 95-105 kg, which is significantly more than steel bath the same sizes or especially acrylic;

- high pricedue to production technology and the large amount of cast iron used;

- small selection of shapes and sizes. From cast iron, as we have said, it is difficult to cast something elegant. In this parameter, cast-iron baths are inferior to acrylic samples, but there is still a choice. In addition to standard rectangular bowls, there are oval, angular and round options for sale. Moreover, they learned how to incorporate hydromassage systems into cast-iron bathtubs; however, such samples will cost a lot.

Many rightly believe that it is better to spend some time and work hard on the delivery and installation of the bath, so that after decades you will not know any problems.

No. 3. Which bath is better: cast iron, acrylic or steel

Bath selection - this is, first of all, the choice of material, because it is he who determines the set of operational characteristics. If you do not take into account new-fangled options, then the choice comes down to three samples: a cast-iron, steel and acrylic bath. We will not dwell on the advantages and disadvantages of each option, but we will conduct a small indicative comparison.

So, cast iron or acrylic bath? The cast-iron sample wins in strength, ease of maintenance, durability, but inferior in terms of price, assortment, ease of transportation and installation. In terms of thermal conductivity, the materials are almost equal, but acrylic is still a little “warmer”. If the cost of the product, its design and weight is in the first place for you, then the choice comes down to an acrylic bathtub, which today is the market leader. If you prefer longevity and durability, are ready to spend on expenses and installation difficulties, then it is better to take a cast-iron bathtub.

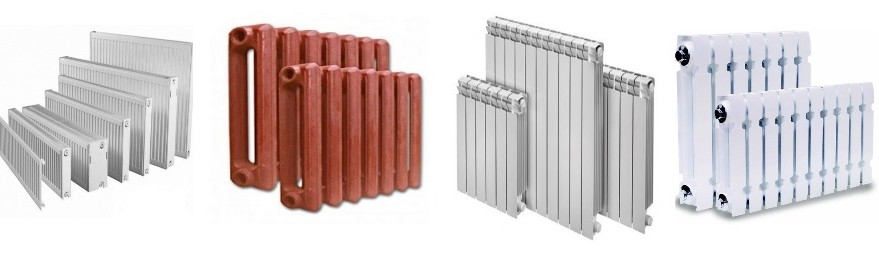

If you don’t know which bath is better to choose, cast iron or steel, then keep in mind that the steel version will be cheaper, it will be easier to install, and the variety of shapes in this case is higher. In terms of ease of maintenance, durability and weight, steel bathtubs occupy an intermediate position between acrylic and cast iron, but they are the cheapest. Under the weight of a heavy person, a steel bowl can bend a little, and falling water will produce loud loud noises. In terms of thermal insulation, steel is significantly inferior to cast iron and acrylic.

Number 4. Cast Iron Bath Size

The choice of bath size depends from the dimensions of the bathroom and the growth of households. Unfortunately, it often happens that these two factors are difficult to reconcile: the room is small, and family members are not very short. Then you have to compromise and look for the most suitable options, so that it was comfortable to swim, and everything fit in the room.

Standard sizes for a cast iron bath is considered length 150 cm and width 70 cm. Such products are placed in typical bathrooms and can be placed on modest square meters the sink, and sometimes also a washing machine or several small furniture items. A bath of this length and width will be convenient for people of average height without excess weight.For those whose height approaches 180 cm, a bathtub with a length of 160-170 cm will be much more comfortable. Longer bathtubs can also be found on sale, only they will weigh well, and they will not fit everywhere.

Bathtubs and 120-130 cm long, but selling them is not easy. They are installed near the short wall of the bathroom in order to save space. Lying there to someone larger than a 10-year-old child will not be particularly comfortable. Slightly departing from the topic, let us advise you in case of a critical shortage of usable space in the bathroom to use shower cabinsor just pallets with curtains.

Another parameter that is important to consider when choosing a cast-iron bathtub is its depth. This is the distance from the bottom of the bowl to the overflow hole. Most products have a depth of about 40-46 cm, and this is an excellent parameter for comfortable water procedures. Products with a depth of 32-40 cm may not completely cover the body of the swimmer.

No. 5. Wall-mounted or freestanding bathtub?

When going to the store to buy a cast-iron bath, it is important to decide where exactly it will stand. Not only product parameters, but also its type depend on this.

Cast iron bathtubs can be:

- wall. Mounted near the wall, then are closed by the screen or are faced with a specific pattern. This is the most familiar and simpler installation method, which in the conditions of insufficient space remains the only possible option;

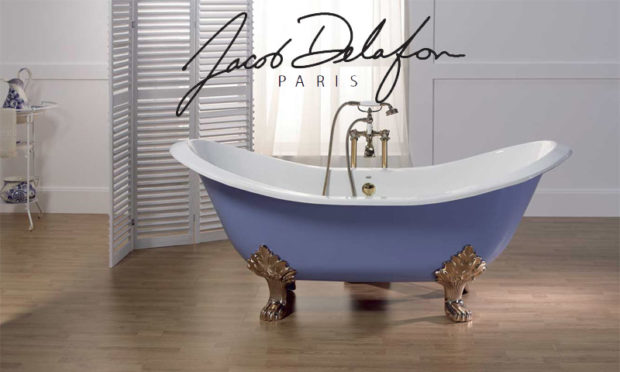

- freestanding. Often such bathtubs are supplied with beautiful legs. Products are installed anywhere in the bathroom. A freestanding bathtub can be a wonderful decoration for a spacious bathroom, but in this case you will have to carefully consider the nuance of the connection plumbing and sewer pipes.

No. 6. The shape, color and style of the cast-iron bathtub

Despite the fact that cast-iron bathtubs are accused of a small variety of forms, there is still a choice. In addition to the popular oval and rectangular bowls, on sale you can find round, angular and even asymmetric models. The process of their production is more complicated, and therefore they will cost more than samples of more familiar forms. Rectangular and oval bathtubs Perfectly fit into a room of any style and size. Corner bowls allow to use the space of the room with maximum benefit, and round and asymmetric samples Is the privilege of owners of large bathrooms.

Concerning colors, then there are few options. Enamel usually has a white or cream shade, less often - light blue. It will not be possible to show the subtlety of design thinking, but there will be no problems with combining with other plumbing, because most toilets, sinks and bidets are made in white. Some manufacturers (particularly Italian) produce bathtubs that from the outside covered with a beautiful pattern.

Bath style should be combined with room style and all items in it. A win-win option is an oval or rectangular wall-mounted bathtub. For fans of the classical style, foot baths are suitable, and lovers of modern trends in interior design will appreciate round and asymmetric models.

Remember that modern manufacturers have learned to integrate into cast-iron bathtubs. hydromassage nozzlesthan significantly expanded the functionality and target audience of such products. The principle of operation of the hydromassage boils down to the fact that the water from the bowl of the bathtub is taken by a special pump that pumps the liquid and returns it to the bathtub through special nozzles under considerable pressure. Water mixes with air bubbles and pleasantly affects the human body. If you are interested in cast-iron hot tubs, then pay attention to how the nozzles are located on the surface of the thicket and evaluate how comfortable and effective such massage procedures will be.

Number 7. What else to look for when buying a cast-iron bathtub?

When you have decided on the size, shape, color and other parameters, the most crucial stage begins - to evaluate the quality of the product, because at stake is the durability of the bath. During an external examination, pay attention to the following parameters:

- enamel workmanship. Ideally, it should be applied evenly, have a smooth surface without cracks, chips, smudges and areas painted in other colors. The thickness of the enamel layer should be 1-1.2 mm, a barely noticeable waviness of the coating is allowed. If the enamel is applied qualitatively, the bath will be durable and easy to care for, and you will not soon begin to think about restoration. Even a small crack and an almost imperceptible chip under the constant influence of water can turn into an unaesthetic dark spot;

- cast iron quality. Ideally, the wall thickness of the cast-iron bath should be 6-8 mm, at least not less than 5 mm. The outer surface of the bath should not have any roughness, chips and other defects. The ideal coating for it is powder coating, which perfectly protects the surface of the bath and gives it an aesthetic appearance;

- supporting elements must be very strong, because they have to withstand the weight of the bath, water and a bathing person;

- many manufacturers put special on the bottom of the bowl non-slip coating. This will be an additional advantage, as well as an antibacterial coating;

- if provided in the bathroom headrests, handles, hydromassage nozzles and other additional elements, then be sure to study the quality of performance of these elements;

- rate the location of the drain and overflow holes and relate them to location of communications in your bathroom. You may need to drain in the center of the bowl. Such models are also available.

Although this is obvious, we emphasize once again that it is very important to know exactly what size a bathtub will fit in an apartment, especially when it comes to a heavy cast-iron product that still needs to be able to be raised to the necessary floor. So, we arm ourselves with roulette, measure free space, take roulette to the store and check each item considered for purchase.

Number 8. Cast Iron Bathroom Manufacturers

The topic of cast-iron bath manufacturers requires more detailed consideration. Note that it is better to give preference to products of famous brands that have modern production, monitor the quality of products at each stage of manufacture, use the best materials and constantly replenish collections with new models.

Among foreign manufacturers, the most popular cast iron bathtubs spanish firm Roca. Spanish bathtubs Novial, Italian Artex and Castalia, Finnish Timo and Portuguese RECOR are also in demand. The products of Chinese manufacturers are rarely of high quality (they often save on cast iron and apply enamel by painting, rather than sintering in an oven), but there are exceptions. A prime example is Goldman bathtubs.

Products domestic manufacturers It will cost much cheaper, but at the same time it is practically inferior in quality, and by design it is almost catching up with European analogues. Let us single out the cast-iron bathtubs manufactured by Zavod Universal and Kirovsky Zavod.

In any case, do not hesitate to ask for documents that confirm the quality of the bath.

No. 9. How to care for a cast iron bathtub?

A cast-iron bath will last almost forever if you learn how to properly care for its enamel and remember the basic rules of operation:

- do not overload the bath. The maximum weight for which the product is designed is indicated in the instructions for each product. If you regularly violate the manufacturer’s recommendations, then the legs or mounts may not stand up;

- after each bath, a bowl is necessary rinse and wipe dry. If you notice that flowing cranethen it is necessary to repair immediately.Otherwise, a yellow patina appears under the mixer;

- for bathroom care choose facilitiesthat do not contain chlorine, acids and abrasive particles. Fresh impurities are easily washed off with soapy water. To clean the bath of plaque and lime there are special products, as well as mass of folk ways based on soda, vinegar and other available substances;

- if there is a bathroom anti-slip coating, then with his washing after each water treatment, pay special attention, since dirt accumulates more intensely on the relief surface;

- in case of damage to the enamel can to restore, and different methods are used. The fastest is to install an acrylic liner. A slightly more time-consuming option is to apply liquid acrylic. You can restore the surface by applying several layers of enamel paint, but here you will need specific skills - it is difficult to manage on your own.

If you carefully handle the cast-iron bath, then the period of its operation can significantly exceed the one indicated in the warranty card.