Features of the manufacture of paving slabs - TOP 5 tips and tricks

Why make a tile yourself if you can go and buy it, because in any city there are a lot of manufacturers and shops selling this material? The answer lies on the surface. Pursuing the whole process personally, you can get good savings, confidence in quality and unique tile design. Masters say that over the summer, at a quiet pace, you can make so much tile to lay out an area of about 500 m2. Some are so addicted to the process that they turn simple savings into a lifelong business. Tile production on a small scale does not require large expenses, therefore it is excellent fast payback business option without major investments. Anyway, first you need to know all the features of making tiles with your own hands in order to be able to weigh everything and decide whether it is worth doing such a thing.

No. 1. Tile Molds

The manufacturing process itself paving slabs simple enough. It is necessary to make a solution, pour it into pre-prepared forms and let it dry. Each stage has its own nuances, and we will begin to analyze them from the forms.

Molds for tiles can be ready-made or home-made. Buying ready-made forms significantly reduces the time spent. If you find a good manufacturer, this will ensure the optimal quality of the product, since with independent production of molds it is unlikely that the desired result can be achieved the first time. There is also a wide range of samples, which can be selected based on the goals and the raw materials used.

Piece ready forms

Finished forms can be designed for tile casting or let cast block immediately. If you need to lay out a track with a regular pattern, it is better to take piece forms. Blocks are great for creating an imitation of natural stone, and tiles come out much cheaper.

Ready block for casting tiles

By material of manufacture finished forms can be rubber (resource up to 450 castings), plastic (up to 250 castings) or polyurethane (up to 100 castings). There are a lot of options for construction and design. There is always something to choose from.

You can purchase liquid silicone for molds and make molds yourself. Such an idea is in demand when creating unique matrices. However, it is useful to know a lot of specific features so that the product turns out to be of the proper form.

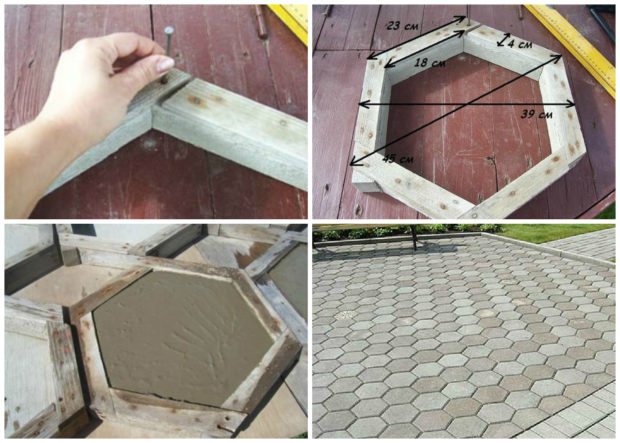

Wooden molds

Suitable when it is necessary to cast a tile of simple shape, for example, rectangular, square. It is a formwork, parts of which are made of wooden battens connected by nails. It is quick and easy to manufacture, but will not survive repeated use due to moisture, and is also not suitable for creating forms of complex configurations. In addition, many modern matrices lack formwork, which simplifies the removal process, and here you will have to make more efforts at the end.

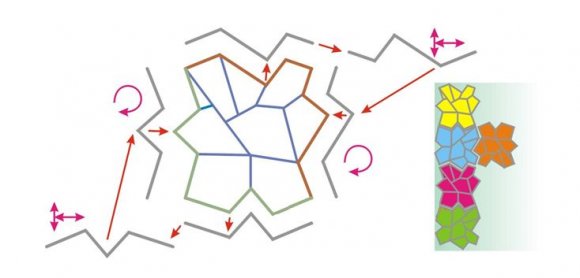

If the tile is made only for yourself, and not for sale, then you can make a form from the boards or bars, thanks to which you can cast tiles imitating the chaotic shape of natural stone. Knowing the simple features of the human perception of the world, you can do with a minimum number of forms to create the effect of non-repeating elements.

A method of manufacturing a mold is as follows:

- we draw the upper and lower sides of the mold as you like, the main thing is that in the end the workpiece fits into a square;

- Now you need to draw each of the previously created lines in mirror image and rotate 90 degrees. Thus we get two horizontal sides of the form;

- outline the inner space as you like, avoiding only central symmetry;

- when casting, the mold will need to be rotated 90 degrees each time.

Similar shape is suitable for tile castings directly to the place where it will lie. This is not the most durable, but simple, fast and cheap option.

Plaster molds

Convenient, practical and easy to manufacture. To obtain such a shape, a favorite element is coated (previously lubricated with a special lubricant, soap can be diluted with water) with a gypsum mixture, which is mixed immediately before use. Then all this is placed in the workpiece and left to solidify.

Such a pattern allows identical repetition of geometry and patterns, however, the disadvantage is fragility. To eliminate this, there are various additives.

Plastic mold

Plastic molds boast sufficient wear resistance and durability, repeat the pattern well. Products are not afraid of chemically active substances, resistant to mechanical stress. You can fill in them concrete, polymers and other materials. Another plus of such forms is that patterns and faces do not erase for a long time, and the inexpensive cost of this type of form makes them extremely popular.

Silicone forms

The most versatile variety, as it has the advantages of all the types listed above:

- strength and resistance to loads;

- the design does not stretch and does not change;

- maintains a large number of cycles;

- not afraid of significant temperatures;

- repeats a relief with ideal accuracy;

- suitable for cement, gypsum, polymers;

- extraction does not require much effort, the product is not damaged.

The elasticity of silicone plays a trick on him: under the influence of heavy concrete, the form can expand and swell.

If you plan to make tiles only for yourself (for example, for the organization of a local area and garden paths), then with the manufacture of silicone molds it is better not to bother. If the matter is put on stream, then the game is worth the candle. For the manufacture of silicone molds, different compositions are used, but the liquid three-component is the most optimal of all.

When cooking, you must adhere to the following steps:

- In the design, where the base matrix will be installed, the sculptural clay is laid first. "Cast" can be removed from a stone of your favorite shape, board and other elements.

- Then they put a matrix, which is lubricated with a special solution so that the silicone does not stick.

- After making sure that the mixture is ready, and there are no bubbles, slowly pour in the liquid and allow to congeal.

Polyurethane Molds

Creating a polyurethane house template is more difficult, since special protection is required and good ventilation of the room. It is necessary to work neatly with glasses and overalls, and only after filling your hand will you be able to get a workpiece of a decent level. A high-quality product has high strength and flexibility, does not require formwork, allows you to transfer relief, better than silicone, keeps its shape. The main disadvantage is a higher price.

No. 2. We choose raw materials

It will be necessary to fill in the forms, and the operational qualities of the tile directly depend on this “something”. The most commonly used materials today are:

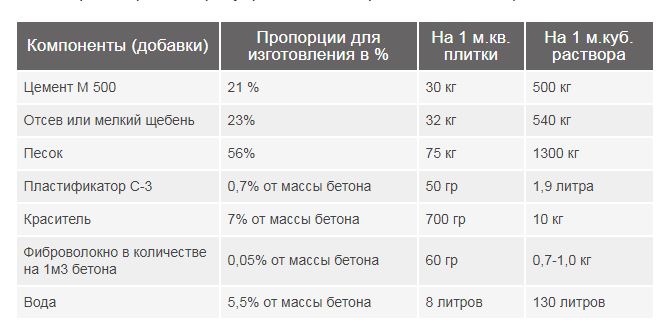

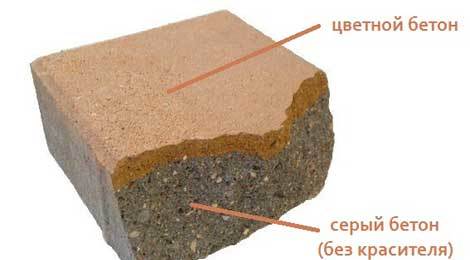

- Cement mixture may consist of cement and sand in a different ratio. Additives are sometimes added to strengthen: expanded clay, polymers, glue, fiber, etc. It all depends on the tasks.For the production of paving slabs, stones, which will be applicable for decoration on the street, the most suitable durable brand of cement M500but sometimes the M400 is used. This allows you to make a durable, durable product. To check the quality of cement, it will be necessary to compress it, and if a lump forms, then such raw materials should not be taken. To obtain a ductile structure, lime is added. Hardened building materials will last for many years, withstand environmental stresses, they can lay garden paths and even indoor floors. Excellent tile replacement. There are many options to prepare a solution, but at home, you can use this recipe: cement grade M400 or M500 - 25%, sand fractions of 0.4-0.6 mm - 20%, screening - 55%, also some plasticizers are added. Water is about 15-17 liters for every 20 kg of cement - the solution should be grainy, mushy, not break up into lumps. For cooking colored tiles the following proportions can be used: cement 20 kg, sand 35 kg, crushed stone 35 kg, plasticizer 70 g, color pigment - 0.5-0.7 kg. In industrial conditions colored tiles make layeredso as not to sacrifice the quality of the product, but to produce laminated tiles at home without a high-quality vibrating table with damping unnecessary vibrations will not work.

One of the recipes for the preparation of cement mortar for tiles

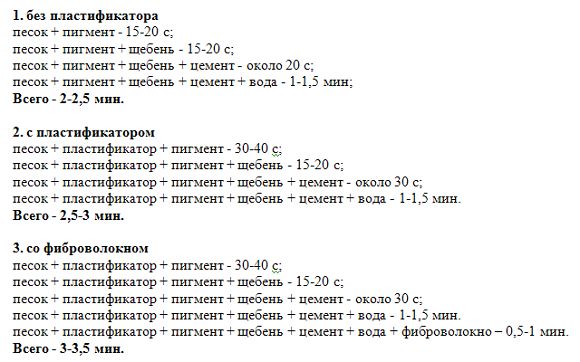

The sequence of adding components to the mixture and cooking time

Double layer tile

- Gypsum compounds not so strong, therefore, they are suitable for the development of products for interior decoration, but any relief models can be made of them. With their help, it is possible to create even an imitation of a saw cut of a tree, mosaics, pebbles, etc. For external use, additives are added to increase moisture resistance. When mixed with other components, gypsum concrete is formed, which has a stronger structure.

- Polymer sand are becoming more popular every day. The bulk, almost three quarters, is sand (not river, but quartz). The rest is polystyrene, polypropylene. A feature of the composition is an incredible hardening, it will withstand temperatures up to -700C, not afraid of sudden changes in temperature, moisture, wear-resistant. With this composition, you can achieve a matte and glossy surface. There is no marriage in the manufacturing process. The downside is that dispensing with special equipment will not work.

By the way, warehousing and storage are factors that also affect the properties of the goods.

No. 3. Tile coloring

Color pigment affects product propertiesTherefore, it is important to choose the right proportions and not go too far with the amount of dye. Better to take a richer color than add a lot of paint in anticipation of the desired shade.

So, there are two ways to apply paint:

- Surface, i.e. dyeing at the end. First, the plane is carefully prepared: cleaned of debris and primed to achieve maximum adhesion. Such a view is not suitable for the street, because when exposed to rain, snow, wind, the sun and other factors, the pigment is washed off, and the color leaves.

- Penetrating - adding pigment directly to the solution. This method makes the tone more persistent. It is only necessary to properly clean all contacting devices so that the color does not mix, or use, for example, several blanks for pouring tiles of different colors.

Number 4. Admixtures and additives for strengthening tiles

For concrete, there are several options for reinforcing additives:

- Crushed stone is used to strengthen the structure.

- Polypropylene filaments (fiber) are necessary to improve wear resistance, strength, extend the life of building materials.

- There are special additives that increase resistance to shock, temperature jumps, etc. are selected individually.

- The plasticizer increases frost resistance and abrasion resistance.

For gypsum, just add a little plasticizer, cement.This will positively affect the strength, the element will not be so fragile.

No. 5. Equipment

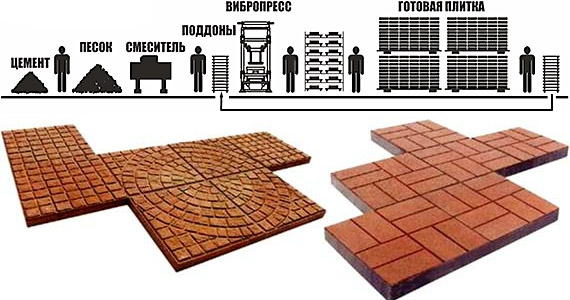

With large-scale production, you can not do without special equipment. From the point of view of the technology used in production, paving slabs are divided into vibrocast and vibro-pressed. Naturally, in the manufacture of various machines are used:

- vibrocast tile made by installing solution-filled forms on a vibrating surface. Under the influence of vibration, the solution is evenly distributed in shape, and all the bubbles come out. After this, the molds are dried on shelves for 2-3 days, then the resulting tile is removed and dried. The result is a fairly durable product. Such technology is widely used in private construction and in small enterprises;

- vibropressed tile it turns out in a similar way, but the solution vibrating in the forms is additionally pressed with special equipment. As a result, the tile is more dense and wear-resistant, suitable for laying in places with increased load. Drying is carried out in special chambers. In this way, tile is manufactured in the factory, in terms of performance, it is superior to vibrocast, but inferior to it in terms of a variety of shapes and colors.

When vibrating, a special vibrating table is needed. It is an ordinary table, the surface of which vibrates, it is manual and automatic. You can buy ready-made equipment or make everything yourself. If the tile is necessary in order to pave the pedestrian paths, then the most primitive device will be enough: a thick stove is laid on the old bus (as from an old stove on wood), and in the middle jigsaw or other instrument that gives vibration. We plug the device into a power outlet and put the forms, but complete degassing in this way is difficult to achieve. If you put things on the stream, then you can not do without professional equipment.

Keep in mind that under the influence of vibration, the solution gives a foam that rises, and then begins to settle. It is at this moment that it is necessary to stop the process, otherwise the composition may delaminate. To make a two-layer tile (the first layer is gray, the second color), a 2/3 mold is filled with a colorless composition and waiting for the appearance and deposition of foam, then a color solution is added, wait 2-3 minutes and remove the form from the vibrating table.

Vibro press technology will require vibropress. There are manual and automated devices. You can choose a model equipped with a concrete mixer. Automatic installations are convenient for large factories; private companies will benefit from manual installations. At the same time, the vibrating machine is not as effective as the vibrating press. However, with the correct filling of modern forms, such devices will be needed only for large enterprises.

Of the tools still need hammer drill with a mixer nozzle or concrete mixer (it all depends on the volume of production), containers for dosing the components of the mixture and kneading. It is also better to prepare racks for drying tiles.

Drying in natural conditions in the summer in the middle lane takes about 16 hours. To remove the tile from the mold, the latter can be turned over and shaken. The piece form can be lowered into a basin with water so that the water reaches the side of the form, then move into a basin with hot water. Due to the temperature difference, the shape will increase slightly, and the tile will fall out by itself.

It is better not to use the finished tile right away - let it mature for 5-7 days and gain maximum strength.

Conclusion, or How to control

Well-known factories with huge volumes of sales use computer equipment to check for the slightest damage, defects and deficiencies. But you can do without it.

Everyone is interested in knowing how to establish the quality factor of a product in artisanal conditions. First of all, a visual inspection is needed: we look at what defects are there, whether the pattern, the pattern has taken.We carefully examine the corners for chips.

You can determine whether proportions are properly maintained using sound. Take two plates and knock them. If the sound is dull, then something is wrong, it should sound loud. This rule applies not only to ceramic tiledbut also with cement.

It should be remembered that the consumer is important not only the price of facing building materials, but also the characteristics that affect the operation. Therefore, you should not reduce costs at the expense of quality, but look for other possibilities.

Good article! I’ll add from myself that in the manufacture of products by vibrocompression or by vibration casting, it is important to take into account the proportions of the components, observe the technology so that one of the main “enemies” of such a product is not air. For private production at home, vibrocasting, in my humble opinion, is better suited, plus there is no production framework in time.