7 tips on which ventilation pipes to choose in a private house

Remember how famously the heroes of Hollywood films move through the intricate labyrinths of ventilation ducts? This, of course, is spectacular, but the main function of these pipes is to draw air into the street. If you don’t pay ventilation organization due attention, then stuffiness, foggy windows, dampness and mold Do not take long. Fresh air enters the home through leaks in the windows, special valves, ventilators and breathers. Exhaust air goes out through special ventilation ducts, which can be additionally equipped with fans. If in high-rise buildings all these nuances are thought out for us, then when building your own house you will have to delve into the essence of the matter to ensure a normal microclimate. What ventilation pipes in a private house is better to choose? What material to prefer? What size pipes to choose? And, most interesting, is it possible to adapt cheaper sewer pipes to organize ventilation? Let's get it right.

No. 1. Ventilation pipe requirements

Well, if the arrangement of the ventilation system occurs at the stage building a house, because in this case the air ducts can be hidden, and they will not violate the aesthetics of the room. Channels allowed to spread brickbut it is a long process. Today, mainly used, special ventilation pipes that simplify and speed up the entire installation process.

Note that most often ventilation ducts in a private house are necessary for air removal. However, if it is necessary to take all air movements under maximum control, a forced supply and exhaust ventilation. This is a complex system, but in this case, pipes will be needed in order to let in fresh air from the street.

The choice of duct material and its diameter depends on a mass of factors. First of all, this is the type of room and the features of the air that must be removed (temperature, chemical composition, etc.). Whatever the case, and whatever option you choose, there is a number of requirements that the duct must meet:

- perfect tightness;

- the ability to provide free passage of air flow of a specific volume and at a given speed;

- safety for human health (non-toxicity) and minimal noise during passage of air masses;

- if the pipes are not hidden, then decorative qualities are also important.

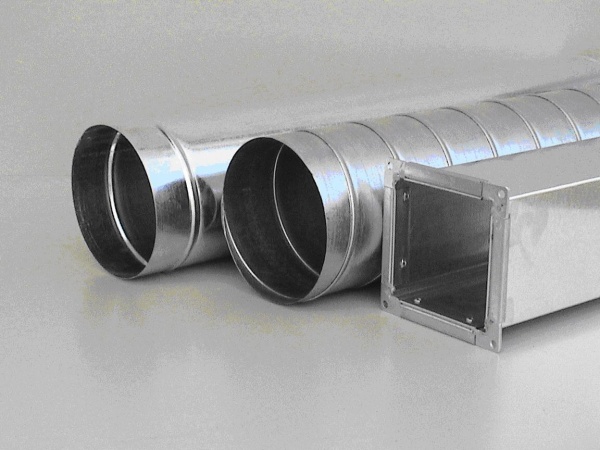

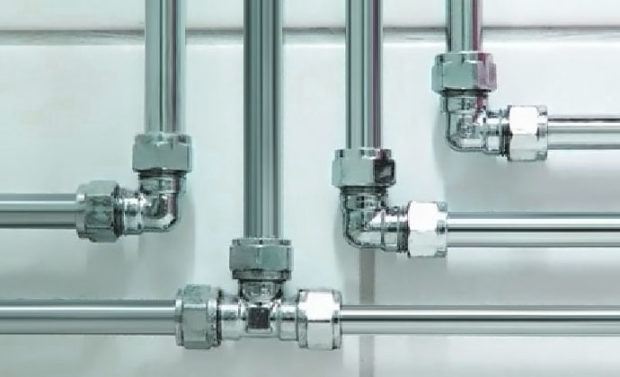

Ventilation pipes are produced metal and plasticand the latter is used more and more often today. Products with round and rectangular section, different sizes. Separate sections are connected thanks to bends, connectors, tees, flanges and other elements. Thanks to the widest choice of pipes and connecting products, you can build a ventilation system of any complexity. Residents of Moscow and the region can find everything necessary for organizing ventilation in the online store WhereMaterial. Ventilation is equipped for many years, so it is better to contact a trusted supplier who provides assistance in choosing, favorable prices and prompt delivery.

No. 2. Metal pipes for ventilation

This group includes pipes from stainless steel, galvanized and black steel. To general the benefits The following qualities can be attributed:

- resistance to high temperatures, pressure and hostile environment;

- a wide selection of shapes and sizes, in which metal pipes are significantly superior to plastic;

- stiffness and strength;

- durability.

High weight, considerable price and installation complexity - those are the reasons why many people prefer to abandon metal pipes in favor of plastic ones. In private homes today, almost no one is using metal ducts - there is no need for them. They are more suitable for organizing ventilation in industrial premises.

To the general disadvantages we add the disadvantages of different types of metal pipes. Cink Steel although it receives protection in the form of spraying zinc layer, but does not differ in special durability. The coating, of course, pushes back the time of the appearance of corrosion and slows down its development, but does not completely save it. The weakest points in galvanized pipes are joints. It is in these places that rust first appears, and as soon as it begins to develop, an unpleasant smell is formed. If we are talking about living quarters, then this is a very serious drawback.

Stainless steel in operation behaves much better. It is more resistant to corrosion and therefore more durable. This material has high refractoriness and is suitable for transporting aggressive air masses. For production - an ideal option, but at home, massive metal pipes are justified to use only if you got them for free and will be hidden in the wall.

All metal ducts have another unpleasant property. Air passing through such a pipe and forming streams can cause significant noise. To reduce the number of air vortices, it is necessary to minimize the number of turns of the pipe and avoid angles of 90 degrees. In addition, the metal walls of the channel will resist the passage of air flow.

No. 3. Plastic pipes for ventilation

Plastic ventilation pipes replaced galvanized from residential premises and are already actively used in some industrial buildings. Such ducts are made from polyvinyl chloride (PVC), polyurethane and polypropylene, and the last two species are not widespread. When talking about plastic ventilation pipes, they usually mean PVC products.

Main advantages:

- price. Plastic pipes are much cheaper than metal;

- light weight, ease of cutting, easy assembly and fastening technology of pipes allow talking about the maximum ease of installation;

- resistance to corrosion and decay;

- smooth walls allow maximum free flow of air;

- excellent noise insulation, which is important;

- durability;

- nice appearance, so if you can’t hide the pipes behind the walls or the ceiling, they will not spoil the picture;

- plastic pipes are certainly inferior to metal pipes in the assortment of possible sizes, but in the vast majority of cases the existing choice will be enough to equip even the most complex ventilation system. Plastic pipes are available in length from 3 to 12 m, section from 16 to 1600 mm.

The main disadvantage of the material - inability to withstand high temperatures. PVC retains its original performance at temperatures not exceeding +800C. If we talk about ordinary home ventilation, then there are never such temperatures. If we are talking about the removal of hot air, for example, from fireplace or in production conditions, you will have to make a choice in favor of a metal counterpart.

A few opponents of plastic pipes reproach the product with low strength.It would be foolish to argue that plastic is softer than metal, but ventilation pipes are usually mounted in a hidden way, so external exposure to them is minimal, which means that less strength can in no way affect durability.

Number 4. Corrugated ventilation pipes

Ventilation pipes can be divided into two large groups:

- hard;

- corrugated.

The former keep the shape given to them at the factory, the latter, due to the presence of numerous ribs, can take virtually any shape. Naturally, the installation process is greatly facilitated, because there is no need to use all kinds of connecting elements, but not everything is so simple.

The main advantages of corrugated ventilation pipes include:

- flexibility and elasticity. The product can be bent at any angle, give it the desired shape, and this is an invaluable quality when it comes to installing ventilation in complex areas;

- strength;

- ease of installation;

- no need to use tees, adapters and other auxiliary elements.

It makes no sense to build the entire ventilation system only from corrugated pipes. Of these, only those parts of the air ducts are equipped where, when using rigid pipes, too many turns and connections would have to be made. Everyone knows that the more bends, the worse the air will pass, but a smooth bend in terms of aerodynamics is much better than turning at an angle, so a corrugated pipe is chosen from two evils.

Why corrugation use only on short complex segments? Because she has a lot cons:

- the ribbed surface worsens the air flow, slowing it down and reducing the ventilation efficiency. If in short sections this is not particularly noticeable, then in long sections the effect will be impressive;

- the appearance of vibrations and noise with a stably strong air flow;

- difficulties with fastening.

The fact that corrugation is not used in long sections is also confirmed by manufacturers who do not produce connecting elements for this type of pipe.

Corrugated pipes can be:

- aluminummore precisely, made of multilayer aluminum foil, they are slightly heavier than plastic, more prone to condensation, but tolerate higher temperatures;

- plastic pipe made on the basis of polymers that are reinforced with aluminum. Such products are lighter, less noise, but can not stand high temperatures.

No. 5. Ventilation from sewer pipes: is it possible or not?

A domestic person has a thirst for savings, probably in the blood. Once, someone noticed that sewer and ventilation pipes are made from the same PVC, but for some reason air ducts are several times more expensive. And since the products are the same, so why pay more? You can sewer pipes adapt for air venting? Or is it impossible?

Two factors usually prevent the use of plastic sewer pipes in a ventilation system:

- mismatch in the diameters of ventilation and sewer pipes;

- There is information that plastic used in sewer pipes emits harmful substances.

Indeed, sewer and ventilation pipes do not match in diameter. Difficulties will be avoided when arrangement of ventilation from scratch. If you immediately lay a ventilation duct everywhere from sewer pipes, then there will be no problems. Difficulties arise when it will be necessary to connect a ventilation corrugation to such an air duct. It will also not be easy to expand existing ventilation, made of conventional ventilation pipes, using a piece of sewer pipe. But craftsmen here find a way out, hermetically connecting the sections of pipes of different sizes with adhesive tape. They believe that a narrowing of 10 mm will not affect ventilation efficiency.

The rules for building a ventilation system say that switching to a different pipe diameter is not recommended, but a smooth transition can save the situation, without the so-called. "Steps". It can be difficult to secure.

As for the theory of plastic toxicity, there is no well-reasoned evidence for it. However, even the most cautious in this regard, people boldly use sewer plastic to organize exhaust ventilation.

When choosing sewer pipes for constructing an air duct, remember that in this case, flush mounting is a necessity.

No. 6. Form and method of production

Ventilation pipes in shape are:

- round and oval, they are easier to manufacture, have better aerodynamics, are used more often in industrial buildings;

- square and rectangular more often used in houses and apartments, as they are easier to mount, and they use the space more rationally. If ventilation ducts are not closed by anything, then rectangular pipes in the color of the walls will be minimally conspicuous. Minus - the worst aerodynamics.

Round pipes come in spiral and longitudinal, square - only straight-seam. Spiral pipes are considered more rigid, but they are also more expensive.

The pipes are attached in increments of 1-2 m, if you make the distance greater, you may encounter sagging and disruption of the ventilation system. Keep in mind that with a significant temperature difference, condensation may form inside the duct and outside. For example, in winter, heated air is discharged through the ventilation duct, and if it passes through an uninsulated attic, condensation will appear on the walls, which, with constant influence, reduces the durability of the system. The way out is to insulate the ventilation pipes yourself or buy already insulated products.

Number 7. What pipe diameter / size will you need?

Calculation of ventilation is not an easy task. There are programs where you can drop all the source data, and then get the recommended values of the air exchange and the size of the ducts. There are specialists who will perform the calculation taking into account all the features of the premises of the house. The general principle of calculation is as follows.

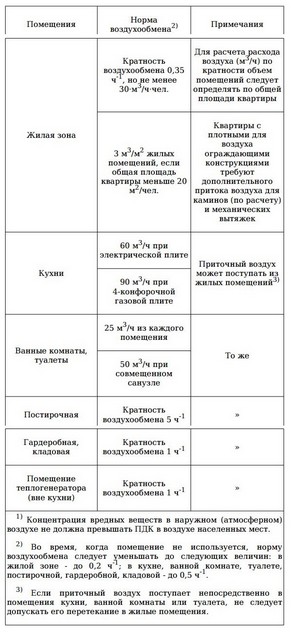

First you need to find the amount of air, which should enter the house and be removed from it in a unit of an hour. In theory, the volume of incoming air = the volume of the extracted air. How much air should go in and out to make us comfortable? In normative documents everything is already counted.

According to SNiP 31-02-2001, air exchange for residential premises is equal to the volume of the room, i.e. in 1 hour the air should be completely renewed 1 time. For the kitchen, this figure is at least 60 m3 / hour, for the bathroom - 25 m3 / hour. The volume of the room is easy to calculate.

The design standards of "ABOK" 2.1-2008 speak of the following standards of air exchange.

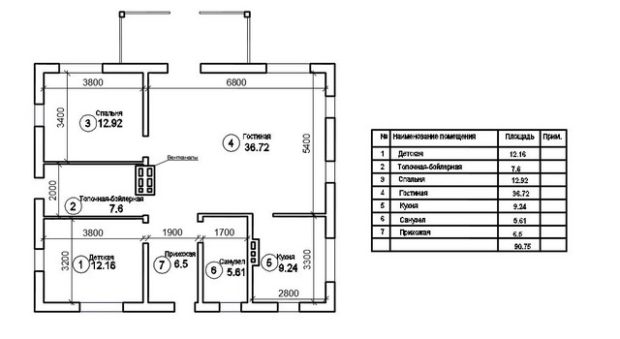

Sometimes, according to these standards, slightly different values are obtained, it is better to take into account what is greater. For the correct calculation, it is necessary to arm yourself with a house plan, where the parameters of each room are indicated. It’s convenient to do everything in the form of a table.

From each pair of numbers we select the largest and sum them. In the example, the total air exchange is 430 m3 / hour. In living rooms it will be necessary to organize the influx and exhaust, and in the kitchen and in the bathroom - only the exhaust. Fresh air will come there from neighboring rooms.

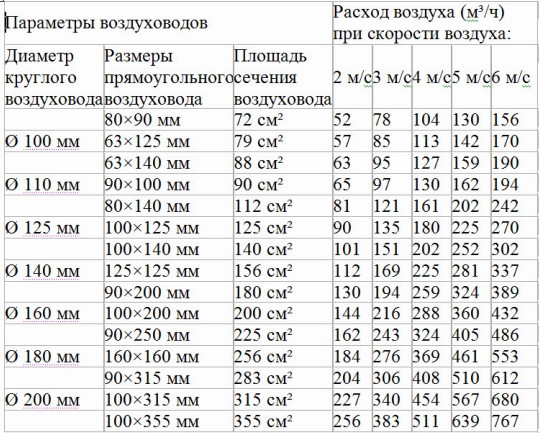

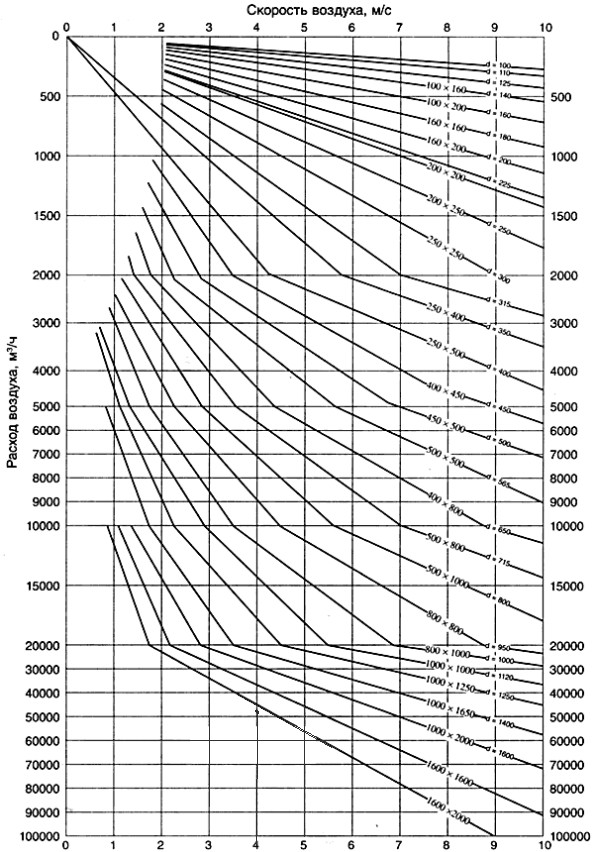

Further, when calculating, it is necessary to consider how will air be discharged, naturally or forcefully. In the natural method, the speed of the air flow inside the duct will be no more than 1 m / s, with a forced one - up to 5 m / s, in the branches - up to 3 m / s.

Channel cross section consider according to the formula S = L / (V · 3600) m2, where L is air exchange, and V is the flow rate. You can also use a special chart. In this case, fans are indispensable. If we take the flow velocity as 3 m / s, then we get S = 0.0398 m2, or 398 cm2. You can organize ventilation with one duct 200 * 200 mm, two 170 * 170, or three 150 * 150.This is just for you to understand the general calculation scheme. More reliable, of course, turn to specialists.

To the arrangement of ventilation, many are too dismissive. If you do not want to encounter microclimate problems later, break walls and ceilings or mount pipes for finishing, it is better to think over everything in advance.