7 tips for choosing PVC sewer pipes

Many scientists call our century the era of plastic. Polymers created by mankind are used in absolutely all spheres of life, often showing themselves much better than traditional materials. A striking example is the arrangement of a sewage system. For a couple of decades, there was simply no alternative to cast iron pipes. Today, they are actively replaced by polyvinyl chloride analogues, which are not susceptible to corrosion, do not overgrow, weigh less, and are cheaper. The excitement around such products can be understood. It remains only to figure out how to choose PVC pipes for sewage, and what their features are important to consider during operation.

No. 1. What are PVC sewer pipes

Often PVC pipes are called simply plastic, which is not entirely true. Plastic pipes are a whole group of products where you can also include polypropylene pipes, cross-linked polyethylene pipes and, in fact, pipes made of polyvinyl chloride (PVC). The latter are made of polyvinyl chloride thermoplastic, which also includes special additives that provide additional strength to the product. Pipes from the prepared mass are created by extrusion, they retain their shape well.

Depending on the characteristics of the production, two types of PVC pipes are distinguished:

- plasticized PVC pipes (PVC) are notable for their low price, good elasticity, but cannot boast of high strength. Such pipes for the organization of individual sections of the sewer;

- unplasticized PVC pipes (PVC-U) are more expensive, but also more rigid, resistant to all kinds of external influences, are excellent for arranging internal and external sewers, provide sufficient durability of the system. Such pipes can be used even in pressure sewers.

PVC pipes are actively used in the arrangement of internal and outdoor sewage, they are also used for installation cold water systems, to create drainage systems, when laying the Internet and telephony cables. Such a wide scope is a consequence of the huge number of advantages of this type of product.

No. 2. PVC pipes: advantages and disadvantages

Before choosing anything, every sane person weighs all the pros and cons. Sewer pipes will not be an exception.

Advantages of PVC sewer pipes:

- affordable cost. Arrangement of sewage using PVC pipes will cost several times less than the organization of the same pipeline made of cast iron;

- corrosion resistance. Plastic does not rust, unlike the same cast iron, which means that PVC will create a more durable sewer system;

- durability both external and internal surfaces to aggressive environments;

- high tightness. Since the material is not afraid of corrosion and other negative factors, you can not be afraid that under the ground the pipe will lose its integrity, and waste water will fall into the ground;

- smooth inner surface minimizes the likelihood of overgrowing pipes and their fecal blockage;

- resistance to low temperatures. PVC pipes do not deform even under prolonged exposure to freezing temperatures;

- light weight, which greatly facilitates the transportation and installation of PVC pipes;

- sufficiently high strength and environmental safety;

- durability. Manufacturers talk about life up to 50 years;

- plastic does not conduct stray currents, and this is another plus in terms of your safety;

- a huge selection of pipes of different diameters and lengths, there is also a sufficient number of adapters and mounting elements, so arranging a sewer system from PVC pipes is a relatively simple task.

Not without flaws:

- sensitivity to high temperatures. Maximum working temperature for PVC pipes +400C. Products withstand heat up to +800C, but similar effects should be rare and short-term. With prolonged contact with hot liquids, the material loses a number of useful operational qualities and quickly fails;

- PVC pipes behave better than cast-iron pipes, but still, over time, even on their smooth walls begin to form raid. With regular, albeit short-term exposure to high temperatures, the pipe from a round pipe begins to turn into an elliptical. All this together can lead to a decrease in throughput or even leakage, so it is important to follow the rules during the installation and operation of pipes;

- low fire resistance;

- Despite the fact that manufacturers say that PVC is completely inert to aggressive substances, individual compounds can still gradually corrode the pipe walls. In fairness, we note that such compounds are usually not found in home sewer systems.

No. 3. The main types of PVC sewer pipes

Polyvinyl chloride pipes are used for laying internal and external sewers, they are operated under various conditions, so manufacturers offer us several types of products that differ not only in performance, but even in appearance.

For the arrangement of sewage, the following types of pipes are used:

- rigid gray pipes used for laying domestic sewage. The wall thickness varies from 1 to 3.2 mm, the diameter is from 32 to 160 mm, and the length of the segments is from 0.3 to 3 m;

- hard orange pipes designed for laying the outer part of the sewer. The diameter of such products ranges from 110 to 500 mm, the length is from 1.2 to 3 m, and the walls have a thickness of 3 mm. These pipes are strong enough to withstand the load of the soil. They have a small expansion coefficient, so they are not able to deform strongly even with a significant temperature difference. Between themselves, individual sections are connected by a bell-shaped method;

- corrugated sewer pipes gray color and small diameter is used to connect washing and dishwashers. Two and three-layer orange pipes are used to equip the external sewage system. They are quite durable and elastic, withstand decent loads, can be mounted to a depth of 15 m. Such strength properties are achieved due to the presence of numerous stiffeners. Corrugated pipes are also used for laying rain sewer systems, and arranging drainage pipelines.

Number 4. Strength class of PVC sewer pipes

About what load a PVC pipe can withstand, says its strength class. This information is most needed when it comes to pipes for arranging external sewers. The strength and resistance of the pipe to external pressure show how deep it can be buried without being afraid for its integrity.

Total exists three strength classes of sewer pipes:

- light pipes (SN2) withstand pressure up to 630 Pa, have a wall thickness of up to 2.3 mm. Such pipes are used inside the apartment, they are buried to a shallow depth (up to 2 m), and where large loads are not expected, for example, under the lawn, flower garden, pedestrian zone and in other places where there is no traffic load;

- medium pipes (SN4) they have walls with a thickness of 2.5-12.3 mm, withstand pressure of 600-800 Pa, can be safely used for laying under the road with a small load, depth 2-6 m;

- heavy pipes (SN8) with a wall thickness of 3.2-15.3 mm withstand a load of 800-1000 Pa, they are designed for laying under roads with heavy traffic, buildings. The maximum depth is 8 m.

In the most difficult areas, it is naturally better to use unplasticized PVC pipes, which can withstand pressure up to 1.6 MPa.

No. 5. Pressure and non-pressure sewer system

Pressure on the pipes can be exerted not only from the outside, but also from the inside. Depending on how the flow is organized, the pressure will be different. there is pressureless sewer systemswhen drains move by gravity. Similarly, the sewer works in the apartment. The water flow in a private house is also organized when the site is on a slope. Through main sewer pipes, sewers move under pressure. On a flat site, drains to the septic tank will also have to be forced to drive. In this case, you can’t do without pressure equipmentwhose work will put additional stress on the pipes.

The type of sewer system leaves its mark on the choice of PVC pipes:

- for pressureless internal sewerage pipes with a wall thickness of 1.8-3 mm are suitable, plasticized pipes are used. For pressureless external sewage, pipes with a wall thickness of 3.2 mm (for a diameter of 110 mm) to 12 mm (with a diameter of 500 mm) are taken;

- pipes for pressure sewer made of unplasticized PVC. Such products, depending on the wall thickness, withstand a pressure of 0.8-1.6 MPa. The wall thickness varies from 2.2-6.6 mm for pipes with a diameter of 90 mm to 12.3-23.9 mm for pipes with a diameter of 500 mm.

No. 6. PVC sewer pipe size: diameter, thickness, length

Selection sewer pipe diameter - This is a matter of increased importance. If you take pipes less than required, they will not provide sufficient throughput. What this means is probably not worth explaining. In the best case, the sewage will leave poorly, in the worst - in some places they will start to go outside. In fear of encountering similar consequences, many decide to play it safe and take pipes with a diameter much higher than required. Efficiency compared to pipes with correctly selected diameters will increase slightly, but the costs and the area that must be allocated for these pipes are greatly increased.

Before you go shopping, you must draw up a sewer system diagram and mark on it all the points of discharge of the liquid. The more drainage points there are, the larger the drain pipe should be. However, when choosing pipes, it is necessary to take into account not only them diameter, but also length and wall thickness.

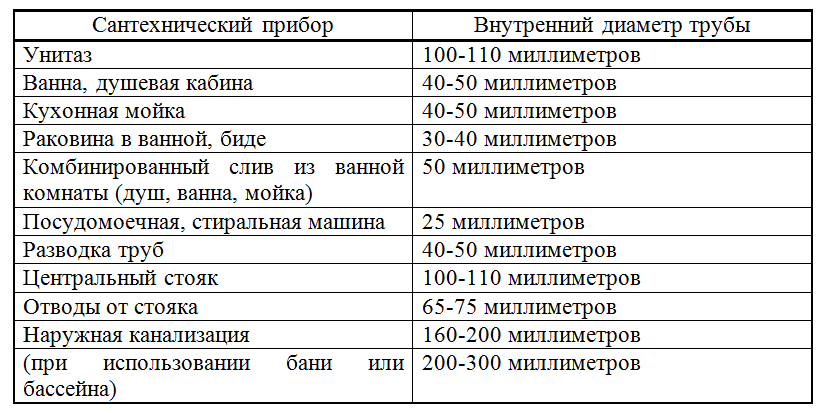

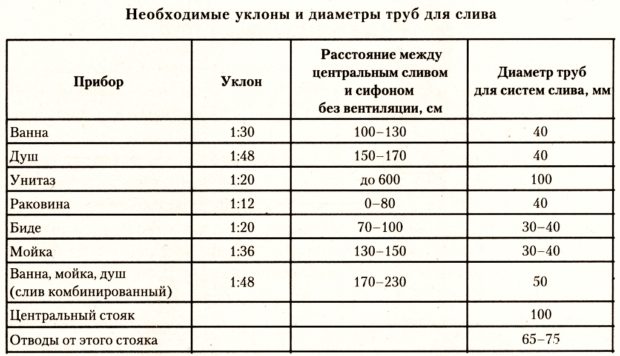

To choose the right diameter of sewer PVC pipe, ideally, it is necessary to calculate the estimated volume of effluents, but often this calculation is neglected using parameters verified by millions:

- pipes from shower stall, bathtubs, washbasin and the bidet may be 40-50 mm in diameter;

- for kitchen sink - 32-50 mm;

- for toilet bowl - 110 mm;

- for dishwasher and washing machine - 25 mm;

- central riser - 110-160 mm;

- pool - 200-300 mm.

The diameter of the sewer pipe that exits the apartment must be at least the diameter of the common highway. For houses up to 5 floors, these are pipes with a diameter of 110 mm, for taller buildings - 160-200 mm. External sewage can not have a diameter of less than 110 mm, which must be remembered when arranging the sewerage of a private house. As a rule, in summer cottages and country houses, pipes with a diameter of 110-200 mm are used to equip the outer part of the sewage system. If a sewer system is being built to service several houses, it is better to take a larger diameter - about 315 mm.Pipes with a diameter of 630 mm are suitable for arranging the main sewage section for servicing a small village.

Wall thickness depends on pipe loads. For internal pressureless sewage pipes with walls of 1.2-2.2 mm are suitable. They have a diameter of up to 110 mm and belong to the strength class SN2. SN4 pipes are most widely used. They are used for arrangement of both external and internal sewage. Such pipes with a diameter of 50 mm have walls of 2.6 mm, with 110 mm - already 3.2 mm. Suitable for organizing a common house riser, as well as outdoor pressureless sewage in a private house. If it is necessary to equip a pressure sewer, it is better to take pipes with the thickest walls (class SN8). With a diameter of 90 mm, the wall thickness is 3-6.6 mm.

Length selection depends on the length of the pipeline. It is better to reduce all connections to a minimum, but too long pipes are not worth buying - it is economically unprofitable, and uncomfortable. Usually PVC pipes are sold in pieces. 0.5 m, 1 m and 2 m eachbut you can find products long 3 m vs 0.3 m. Some manufacturers offer pipes with a length of 6 m and even 12 m, they are convenient to equip the external sewer.

Remember that the junction of individual sections is the most dangerous, so try to make the installation so that the connections are as few as possible. A competent preliminary calculation will help here. In which case, the pipe length can be reduced using a hacksaw.

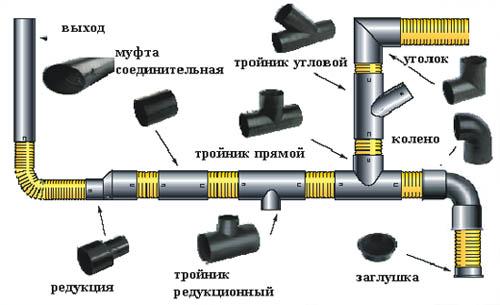

Using PVC pipes, you can assemble a sewer system of any complexity. Not only different pipe diameters come to the rescue, but also all kinds of adapters, rotary branches, tees, crosspieces, reductions, caps, etc.

Number 7. Features of installing PVC sewer pipes

If you have certain skills, then you can cope with the installation of the internal sewage system yourself, because the main advantage of PVC pipes is the ease of installation. The sequence of actions will be as follows:

- to prepare all sections of pipes and connecting elements, if necessary, sign them so as not to confuse them later;

- PVC pipes are connected by a bell-shaped method. Before starting installation, it does not hurt to check whether the ends of some pipes enter the socket of others. Ideally, the pipe should easily go into the seat nest by 2/3;

- The connection itself follows immediately. The end of the pipe is greased with glue and inserted into the bell. To glue better, you can first scratch the surface of the pipe a little before the appearance of small scuffs. As soon as the glue is applied, a connection is made, and for the complete entry of the pipe into the socket, it will be necessary to apply a small force;

- tees, crosses and other elements are mounted exactly the same way;

- Do not forget about the slope necessary for gravity drainage. The smaller the pipe diameter, the larger the slope angle is needed. For pipes with a diameter of 40 mm, the slope should be 3.5 cm per linear meter, for pipes 50 mm - 3 cm, for 80 mm - 2 cm, for 100 mm - 1.5 cm. The slope is formed by clamps that are mounted to the wall;

- when the glue dries (the term is indicated on the packaging), the system is checked for leaks;

- do not dispose of pipe residues - useful things can be made from them.

If the existing sewage system in the apartment is being repaired, then first it will be necessary to dismantle the old cast-iron pipes. Before this, it is necessary to warn the neighbors from above so that they temporarily do not use the sewage system. It will be necessary to act promptly, since it is unlikely that anyone will want to endure such inconveniences for a long time. Rubber sealing cuffs are inserted into sections of cast-iron pipes, an adapter and a tee are installed.

The outside of the sewage system is best left to professionals. It is important to properly insulate, provide for inspection wells, create a sand cushion, take care of the slope of the pipes and the correct angle of rotation of the knees.Details of the installation of internal and external sewage can be seen in the video.

Of course, polyvinyl chloride sewer pipes will not last you for centuries, but from what the market offers us, this is almost the most durable option, and given the cost, performance and ease of installation, PVC pipes can be considered the best option for organizing sewage.