Which tile adhesive is better

Ceramic tile is considered one of the most popular finishing materials. It is not surprising that a lot of different compositions were developed for its installation. Tile adhesive It differs in price, purpose, properties and mass of other parameters. The manufacturers wanted to do the best and give us the opportunity to choose the most suitable composition. No problem, because the larger the range, the more difficult it is to make a choice. How to figure out which tile adhesive is better to choose for various purposes? What is important to pay attention to when buying? Which manufacturers can you really trust? We offer you a guide on the whole range of tile adhesives.

What determines the choice?

As you might have guessed, there is no one single and the best glue that could be used absolutely always. The choice depends on several factors:

- type and size of tile;

- type of base;

- operating conditions (indoors or outdoors, at high humidity, high temperatures, etc.);

Anyway, good tile adhesive must be ductile and have high adhesion rates.

Types of tile glue by composition

The first and most important thing that tile adhesives differ from each other is the composition. Depending on the main components, glue can be divided into three main groups: cement, dispersion and epoxy. Sometimes a polyurethane compound is also isolated.

Cement tile adhesive

Sold as dry mix in bags. Composition includes up to 90% portland cementthe rest is sand, latex and polymer additives. To prepare the solution, it is necessary to fill the dry mixture with a certain amount of water and bring to a homogeneous consistency. Mixtures, which already include special additives, are called modified. If the manufacturer has not added additives, then they can be added to the composition yourself. It is about resin, liquid latex, etc.

Main advantages:

- low price, 150-750 rubles per 25 kg, depending on the manufacturer and composition;

- universality. Due to the introduction of additives, it is possible to obtain a solution with specific properties, for example, moisture-resistant, frost-resistant, etc .;

- ease of preparation and application;

- availability. Cement glue is sold in every city in any hardware store.

In construction, mainly cement compositions are used, however, when glue with special properties is required to perform the most critical jobs, epoxy and dispersion compounds are taken.

Cement glue happens thin and thick. The first is chosen when the surface drops do not exceed 10 mm, and the second is needed if there are large cracks. However, it is often more appropriate to first conduct alignment, and then glue the tiles.

Dispersion Tile Adhesive

Dispersion adhesive sold ready to use - nothing to breed and stir will not have to.The composition of the paste-like glue includes synthetic resins, mineral fillers and organic additives.

Benefits:

- plasticity, high adhesion and strength, therefore, the composition is chosen when installing the tiles on a complex base (absorbent or moving), for example, on a wooden floor and walls, drywall or even on an old tile;

- suitable for fixing natural stone, clinker tiles;

- since the composition is already ready for use, there will be no dust during cooking, and mixing errors are eliminated. Glue always has an invariable composition;

- within 40 minutes it will be possible to correct the position of the tile, then the glue will seize and dry quickly.

Of cons note the price and the inability to use for outdoor work. The glue is not suitable for use on painted surfaces.

Epoxy (reactive) tile adhesive

The composition is a two-component mixture. Before use, the components are mixed in the proportions indicated on the package. The composition includes epoxy resin, organic additives and fillers.

Benefits:

- absolute waterproofness after drying, therefore it is the best tile adhesive for pools, saunas and places with a heavy load;

- high-strength connection with any type of surface, even with metal;

- resistance to frost, temperature extremes, high loads, acids.

Main minus - a very high price, and besides, one must be able to work with such glue, observe strictly certain conditions when laying.

Polyurethane adhesive

A one-component composition that is suitable for mounting tiles on complex substrates. Differs in high elasticity and not less high price.

The main characteristics of tile glue

To understand which tile adhesive is better, it is not enough to take a quick look at the packaging - you need to understand the physical properties that are indicated on the bag / bucket:

- adhesion to concrete after 28 days indicates how firmly the adhesive adheres the tile to the surface. For a quality mixture, this indicator is 1-1.3 MPa, but for installation of a small-sized tile, adhesion of 0.8 MPa will be sufficient. For porcelain stoneware, glue with an adhesion of 1.5 MPa or more should be taken. The price of tile glue with increased strength properties is slightly higher, but you will be sure of the quality of work. For the installation of porcelain stoneware and natural stone glue is excellent Klester ZM-54which is characterized by moisture resistance, frost resistance, low consumption, sufficient time for adjustment and quick hardening. It can be used with underfloor heating, it is also suitable for outdoor work;

- adjustment time - the period during which you can slightly change the position of the tile. For cement compositions it is about 20-30 minutes;

- open hours - the period during which the adhesive retains its properties, and it can be mount tile. For conventional formulations - 10-20 minutes, for quick-setting - 5-10 minutes;

- hardening time - the period after which the glue completely dries, and the surface becomes usable. The period is from 3 hours for quick-hardening mixtures to several days;

- shelf life of the solution - the period during which the prepared glue does not lose its basic properties. The longer, the more convenient. As a rule, this period is 1-3 hours;

- thixotropy speaks of resistance to sliding tiles after installation. A standard solution provides a slip of not more than 0.5 mm, but there are formulations with increased thixotropic qualities (creep of not more than 0.1 mm). Glue, where the slip is more than 0.5 mm, should not be taken;

- operating temperature. Almost any glue is suitable for a normal living room, but for fireplace trim and furnace a specific composition will be required. Also, the temperature indicator is paid attention to when installing tiles on warm floor, facades and socles. The composition must be flexible, heat and water resistant. When mounting on the street, it is also important frost resistance, ideally at least 100 cycles.

Tile adhesive consistency

By consistency, tile adhesive is:

- liquid. These are mixtures that are already sold ready-made. There is a saving of time and a reduction in the risks of doing something wrong, but you will have to pay for convenience. Separately, you can select liquid Nails, which are used for fastening small parts and fallen tiles;

- dry. Sold in the form of a powder that is diluted with water. It is characterized by low price, ease of transportation, versatility, reliability and the ability to use on surfaces with level drops and cracks.

Tile adhesive and tile type

It is impossible to answer the question which tile adhesive is better without considering the type of tile. It is necessary to take into account the dimensions and weight of the tile, its type and color, the ability to absorb moisture, as well as the type of installation (wall or floor). You will find many necessary parameters on the packaging of tiles. It will be logical to buy glue after the tile is selected and purchased.

So, when choosing glue, consider the following features of the tile:

- the size. For mounting elements from 10 * 10 cm to 30 * 30 cm in size, you can use a universal mixture with adhesion up to 0.8 MPa. For large images with a large weight, it is better to take reinforced glue. When it comes to floor tiles, adhesion rate is not so important. Also note that the thickness of the glue is approximately equal to the thickness of the tile;

- kind of tile. For mosaics and light natural stone it is better to take glue based on white cement. So the seams will look much more aesthetically pleasing. Marble, by the way, has the ability to absorb the solution, so when using conventional gray cement glue, the stone may darken over time. For mosaics, it is better to take the composition with the smallest possible grain size. For heavy and non-absorbent porcelain tile There are special formulations with enhanced adhesion.

Tile adhesive and base type

All types of bases are usually divided into:

- simple;

- complicated.

To simple reasons carry stable hard surfaces subject to minimal deformation. it concrete, brick, cement screed, cellular concrete blocks. Difficult grounds - those surfaces that are able to expand, strongly absorb moisture, are not resistant to increased loads. This group is usually classified tree, drywall, plastics, glass, metal.

For simple reasons the best tile adhesive will be cement: cheap and cheerful. When it comes to wood and drywallit is better to take a dispersion composition, but some manufacturers produce special cement glue with additives for use with drywall surfaces. For fixing tiles on metal and glass it is better to take epoxy glue. Install if necessary on a layer of old tile dispersion glue can be used.

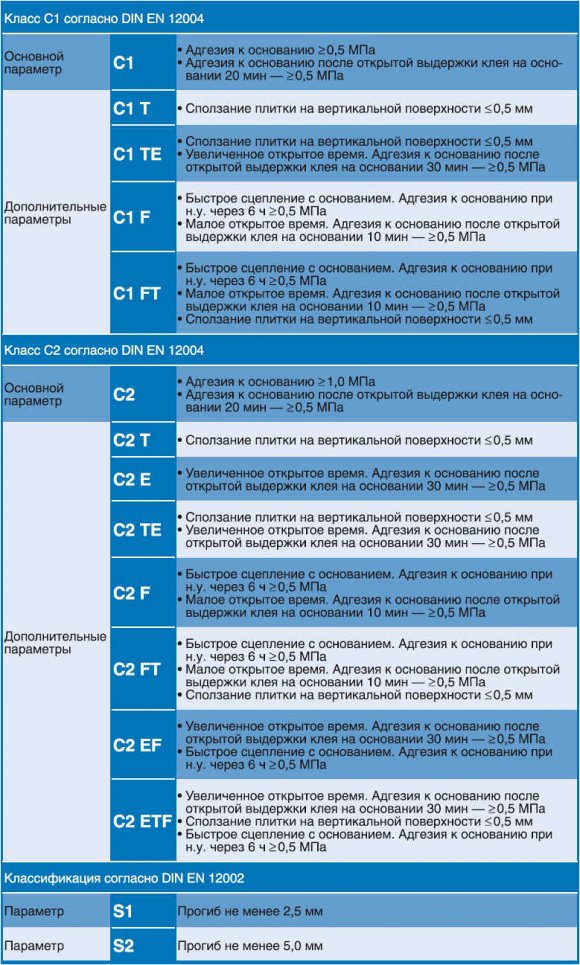

International classification

All European adhesives and many domestic ones have markings according to the European standard DIN EN 12004. Several letters and numbers on the packaging can say a lot.

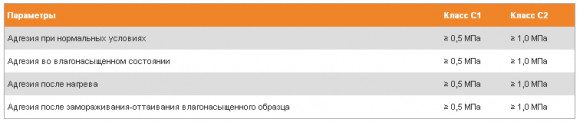

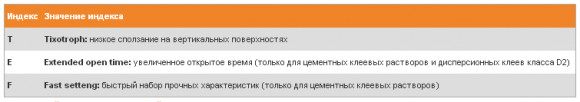

So, for example, depending on the adhesion index cement adhesives are:

- C1 - composition with adhesion to the base of more than 0.5 MPa;

- C2 - composition with adhesion of more than 1 MPa.

If the manufacturer added to the mixture modifying substances, this will affect the marking: the letter T indicates a low creep rate, F - a quick set of strength characteristics, E - increased open time.

Digital indices “1” and “2” indicate the basic (1) or enhanced (2) composition properties. Dispersion Adhesives labeled as D1 and D2: the first has lower adhesion properties, the second - higher. Polyurethane and epoxy adhesives are designated as R1 and R2.

By elasticity glues come in two classes: S1 and S2. Elasticity suggests the possibility of deflection of the adhesive after hardening, which is important for floor tiles, as well as when installing tiles on complex substrates. Glues S1 can bend by 2.5-5 mm, and S2 - more than 5 mm.

Special properties of glue

When it comes to laying tiles in particularly important places or places with specific conditions, you can take a composition with special properties:

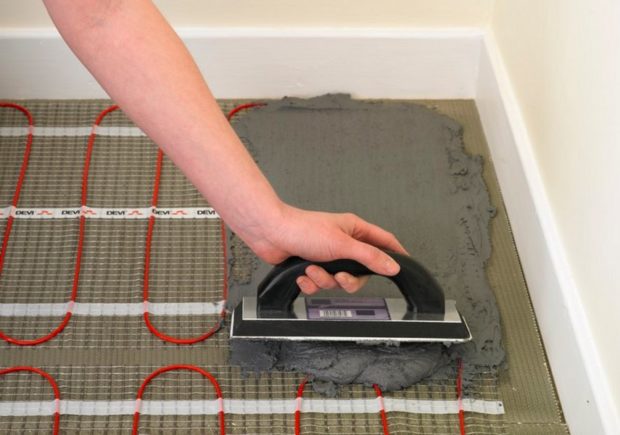

- heat resistant compounds necessary when lining furnaces and fireplaceswithstand temperatures above 1000C. They are also used together with a system of underfloor heating, but in this case it is also necessary to take elastic glue;

- quick-drying glue thanks to special additives, it makes possible the operation of the lined surface after 3-4 hours;

- waterproof glue recommend use in basins, bathtubs, on the porch, open balcony, terrace. All epoxy adhesives have absolute moisture resistance, but are expensive. There are cement compounds, which due to additives also give moisture-resistant properties, but such adhesives are not cheap. Masters advise, where possible, to use ordinary glue, and grout perform moisture resistant compounds;

- frost resistant adhesives suitable for simple substrates, quickly lose their ductility;

- acid resistant adhesives used in laboratories, industrial plants and other premises where exposure to aggressive agents is possible. Such compositions have sufficient moisture resistance, are odorless and quickly harden.

On sale you can also find special adhesives for underfloor heating, pools, glue-leveling agent (for laying on a very uneven base), glue with additional warming and white glue for transparent and translucent mosaic.

Universal adhesives, based on the name, can be used everywhere, but this is not so. They are not suitable for underfloor heating, for the installation of porcelain tiles, often can not be used for exterior cladding. Universality is an adaptation to average operating conditions, and such conditions do not always happen in real life.

Tile adhesive, type of room and operating conditions

When choosing a tile adhesive, it is important to consider another factor - the conditions in which the tile will be. Take into account temperature, humidity, load and some other parameters.

Tile adhesive for outdoor use

On the street, the tiles are affected by temperature fluctuations, high humidity, frost, and sometimes mechanical stress. Choose compounds that provide high degree of adhesion, resistant to temperature extremes and have frost resistance of 100 cycles.

For facing the porch, you must take a mixture with moisture repellent properties. For facing the base or facade, a whole waterproof glue with increased fixation is taken.

In the courtyard paving slabs they are laid on a cement-sand cushion, then they are rammed and the seams are filled with cement - there is no special glue for these purposes. If paving slabs need to be mounted on concrete, then you can take any glue for outdoor work.

Tile adhesive for the bathroom

For the bathroom and the bathroom, compositions that differ in increased resistance to moisture. It is advisable to take the composition with fungicidal additivesthat will prevent development mold. For the floor, elastic glue is chosen, since serious mechanical loads will be applied to it. For walls, increased elasticity is useless - fixation and thixotropy are important here. For plasterboard partition walls take more plastic compounds, and do not forget first primer GCR, otherwise the material will absorb glue.

In the bathroom you can use universal tile adhesive, but it is important to pay great attention to grouting. It must be carried out with a waterproof composition.

Tile adhesive for balcony and loggia

On the open loggia better to use moisture and frost resistant composition. Experts advise using frost-resistant compounds even for glazed but unheated loggias and balconies, since in winter the temperature there is much lower than in an apartment.

Tile adhesive for the kitchen

For kitchen and other residential any glue is suitable for rooms, since the operating conditions here are more gentle. In this case, it is much more important to consider the size and weight. tiles, and also do not forget that for mosaics it is better to choose white glue.

Tile adhesive for stoves and fireplaces

For the outer cladding of stoves and fireplaces, glue is selected that can withstand elevated operating temperatures. At temperatures 90-1200C on the outside of the oven you can use cement adhesive with additives from polymers and refractory clay. If necessary, veneer areas where the temperature rises to 3000C and above, the cement glue is not suitable - they take heat-resistant mastic and special adhesive pastes.

Tile adhesive for underfloor heating

Under the action of heating, the physical bodies expand, while cooling, they decrease. A good tile adhesive for underfloor heating should be enough plasticto withstand such impacts and not lose strength. Universal glue will not work - you need to look in the direction of special compounds that can withstand temperatures ranging from -30 to +600C and provide adhesion of 0.8-1 MPa. Do not forget to pay attention to the base material.

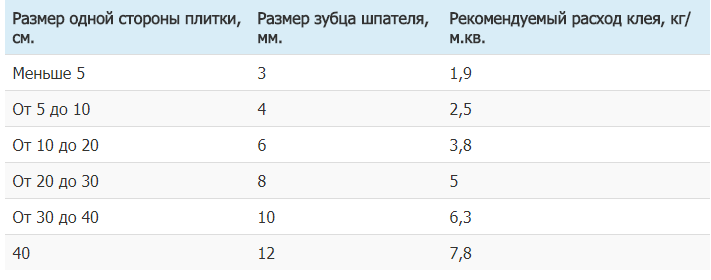

How much glue is needed, or glue consumption

After you determine for yourself which tile adhesive is better, another question will mature: how many packages / buckets of glue to take? The manufacturer indicates the consumption of glue on the package, averaging this parameter. In fact, the expense depends on many factors:

- glue type. For most cement compositions, the consumption is 1-1.9 kg / m2;

- tile features. Porcelain tile does not actually absorb glue, glazed tiles are characterized by minimal absorption, but handmade tiles and cotto tiles can absorb a certain amount of glue, which will affect consumption;

- surface features. If the surface is smooth and non-porous, then the consumption of the composition will be minimal. The more bumps, and the more absorbent the base, the more glue will go;

Is it possible to level the surface with tile glue? In principle, it is possible. There are compounds that can be used with a difference of 10 mm or more. But how beneficial this is is another matter.

- temperature. Ideally, tiles are laid at + 18 ... 250C. If it is too hot, the moisture from the glue will evaporate quickly, and consumption will increase. At low temperatures, installation is even better not to produce - the glue may lose its properties;

- experience and skills will allow laying with less glue;

- used tool. Spatulas with V-shaped teeth are considered to be the most economical in terms of glue waste, U-shaped also show themselves well, but most often the tool has a square tooth shape. The size of the tooth depends on the size of the tile (the larger the tile, the larger the teeth), and this also affects the flow rate of the mixture. However, if the surface is uneven, then the glue consumption will be higher than indicated in the table.

To estimate how many packages of glue to take, you can use special calculators that take into account all of the above parameters. You can approximately calculate if you take the average indicator of the mixture flow rate (indicated on the package) and multiply by half the thickness of the tile. The result will be very inaccurate, so it’s better to take a couple of packages of glue in stock.

Tile Adhesive Manufacturers

When choosing the best tile adhesive, many buyers first look at the name of the manufacturer and do it right, because a large company will certainly not risk its reputation and will not release a low-grade product. There are many manufacturers on the market who can be trusted, but we will single out the largest of them:

- Knauf - One of the best tile adhesives, according to reviews. The German manufacturer offers cement glue for various purposes: reinforced, for outdoor use, quick hardening, flexible, universal. KNAUF Fliesen glue, which can be applied in a thin layer, is especially praised;

- Unis - The company has 5 factories in Russia and produces a wide range of adhesives, which are characterized by high adhesion and drying speed. The manufacturer offers quick-acting (dries in 3 hours) and highly elastic adhesive, adhesive for underfloor heating, for laying on inclined surfaces, for porcelain stoneware, for swimming pools, for outdoor use. There is also white glue and high strength compounds. Warranty on products 15-20 years;

- Ceresit - adhesives, the quality of which many domestic masters have long tested. Standard glue is produced for internal work, for outdoor work, a series of elastic compounds for porcelain stoneware and other types of heavy tiles, as well as white glue and glue for facade tiles. Ceresit SM-11 Plus glue is especially popular for internal and external works;

- Miners - domestic glue of high enough quality. Standard glue can be used in rooms with any humidity, Premium glue is suitable for fireplaces, stoves, pools, large stoves, and Lux can be used for complex substrates and porcelain stoneware. There are separate compounds for the installation of porcelain and “quick” mixtures;

- Vetonit produces standard compositions (are inexpensive) and special. Mixtures suitable for use with underfloor heating, porcelain stoneware, for exterior decoration are more expensive;

- Litoflex, Betonkol, Litoplus - adhesives from the company Litokol. The range includes not only cement, but also dispersion and epoxy compounds. There are compositions for absolutely any need. Litoflex K80 glue for porcelain tiles is especially popular;

- Bergauf - universal, reinforced cement adhesives, for porcelain stoneware, mosaics. Bergauf Mosaik glue is especially popular, which allows you to maintain maximum aesthetics even when laying transparent mosaics;

- Mapei - dry adhesive mixtures and pasty compositions, the range is so diverse that there is always a suitable option;

- Ivsil - A company that offers a huge selection of dry adhesive mixtures. There are universal adhesives for indoor and outdoor use, there are compositions for porcelain tiles, thin and thick adhesives, frost-resistant products, super-strong, frost-resistant, heat-resistant, white and quick-hardening compounds.

Also worth noting are the products of Volma, Sopro, MIRA and Kilto.

When determining which tile adhesive is better, do not be lazy to consider all possible factors and carefully study the characteristics of the adhesive indicated on the package. Only in this case can we say that the efforts to install the tiles will not be in vain, and the coating will not fall off after a few months.