Dry mix for floor screed: 7 tips for choosing and calculating

If the theater begins with a hanger, then repair in the apartment - with the alignment of all surfaces. Probably, it will be superfluous to tell what sad consequences a crooked floor can lead. In order not to have problems with laying decorative cover and installing furniture in the future, we must very responsibly approach floor leveling process. Previously, a mixture of sand and cement, prepared by hand, was used for these purposes. The process was time consuming, long and dusty. Now, everything has become a little easier, because a dry mix for floor screed, of different types, has appeared on sale. Let’s try to figure out why it is better than classic hand-made mixes, and which mix for floor screed is better to use in certain cases.

No. 1. Pros and cons of dry screed mixes

How was floor screed done before? To one piece cement brand M400 added three to four parts sand. It only remained to dilute the resulting mixture with water and fill it with the floor. A more advanced method involves the addition of plasticizers and fiber to improve the performance of the mixture. Many still use this technology, despite its many disadvantages. Not only is it heavy and dusty, you also have to knead a huge amount of mortar, so it will be difficult to do without a concrete mixer. A problem may arise with the purchase of 100-300 kg of sand, since most sellers sell it at least a ton. These are far from all the difficulties that those who wish to save on screed and do everything with their own hands encounter.

You can overpay a little and buy a dry mixture for screed. In it, all the components are already dosed in accordance with the optimal proportions, and you just need to add the specified amount of water, mix the mixture with a drill with a special nozzle and equip the screed. Saves time, nerves and strength.

The main advantages of dry mixes for screed should include:

- ease of preparation. The manufacturer has done the most difficult and crucial part of the work for you - mixed all the components in the correct proportion;

- easy kneading. After you have added the amount of water indicated by the manufacturer, it remains to mix everything with a construction mixer or drill with the appropriate nozzle. No special equipment, no concrete mixers - everything is simple and affordable;

- almost anyone will be able to complete the screed using dry mixes - special professional skills are not required for this, and all the basic actions and tips, as a rule, are set forth even in the instructions on the package;

- it is much more convenient to transport packages with dry mix (as a rule, weighing 25 kg) than large bags of cement, buckets or sand trucks;

- screed consumptionmade from dry mix smaller, which means that the load on the floors will be lower. Achieve a reduction in consumption of 1 m2 succeeds due to the accurate dosage of all components and the introduction of additional substances;

- it is difficult to arrange an ordinary screed with a thickness of less than 30 mm, since in the process of drying such a base can become cracked and collapse. In the case of dry mixes you can get a screed only 5 mm thick, and in its basic properties it will not be inferior to the classical analogue. The reason is mentioned in the previous paragraph;

- freezing time is shorterthan with classic screeds, since the composition includes special modifying substances that accelerate this process;

- huge selection of ready-made compoundsso that you can choose the most suitable solution for dry and wet rooms, as well as find a screed that will dry record fast or have self-leveling properties.

TO cons usually include the cost and inability to control the components used by the manufacturer. As for the price, it’s not so high, especially if you take into account all the many amenities. With the quality of raw materials, it’s more and more difficult, so it’s better to take products from trusted brands that have been working in this area for decades.

No. 2. Types of dry mixes for floor screed

The assortment of mixtures is really huge, but all the variety that manufacturers offer us can be divided into two large groups:

- cement mixes are made on the basis of cement of different grades. Depending on the brand, as well as on the fillers and modifiers used, formulations with different properties are obtained, which are used at different stages of surface leveling;

- gypsum mixtures made, as you might guess, on the basis of gypsum, are used less often, despite the low cost, as they are demanding on operating conditions.

No. 3. Cement mixes for floor screed

Cement mix is more expensive than gypsum and dries longer, but it almost universal and can be used in any premises: residential and bathrooms, apartments and shops.

Depending on the composition these types of cement mixtures are distinguished:

- roughing mixes produced using sand fractionsgranite crumbs or even small expanded clay. Such compositions are used when the base drop is significant and you have to make a screed of impressive thickness. Specialists use such mixtures to equip screeds from 30 to 80 mm. The surface, as a result, evens out, but does not become smooth, so one more layer of screed (finish) cannot be dispensed with, especially if the coating is laid, such as linoleum or laminate flooring. If to be used ceramic tile or porcelain tile, all irregularities will level out during application glueso that you can do without the finish layer of the screed and save. Such compounds can even be used on the street as an independent coating. They are also suitable for installation on top of a system of underfloor heating (it is undesirable only to use a mixture with expanded clay). If it is necessary to level the floor with a difference of more than 80 mm, then it is better to use concrete, since the mixture in this case will be an extremely uneconomical solution;

- mixes for finishing work contain fine sand (fraction up to 0.6 mm) and plasticizers. This composition allows you to get a perfectly even and smooth base, which is suitable for laying any type of facing material. The mixture is used when it is necessary to create a screed with a thickness of 4-5 mm to 10 mm. Often such mixtures are called bulk floors. If it is necessary to strengthen the screed, then you can additionally use a reinforcing mesh made of fiberglass or immediately take a mixture of fiber. It makes sense to use such reinforced compounds when a really increased load on the base is supposed, otherwise there is no point in overpaying;

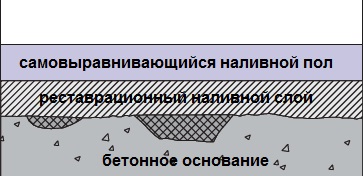

- self-leveling mixes contain a filler with particles less than 0.3 mm and special additives. Due to this, the finished composition has excellent fluidity and the ability to self-level under the influence of gravity. Such mixtures are used as a finishing base; the recommended layer thickness is up to 5 mm. This screed dries quickly, gives an excellent result with minimal effort, but costs more than other types;

- mixes for warm floors produced using plasticizers, which in the process of solidification of the screed “expel” all air bubbles.The latter are a kind of heat insulators that prevent heat from warm floor into the room. It turns out that the heat conductivity of the screed is similarly increased. In addition, these compositions can boast of high ductility and inertia, which is important with frequent changes in temperature. Of course, when arranging warm floors, other types of screeds are also used, but in order to get an effective system, it is better to use a special composition.

Number 4. Plaster mixes for floor screed

Gypsum compounds are used less often than cement ones, their non-universality is to blame. They are produced on the basis of finely ground gypsum mixed with various mineral fibers and sand. The main advantages of such compounds we attribute:

- high drying rate;

- high strength;

- low price;

- environmental friendliness, lack of dust during cooking;

- high rates of heat and noise insulation.

The main minus - gypsum mixtures are not resistant to moisture, so they can be used only in residential premises. Experts say that the gypsum composition is ideal for screed wooden floors, since such a base will be able to effectively control the level of humidity, long keeping the wood in its original state.

Gypsum screed will dry for 14-15 days, cement - 25 days. During this period, further work on the lining is impossible. If there is no way to wait, then use dry screed technology. To do this, use a filling based on expanded clay chips or polystyrene granules. The material is rammed and leveled, the sheet material is laid on top (drywall or OSB-plate). Water is not used, so waiting for it to freeze is unnecessary. You can start the next step instantly.

No. 5. Calculation of dry mix for screed

Perhaps the issue of cost sometimes worries us even more than the quality of the screed obtained. The price depends on how many bags of mix do you need. It is not difficult to calculate this amount. The procedure is as follows:

- determine the floor area and the thickness of the layer of the future screed. The last parameter depends on the degree of roughness of the main surface. Let's say we will perform a screed in a room 3 * 4 m (area 12 m2), and we need a layer 13 mm thick;

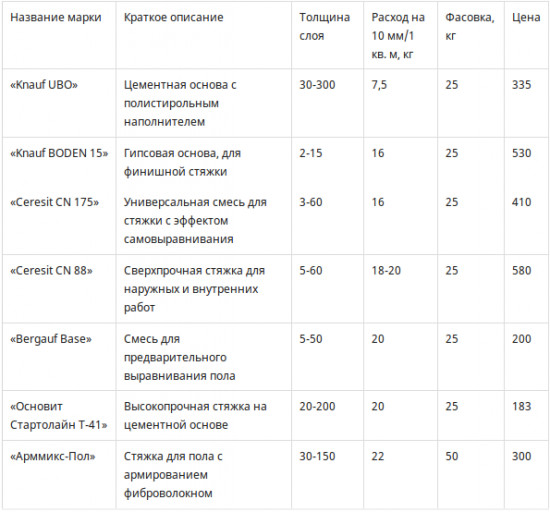

- carefully study the packaging of the selected mixture and look for the flow rate of the mixture. The manufacturer usually indicates consumption in kg per 1 m2 with a layer of 10 mm. At this stage, you can study the declared characteristics of several mixtures and compare the results. Some nameless companies (read unscrupulous one-day manufacturers) may specifically underestimate costs. For example, take a mixture of Bergauf Base with a consumption of 22 kg;

- if 10 mm screed mixture consumption 22 kg / m2, then with a layer of 13 mm, 1.3 times more mixture is needed (13/10 = 1.3). On 1 m2 screeds will leave us 22 * 1.3 = 28.6 kg, and the whole room will take 28.6 * 12 = 343.2 kg of the mixture. Just in case, it is better to add a margin of 5%. It will turn out 360.36 kg of the mixture;

- dry mixes are sold in bags of 25 and 50 kg. Taken as an example, Bergauf Base is delivered in 25 kg bags. It will take 360.36 / 25 = 14.4 bags, round off and buy 15 bags of 25 kg each. It should be enough. The average cost of one bag of such a mixture is 230 rubles, i.e. 3450 rubles will be needed, and for example, we took far from the cheapest composition.

No. 6. Large manufacturers

The manufacturer is responsible for the quality of the products with his reputation. If you want to be sure of the correct proportions and the adequacy of the indicated flow rate, then it is better to buy mixtures from trusted manufacturers. Among the largest, we note the following:

- Knauf - A German company, which, among other things, produces dry building mixes. For floor screed there is a cement and universal gypsum-cement self-leveling screed. The cement composition costs about 500 rubles. over 25 kg;

- Ceresit produces a wide range of cement and gypsum compositions. The universal composition of the CN 175 will cost about 400 rubles.for 25 kg, and DD self-leveling mixture to create a screed with a layer of up to 5 mm - 850 rubles;

- Bergauf produces a lot of solutions for roughing and finishing flooring. Mixtures of Base (about 230 rubles per 25 kg) and Erste Grund are suitable for basic leveling, Easy Final (300 rubles) and Boden Nivelir can be used for finishing, there are self-leveling mixtures;

- "Found" - one of the most famous domestic manufacturers, produces draft, finishing and high-strength compounds, as well as mixtures for use with underfloor heating. The prices are moderate. A bag of 25 kg of FC44 M mix costs about 175-220 rubles .;

- Unis offers the widest range of floor screed mixes. There are roughing and finishing compounds, reinforcing and rapidly hardening mixtures, as well as self-leveling and high-strength compounds. A bag of 25 kg of the mixture for roughing will cost 205 rubles.

Brand products are also worth noting. Ilmax, Ivsil, Polygran and Sarmat". It does not interfere before buying a look at the Internet and read reviews on the specific composition of a particular manufacturer.

Number 7. Screed pouring procedure

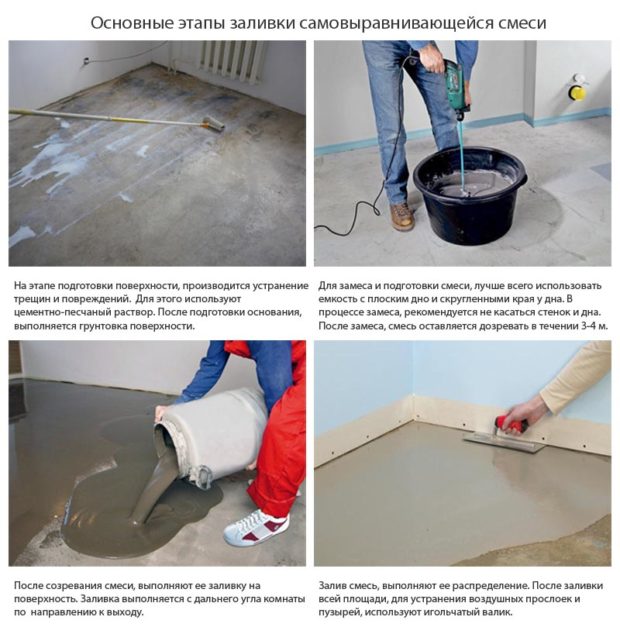

It is very simple to work with dry mixes, the procedure is as follows (you can read more about determining the zero level and the specifics of the work in this article):

- clean the floor surface from dust and dirt, cover it with a primer layer. Many experts recommend the use of coating waterproofing;

- place a damper tape around the room’s perimeter, set guiding beacons at the level;

- dilute the dry mixture in water in the proportion indicated on the package, mix thoroughly;

- the finished solution is applied in strips, evened out with a rule or a doctor blade. The packaging will say how much time you have to wait until you can walk on the screed and equip the coating. Details are described in the video.

As you can see, everything is simple - even a layman can handle it.