8 tips for choosing welded gratings

An enforced security measure for all residents of the first floors becomes grill installation. If tall trees grow under the windows, then those who live on the second and third floors have to think about installing such a protective structure. Lattices are also recommended for residents of the upper floor and attic. In many stores and offices, even if available alarm Do not neglect these designs, because while the attacker spends time hacking it, protection will arrive. The main thing is that the lattice could resist hacking for some time and not irritate the peaceful inhabitants of offices and apartments, who will see it every day. If at the same time there is also a question of price, then it is better to choose a welded grate. These are inexpensive designs that many mistakenly consider primitive in terms of design.

No. 1. Welded Grid Production Technology

Welded gratings production process is easier and faster than forged. The main material used is a steel bar, fittings or corner. The technology consists of the following steps:

- sketching of the future lattice;

- cutting of blanks according to the sketch. In the presence of complex elements, the workpieces are bent accordingly;

- all elements are laid out on a flat, non-combustible surface; welding, at the same time the equality of diagonals between themselves is strictly controlled;

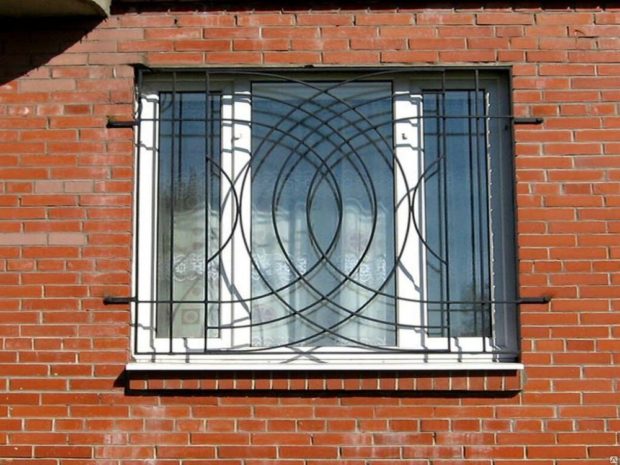

- usually a welded lattice consists of simple geometric shapes, but you can use numerous curls, so that the aesthetics of the structure are increased;

- some welded lattices are decorated with forging elements to get an inexpensive and most aesthetic design. As a rule, forged elements are produced by cold forging, and then they are welded to the rod by welding;

- after the work is completed, the welds are smoothed out and the scale is removed grinder with a treatment circle. After this follows the final stage - painting the structure.

To make the welded grate more attractive in appearance, welds can be seized with a metal clamp. It is called "banding", And, ultimately, she looks quite aesthetically pleasing." There is another trick - torsionwhen the square rod is twisted several times along the axis. Thanks to such solutions, the welded structure will not look too strict, boring and gloomy.

No. 2. Pros and Cons of Welded Gratings

From a brief description of the technology, we can draw conclusions about the main advantages of welded structures:

- reliability and durability;

- low labor costs in manufacturing;

- affordable price.

More than half of the installed grilles are precisely welded structures. As a rule, they are manufactured according to standard designs, in which the strength of all elements and the resistance of the structure to cracking are calculated in advance. IN minuses often include insufficient aesthetics. Perhaps earlier, when the “sun” welded gratings dominated, indeed, one could speak of a certain primitiveness, but today even standard solutions will not spoil the facade of the house. The Metalist company, for example, produces welded gratings for windows in dozens of different designs, and only a small part of them are presented on the site.Customers from Moscow and the region can choose any solution or order the manufacture of a lattice according to an individual sketch. Measurement and coloring of the grating with nitro paint is free of charge, often there are discounts.

Due to the presence of various rounded and forged elements, bulges, the welded grate can be not only protection, but also decoration. Such designs will cost more than the most ordinary gratings with a simple geometric pattern, but will still be cheaper than forged products. The most budgetary welded grilles are often placed on the windows of basements and summer cottages - where aesthetics are not so important.

No. 3. Welded grate materials

Welded gratings can be made of the following materials:

- structural steel - an inexpensive option, which is not the highest strength;

- reinforcing steel - the most balanced option in terms of the ratio of reliability and price. A 14 mm reinforced steel bar is equivalent in strength to a 20 mm structural steel bar. It will not be easy for an attacker to break such a grill - special hydraulic scissors will be needed. The reverse side of the coin is less plasticity of the material, so it will be almost impossible to perform some decorative elements from it;

- steel grilles - the standard in terms of strength, while the rods can be quite thin, so that the view from the window will be spoiled minimally. Thieves are unlikely to be able to damage the rods of this design, even with relatively long attempts. To cut special steel, use a plasma cutter. It is precisely the employees of the Ministry of Emergency Situations who use it when it is necessary to free people from a burning apartment. But not all Emergencies Ministry teams have a plasma cutter, so a special steel grill may not be as safe as it seems: it will protect it from thieves, but in case of a fire the apartment will turn into a cage. The disadvantages of such structures include the high price and complexity during the manufacture of the lattice.

There are also grilles where all these materials are combined.

An important role is played by type of workpiece. By production of welded lattices use bars, strips, square and combined profile. The most aesthetic products can be made from a profile with a round and square section. Lattices made of metal strips do not look particularly presentable, but they will do for cottages and basements.

Number 4. Type of coating

You will see the grill many times every day, so that it should be not only impregnable for thieves, but also quite aesthetic. To cover the structure using:

- nitro enamel It is inexpensive, dries quickly, has a wide selection of shades, however, it is necessary to apply the coating in several layers to get a dense structure and the desired color. The main disadvantage is the low resistance to weathering. Nitro-paints should not cover surfaces previously painted with oil or alkyd paints;

- Oil paint it is rarely used in the production of finishing gratings - it is used when the grating needs to be repainted. The composition has a sharp unpleasant odor and dries for a long time, over time, the coating loses its luster and fades. With metal, oil paints have low adhesion;

- polymer powder paints basis - the best option for gratings. They tolerate moisture, precipitation, temperature changes, exposure to aggressive substances. Processing with such compounds is possible only under production conditions. A polymer powder is applied to the surface of the grate, which melts under the influence of high temperatures in special furnaces. As a result, polymer particles sinter between themselves and with the metal, forming a durable coating. Shades of mass, including imitation of bronze, silver and gold.

When choosing the color of the lattice, focus on building's facade and house style. White and black gratings are considered to be classics, and the designs of light shades absorb less light, seem less bulky, harmonize well with white plastic windows. The grilles of red and brown shades are in good harmony with the brick facades; they will also look black and made in bronze.

No. 5. Types of Welded Gratings by Purpose

Welded gratings, depending on the purpose of the installation, are divided into the following types:

- decorative, are made of a strip 1-4 mm thick, with significant distances between the rods, additional protective elements are excluded. Such gratings create the appearance of a barrier rather than a real barrier. Burglar resistance is low, so this is a good option for use in conjunction with a burglar alarm;

- security and decorative grilles - This is the most popular type of design. They simultaneously protect the home, and do not spoil the window openings. They are made from a square profile of 8 * 8 mm, strips 16 * 4 mm, a rod with a diameter of 10 and 12 mm. Such elements can be bent and twisted, getting an interesting pattern. During installation use reinforcement with a diameter of at least 12 mm, outer platbands are also installed;

- security grilles perform from a profile of a circular or square section of at least 16 mm. The burglar resistance of the structure is high, but the visibility of such thick rods greatly limits. It makes sense to put such products in warehouses, in banks and other similar institutions. Fasteners are made using 16 mm fittings.

When choosing a welded grid, pay attention to the distance between adjacent rods. It is not recommended to order options with mesh size over 15 * 15 cm, as thin-skinned teens can squeeze through such a gap.

No. 6. Welded grid design

The easiest option is a lattice tightly mounted in the window opening. Until recently, this design remained almost the only possible one. Alas, this option does not meet the fire safety rules, so other types of gratings have also appeared. Firefighters recommend that at least one grille in an apartment can be quickly removed or opened. Fortunately, today there is plenty to choose from.

By design, welded gratings are:

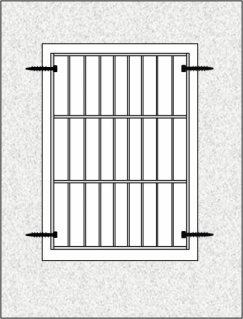

- fixed or stationaryfasten to the wall with anchors. In 99% of cases, the grille is installed on the outside. The stationary grid resists breaking for the longest, but in case of emergency, rescuers can take about 3 minutes to cut or break such a structure, and often these minutes are decisive;

- removable grilles mounted with special bolts, which can be unscrewed if necessary. Sufficient burglar resistance can be achieved with at least 8, and preferably 10, attachment points. It will take a lot of time to unscrew each bolt, so that rescuers will open such a grill as a regular stationary one. The plus is that if necessary, replace the windows, the grille can be removed. These designs are mainly used in wooden houseswhere it is impossible to make reliable fasteners using anchors;

- swing gratings equipped with one or two wings, which in case of emergency can be opened to leave the room. Such structures are hung on hinges, closed and opened by means of locking-swinging devices, which the landlord can quickly open. Swing gratings are slightly inferior in terms of reliability to stationary ones, they are more expensive;

- sliding gratings made of strip, corner or U-shaped profile. The selection of drawings is limited by design features. In order for the lattice to move, it must consist of numerous rhombuses. There are constructions where only the lower and upper parts of the lattice are made with diamonds, and vertical rods are located between them. Since there are a lot of moving elements in the lattice, it is difficult to call it reliable. This is a good option for a summer residence.An apartment where there are valuables, such a grid will not protect - even roller shutters will resist hacking longer and better.

Number 7. Type of weld grate installation

A welded grate, however, like a forged one, can be installed in one of the following images:

- in a window opening (outside or inside);

- overlay on the window opening;

- sometimes strongly protruding inflated structures are separately isolated.

The most popular solution is to install a window opening at the ends, and outside the apartment. It is convenient, aesthetically pleasing and practical. If, on the outside, the window is installed at the same level as the wall, then you can put the grille inside, or in an overlay way. Indoor installation unpopular, since few people want to watch metal bars in front of them - associations are not pleasant. Security experts say the internal mounting option is even better. The thief, trying to get into the apartment, first opens the window, and then begins to try to cope with the bars. If there is an alarm, the signal to the security post will arrive already when the window is damaged, and while the attacker is busy with the bars, they will take him red-handed.

Way way Mount the grilles when it is not possible to install it on the end. In addition, some prefer that the rods be a little further away from the window itself. Even install convex gratingswhich allow you to increase visibility and make the protective structure more airy. However, it is important not to overdo it. If the bulge is too large, then the attacker will be able to get close to the side.

Previously, the option of installing a grille between window frames, but with the advent of double-glazed windows this method is no longer used.

Number 8. Installation Features

It is better to entrust the installation of the grill to specialists who will surely do everything so that the structure protects the home as reliably as possible. Most companies that manufacture lattices are ready to provide installation services. There are times when you can do it yourself. Suppose there is a ready-made grill that was already in operation, and it must be installed on a country window. In this case, adhere to the following rules:

- if the lattice is unpainted for you (some companies also sell such lattices in order to reduce the cost of construction), first the surface must be primed and coated with alkyd enamel, which will make the product more aesthetic and durable. The old grill will also need to be coated with a primer and paint. If the old paint layer is badly damaged, it is better to remove it;

- the installation method depends on the material of the walls, the features of the window opening. The most popular and reliable is welding fasteners. First you need to attach the grill to the window opening, outline the places for future fastenings, and with the help of a punch, prepare horizontal holes with a diameter, like reinforcement, i.e. not less than 12 mm. The pin should go into the wall for 15-25 cm, if less, then the lattice can be easily broken out, and if more, then the strength of the house can be broken. An anchor with a length of more than 25 cm can be used when installing mortgages for the grate at the stage of building a house, then the most durable structure is obtained. Prepare 2-3 holes on the sides and 1-2 on the top and bottom. The pins should protrude outward so that the grill can be welded to them. Mounting method suitable for brick and concrete walls;

- if the house is wooden, the grill is mounted in a patch way using bolts that pass through the wall. Bolts are tightened with nuts on the inside;

- when installing the lattice in the end (walls can be both wooden and brick), you can use special eyes that are welded to the lattice. Anchor bolts are inserted into them, which are 10 cm into the wall. Pre-make holes with a diameter equal to the diameter of the bolt. It is important to bore the slot on the bolt so that the attackers could not remove the structure.

Remember that the grill becomes not only a protection, but also a window decoration, which means that it must not be allowed to rust. Expensive products are coated with special substances that adhere well to metal and prevent corrosion. Cheaper coatings can begin to fall off in a year or two. In this case, it will be necessary to degrease the surface and re-paint.