Parquet Oil: 11 Tips for Choosing

Everyone knows that parquet is expensive. If you really spend money on such a finish, you need to be sure that it will delight you for a very long time. Wood - the material is not the most durable and resistant, it is afraid of moisture, pests and temperature extremes. If you leave it without protective coating, then the floor will serve extremely little. Most often, special varnishes are used for protection. Oil is a less popular, but much more environmentally friendly choice. By the way, this is how floors in ancient buildings were treated, and that is why they have survived to this day. How to choose the right oil for parquet? How is it better than traditional? What types of parquet oil are there? We will try to answer all these questions as fully as possible.

No. 1. What is customary to cover the parquet floor?

Surely you know differences between parquet board, piece parquet and solid boardbut just in case, we’ll repeat it. Parquet - This is solid wood, cut into planks with grooves and spikes, it can be looped many times. Piece parquet can be laid according to a complex scheme with the formation of interesting patterns or drawings. Solid board - almost the same as piece parquet. Sometimes called her solid flooring. The difference lies only in size - the massive board is larger, and therefore it is impossible to lay it in an artistic way. Parquet board - This is a three-layer material, where only the upper layer is made of valuable wood, the middle and lower - from cheaper conifers. Such material is cheaper, but less durable.

Usually piece and massive parquet are sold without processing - you can choose for yourself, varnish or oil. However, there is already already varnished parquet. Parquet board, on the contrary, is more often sold already processed. It remains only to lay it down, and the floor finish is ready - conveniently and quickly. The manufacturers' collections are, of course, extensive, but it is not always possible to find the right shade, so today there is a tendency to sell uncoated parquet boards, so that everyone decides what it is better to cover.

Typically, the following materials are used to protect wood:

- varnish - The most durable and popular coating. Lacquer forms a film on the surface of the wood, protecting it from moisture. If repairs are needed, the varnish layer can be cleaned and then treated with either a new varnish layer or oil. True, local repairs will be difficult to accomplish - will have cycle coating throughout the room and reapply protection. In addition, coating parquet with varnish is a long and difficult task. The varnish coating can be damaged by metal heels, furniture legs and liquids containing alcohol, so you need to take precautions in time;

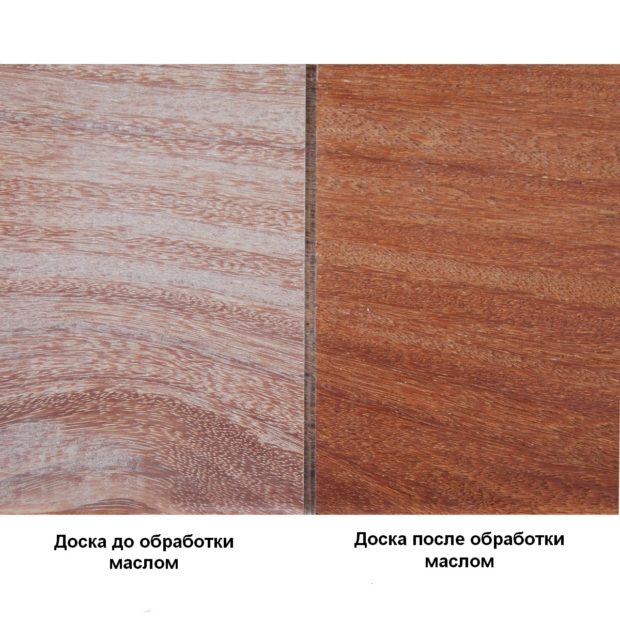

- oil does not create a film on the surface, it penetrates the structure of the tree, allowing it to breathe. The floor treated with oil looks more natural, the application process is much simpler than in the case of varnish, and repairs are easier.We will talk about other nuances of use below;

- wax usually applied in combination with oil, on top of it. Less commonly used as an independent coating. Wax gives wood a pleasant shine and additionally protects its surface.

Wax and oil are more natural and environmentally friendly materials; they allow to preserve the unique natural properties of wood to the maximum, giving it additional protective characteristics.

No. 2. How does parquet oil “work”?

If the varnish creates a protective film on the surface of the wood, then oil penetrates the tree, in its pores and remains there, only a small amount remains on the surface. Oil and varnish approximately equally protect the tree from the harmful effects of moisture: neither the one nor the other material is able to give 100% protection. The difference is that the varnish complicates the natural processes of moisture exchange between the parquet and air. The tree absorbs and gives away moisture - this is a normal process. Oil does not interfere with this, but varnish complicates the removal of excess moisture. The result is the appearance of peeling and cracks in the tree, damage to the varnish layer.

It turns out that the oil protects the wood no worse than varnish, but at the same time provides the wood with greater durability. Before choosing parquet oil as a protective coating, you must clearly understand the fact that oiled wood will be almost impossible to varnish. Sometimes a multi-layer primer helps, which prevents the release of oil, but in most cases, even such a treatment will not save from quick peeling and cracking of varnish.

No. 3. Advantages and disadvantages

The principle of action of parquet oil determines the main coating benefits:

- oil floor treatment takes place much faster and easier than varnish. You can do all the work yourself, without having a tremendous experience in the field of repair work;

- if damage appears on the floor, repeat processing can be done locally - you do not have to remove the coating from the entire floor and cover its entire surface again;

- oil retains the ability of the tree to breathethat positively affects its durability;

- oil is good protects wood from moisture, before, similar decks processed ship decks, and this says a lot;

- oil more abrasion resistantthan varnish, and the reason should be sought in the fact that oil fills the pores of a tree, and does not lie with a continuous film;

- oil-treated parquet tolerates temperature changes betterthan the same parquet, but varnished. That is why this treatment is preferred in the open air and in unheated rooms;

- oiled parquet retains its unique relief, he looks more natural, and it’s more pleasant to walk on it;

- no harmful fumes, as is the case with some types of parquet varnish;

- with varnish you can give wood deeper shade. The presence of oils with different shades allows you to realize any interior idea;

- oil is cheaper than varnish.

Even oil cannot be called an ideal protective material. Choosing such a coating, it is worth considering Some of its disadvantages:

- protection will have to be updated every 3 yearsif the permeability in the room is not very high, and every 2 years with increased loads;

- for regular cleaning of oiled parquet it is necessary to use special substances. Otherwise, the oil will be quickly washed out of the tree, and the parquet will lose attractiveness;

- parquet, varnished, more easily soiledthan varnished coating;

- contact with metal surfaces is undesirable. If the legs of some furniture are made of metal, then they will have to purchase protective pads;

- will need more thorough surface preparationthan before applying varnish;

- to obtain a glossy surface, additional waxing is required;

- then it will be difficult to varnish, more precisely, almost impossible.

Number 4. When is it better to use parquet oil rather than varnish?

Which is better, varnish or oil for parquet, it is definitely impossible to say. The choice, as always, is yours, and it should be built on your own requirements for the appearance of the flooring, budget and the desire to regularly look after oiled parquet. There are also situations where it is not that there is no choice, but it is advisable to make it specifically in the direction of oil.

Oil will be the best choice for parquet protection in the following cases:

- if the coating is located in the open, for example, on terrace or at unglazed balcony;

- if the parquet is laid in a room with high humidity, for example, in the bathroom or at the kitchen;

- if the system is laid under the floorboard "warm floor". With temperature fluctuations, wood can expand, and varnish forms an inelastic film on its surface, on which cracks can occur. Please note that underfloor heating and piece parquet are not compatible. With a massive board, a warm floor can be used, but the installation process will be difficult. Such a heating system combines well with a parquet board, but to warm the surface to a temperature of more than +260C not recommended;

- if wood already contains a sufficient amount of natural oils;

- if wood is highly susceptible to temperature fluctuations. A striking example is beech.

Oiled parquet fits well for the hallway. This is a high traffic area, and if natural wood finishes are chosen for it, then it is better to use oil that protects the wood well and needs to be repaired locally.

Parquet is not the best option for a terrace and veranda, but if for some reason the choice fell on it, then it is better to choose oil for protection, and update the coating more often than indoors, 2-3 times a year.

No. 5. Types of oil for parquet composition

Depending on the origin of the main components, parquet oil can be:

- natural;

- artificial.

Basis natural oil constitute plant and mineral substances of natural origin. Such compositions are as environmentally friendly and harmless as possible, but inferior in performance to artificial analogues. Often, wax is introduced into the composition of natural oils, which gives the finished surface a beautiful shine and additionally protects it.

Depending on the presence of wax emit:

- hard wax oil allows you to get a coating that looks not much different from varnished. The composition preserves the natural relief of the tree, but, alas, as in the case of varnish, local repair will be difficult, but this oil is well suited for use in rooms with high humidity, and the care of the coating is not very difficult. Wax does not penetrate the pores of wood very well, so manufacturers use an increased amount of artificial solvents, which means that it is better not to stay in the room for a long time until the composition is completely dry;

- soft wax oil better fills the entire structure of the tree, so it is used with expensive varieties of wood. Such a coating quickly attracts dirt, requires care using special means, but for a long time it will be possible to do without scrapping the floor, which will extend the life of the coating. Wood with this treatment acquires a beautiful matte sheen, while maintaining the structure of the tree. Such compositions provide a sufficiently high level of wear resistance, can be updated locally. Environmental friendliness is at its best, but the need for careful regular care makes many refuse this option of protection;

- wax free oil in greatest demand, penetrates well into wood, has maximum environmental friendliness. For processing parquet, you can use linseed oil. Such protection will dry out in about 3 days.If the house has allergies, it is better to use natural compounds, because it is not known how the body will react to a particular synthetic supplement. Some time after applying natural oil, you will notice faded areas - they must be re-coated with oil. Natural wax-free oil is the most difficult to clean, it is better not to cover the floors in rooms with high humidity.

Artificial base oils lose in terms of environmental friendliness. The composition may contain polyurethane, which replaces natural wax. Such compositions provide a more wear-resistant coating. Pay attention to the “blue angel” icon on the packaging - it means that the product can handle floors that will be in prolonged contact with children. White spirit or dearomatized gasoline is used as a solvent in almost all oils.

No. 6. Parquet Oil Color

The oil may be colorless or colored. FROM colorless everything is clear - it only protects the wood and gives it a pleasant matte sheen. There are options that can give a glossy gloss, but such a surface will be more difficult to care for, because even the slightest defects on it will be visible immediately. The degree of gloss can be judged by the percentage indicator: the higher it is, the more glossy the floor will result.

Colored oil obtained by adding color in the composition, and this can occur both during production and at home using a separately purchased color. The proportion of pigment is 7-10%, on which its saturation depends. Kohler allows you to give the wood an interesting shade, for example, amber or honey. Colored oils are used both to cover the old parquet, to renew its surface and restore its original appearance, and to process the newly laid board. Thanks to the color scheme, the most inexpensive wood can be given an exclusive look. Already painted formulations and separately tinted colors are offered in a wide variety of colors, so choosing the right shade is easy. Masters with experience sometimes mix different pigments to get the desired color.

Separately, it is worth highlighting white oil. No, it does not repaint any parquet in white, because it is not paint. The task of white oil is to give a silvery shade that looks especially noble on ash and maple wood. The natural pattern is preserved and remains clearly visible.

Number 7. Parquet oil concentration

The concentration of the finished product largely depends on how many natural substances are in the composition:

- if the proportion of natural components reaches 80-90%, then the consistency will be dense. Such impregnations are worse absorbed;

- in the presence of natural components in an amount of about 50%, the composition will be of medium viscosity;

- a low amount of natural substances and a high content of synthetic additives (up to 60-75%) allows to obtain liquid compositions that are perfectly absorbed into the structure of wood.

If the treatment of parquet occurs for the first time, then the first layer is best done from a more liquid oil, which will play the role of a primer. Due to the large amount of solvent, it penetrates perfectly into all pores.

Number 8. Wear and moisture resistance of parquet oil

Artificial and hard wax oils are leaders in terms of wear resistance. You don’t have to look at the label for a long time and study the composition - manufacturers indicate for which type of room this or that oil is suitable. If it can be used in the hallway or kitchen, you will definitely see either in the name or in the description of the composition that it is intended for places with heavy workload. True, such oils are more expensive than usual.

The manufacturer also usually indicates the degree of resistance to moisture on the packaging. As a rule, they also report on the preferred temperature in the room.For example, for saunas, baths and other rooms with a high temperature, only natural oil is suitable.

On the packaging of the composition it will be possible to find information about the conditions for which the oil is intended: for indoor or outdoor use. Naturally, it is impossible to use the internal composition for covering the terrace.

No. 9. How to cover the flooring with oil yourself?

One of the key benefits of parquet flooring with oil is its easier application when compared to varnish. You can cope with your own hands if you devote sufficient time to preparing the surface.

Preparation of parquet for applying oil is as follows:

- it is best to use a looper or grinder. You can hire a specialist with your equipment, and he will do everything for you. To save money, you can rent a car and polish yourself;

- if you need to process a small area, you can do without using sand paper. They start polishing with an emery cloth with a grain size of 20, gradually reach a skin with a grain size of 230. Smaller sandpaper is not needed, otherwise you can close all the pores of the wood and the oil will not be able to absorb into them;

- the final appearance of the parquet floor greatly depends on the quality of the grinding;

- in the presence of defects on the wood, puttying is carried out, and the color of the composition should match the color of the wood. One layer of putty is enough. When it dries, carry out another grinding;

- The final chord is polishing with felt or microfiber cloth. With a large processing area, you can use a grinder;

- after completion of preparation, the floor surface is thoroughly cleaned of dust and dirt;

- birch and pine wood can be additionally treated with alkali - this is the prevention of dark spots.

The oil itself does not need special preparation:

- mix the color composition well before application;

- if necessary, color is added separately.

Suitable for application wide brush with a long pile. Use of the roller is allowed.

The process of applying the oil itself can be cold or hot.

Cold application

Procedure:

- the prepared oil is applied in a thick layer on the floor, left for 15-20 minutes, during which time the tree absorbs exactly as much substance as it can;

- after 20 minutes, wipe off the oil residues with a cotton cloth, otherwise a hard crust will form on the surface;

- polishing parquet with a grinder, while a small amount of oil may be released, it must be wiped with a rag;

- the second layer is applied 5-12 hours after the first, the specific time will be indicated on the package. It is advisable to first process the surface of the parquet with sandpaper to make it matte;

- the second layer is applied according to the principle of the first, only the layer of the substance will be much smaller - the tree is already saturated with oil, and does not absorb a lot of substance;

- final crystallization occurs after 3-14 days. It is advisable that at this time the room temperature was about +200C. To carry out processing at a temperature below +50C is undesirable.

Correctly applied coating has a light satin sheen, which emphasizes the beauty of the tree.

Hot way

Procedure:

- oil is preheated in a steam bath to +800C - in this state, it is much better absorbed into the wood;

- the surface of the floor is heated by a thermal drop;

- heated oil is applied to the floor with a brush, rubbed with a thermal drop in order to prevent surface cooling;

- after 2-3 hours, a second coat can be applied.

Waxing

To give the parquet a shine, it is possible to further process it with wax, due to which the wear-resistant qualities of the surface are increased, and the rate of contamination is reduced. Wax is applied with microfiber or a roller, which is made of a material that does not leave its particles in the wax. Try to apply the wax evenly, removing excesses in time.Full hardening occurs after about 12-36 hours, after which the surface can be additionally polished if desired.

If local repair of parquet, previously treated with oil with wax, is performed, then the composition recommended by the manufacturer is chosen so that the treated area does not stand out from the rest.

No. 10. Care and Repair

Oiled parquet should be regularly cleaned of dust, and when carrying out wet cleaning, use special products that indicate that they are suitable for parquet treated with oil. In order for the coating to last as long as possible, and the tree itself to remain safe and sound, it is better not to walk on the floor in shoes with sharp stilettos. Stick felt pads on furniture legs, lay a mat near the threshold, and squeeze a cloth well during wet cleaning. Abrasive materials for cleaning parquet are not suitable - they can leave a scratch.

If you suddenly did not keep track, and small defects appeared on the floor, they can be quickly and simply removed:

- scratches can be wiped with sandpaper and then coated with oil. When it is absorbed, the tree will swell a little and the scratches will heal;

- spots they are easily removed from the surface, since the pores of the wood are filled with oil - the pollutant has nowhere to go, so you can handle ordinary water, in reasonable amounts, of course. If the stain is difficult, use a special tool for oiled parquet. If even after that it did not appear, then applying another layer of oil will help;

- if relatively major damage First, grinding is carried out, and then rubbed oil with a piece of rags.

Remember to regularly re-treat with oil and wax.

No. 11. Parquet Oil Manufacturers

It is foolish to hope for a good result if you use the cheapest oil from a little-known manufacturer. Laying an expensive parquet and ditching it with bad oil is almost a sin, so use it when processing oils of verified manufacturers:

- OSMO - famous German oils that are of the highest quality. The assortment is extensive and includes, oils with hard and soft wax, without wax, oils for exterior and interior use, special quick-drying compounds, color and colorless impregnations, anti-slip oils, silver effect oil, waxes;

- Glimtrex - German-made products. In the manufacture of linseed, sunflower oil and jojoba oil, natural waxes are used. The assortment has colored compounds, as well as white oil;

- Lobasol - German manufacturer of oils under the brand name Loba. The trick of the company is their maximum environmental friendliness. The manufacturer refused solvents and synthetic additives, which allows you to create the most natural compounds;

- Bona - oils of the Swedish manufacturer, which pays great attention to their safety. The range is not very wide, but you can find a suitable solution for processing parquet inside or outside the room in any case;

- Saicos - German oils, which have gained wide popularity due to their low price, high environmental friendliness and resistance to damage. In the assortment there are compositions for indoor and outdoor use, colorless and colored, with varying degrees of gloss;

- Pallmann - German high quality oils, in the assortment there are compounds that are suitable for any purpose, up to processing wood in the area of the berths.

- Products of the following brands are a little less common in our market, but no less high-quality: Neopur (Germany, trademark - Neooil), Arboritec (Sweden), Berger (Germany), Sika (Germany).

If there is any doubt that all work on applying oil on the parquet will be performed efficiently, it is better to seek help from professionals.