7 Tips for Choosing Road Slabs: Size and Types

Road slabs are a great alternative to the usual asphalt surface. They are used for the construction of temporary and permanent roads, airfields, storage and production sites, as well as where as soon as possible it is necessary to obtain a durable coating that can withstand the weight of tracked and heavy wheeled vehicles. Road slabs are also used in private construction, for example, to equip a house territory. A wide range of plates allows you to find the product with the most suitable performance characteristics. To choose the right slab, you need to know what types and sizes of these products are, as well as to understand the nuances of marking. We will shed light on all these questions.

No. 1. Road Plate Production Process

Today, road slabs are understood to mean flat reinforced concrete products with a thickness of 120-240 mm, which can take on and evenly distribute large loads, therefore even airfield platforms are performed with their help. The first road slabs were used at the beginning of the twentieth century. It was an experiment in which they wanted to compare the strength of ordinary asphalt and concrete slabs. The experiment lasted several decades, since it was necessary to compare the durability of the coatings. It turned out that asphalt needed to be replaced after 10 years, and every 3-4 years it had to be repaired. Concrete slabs lasted about 40 years without serious deformations and won in this competition.

What is the secret of such record-breaking durability of concrete slabs and their high strength? It is necessary to look for the answer to this question by studying Features of the production of road plates:

- the base of any slab is heavy brand concrete M350 and higher. The parameters of frost resistance and water tightness of concrete may vary, the choice of these characteristics depends on the climate in the region where the slabs will be used. Anyway, concrete with frost resistance less than 100 cycles is not used in production;

- to make the slab stronger, add to concrete granite filler or crushed stone, air-entraining additives may be used. Granite-filled slabs are characterized by maximum durability;

- the heart of the plate, or rather its frame, stands fittings. It can be unstressed and prestressed. The second option allows you to produce more durable products that can withstand solid loads. To create an unstressed frame, use fittings grades A-1, A-3, A-3s, as well as a wire of type VR-1 (diameter 6-8 mm). For a stressed frame, A-5, AT-4, and AT-5 fittings are used;

- plates are made using special forms, they install two reinforcing mesh, which are fixed at a certain distance from each other. The walls of the mold are lubricated to facilitate formwork. When the form is ready and the frame is installed, concrete is poured. In order for it to be evenly distributed and fill all the voids, a compaction is performed on the vibration units. After this, the form is sent to the heat chamber for 8-12 hours, where the product is exposed to hot steam. When the mixture has frozen, stripping and marking is performed;

- finished plates are stored on a flat base, between the rows of wood gaskets are used;

- metal plates are provided to facilitate installation mounting loops. After installation, the hinges will not protrude above the surface of the road surface. Less often, instead of loops, grooves or holes for collet gripping are made.

All concrete slabs have a sufficiently high frost resistance, strength, resistance to precipitation and mechanical damage, high durability. The maximum load depends on the concrete used in the production.

No. 2. Pros and Cons of Road Plates

Road plates are quite popular due to many advantages:

- simplicity of laying and high speed of installation. Ready-made pavement from slabs can be obtained much faster than with classical asphalt technology;

- relatively low cost of road plates. Works on the arrangement of pavement of this type are also cheaper due to the lack of the need to carry out excavation and other related work;

- concrete road slabs withstand significant loads;

- durability of concrete products;

- resistance of plates to temperature fluctuations, frosts, moisture, vibrations, ultraviolet and other negative factors;

- the ability to reuse slabs, which is especially convenient when arranging access to a construction site. After the construction at one facility is completed, it is possible to dismantle the slabs and lay them at the new facility. Outwardly, they are unlikely to look like new, but their technical characteristics will remain at the same level. Such a trick allows you to save a lot of money when organizing the roadbed at the construction site.

Of cons it is possible to note only the presence of seams, but for temporary roads this is not such a significant drawback, and permanent roads can be covered with asphalt. An alternative is to grout joints with mortars.

The main thing in the construction of the pavement from the finished plates is the quality of the material. His guarantee may be the name of the manufacturer. In Moscow and the Moscow region, reinforced concrete products for road works are offered by the Stroynerud factory of concrete products, which manufactures products according to GOSTs and conducts constant quality control. High production capacity allows us to fulfill the largest orders in the shortest possible time, and our own fleet of vehicles allows us to quickly deliver products. Cooperation directly with the plant is a guarantee not only of quality, but also of a favorable price, since it is possible to do without intermediaries.

No. 3. Where are road plates used?

Reinforced concrete products slabs are available in different sizes and shapes, different thicknesses, with different types of reinforcement and using concrete of different grades. It is easy to guess that the scope will be quite wide. Here main industries where concrete road slabs are used:

- to build permanent roads for intercity and intercity destination. Plates can be used even in the northern regions, as they tolerate temperatures up to -400C, and some types - below;

- for the construction of temporary roads leading, for example, to a construction site, a career being developed, etc .;

- for the arrangement of taxiways and runways of aerodromes;

- airfield plates are also used as the basis for heavy structures made of reinforced concrete and metal;

- for repairing worn asphalt;

- for the construction of tram tracks;

- for reuse in the construction of temporary roads, since the slabs are not only quickly laid, but also quickly dismantled;

- in private construction of concrete goods, slabs can be used to organize the territory near the house, when creating the entrance to the building, pedestrian walkways, etc .;

- There are non-standard options for using road plates. Sometimes they are used for fencing industrial enterprises.

Moreover, for private construction, piece plates are produced that have not a boring gray and smooth surface, but color and grooved. The embossed surface has a positive effect on the anti-slip properties of the plate. On sale you can find plates of hexagonal, triangular, rhombic and polygonal shapes. As a result, you can get a fairly original design of the site, and if you combine the plates with paving stones or gravel, the result will be very spectacular.

Road slabs are becoming more versatile, because they are applicable not only in industry and large-scale construction, but also when performing private construction work.

Number 4. Types of plates, marking and size

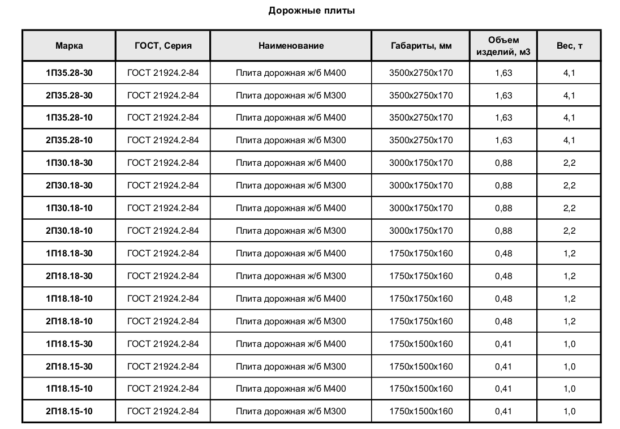

The manufacture of concrete products for road slabs is regulated GOST 21924.0-84. By the same document, all manufactured plates are divided into three types:

- RAP - Universal road slabs, which are suitable for the construction of temporary and unloaded permanent roads. Withstand a load of 10 to 30 tons, tolerate frosts up to -500C, can be reused;

- PDN - road slabs are prestressed, have higher strength, can be used under difficult conditions, for example, in regions with harsh climates (up to -550C) and with a soft soil base;

- PAG - aerodrome plates, there is a separate standard for them, GOST 25912-2015. These are heavy plates of increased strength, which can withstand the load of heavy vehicles and can be used to equip runways. Products withstand loads up to 75 tons at temperatures up to -350FROM.

The size and shape of the plates vary widely; products are produced with a smooth and corrugated surface. The latter option is beneficial in terms of better traction with the wheels of the car.

Above mentioned GOST 21924.0-84 regulates the labeling of plates. It encrypts the purpose, shape and size of the product. Marking Example - 2P 30-18-30. To understand what kind of stove we are talking about, you need to know the nuances of compiling similar formulas:

- the first numerical symbol (1 or 2) indicates the type of coating that can be obtained using such boards. 1 - slabs for permanent roads, 2 - for temporary;

- the second character (or group of characters) denotes the shape of the product. П - a rectangular plate, ПБ and ПББ - rectangular plates with one or two combined sides, respectively; ПТ - a plate in the form of a trapezoid, ПШ, ПШД, ППШ, ДПШ, ПШП - hexagonal plates and their parts;

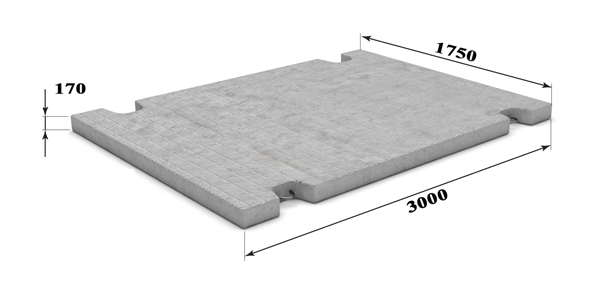

- the third part of the formula is written through a dot or dash. In our example, this is 30-18, but marking 30.18 may occur. These are numbers indicating the rounded length and width of the plate in decimeters, i.e. 30-18 is a plate 3 m long and 1.75 m wide;

- the last number means the maximum allowable load on the stove in tons. In our case, it is 30 tons.

The most popular plates are rectangular, they are easy to connect with each other, they are universal. Trapezoidal and hexagonal elements produced in small quantities. For them, only one parameter is indicated in the marking: for trapezoid (PT) - the length, for hexagonal (PN) - the size of one side.

Combined Borot in plates they call a small protrusion 15 cm long on the lower surface. If he is one, he is made on the long side, if two - then on two short ones.

Among additional designations in marking it is worth noting:

- the letter B at the end means that the plate has slots for loopless mounting or holes for collet grips;

- for prestressed plates, after the maximum load value indicate rebar class. If 1P60.18-30AV is written on the plate, it means that you have a rectangular plate for constant expensive 6 * 1.75 m in size, it can withstand a load of 30 tons and is made using steel of type AV.

Separately, it is worth highlighting PAG aerodrome plate marking according to GOST 25912.1.In their marking there is an indication of the type of plates (PAG), followed by the thickness of the plate in centimeters, then the class of reinforcing steel used (A-IV, A-IVC, At-IV, AV, etc.). An example is PAG-14AV.

GOST R-56600-2015 governs marking plates type PDN. The designation must include an indication of the type of plate (PDN), its purpose (1 or 2), and also the thickness in centimeters. Example - 1PDN-14. Another type of marking may occur, since several GOSTs and TUs are currently in force.

In road construction, the following types of plates are most often used:

- 1P 30-18-30 - suitable for the construction of roads of constant use in regions where the temperature does not fall below -400FROM;

- 2P 30-18-30 - the same slabs, but for the construction of temporary roads;

- 2P 30-18-10 - slabs for temporary roads with a maximum load of up to 10 tons;

- ПДП 3 * 1,5 Н30 - slabs with a length of 3 m and a width of 1.75 m, weight 2.2 tons, withstand a load of 30 tons. This is a universal material for the construction of roads of any type;

- PAG-14 is used for airfields and roads with increased load, withstand up to 75 tons.

Road plates are produced in a greater variety than airfield. You can purchase road slabs 1.5-6 m long and 1.0-3.7 m wide, the height ranges from 12 to 24 cm. Airfield plates are more standardized, they are produced, as a rule, 6 m long and 2 m wide, it differs only thickness, from 14 to 20 cm. PAG 14 plates can be used to equip airports designed to receive light aircraft, PAG 18 and PAG 20 plates are an option for a runway where heavy aircraft land.

Marking is applied directly to the stove, more precisely on its butt. It is important that the label is clearly legible and remains visible during storage. It is also important that the manufacturer or brand name, plate weight, manufacturing date and quality control stamp are indicated on the end. In addition to marking, there should be signs on the plate indicating the center of gravity, and bearing points during storage.

Marking is done using a stencil, a stamp or a marking machine, hand-drawing is allowed. It is important that the paint is moisture resistant and quick-drying, dark in color.

No. 5. What to consider when buying?

Analyze all the factors that will affect the slabs for future use. The main parameters are load and temperature. If there will be heavy traffic along the road, then it is necessary to take plates that can withstand up to 30 tons or more. If an entrance to a private house is arranged, then you can easily get by with slabs that withstand a load of up to 10 tons. It is also important to take into account the type of constructed canvas - permanent or temporary.

The price of road slabs depends on the brand of concrete used, the class of steel, the weight of the reinforcement and the production technology. When it comes to the construction of critical facilities, it is very important to pre-calculate and determine the most suitable type of slabs. If it is necessary to build a temporary road or a road with a small load, then it is allowed use used road slabs. This is a great way to save. In addition, the plates are easily dismantled, and the high-quality materials used during production allow them to be used repeatedly.

Used road plates come in two grades:

- first - slabs, which were under construction trailers and parking lots, preserved their geometry, have an almost perfect appearance;

- second - slabs that were used for roads with a decent load, have visible chips and cracks, which, in principle, do not so much affect the performance.

No. 6. Features of transportation of road plates

Road slabs are heavy products that require compliance with special transportation conditions so that they reach the place of laying safely and soundly. Manufacturers usually deal with all delivery problems, but the buyer does not bother to know the general rules for the delivery of such goods.

Concrete goods plates are transported by open body trucks and loader crane. Long trucks are used to deliver heavy plates or a large number of products. If it is necessary to transport plates of non-standard large sizes, then gliders, heavy-duty trucks with an extended body come to the rescue.

It is important that the seller, manufacturer or carrier correctly stacks and fastens the boards. Otherwise, the plates may move and be damaged on the go. Loading and unloading are carried out smoothly and accurately, at delivery choose a low speed.

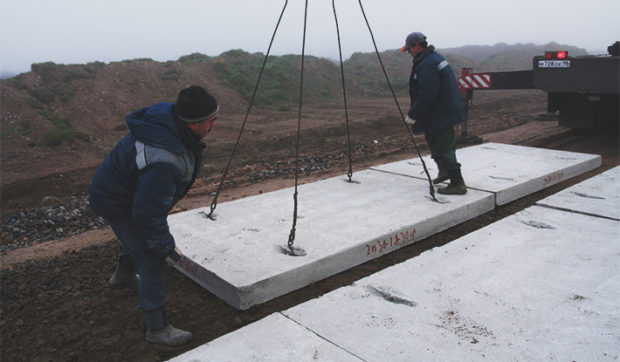

Number 7. Features of laying road slabs

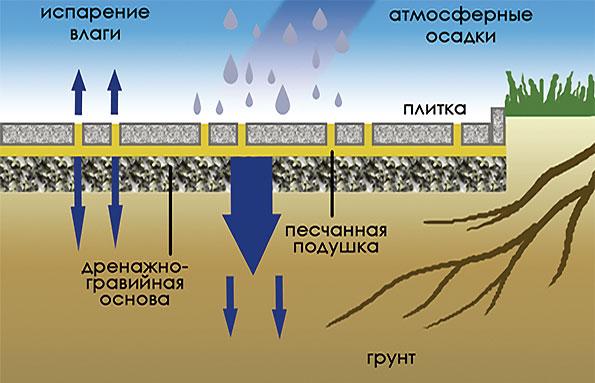

Public roads and temporary sites do not require serious preparation of the foundation. It is enough to create a sand cushion, carefully tamp it and mount the plates; you will not need a curb stone.

Permanent roads are mounted taking into account the following nuances:

- under the future road, soil is taken to a depth of 25-50 cm, the bottom is covered with geotextiles;

- sand and gravel cushion is poured onto the geotextile with a layer of 20-30 cm for the stability of the future road. Strengthen the strength by adding a dry cement mixture;

- the soil is moistened and compacted;

- after tamping the sand layer, the plates are installed, at this stage the mounting grooves are closed with cement or concrete;

- in order to get a smooth road surface, a cord is pulled along the canvas, on which they are oriented when installing the plates;

- at the edges it is better to use slabs such as PB and PBB with protrusions adjacent to the curbstone;

- the plates are heated using a sledgehammer and a board, comparing them with the ground level;

- along the edges of the road, a curbstone is required. Every 10 m, a gap of 5-7 cm is necessary for the outflow of rainwater;

- if necessary, the slabs are poured on top with concrete screed or rolled with asphalt.

In private construction, stoves are used that are designed for a load of 10 tons. The entrance to the house, parking lots are equipped with large rectangular slabs, for track organization smaller plates can be used, as well as trapezoidal and hexagonal products. The technology for installing slabs is the same as for public roads. The base can be made of sand cushion - it will cope with small loads. It is important to pre-mark the surface. It is advisable that the distance from the road to garden trees is at least 1.5 m, otherwise the roots may damage the concrete over time. Do not forget about the slope, which will provide free outflow of rainwater.

Reinforced concrete products road slabs - the ideal solution when you need to quickly build a road that can withstand decent loads. Often, such coverage is arranged in regions with a difficult climate and at a great distance from the main route, i.e. where it is unprofitable or impossible to use asphalt.