5 tips for choosing a wooden siding to decorate the facade of the house

A house with a wooden finish will always look attractive, only natural wood is a rather delicate material that is afraid of moisture, temperature extremes, fire and pests, because it requires careful care. Anyone who sheathed a house with a wooden paneling knows well how much effort and money is required to maintain the decoration in good condition. To save us from these problems, a tree siding was invented. It is made from polymers, metal and other materials, but it does not simulate wood well enough and has its own drawbacks. To combine the naturalness and beauty of wood with durability and durability, it is better to choose a wooden siding for finishing the facade. What happens, and what to consider when choosing?

Types of wooden facade

There are many facade materials on the market, many of them can be easily confused with each other, and some manufacturers achieve this by promoting their product under a louder name. Under the wooden facade of the house is usually understood:

- solid wood trim i.e. wooden clapboard. Lining is made from different types of wood, which is well dried and treated with antiseptics. The material differs by type of profile, class and size. The main advantage is naturalness. In addition, the lining has a beautiful appearance, good heat and sound insulation qualities. Cons more: low moisture resistance, sensitivity to temperature extremes, tendency to rot, the ability to maintain combustion, and tree pests like. The material is expensive, it will also be expensive to take care of it, because the industry began to look for a decent replacement for wooden lining;

- wood siding It is made from wood waste, which is pressed under the influence of polymer additives. The technology allows you to give the product any color and texture. Of course, you cannot call a material completely natural, but it shows itself much better than wood. Wooden siding does not rot, keeps heat well, but cannot boast of high strength. It is possible to consider such a wooden finish only conditionally, but now often such a material is called wooden siding;

- Thermodecking material It is made from solid wood under the influence of high temperatures and steam, as a result of which the structure of the tree and its properties change somewhat. The fear of moisture disappears, but the original look persists and even improves. The material does not rot, has high durability and good thermal insulation properties. The downside is the price that you will have to pay for freedom from constant care and a beautiful look of material for many years.

Often from sellers and on the Internet you can hear about "Wood siding." This is a material made of vinyl, acrylic, metal, ceramic and fiber cement. It just mimics the structure of a tree. Some types of such siding are really durable, some look good, but when it comes to wooden siding, we will talk exclusively about wood fiber boards and Thermodecking.

Production of wood siding

In the manufacture of wooden siding, wood fibers are used, to which binders are added and the resulting mass is pressed under high pressure. Due to additives, you can get siding of any shade.

If you look at a slice of wood siding, it can be noted that it resembles the MDF panels that are more familiar to all of us - the production technology is similar, and it allows you to get, though not natural, but completely safe material.

Sometimes you can find the name "wood-polymer composite siding (WPC)". This is, in fact, all the same material made from wood waste, modifiers and thermoplastic polymer. In the production of WPC, it is believed that the optimal ratio of wood and additives is 50/50. At the same time, the best strength characteristics are achieved and a good appearance is maintained. If more wood is included, then the material will be more fragile, if more polymers will lose aesthetic qualities.

The siding can be sanded or embossed, a print can be applied to it. The boards are also treated with paints and varnishes, covered with veneer, synthetic film or polymeric materials. Hence the diversity of appearance.

WPC siding

Wood siding: advantages and disadvantages

Since polymers are introduced into the wood siding, a material is obtained that is devoid of many of the disadvantages of solid wood. Among the main advantages we note:

- resistance to moisture, snow, wind, sunlight and other environmental factors. Wherever a tree begins to rot for a long time, wooden siding retains its original appearance;

- resistance to low and high temperatures, as well as to temperature extremes. A solid array, as you know, can expand and contract depending on weather conditions. Siding is not subject to such changes;

- strength and durability. By strength, the material is not inferior to solid wood, and sometimes surpasses it. The durability of the siding allows it to serve longer than a tree;

- good indicators of heat and sound insulation, which are inherited from natural wood, which is part of the material;

- attractive appearance. The technology allows you to create a siding of any color and shape. It can successfully simulate a block house or have a flat profile;

- security. Although siding is not completely natural material, it does not cause any harm to health;

- ease of installation;

- ease of care. It is unnecessary to treat with antiseptics, varnishes and paints.

Minuses:

- wood siding can not be called natural. This, of course, allows him to be more resistant to the external environment, but robs him of the noble appearance of wood;

- combustibility is lower than that of a solid tree, but still quite high;

- the price is much higher than that of a tree, but if you take into account the costs of caring for the array, then the siding pays off in a few years.

Types of Wood Siding

From a wood-polymer mixture you can get products of any shape, but the most popular is wooden siding of the following types:

- block house - lamellas that mimic a natural log house and have a convex shape;

- false beam It has a flat profile and is suitable for creating perfectly even facades.

As for colors, then it can be absolutely anything. Most buyers want to get the most similar material to natural wood, because siding from light yellow to dark brown with a characteristic wooden pattern has gained widespread acceptance. For lovers of brighter solutions, material painted in calm blue, green, white, burgundy and other shades is suitable. The technology allows you to get material with almost any desired appearance.

Dimensions, as a rule, standard, but many domestic manufacturers make concessions to customers, producing products on an individual order.The length of a wooden siding board is 3, 4 or 6 m, the width can be 8-12 cm, 14-16 cm or 18-20 cm. Thickness - 1-2.1 cm.

Thermodecking Material

Wooden siding was enjoyed by many buyers, but there was still a demand for something natural but durable. And such material appeared. This is a Thermodecking material. Production process simple and complex at the same time:

- preliminary drying of wood in special chambers at a temperature of 130-180 degrees;

- an increase in temperature and pressure in the chamber, its saturation with water vapor, and sometimes with chemicals. The result is decomposition of hemicellulose, a change in the structure of wood, the breakdown of its fibers and the bonds between them. The material becomes less porous, which means it is more resistant to moisture, rot, decomposition and the effects of fungus, i.e. significantly increases the biostability of wood;

- stabilization of the resulting state by lowering the temperature or by exposure to certain chemicals.

Different manufacturers may have different nuances of technology, but the general Thermodecking Benefits remain the same:

- safety and environmental friendliness. This is a natural material that is not able to emit harmful substances. If only steam and temperature were used in the production, an absolutely safe product is obtained;

- beautiful appearance. Wood not only preserves its natural beauty, but also gets a more pronounced pattern. Even the simplest and cheapest species begin to resemble expensive varieties of wood;

- resistance to moisture, so that the rotting, swelling and mold of the material are not afraid;

- resistance to temperature differences;

- higher strength and durability than ordinary wood;

- practically does not dry out and does not shrink.

Of significant cons only one is the high price, which is explained by the complexity of the technology. If we take into account that the facade will be decorated with durable natural wood, which is not afraid of moisture and the sun, then the high cost can be considered an investment.

WestWood Manufacturing Technology

The final quality of the wood will depend on the technology and equipment used. Technologies such as VacuumPlus, PLATO, Bikos-TMT, Thermowood and others are used. For example, consider in detail technology Westwood, which is characterized by the use of sufficiently high temperatures and a complete rejection of "chemistry".

WestWood Technology is developed and patented by Thermodecking. The company gives a 20 year warranty on all products, and the selected production technology allows you to be sure of its quality:

- careful control over the quality of raw materials on their own procurement bases;

- the use of modern equipment for sawing an array;

- high-quality drying, organized due to the uninterrupted operation of the equipment;

- the nuances of heat treatment. Wood is heated in chambers at a temperature of 185-205 degrees at high pressure and in the presence of water vapor. The latter prevents fire and is involved in chemical processes occurring in wood. Drying lasts several hours, and the whole cycle takes 30-36 hours. No chemicals are used, which allows us to talk about maximum environmental friendliness;

- finished products are stored in modern warehouses.

Ash, birch, alder, pine and linden are used in the production. In addition to wall panels, this technology also produces a terrace board, furniture panel, timber and other products. The company's specialists can help with the choice of material, as well as with delivery and installation. In addition to high quality products, customers with regular orders receive a discount of up to 9%.

Thermal tree species

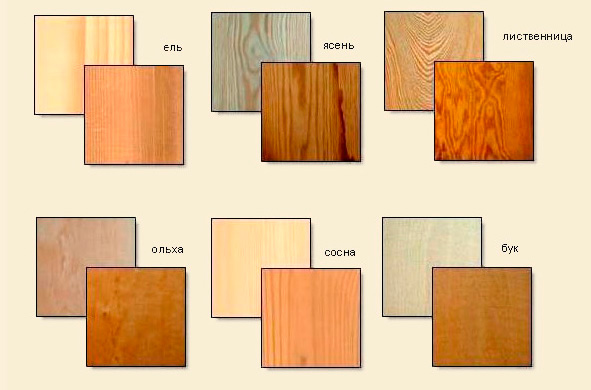

Wood species selection Depends on the requirements for performance and appearance:

- thermal ash gained the greatest popularity due to its excellent shade, high moisture resistance and geometric stability.According to the latest indicators, the material is superior to heat-treated oak and beech;

- thermosnow It has a pleasant light color and quite high softness. It is not used as a floorboard, but it is suitable for facades;

- thermolime It tolerates extremes in temperature and humidity, has high wear resistance and is immune to biofactors;

- thermoclean well tolerates high humidity, temperature changes and maintains a stable geometry.

Thermo alder is often used to decorate baths, and a thermal beech and a thermo-oak are more suitable for interior decoration.