Polymer-coated corrugated board - 8 tips for choosing and processing

Decking is used in roofing works, when arranging fences, warehouses and garages. A steel sheet is protected from external influences by various kinds of coatings. The simplest and cheapest option is a galvanized coating, a little more durable will be an aluminum-zinc coating, but the best option is a polymer protection. How is it applied, what materials are used, what should be the thickness of the coating? We answer all questions and understand how to choose a polymer-coated corrugated board.

Production technology

Decking is a sheet of cold rolled steel on which a protective coating is applied, and then give it a certain relief. This is if it is very short. The final characteristics of the sheet depend on what coating was used, on its thickness and the mass of other parameters.

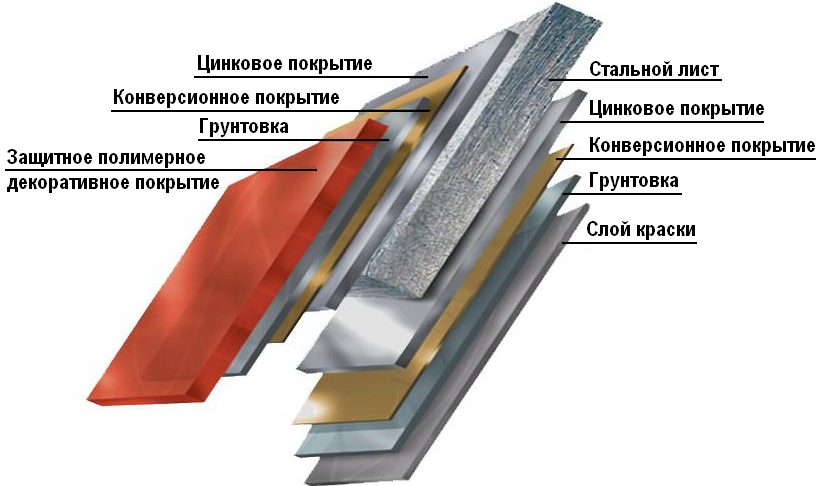

The manufacturing process of polymer-coated corrugated board is as follows:

- applying a protective zinc coating to steel sheets;

- degreasing and drying;

- primer, due to which the adhesion of galvanization and the polymer layer is significantly increased;

- application polymer coating with a thickness of 25-200 microns. Typically, polymer protection is applied only to the front side of the sheet, and the back is covered with a layer of varnish, but in some cases both sides are protected by a coating. Such sheets are usually used to organize fences in order to provide him with high decorative qualities;

- final polymerization and strengthening of the protective layer in chambers with high temperature;

- sheet rolling on a roll forming machine to give it a relief (wave or trapezoid, height 8-180 mm). In some industries, the relief is given to the sheet after galvanizing, and only then is the polymer coating applied.

Usually use powder coating method. A positive charge is passed through the metal, and a negative charge is imparted to the polymer powder. An electromagnetic field is created, and the powder is attracted to the metal, and polymerization occurs in the chambers under the influence of high temperatures. Less commonly, the liquid staining method is practiced, but it does not allow to create a uniform layer on the metal, as a result of which the durability of the coating is reduced.

The quality of corrugated board (and in particular polymer coating) depends on how responsibly the manufacturer approached the production. Therefore, it is so important to contact only trusted manufacturers and sellers.

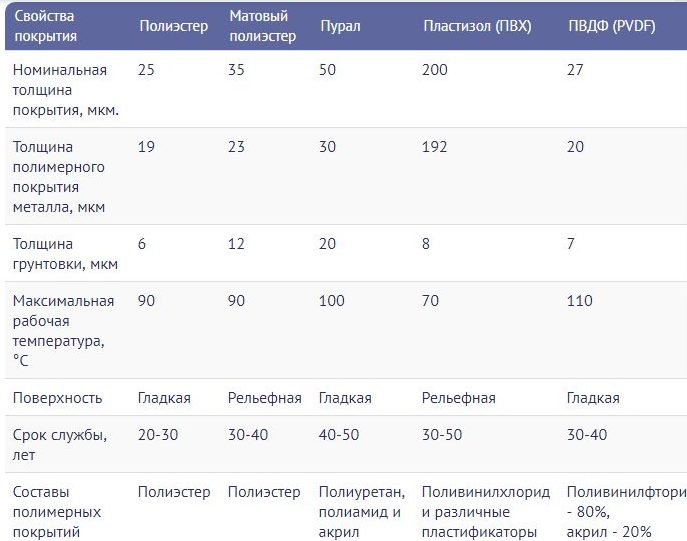

Type of polymer coating

The polymer coating perfectly protects the metal from corrosion, frost and heat, as well as mechanical damage, but how well this protection will work depends on the type of polymer used. Among the materials used, we note:

- acrylic;

- polyester;

- pural;

- plastisol;

- polydifluorionad (PVDF).

Separately, it is worth considering each type of coating.

Acrylic coating

Acrylic coating is relatively inexpensive and aesthetic, but acrylic is applied with a layer of about 25 microns, i.e. it can only be used in the construction of temporary structures.

Advantages of acrylic coating:

- aesthetics;

- cheapness;

- high temperature resistance (up to +1200FROM);

- fire safety.

Cons much more:

- fragility and low resistance to mechanical damage - the coating can be damaged even during installation;

- Acrylic loses color after 4-5 years of use, and this despite the fact that the material is resistant to high temperatures;

- low level of corrosion protection, since the coating can begin to peel off after 3-4 years.

All these properties allow the use of acrylic coated sheeting only when creating temporary structures.

Polyester coating

Polyester is the most commonly used coating for corrugated board. It is cheap, durable, and well resists negative environmental factors.

Benefits:

- UV resistance - the material does not fade in the sun and retains its original appearance for a long time;

- resistance to corrosion;

- resistance to temperature extremes;

- low price.

The main disadvantage is the small thickness of the applied coating, because it may not be particularly durable. To verify the quality of the material, it is necessary to bend the corner of the sheet carefully: if cracks and small folds do not appear, then the corrugated board will last a long time.

Material with matte polyester coating wins in terms of strength. Technology involves coating unevenly. The thickness of the spraying will be slightly larger than in the case of glossy polyester, therefore, the strength properties increase. Such a professional sheet often gets a surface with imitation of brickwork, wood or stone.

Plastisol coating

Plastisil is called polyvinyl chloride, to which plasticizers have been added. Coating Layer - 175-200 microns, and this is quite a lot, so we can talk about the high strength and durability of the material.

Benefits:

- resistance to mechanical stress, because the coating is loved in regions where hail often falls or there are dust storms;

- You can get a beautiful relief pattern on the coating, which is possible due to the thickness of the protective layer.

Minuses:

- low resistance to UV rays, because the coating is more suitable for the northern regions.

Pural coating

Pural (aka armacor) is a relatively new type of material, made on the basis of polyurethane, to which acrylic and polyamide are added. Even though the coating is applied about 50 microns thickIt turns out to be very strong and durable.

Benefits:

- durability up to 50 years;

- the safety of decorative and protective qualities throughout the entire service life;

- resistance to mechanical loads, temperature extremes, negative influences of natural and man-made nature.

Minus only one is a high price, but in areas with high humidity, air pollution and other factors that are aggressive for the metal, this is almost the only option.

Polydifluorionade (PVDF) coating

The coating consists of 80% polyvinyl fluoride and 20% acrylic. This mixture allowed to achieve a lot of positive qualities.

Benefits:

- durability. The coating does not lose its original color and properties for 45-50 years;

- resistance to sunshine;

- the ability to use in any climate.

Minuses:

- high price.

This type of coating can be either glossy or matte.

What else to consider when choosing a corrugated board?

When choosing a corrugated board with a polymer coating, it is also worth considering some other parameters, namely:

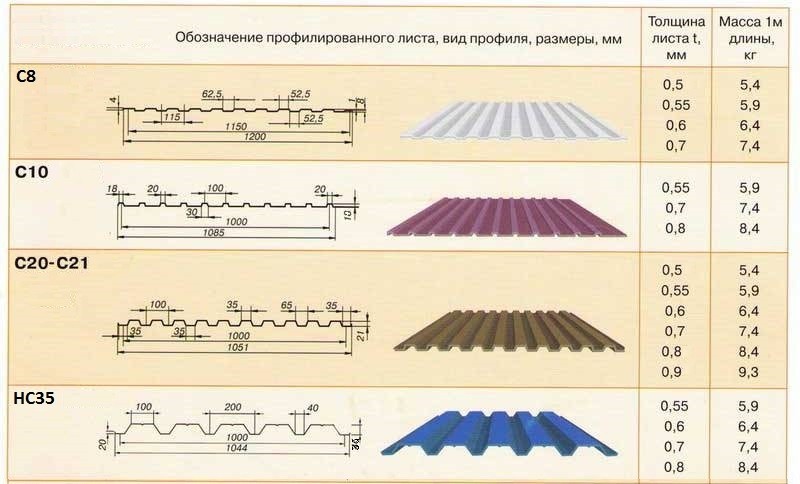

- material type. For the construction of internal partitions and cladding of buildings, wall corrugated board (C) with a profile height of 8-35 mm is used. Roofing corrugated board (H) is used in the arrangement of roofs, fences, in the construction of non-residential buildings (hangar, garage, etc.), the profile height is more than 44 mm, it is a hard and durable material. Bearing corrugated board (NS) - a universal material that is suitable both for the organization of the roof, and for the construction of structures or for their decoration;

- wave height affects the strength of the sheet, and the higher the height, the higher the strength. This parameter is indicated in the marking, for example, C8 is a wall profile with a wave height of 8 mm;

- the size. The width of the sheets of corrugated board ranges from 113-120 cm, the length is 0.3-12 m.The choice depends on the size and geometry of the object to be erected;

- surface quality. The polymer coating should be free of scratches, dents and other defects; the sheets themselves should not have any burrs at the edges;

- warranty. If the manufacturer claims that the durability of its products is 20 years, and gives a guarantee for 6 months, then this should be alarming. It is best to purchase a professional sheet directly from the manufacturer or from its authorized dealers. Give preference to large companies.

In conclusion, we note that when choosing a professional flooring for a fence, it will not be superfluous to pay attention to double-sided material - a polymer coating is applied to it from two sides, which ensures maximum aesthetics and durability.