7 tips for choosing slopes for plastic windows

The attribute of a modern apartment has long been plastic windows. They conquered the world with practicality, excellent heat and sound insulation qualities, durability and appearance. But just putting plastic windows does not mean finding reliable protection from the cold and drafts. It is equally important to choose the right slopes for plastic windows. A mistake can lead to the fact that moisture will begin to accumulate near the window, causing development mold. Incorrect slopes may need to be repaired much more often than you would like. So let's understand the nuances of the right choice.

What should be the slope?

For starters, it’s not a problem why do we need slopes at all. There are several reasons to put them:

- a window with neatly lined slopes looks more beautiful than without them. Non-aesthetic joints may remain after installation. polyurethane foam. If we are talking about an apartment, then this view will greatly spoil any interior, depriving the point of further repairs;

- polyurethane foam, which is actively used when installing plastic windows, has excellent thermal insulation characteristics, but easily absorbs moisture. If it is not protected, then it will soon become damp and collapse, and the window will lose proper thermal insulation properties. It is especially important to protect the mounting foam from the outside of the window, but you should not forget about the internal slopes;

- correctly executed slopes increase the level of heat and sound insulation of the window structure, protect it from condensation.

Consequently, window slopes must meet the following requirements:

- Do not spoil the performance of plastic windows, and even better - improve them;

- have a durability not less than that of plastic windows, i.e. about 15-20 years;

- meet the general style of the window and interior;

- external slopes must be resistant to precipitation, temperature extremes, sunlight.

Types of slopes for plastic windows

Even 20-30 years ago, when plastic windows did not begin their victorious march around the world, the slopes were simply plastered and then painted. That's all the finish. Today there are a bit more options:

- plaster followed by painting is still in use;

- drywall sheets allowed to carry out work faster and achieve a more aesthetic result;

- plastic slopes;

- metal - a more rare option for the design of slopes, used in the outer lining;

- decorative stone is also used infrequently, suitable for both external and internal slopes.

To understand which slope for a plastic window is better to choose, you need to familiarize yourself with the basic properties each of the available options.

Plaster slopes

Stucco used to create internal and external slopes. In the latter case, it is better to take the composition for facade work. The process of creating slopes consists in applying several layers of plaster and leveling them, after which a finishing layer of plaster is applied, then painting is done.

The advantages of plaster slopes:

- relatively low cost of creation;

- resistance to mechanical stress;

- the ability to choose plaster with the required set of characteristics, which makes such slopes universal;

- lack of seams, in contrast, for example, from drywall.If there are no seams, then the surface is easier to finish, and there are fewer vulnerabilities;

- ease of repair and upgrade. If desired, the slopes are easy to repaint, and the cracks that appear are simply masked;

- the ability to trim slopes of complex shape.

disadvantages:

- the complexity of the work performed. To get the slopes aesthetic, you must have the skills of plastering. In addition, you need to be patient, because each layer of plaster should dry. In the process, dust and dirt are inevitable;

- the frame of the plastic window and the plaster will not be able to become one, since they have not yet come up with a sealant that would have equally good adhesion to plastic and plaster, then during operation you may encounter the appearance of cracks;

- the plaster has low heat-insulating properties (the exception is warm plaster), so that in winter the material can freeze, and there it is not far from the appearance of condensate. An additional layer of thermal insulation from mineral wool or polystyrene foam;

- slope repairs will have to be carried out after a few years, since cracks and shedding are common.

There are enough disadvantages of the plaster, so if you are not a master plasterer, for whom there is no problem updating the slopes every few years, then it is better to look in the direction of other options.

Plasterboard slopes

Drywall became a universal material that is used in finishing work everywhere. So the slopes they also began to revet. The installation process consists in installing the lathing (usually take a metal corner), on which sheets of drywall are attached. Between the slope and drywall lay insulation. If the slopes are fairly even, then drywall can be glued directly to it using putty, glue or polyurethane foam.

Drywall is used to decorate the internal slopes, but some craftsmen risk using it in the exterior. In the latter case, only moisture resistant sheets are selected, which are protected by a layer of plaster.

Benefits:

- low cost;

- relatively simple and quick installation;

- the ability to further insulate the slopes;

- creating a perfectly flat surface without the need for a long and tedious alignment with the level and spatula;

- durability subject to installation technology.

disadvantages:

- drywall is afraid of moisture, so that the accumulation of condensate will be detrimental to it. Even moisture-resistant material does not always normally tolerate such an effect, because more and more people are abandoning drywall in favor of other solutions. Use drywall for exterior decoration - an extreme degree of risk and hindsight;

- low mechanical strength - cracks may occur as a result of more or less strong impact;

- as in the case of plaster, it is impossible to choose a sealant with the same adhesion to plastic and drywall, so that in the future the appearance of cracks at the junction of the two materials cannot be avoided;

- with independent arrangement of slopes, certain skills will be needed;

- gypsum board requires finishing, as well as preliminary puttying of joints.

Plastic slopes

Plastic slopes on the windows are devoid of many of the shortcomings of plaster and drywall. This is the youngest version of the cladding, but in popularity it bypasses other solutions. Plastic panels usually mean sandwich panels, but in order to make the most competent choice, you should know that There are two types of plastic panels:

- Wall panelsin which between two sheets of plastic there are stiffeners with voids between them. The thickness of such panels is about 1 cm, they are quite fragile, therefore they cannot be used on slopes with a depth of more than 25 cm. They are available in white and can imitate the structure of a tree. They allow quick installation, but low strength - their weak point.To insulate the slope, mineral wool or polyurethane foam is used under the panel;

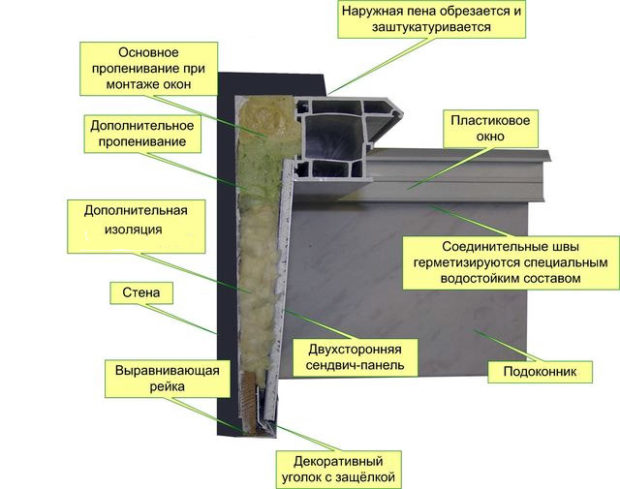

- sandwich panels - a better option, because here a layer of polystyrene is used between the sheets of plasticwhich strengthens the panel and improves its thermal insulation properties. The thickness ranges from 8-36 mm, but for window slopes, 10 mm thick panels are recommended.

Recently, sandwich panels are usually used, so we will talk about them. Their advantages include:

- high installation speed, lack of dust and dirt. Slopes will be installed within a few hours. In addition, additional finishing work, such as puttying joints or painting the surface, will not be needed;

- esthetic flat surface;

- variety of appearance. The standard color of the plastic slope is white, but many companies are ready to offer slopes of different colors, as well as products that simulate different types of wood;

- additional thermal insulation without the need to separately install a layer of insulation;

- since the window frame and the slope are made of the same material, they will expand equally, which means that there are no cracks and drafts;

- durability and lack of need to regularly carry out repairs;

- moisture resistance.

Among the disadvantages:

- a blow can violate the integrity of the panel, and in the presence of deformation it will be necessary to change the entire slope - just filling the crack, as in the case with plaster, will not work;

- cost. You can find very inexpensive slopes, but they are unlikely to boast high quality. Usually cheap plastic quickly turns yellow in the sun, so the savings come sideways.

Metal slopes

Metal applied for exterior decoration of slopes, and use it since the Soviet era. Today, this option of organizing slopes is not very common, but it is definitely worth considering a huge number of advantages:

- aesthetics. Smooth metal can be painted in any color, because it can be combined with any facade;

- resistance to temperature extremes, direct sunlight and high humidity;

- durability;

- maintainability.

The polymer coated metal, which retains its original appearance for a long time and is not afraid of corrosion, shows itself best.

The main minus - A high price, but given that you do not need to constantly repair cracks, metal slopes are not a bad investment.

Other slope options

The following are much less commonly used plastic windows. types of slopes:

- stone. As a rule, they are made when installing wooden windows. Fake diamond can be used for facing external and internal slopes. Such a window will look solid, but it will also have to be spent. In addition, it will be necessary to correctly perform the installation in order to maintain the aesthetics of the structure and its operational qualities;

- wooden slopes even less often complete with plastic windows. This is an expensive pleasure that requires proper installation and specific care;

- ceramic slopes - A great option for the bathroom and kitchen. It turns out to create a harmonious interior and get strong slopes resistant to moisture, the sun and temperature extremes. The only caveat is the complexity of installation. You will have to carefully measure and trim the tile. That is why many recommend using it for this purpose. mosaic.

If you are not sure that you can cope with the decoration of slopes yourself, it is better to contact specialists - save time, money and nerves.

To be sure of the quality and durability of the slopes, you should contact the checked places. Residents of Moscow and the region recommend MasterOtkosov company, which quickly and efficiently install slopes on plastic windows. There are a lot of different shades and textures to choose from, all work is carried out in 1 day, and plastic slopes of 25 years serve.On the company's website you can quickly calculate the cost of slopes and order a free specialist consultation.

To be sure of the quality and durability of the slopes, you should contact the checked places. Residents of Moscow and the region recommend MasterOtkosov company, which quickly and efficiently install slopes on plastic windows. There are a lot of different shades and textures to choose from, all work is carried out in 1 day, and plastic slopes of 25 years serve.On the company's website you can quickly calculate the cost of slopes and order a free specialist consultation.