Laminate Kitchen Worktop (HPL): Basics of Choice

From which they just do not kitchen worktops! Both wood and a rock, and even metal. Not so long ago, paper-laminated worktops, also called laminate worktops, have gained popularity. Since the material began to be used relatively recently, many absolutely do not understand what is at stake, and is there something in common between the usual laminate for flooring and new worktops. Let's figure it out together and find out what constitutes a laminate kitchen worktop, and whether it can become a worthy alternative to more traditional materials.

Laminate kitchen worktop - what is it?

Let's start a little from a distance to thoroughly understand the issue and avoid confusion. What ordinary laminate (the one that many people have in the apartments)? This is a multilayer material, based on it - high density fiberboard, which is made from wood fibers. Under the fiberboard - a stabilizing layer that protects the material from deformation. Additionally, a layer of soundproofing material may be used. Above the chipboard - paper with a printed pattern (imitation of stone, wood, tile, leather, etc.). A protective layer of melamine or acrylic resin is applied on top of the paper. The manufacturer can make the protective layer embossed to ensure maximum similarity between the laminate and natural wood.

Our usual laminate is used not only for finishing floors, but also for wall cladding and even the ceilings. You can also make kitchen worktops from it, and the network is full of materials from craftsmen who make such products with their own hands. But we will talk about a slightly different, albeit very similar, material.

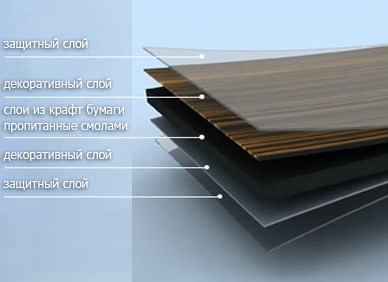

When talking about laminate kitchen worktops, they usually mean laminated paper (BSP). As the name suggests, the basis of the material is paper, its here about 60-70%. Use thick unbleached kraft paper. The rest is thermosetting resins (phenol-formaldehyde and melamine-formaldehyde), which under the influence of high temperatures and pressure turn into a thermoplastic mass. This is the main layer of material. Above it is a decorative layer. This is paper with a pattern, which will determine the appearance of the coating. The paper is also impregnated with thermosetting melamine resin. To protect the decorative layer is used overlay.

Depending on the production technology distinguish two types of material:

- BSP low pressurehe LPL - low pressure laminate. Such a material has a thickness of not more than 0.5 mm. The technology requires the use of a two-belt press, where the prepared mass is loaded. It is affected by a temperature of 150-1700C and pressure 3-7 MPa. Pressure increases gradually, the so-called ironing effect, all gases and air are removed from the material gradually. The technology allows you to get thinner material, it is characterized by plasticity and reliability, is sold in sheet and roll format;

- High pressure BSP, HPL - high pressure laminate. The technology provides for the use of temperatures over 1200C and pressure more than 5 MPa. At high temperatures, the resins melt, and high pressure makes them evenly distributed between the fibers of the paper. Then curing occurs, resulting in a monolithic material.Since gaseous water and formaldehyde are released during curing, high pressure must be applied. It is also used for cooling. As a result, a sufficiently rigid material with a minimum number of pores is obtained; it has excellent operational qualities: resistance to moisture and temperature, mechanical resistance, wear resistance, and durability. The material receives a thickness of more than 0.5 mm, has a wider distribution, is sold only in sheet form. It costs more, but its scope is wider. This is what they usually mean when talking about laminate worktops.

The standard divides the BSP into thin (up to 2 mm), which must be glued to the base, and thick (more than 2 mm), which can be used as a self-supporting base. In addition, plates may differ in the presence or absence of a decorative coating.

HPL is used in the furniture industry for the production of countertops and work surfaces, and it is also used in the manufacture of doors, flooring, interior and exterior cladding materials.

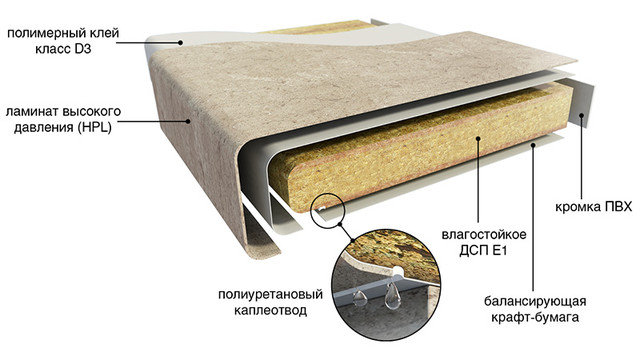

Most HPL laminate worktops on offer are this is a chipboard plate wrapped in plastic up to 1 mm thick. It is advisable that the chipboard be completely wrapped in plastic, as there are options when the plastic reaches only the bottom. In this case, the particleboard can suffer from large leaks.

Advantages and disadvantages

It would seem that what supernatural can be expected from a material that is 60% ordinary paper? But the use of resins and a special production technology allow to obtain unique properties.

The benefits of laminate flooring HPL should include:

- resistance to high humidity, temperature extremes, steam, which is very important in the kitchen, where often extreme conditions are often formed;

- mechanical strength - even a strong blow will not damage the integrity of the countertop;

- resistance to corrosion and most aggressive substances;

- pleasant appearance and a sufficient variety of decorative coatings;

- material with a thickness of more than 5 mm can be used without a base;

- ease of processing and installation, which affects the price and speed of assembly of furniture;

- hygiene and ease of care;

- resistance to high temperatures. The material does not melt, but only a little smoke in a fire. This can be achieved through the presence of special additives;

- security. The formaldehyde emission level is E1, and this is an acceptable and completely safe indicator for life and health.

The material is suitable even for outdoor use, so you can judge for its strength. True, under constant exposure to sunlight, plastic can lose color, therefore, for external use, it is advised to use a material such as EGS / EGF, which receives enhanced protection.

The only negative material - fear of local contact with a hot surface. If you put a frying pan just removed from the stove directly on the countertop, then formation of bubbles, yellowing and loss of brightness are quite likely. However, contact with hot objects without consequences is unlikely to withstand any other material (except metal, unless). To preserve the appearance, special supports for hot have been invented and widely used for a long time.

The quality of the laminate is highly dependent on the reputation of the manufacturer. The world leader is plastic manufactured under the DUROPAL trademark (Germany). Products with high performance are presented in a wide range. Among other things, HPL furniture plastic is produced. In Russia, the products are sold by the Soyuzstroydetal company, which sells finished countertops (plastic with a thickness of 0.6-0.8 mm is glued to the chipboard by postforming) and the HPL plastic itself.

The quality of the laminate is highly dependent on the reputation of the manufacturer. The world leader is plastic manufactured under the DUROPAL trademark (Germany). Products with high performance are presented in a wide range. Among other things, HPL furniture plastic is produced. In Russia, the products are sold by the Soyuzstroydetal company, which sells finished countertops (plastic with a thickness of 0.6-0.8 mm is glued to the chipboard by postforming) and the HPL plastic itself.Design

You can print on paper any image you like, which is why a kitchen worktop made of laminate can imitate almost any surface.The most popular option is a stone, followed by a tree, and solid tabletops are also in constant demand.

When choosing, it is worth starting from the style, of course. kitchen interior and your own preferences. If selected classic style, and the facades are made of wood or wood, then the tabletop can be taken with imitation wood texture, while the color can be absolutely anything. In the interiors in minimalism style look good Plain worktops and stone worktops.

A special niche is occupied by plastics with metallized surface. This countertop fits perfectly into high tech style and will allow you to realize the most daring interior ideas. If desired, you can find a laminate with a fantasy pattern (floral pattern, abstraction, geometric pattern).

Countertop surface may have varying degrees of gloss, but for the kitchen, a solution with a matte surface is more suitable. Firstly, it will glare less. Secondly, it will not be so noticeable scuffs and scratches. Thirdly, the matte countertop looks more noble.

Plastic can be smooth or embossed. Of course, the relief option will look more natural, but keep in mind that the kitchen is a room where crumbs, splashes and dirt are a constant occurrence, and it will be more difficult to keep the relief surface clean. From the same point of view, a light-colored countertop will be preferable - it is less easily soiled.

When choosing a design countertops pay attention to the edge. If the kitchen has straight lines, then the plastic is mounted on the chipboard using the postforming method, i.e. the edge will be exactly the same as the countertop. If a curved worktop is selected, then the edge is closed with aluminum, plastic or melamine. Manufacturers try to select the color and texture as accurately as possible.

Many manufacturers offer the manufacture of countertops to order, so if necessary, you can choose any version of decor.

Dimensions

As mentioned above, in most cases, the plastic layer is glued to the chipboard. The plastic itself may have a different thickness. Many domestic and Polish manufacturers use plastic thickness 0.4-0.5 mm, but most German and Italian companies prefer to apply 0.7-0.8 mm thick plastic. It is not surprising that their products are more durable and durable.

The total thickness of the countertop (chipboard + HPL) is usually 3.8 cm - this is a kind of standard. Sometimes you can find thinner countertops 2.8 cm thick and more massive 4 cm thick; custom worktops are made from 1.2 cm to 6 and even 8 cm thick. Of course, the thicker the countertop, the stronger the headset will be, but and the more massive it will look. On the lower cabinets with a thick countertop, you can easily stand during cleaning. If you order a countertop of non-standard thickness, then the edge will not be made using the postforming method.

Standard depth countertops - 60 cm. A narrower option is used when there is very little space in the kitchen, but think about such a solution three times, as cooking will not be very convenient. In some cases, the countertop is made to a depth of 63-65 cm in order to bypass the ventilation protrusion or prudently make a small “canopy” above the protruding handles of the lower cabinets - so you will not be bumped into them forever.

You can add a laminate countertop kitchen facadesmade of the same material and with the same decor. Naturally, a thinner material is useful for these purposes - a thickness of about 11 mm will suffice.

pay attention to drip tray. This is a special groove in the protruding part of the countertop. With large leaks, water accumulates in it. The groove plays the role of a kind of limiter, preventing the water from coming into contact with the chipboard.

Finally, we note that laminate kitchen worktops are a low-maintenance material. It’s enough to remember that you cannot put hot pans and pans on it. It is better to eliminate all stains, dirt and puddles as soon as possible; almost any detergent can be used for washing. The only limitation is not to use products based on oils and wax for processing glossy surfaces, otherwise you can say goodbye to a beautiful shine.