8 tips on how to use reinforcement for the foundation

As a theater begins with a hanger, the construction of any building begins with laying the foundation. The durability of the building and the safety of the people in it depend on how well it is organized. The foundation is concrete, but a purely concrete foundation would quickly become covered with cracks and cease to cope with its tasks, because concrete is reinforced with thick steel wire - reinforcement. For foundations of a different type and with a different degree of load, a different type of reinforcement is needed. Let's figure out what kind of reinforcement to use for the foundation and what it generally is.

Reinforcement material

Until recently, rebar and steel bar were synonymous. Now, for the manufacture of reinforcement, not only different types of steel are used.

The reinforcement for the foundation can be of the following types:

- steel - classics of the genre. Steel is an alloy of iron and carbon, and its properties depend on the proportions of these components, as well as on the availability of additives. The quality of steel is affected by the method of its production. In addition, the rods can be smooth or embossed, which also affects the performance of the reinforcement. Steel is characterized by high strength and reliability, it does not deform even under significant loads, and it is relatively simple to work with it - directly on the construction site, such reinforcement can be bent. Of the minuses, it is worth noting only exposure corrosion;

- composite reinforcement made on the basis of plastics. It is more expensive than metal, but is not afraid of corrosion, does not conduct electricity, weighs less and withstands solid tensile loads (sometimes more significant than a steel analog). It is smooth and grooved. In private construction is rarely used because of the high price. Composite reinforcement can be of the following types:

- basalt plastic It is made on the basis of basalt - a solid rock. Basalt is melted, stretched into threads that are intertwined with plastic threads. It is justifiable to use such reinforcement in the construction of walls, since it conducts radio waves perfectly, without creating interference. Ideal for buildings where you need to configure wireless Internet;

- fiberglass fittings perfect for building foundations, since it is not afraid of corrosion and does not conduct heat, which means that it will not become the place of formation of cold bridges, which lead to the destruction of structures. Fiberglass, like basalt plastic, transmits radio waves well. Its main advantage is high tensile strength, 1.5 times more than that of steel;

- carbon fiber the fittings are made on the basis of graphite or diamond, hence the high strength, but also the high price. Impact and fracture strength is higher than that of steel, which allows the use of fewer bars to achieve the same level of strength;

- glass reinforced polyethylene terephthalate produced by the method of interweaving fibers of lavsan and glass. Glass is preliminarily heated and stretched, so that it becomes durable. Lavsan, on the other hand, gives the material flexibility, because such reinforcement is well used in moving soils.

Plastic fittings are rarely used so far - in most cases there is no need for it, because hereinafter we will focus exclusively on steel fittings.

Residents of Moscow and the region can order fittings in CityMetall, the region’s leading online store. The company cooperates with the largest domestic manufacturers, offers steel and fiberglass reinforcement of different diameters and lengths. Cutting is free. You can even buy 1 linear meter of fittings, and the order can be delivered on the same day. The store offers some of the lowest prices in the region and constantly holds promotions.

Residents of Moscow and the region can order fittings in CityMetall, the region’s leading online store. The company cooperates with the largest domestic manufacturers, offers steel and fiberglass reinforcement of different diameters and lengths. Cutting is free. You can even buy 1 linear meter of fittings, and the order can be delivered on the same day. The store offers some of the lowest prices in the region and constantly holds promotions.

Types of steel reinforcement by type of production

The properties of steel reinforcement directly depend on the method of its production:

- hot rolled steel (marked with the letter A) is processed at very high temperatures, which lead to some changes in the structure of the alloy. The result is a very durable material that is suitable for use even on critical facilities. Such steel is perfectly welded, because it is used in cases where individual rods must be connected precisely by welding (true, this method is only suitable for stable soil);

- cold rolled steel (marked with the letter B) is produced by exposing the wire rod to steel rolls that roll the workpiece to the required diameter, then the rollers give it a relief. Ready-made fittings are wound into coils, which at the construction site can be unwound, cut and used for their intended purpose. The diameters of the fittings are 3-8 mm. Cold rolled steel is also used in the construction of the foundation, but its use is not always possible - it is worthwhile to carry out the calculations first;

- steel wire (K) it is too strong for building a foundation, it is economically disadvantageous to use it, but when it comes to building structures that will work under extreme conditions, for large-span buildings, etc., its use is justified.

Type of reinforcement surface

Steel reinforcement may have a smooth or corrugated surface:

- smooth reinforcement cheaper in production, but absolutely not suitable for the construction of the foundation. Its scope of use is limited to the construction of walls or the arrangement of floor screed. It can also be used as an auxiliary in the assembly of the reinforcing cage (for connecting ribbed rods), which will save, but not lose the foundation strength;

- ribbed reinforcement has a larger surface area, and therefore it has better contact with concrete. Stronger traction provides high foundation reliability, strength and resistance to stress. Depending on the type of profile, ribbed reinforcement is:

- with ring profile not very suitable for building a foundation. Such reinforcement provides good adhesion, but loses its strength under repeated loading;

- sickle-shaped reinforcement not so well adhered to concrete, but it allows you to build more durable and reliable foundations. This is the preferred option;

- combined profile Designed specifically for valves of class A500SP, suitable for foundation construction.

Rebar class and steel grade

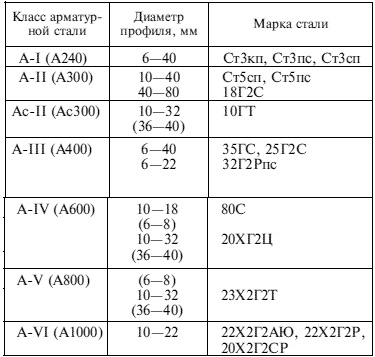

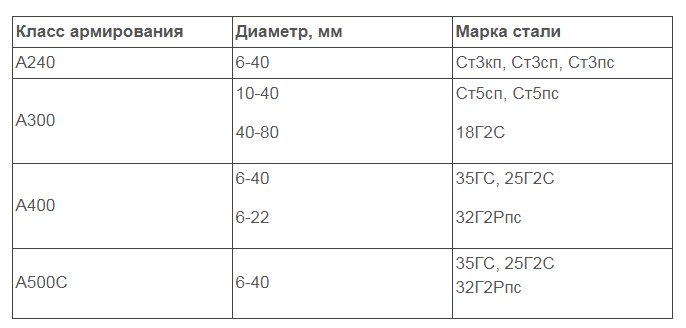

By the class of reinforcement, one can judge the strength of the material. Along with the new marking, the old one is still used, therefore we will mention both:

- A240 (according to the old GOST - AI) is a hot-rolled steel with a smooth surface, diameter - 6-40 mm. Valves with a diameter of up to 12 mm can be supplied in coils and rods, more than 12 mm - only in rods. For construction of the foundation as a working armature is not suitable, but for clamps can be used;

- А300 (АII) - reinforcement with a ring-shaped profile, it is not recommended to use it in the construction of the foundation, but in private construction it is still used for small buildings and non-critical objects. Naturally, it can be used as structural reinforcement;

- A400 (AIII) and A500 are ideal for the foundation. The rods have a relief, the diameter ranges from 6 to 40 mm, the length is from 5 to 11.7 m;

- A600 (AIV) - high-strength reinforcement, used in the construction of critical facilities, suitable for structures with prestressing;

- reinforcement А800 (АV) and А1000 (АVI) are used in the construction of multi-storey buildings, bridges and other structures where special strength is extremely important.

In addition, during the construction of the foundation, other types of steel reinforcement are used, the properties of which can be judged by the marking:

- the letter C indicates the ability to fasten the rods into the frame by welding (examples - A400C, A500C, A600C). Armature class A500C has recently become especially popular;

- the letter K indicates corrosion resistance (A400K, for example);

- At in the marking means that the steel has been hardened thermomechanically. Intermittent cooling, which is used with this technology, increases the strength and corrosion resistance. A popular class of such fittings is At800.

GOSTs and TU require the use of steel of a particular brand for the production of a certain type of reinforcement. The manufacturer must indicate which steel he used - this is very important information for the developer, allowing you to correctly perform all the necessary calculations.

Some steel grades used are listed in the table below. The characterization of each brand is the topic of a separate article. Here we only note that, for example, 35GS steel is low alloyed, and 25G2S steel is made using silicon and manganese as alloying additives. Both of these alloys are highly durable.

Types of fittings by location and purpose

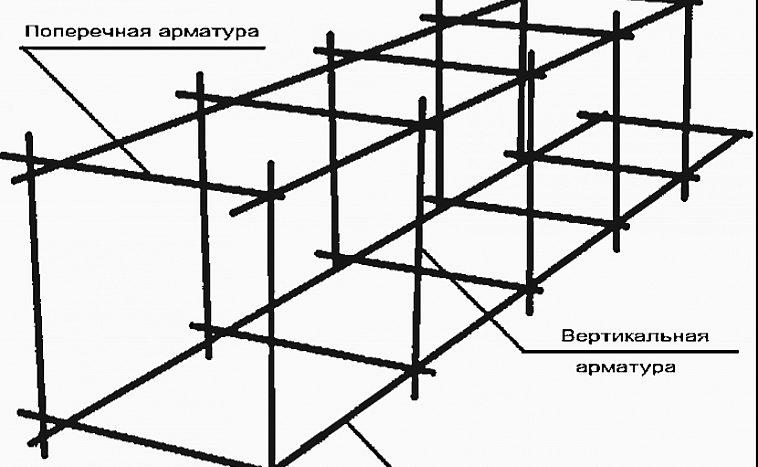

A whole frame is assembled from the reinforcement, in which the steel bars are located in different directions. Working rods - These are those that take on the main burden. To bind them together and the correct orientation in space using auxiliary rods, the so-called clamps. The working fittings are located horizontally in the longitudinal direction, and the clamps can be transverse (arranged horizontally) and vertical. Not all foundations require the use of all three types of reinforcement.

- section working fittings selected on the basis of calculations. The location of the rods depends on the type of foundation. For example, in the strip foundation, the working rods are arranged longitudinally in one or two rows. The number of rows of reinforcement depends on the thickness of the foundation: with a thickness of less than 150 mm, only one row can be used;

- transverse reinforcement necessary to connect the working fittings. When constructing a strip foundation, transverse rods are necessary, and when pouring concrete with a monolithic slab, they are dispensed with;

- vertical reinforcement used where working fittings are located in two or more layers.

According to the purpose, the reinforcement is divided into working, constructive and assembly. Constructive - the one that takes on the maximum load. Structural reinforcement takes on the load from shrinkage, and assembly - serves to combine structural and working reinforcement into a single frame. Anchor reinforcement is sometimes isolated separately - these are embedded parts.

Reinforcement size

The fittings are produced in a wide range of sizes:

- rods of classes A240, A300, A400, A600, A800, A1000 are produced with a diameter of 6-80 mm, and rebars of classes A500C and B500C with a diameter of 4-40 mm;

- the length of the reinforcement in coils or rods (depending on diameter) is 6-12 m;

- Among the additional parameters of the reinforcement, it is worth noting the corrugation pitch, which is 0.51-0.86 parts of the diameter of the reinforcement, and the height of the corrugation protrusions is 0.065-0.07 parts of the diameter.

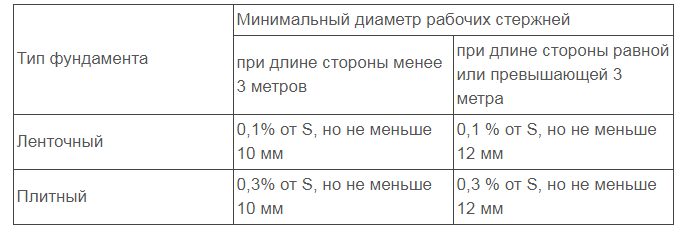

Which reinforcement is better to choose for the foundation? It all depends on the type of foundation and the load on it - in each case, you will need a complex and accurate calculation of the diameter of the rods. In order for you to roughly understand which rods you will have to buy, we give the following information:

- the diameter of the working reinforcement depends on the cross-sectional area of the foundation (S), the data are given in the table;

- for transverse clamps use reinforcement with a diameter of at least 6 mm;

- vertical clamps must be at least 6 mm in diameter with a foundation height of less than 80 cm and at least 8 mm - with a height of more than 80 cm.

Reinforcement and foundation type

It is easy to guess that for different foundations, different reinforcement is required, and it also fits in different ways:

- strip foundation cheaper than a slab, less prone to deformation, allows you to equip the basement, because this is the technology used to create the base most often. As a rule, reinforcement with a diameter of 10-12 mm is used for a strip foundation, if calculations do not require more. Regardless of the height of the belt, it is necessary to use two reinforcing belts (more than two in the case of moving soils). Vertical and transverse rods do not carry a special load, therefore reinforcement with a smooth surface is suitable for them;

- slab foundation expensive, but most reliable. Reinforcement is used with a diameter of at least 12-16 mm - the larger and heavier the building, the more difficult the soil, the thicker the rods should be. With a plate thickness of more than 15 cm, the reinforcement is laid in two or more belts;

- pile foundation - The ideal solution for lightweight buildings. The columns are formed using ribbed reinforcement with a diameter of 10-12 mm, they are connected with clamps with a diameter of 4-6 mm. The number of rods of working fittings depends on the size of the column: a minimum of 2 rods, more often 4, but sometimes more can be used - everything again depends on the construction conditions.

Connection Methods

There are two ways to assemble reinforcement in a single frame:

- welding;

- knitting.

If plastic fittings are used, then there is no question of any welding. However, metal fittings are also infrequently welded, since welding points become weak points of the structure, they withstand less load, are more susceptible to corrosion. Welding provides too tight grip rods, eliminating even the slightest backlash. This design perceives deformation worse, cannot be used when working on moving soils. Moreover, you can only cook the reinforcement in the marking of which is the letter C.

More practical use knitting with wire. It is folded in half, crochet the free end into the loop obtained, and then twisted so that the connected rods could not move freely. Simple, cheap, reliable, but for a long time - an experienced builder will be able to complete up to 20 connections per minute, and a beginner - no more than 5-6.

The knitting process can be simplified with a special knitting gun. He is leaned against the intersection of steel bars, pulled the trigger - and the connection is ready. Up to 40-50 such operations can be performed per minute. The downside is the high price of the equipment and the need to use expensive wire.

Finally, we note that when buying, in addition to the diameter, class and type of surface, it is worth paying attention to the presence of the relevant documentation for the products (first of all, this is a certificate of compliance). The final touch is a visual inspection. If you notice rust marks, scratches and other mechanical damages on the fixture, then it is better to refuse to buy and find really high-quality products - the whole house will stay on them, without exaggeration.